Patents

Literature

45results about How to "Reduce hysteresis error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

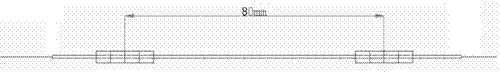

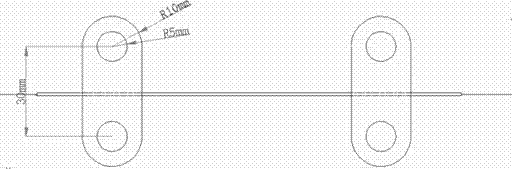

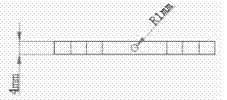

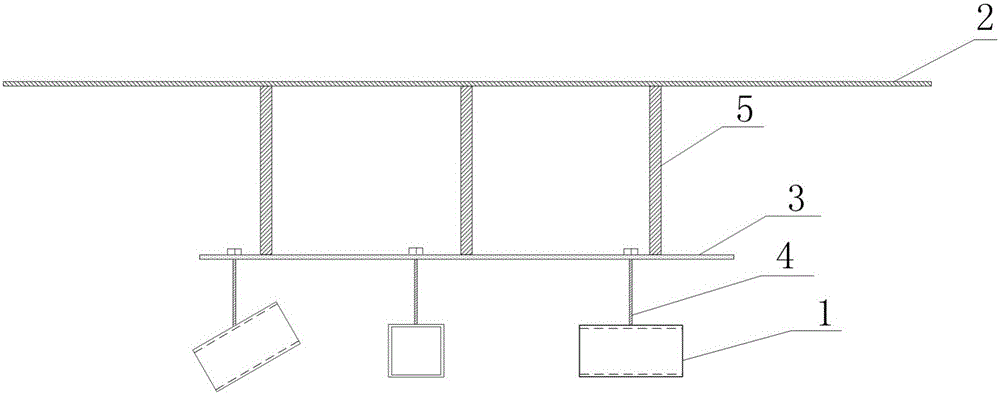

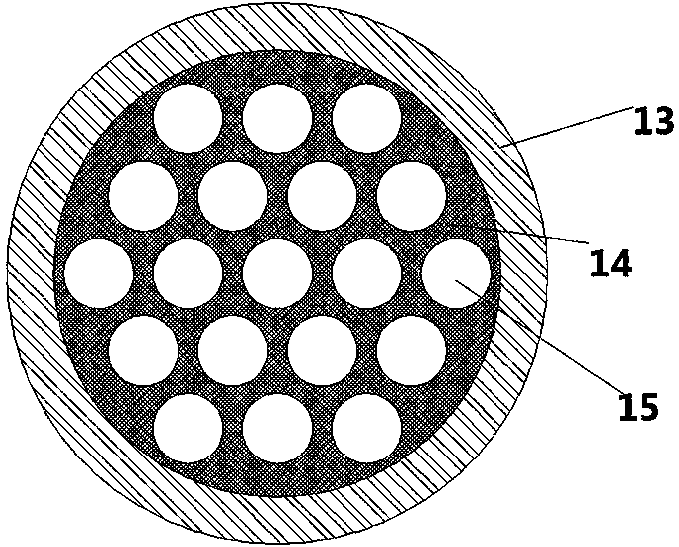

