Water flow power generation automatic thermostatic controller

A constant temperature controller and water flow power generation technology, which is applied to engine components, sliding valves, valve details, etc., can solve the problems of not being able to pass water directly, not being able to use water, and high replacement frequency, so as to achieve expanded use range and performance, simple adjustment, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

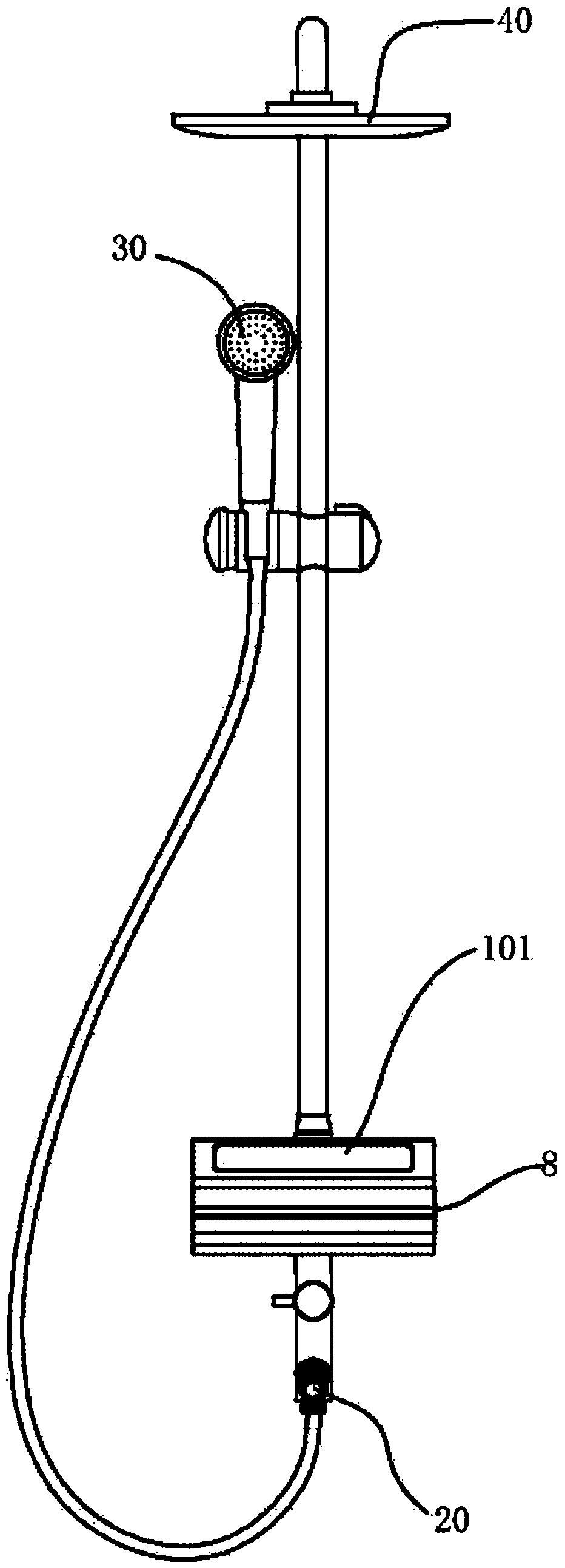

