Urban tree whitewashing machine

A technology for whitening machines and trees, which is applied in the fields of brushing, gardening, and botany equipment and methods, and can solve the problems of large consumption of liquid medicine, low whitening efficiency, and insufficient whitening uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

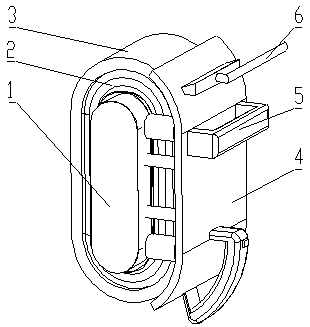

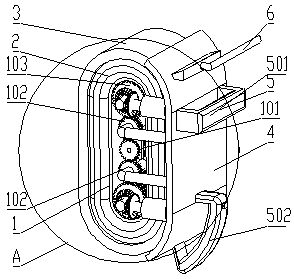

[0024] see Figure 1 to Figure 3 , the present invention provides a kind of whitening machine for urban trees, comprising a rotating roller part 1 as a drive, and a soft bag belt 2 and a sponge belt 3 which are arranged on the outside of the rotating roller part 1 in turn, and the soft bag belt 2 is a closed annular bag Body, the inside of which is filled with liquid materials; both sides of the roller part 1 are connected to the cover plate 4 through the struts, and the outside of the cover plate 4 is provided with a handle 5;

[0025] The cover plate 4 is provided with a feeding hole, and the feeding hole communicates with the inside of the paint bucket through the paint pipe 6 and the paint pump.

[0026] When the soft bag belt 2 is filled with 90% liquid, the inner surface of the cover plate 4 is attached to the outer surface of the sponge belt 3 close to the cover plate 4

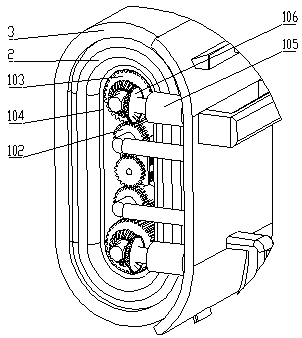

[0027] The rotating roller part 1 includes a motor 101 arranged in the middle, and a driving wheel...

Embodiment 2

[0037] On the basis of Embodiment 1, different from Embodiment 1, the paint hole is a long hole provided on the cover plate 4, and its side facing the sponge belt 3 is a slit, and the paint hole is towards the outside of the cover plate 4. One side is provided with a corresponding elongated cavity, and a through hole is reserved at the top of the cavity, and the through hole is connected to the paint pipe 6 .

[0038] A baffle is arranged in the middle of the cavity, and a number of liquid equalizing holes are arranged in an array on the baffle, and the liquid equalizing holes are through holes with small diameters.

Embodiment 3

[0040] On the basis of Embodiment 1 or 2, the front end of the cover plate 4 is hinged to the cleaning plate, and the end of the cleaning plate away from the hinged part of the cover plate 4 is provided with an arc-shaped notch. The cleaning plate is made of elastic material, and the upper part of the cleaning plate is arranged Air inlet, the air inlet communicates with the air outlet of the air pump through the trachea, and some air outlet holes are arranged at the arc opening of the cleaning plate, and the air outlet communicates with the air inlet through the air channel inside the cleaning plate.

[0041] A torsion spring is arranged at the hinge of the cleaning plate and the cover plate.

[0042]The cleaning plate is supplied with air by an air pump, and its front end sprays high-pressure air to wash the surface of the tree trunk, which is more conducive to the adhesion of white paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com