a cutting tool

A cutting tool and tool holder technology, which is applied to the cutting tools, shearing devices, manufacturing tools and other directions of shearing machine devices, can solve the problems of flattening of heat exchange tubes and low yield of heat exchangers, and improve the yield of finished products. , Improve production efficiency and ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The inventor found that cutting the heat exchange tubes with ordinary scissors cannot be operated because the gap between the heat exchange tubes is too small, and because the wall thickness of the heat exchange tubes is only 0.3mm and the middle is suspended, the heat exchange tubes will be flattened during the cutting process Stress concentration is formed, resulting in low heat exchanger yield. How to improve the yield of heat exchangers has become a technical problem.

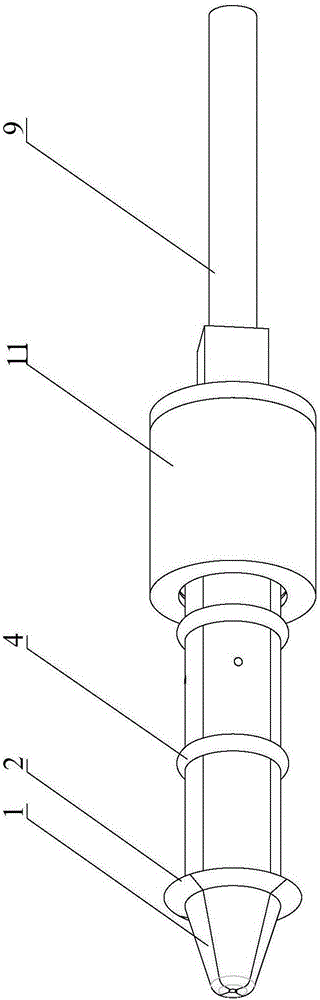

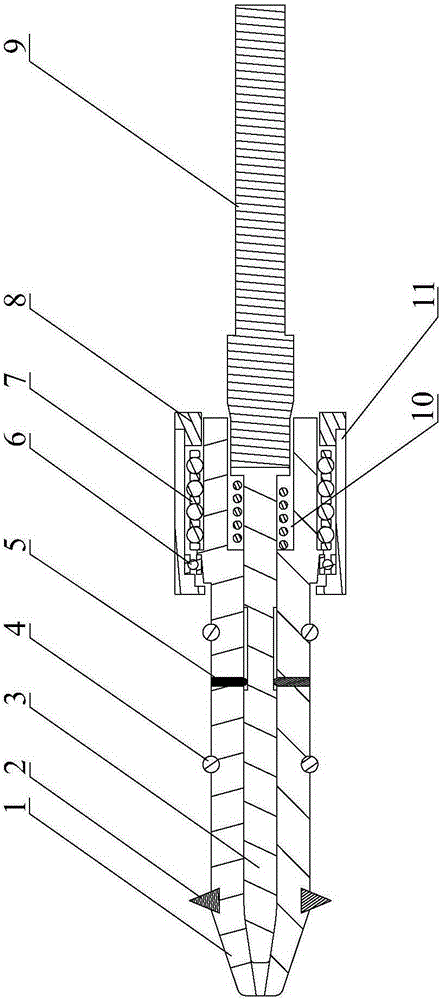

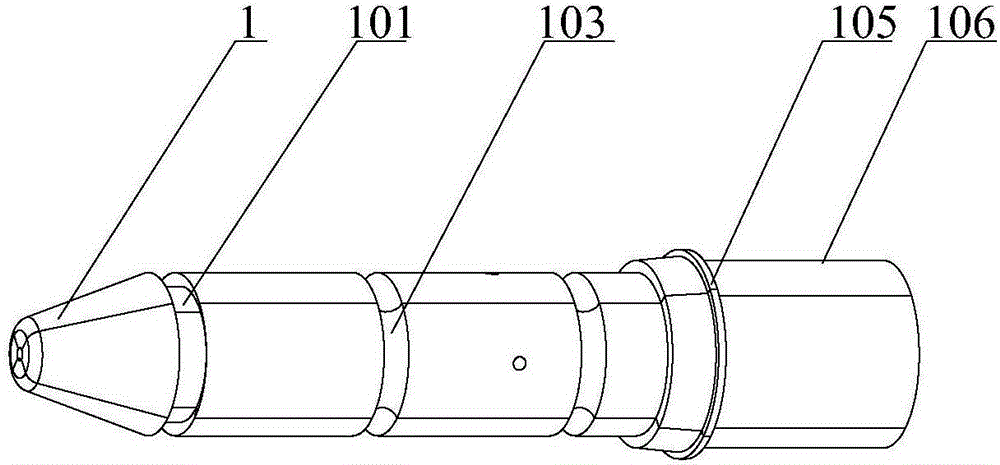

[0046] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

[0047] The invention provides a cutting tool to achieve the purpose of improving the yield of heat exchangers.

[0048] li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com