A method for early fault detection of compressor bearings

A compressor bearing, early failure technology, applied in the testing of mechanical components, testing of machine/structural components, pump testing, etc., can solve problems such as different lengths of vibration data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will be combined with figure 1 The present invention is described in detail, a compressor bearing early fault detection method, comprising the following steps:

[0027] First, obtain the autocorrelation length of the vibration data sequence through the autocorrelation function, and take the maximum value C;

[0028] The acquisition method is to obtain the wind tunnel test data with length L, , , , , , (L can be determined by the actual situation) The autocorrelation length C of the vibration data sequence 1 ,C 2 ,C 3 ,C 4 ,C 5 ,C 6 ,C 7 , and take the maximum .

[0029] Train an autoencoder with C hidden nodes;

[0030] Compress the length L vibration data sequence to a length C data sequence through the trained self-encoder;

[0031] In the data sequence set D of length C, select the data sequence set D in a healthy state H ;

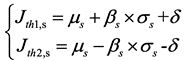

[0032] In the data sequence set D H On the basis of the weighted least square method to find the data s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com