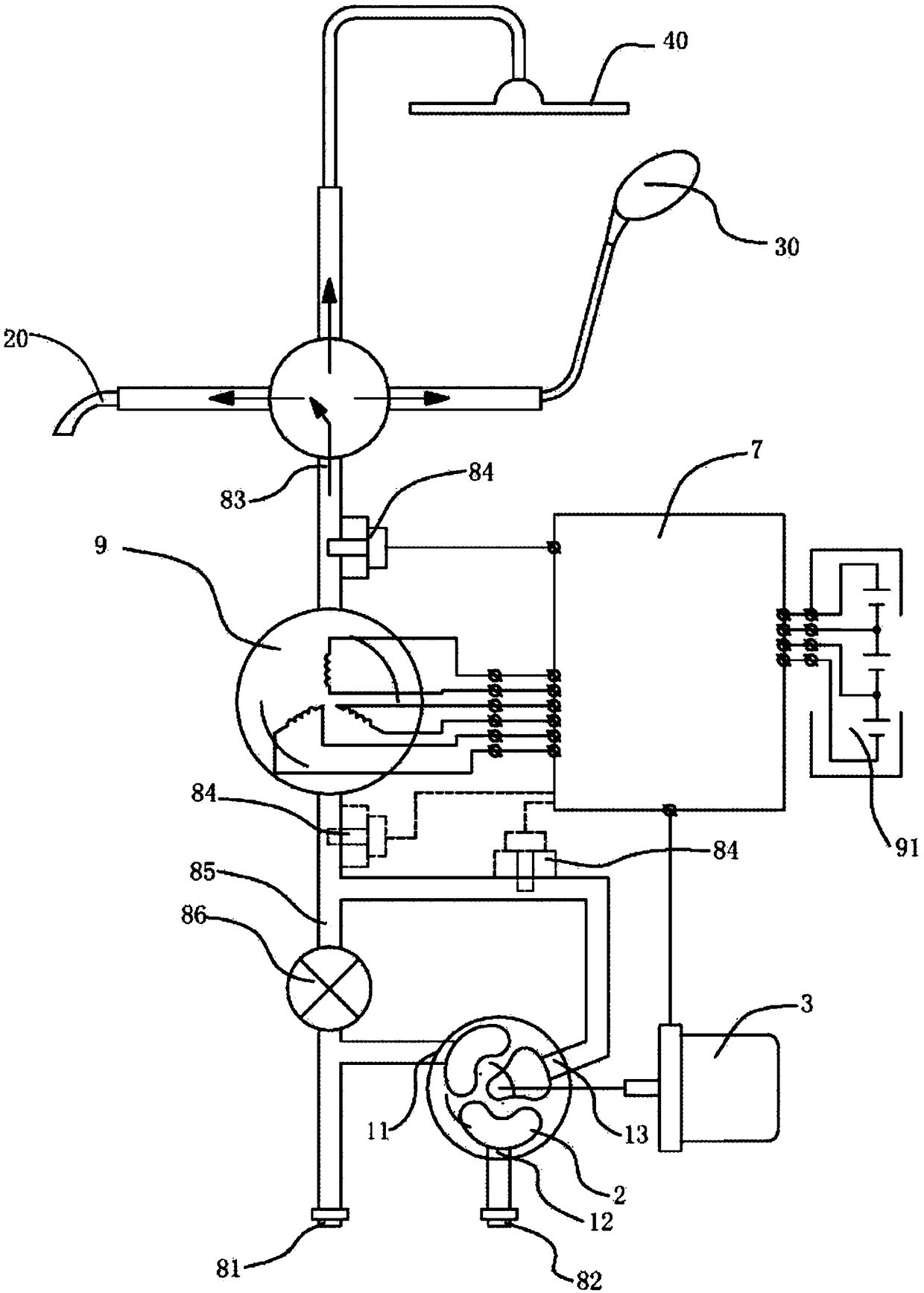

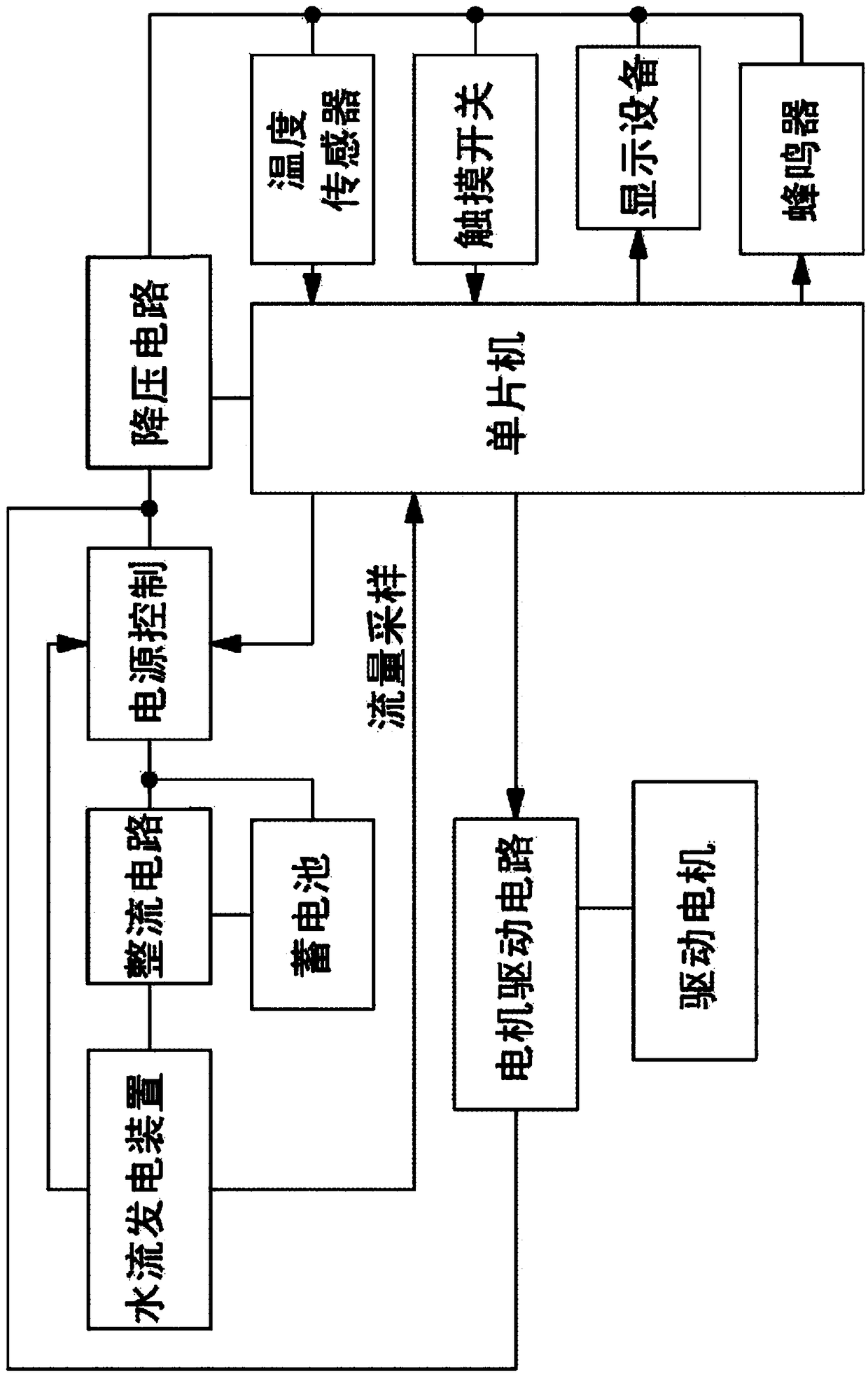

[0031] Such as Figure 1-2 As mentioned above, the automatic constant temperature controller for water flow power generation in the embodiment of the present invention includes a housing 8 and an electric thermostatic mixing valve located in the housing 8. The electric thermostatic mixing valve includes a valve body 1 and a valve core located in the valve body 1. 2, and the driving motor 3 connected with the spool 2 and driving the spool 2 to regulate hot and cold water. The shell 8 is respectively provided with a cold water connector 81, a hot water connector 82, and a water outlet connector 83. The cold water connector 81 is connected to the external cold water pipe, and the hot water connector 82 is connected to the external hot water pipe, that is, connected to an electric water heater or a gas water heater. , the water outlet joint 83 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com