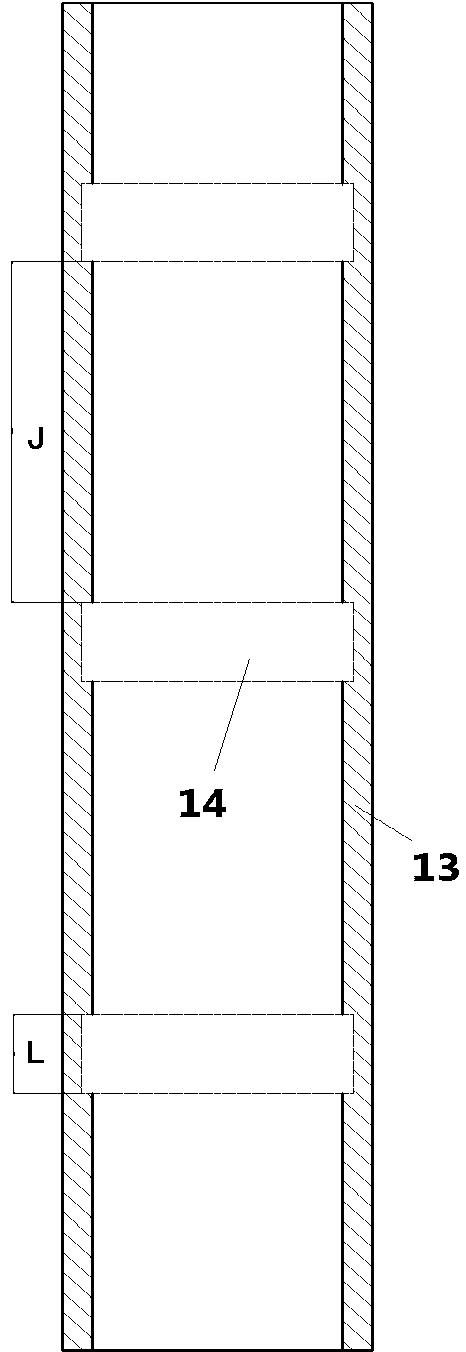

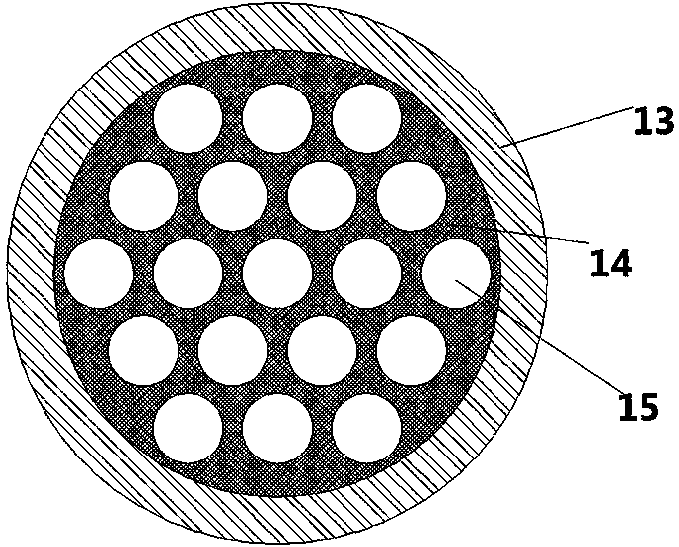

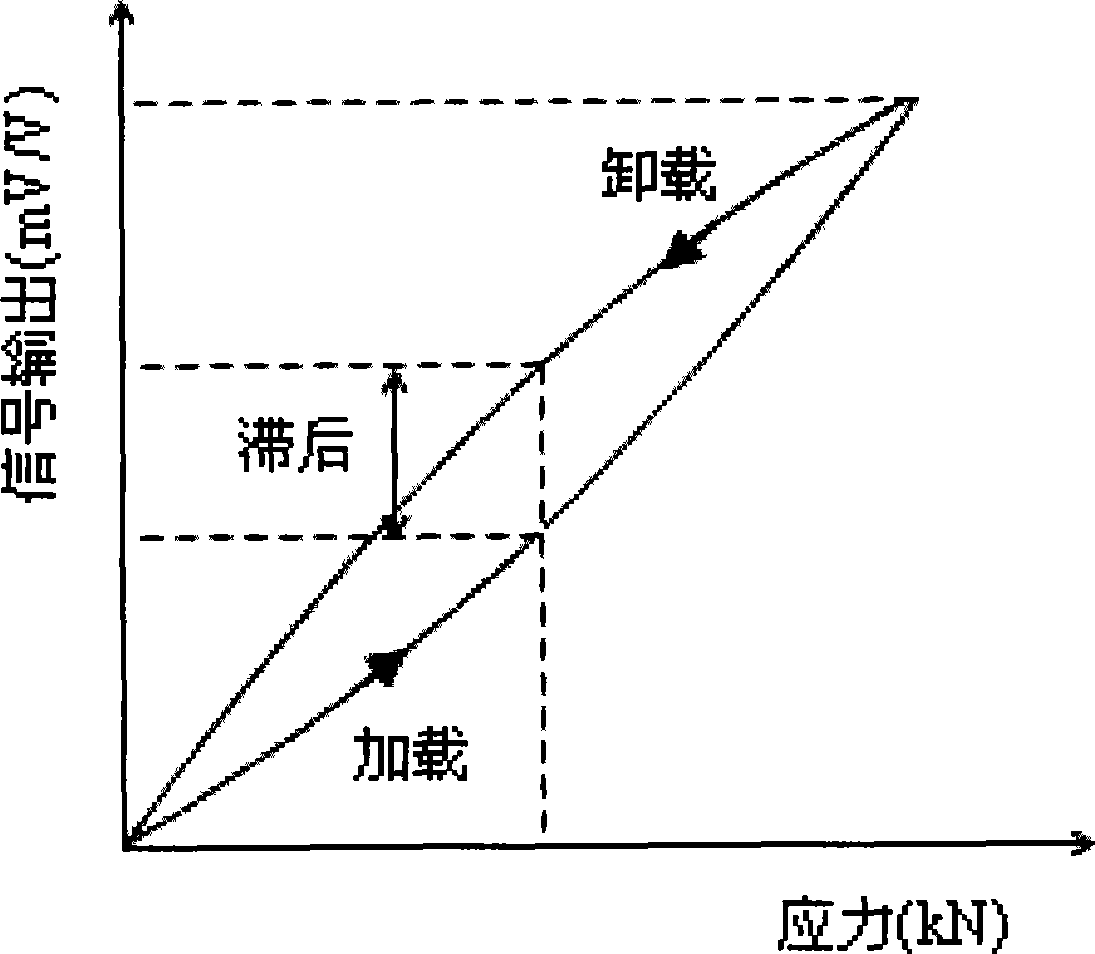

