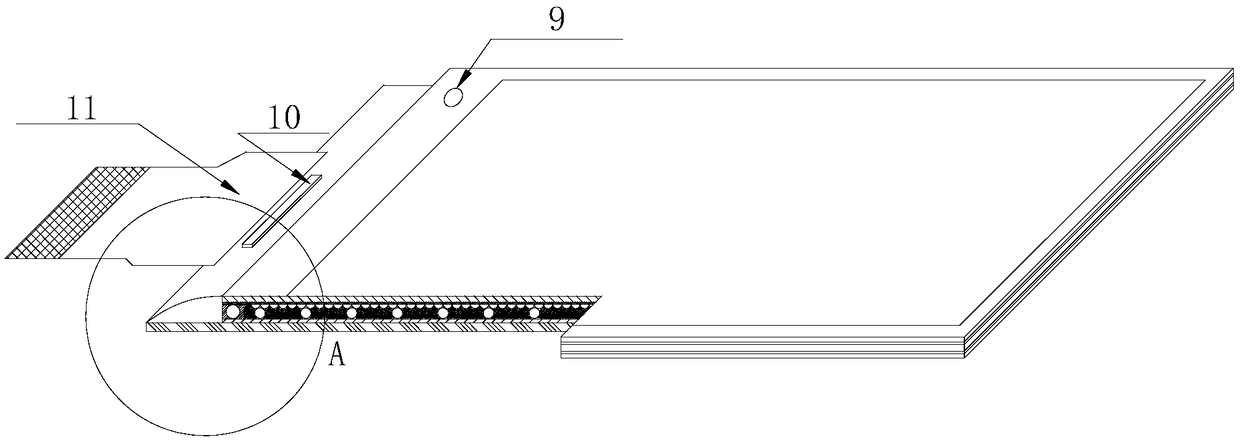

Displaying plasma module with reflective enhancing structure and manufacturing method thereof

A technology of reflection enhancement and plasmonics, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as expanding viewing angles, achieve the effects of expanding viewing angles, good display effects, and enhanced display brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

