Adjustable front canopy clamping cable

A cable and clip technology is applied in the field of adjustable front probe beam and cable, which can solve the problem of affecting the normal use of the front probe beam, the longitudinal failure of the anchor rod and the inability to form a straight line, and the front probe beam passing through less than three clip cables. There are three cables inside or barely penetrated, and only the lower bottoms of two cables are dragging the front probe beam; it may only be able to pass through two cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

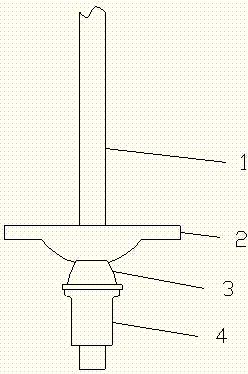

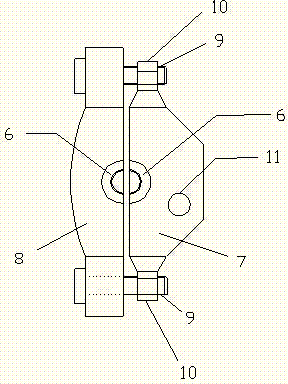

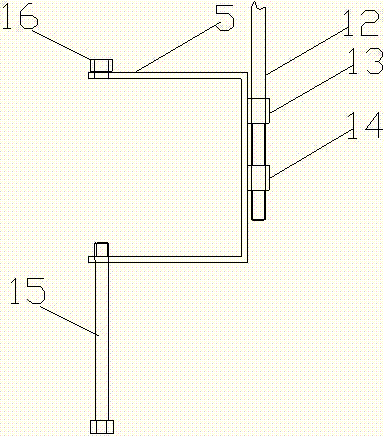

[0021] An adjustable probe beam card cable, such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, including the anchor rod 1, the anchor plate 2 installed on the anchor rod, the anchor nut 4 supporting the anchor plate, and the cable frame supporting the front beam 5. A tapered self-aligning washer 3 with a small upper end and a large lower end is arranged between the anchor plate and the anchor rod nut. A clip is installed on the self-aligning washer, and the clip includes a clip front plate 7 and a The clip rear plate 8, the corresponding positions of the clip front plate and the clip rear plate are respectively provided with half symmetrical self-aligning washer sockets 6, and the size of the self-aligning washer socket matches the size of the self-aligning washer, and the The self-aligning washer is just clamped in the self-aligning washer nest. Both ends of the clip front plate and the clip rear plate are connected by bolts, clamping bolts 9 are installed at both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com