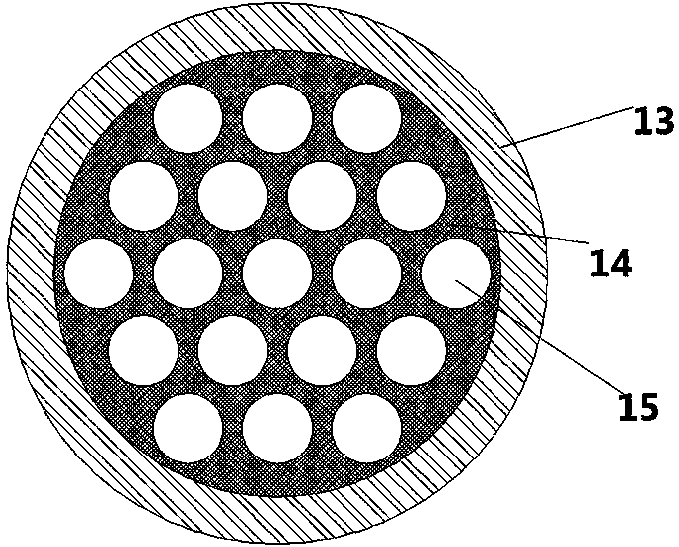

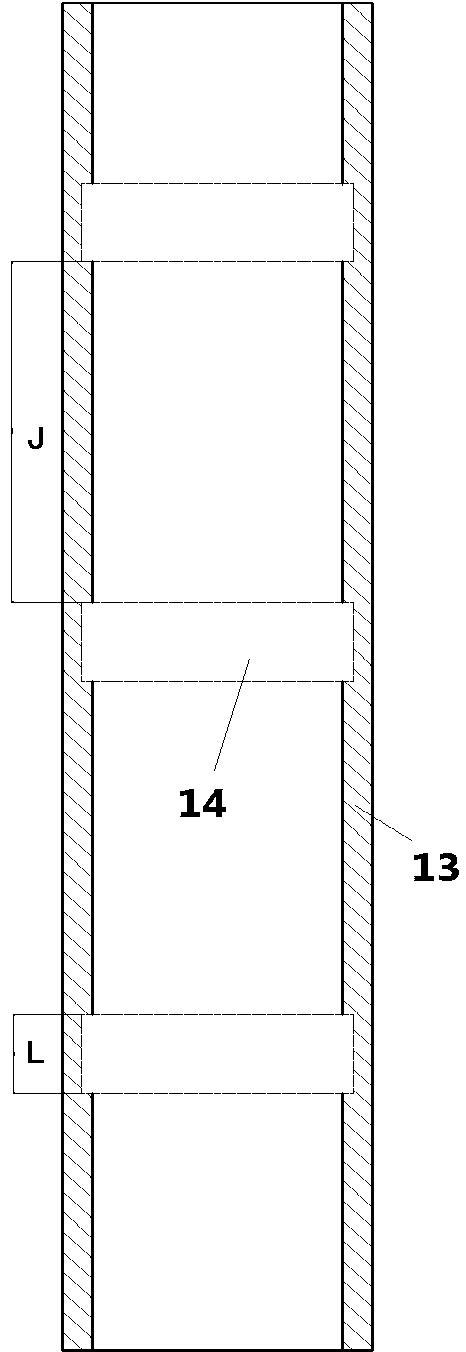

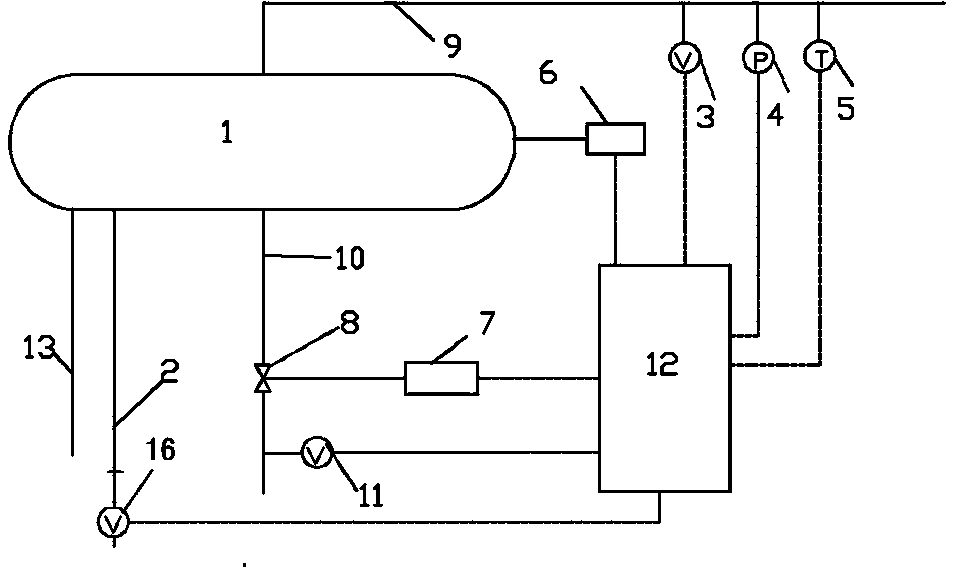

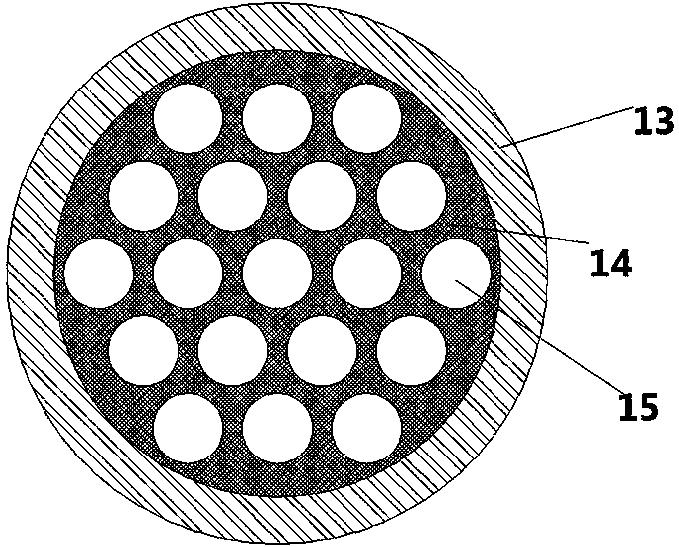