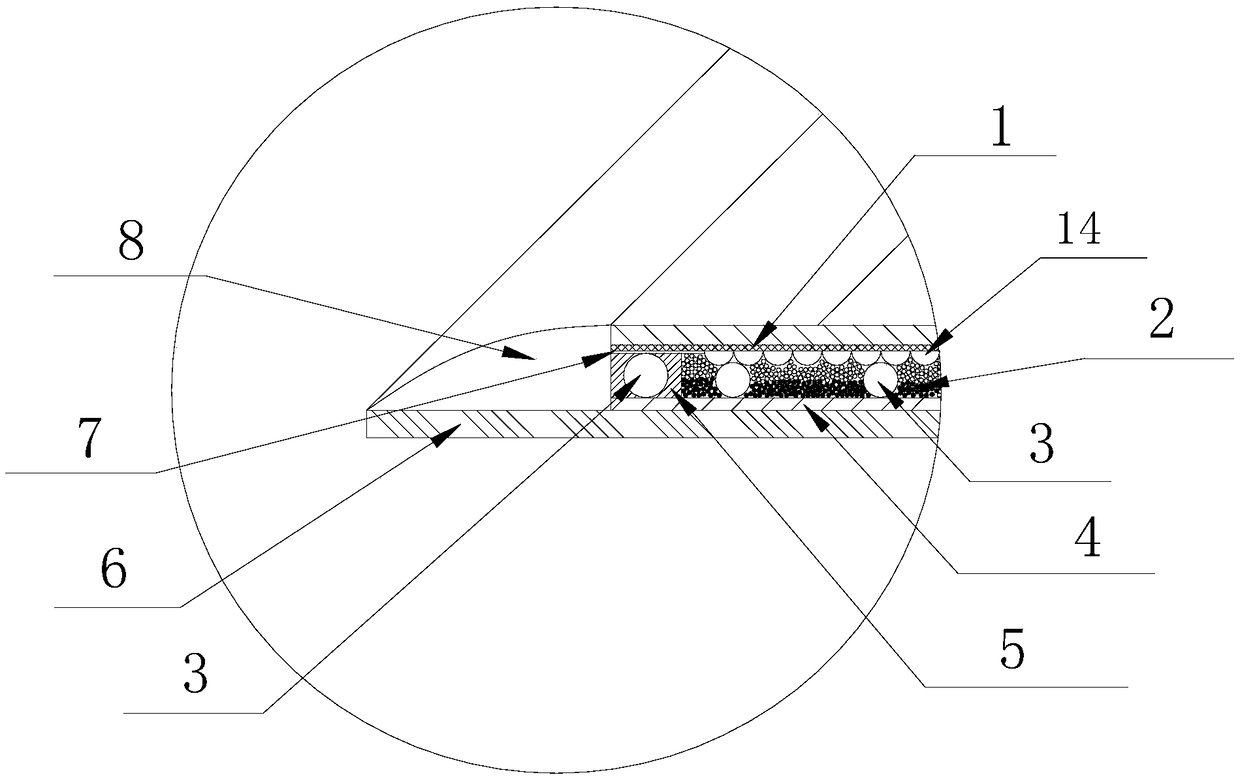

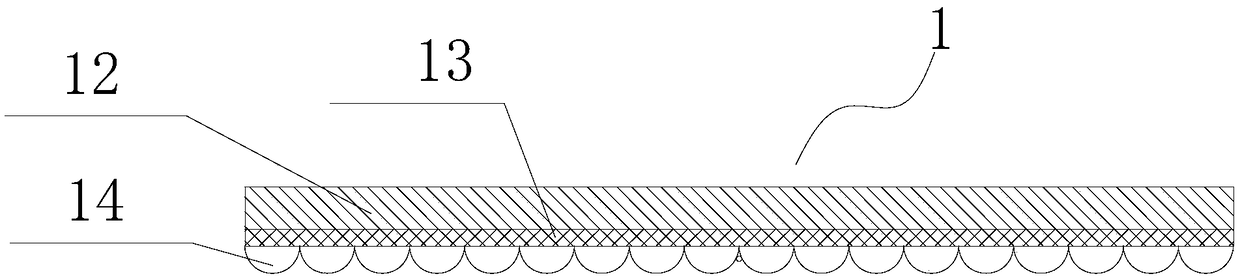

[0053] Embodiment 1 takes a dual-particle electronic ink display screen as an example. The dual particles are white electrophoretic particles and black electrophoretic particles. In this embodiment 1, the grooves of the transparent reflective layer 14 are composed of several long groove-shaped grooves arranged side by side. The notch of the groove-shaped groove is in contact with the conductive layer 13, the bottom and side walls of the groove are in contact with the display plasma 2, and the height of the groove is between 0.5-20 microns, and the width is between 1-20 microns. between.

Embodiment 2

[0054] Embodiment 2 takes the dual-particle electronic ink display screen as an example. The dual particles are white electrophoretic particles and black electrophoretic particles. The notch of the hemispherical groove is in contact with the conductive layer 13, and the bottom and side walls of the hemispherical groove are in contact with the display plasma 2, and the height of the hemispherical groove is between 0.5-20 microns, and the width is 1-20 microns. Between 20 microns.

Embodiment 3

[0055] Embodiment 3 takes a dual-particle electronic ink display screen as an example. The dual particles are white electrophoretic particles and black electrophoretic particles. In this embodiment 1, the grooves of the transparent reflective layer 14 are composed of several long strips of prismatic grooves arranged side by side. The notch of the elongated prismatic groove is in contact with the conductive layer 13, the bottom and side walls of the elongated prismatic groove are in contact with the display plasma 2, and the height of the elongated prismatic groove is 0.5 Between -20 microns, the width is between 1-20 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com