Cloud computing boiler system capable of automatically regulating blowdown according to steam-water ratio

一种锅炉、排污阀的技术,应用在控制系统、蒸汽锅炉、蒸汽锅炉配件等方向,能够解决无法灵活地调整控制程序及参数等问题,达到防止热能浪费、减少滞后性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0046] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

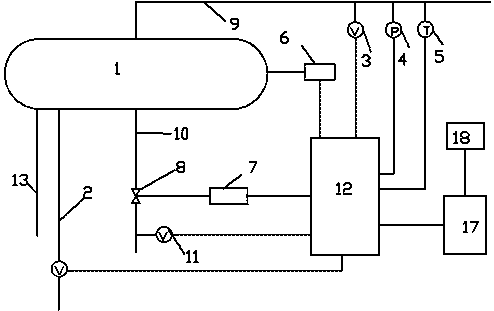

[0047] Such as figure 1 As shown, a boiler thermal system includes at least one boiler for generating steam, and the boiler is connected with a monitoring and diagnosis controller 12 for data connection so as to monitor the operation of the boiler. The monitoring and diagnosis controller 12 is data-connected with the cloud server 17, so that the monitored data is transmitted to the cloud server 17, and the cloud server 17 is connected with the client 18, and the client 18 can obtain various monitoring information through the cloud server.

[0048] Preferably, the client 18 can input data to control the operation of the boiler system.

[0049] Such as figure 1 As shown, the boiler includes an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com