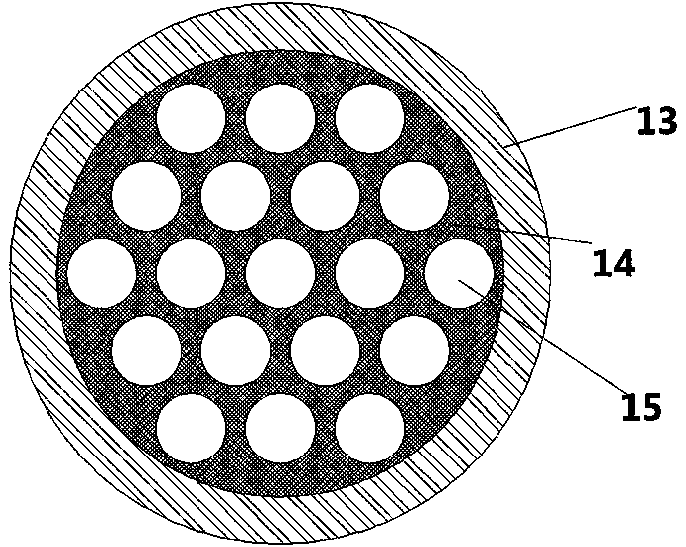

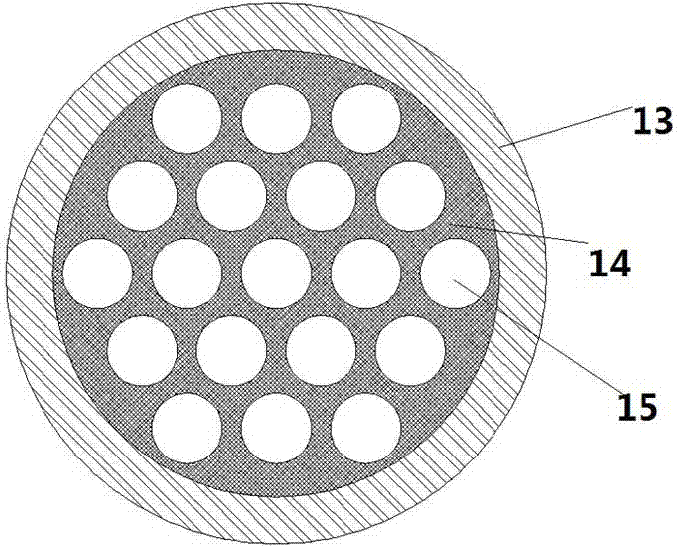

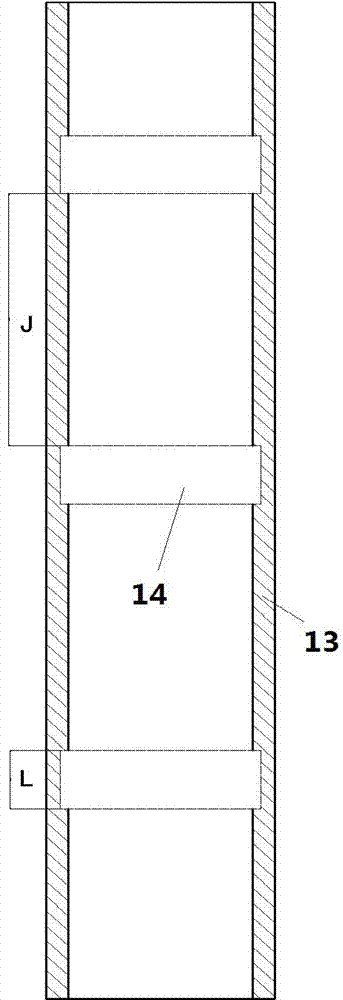

Metal packaged fiber Bragg grating sensor and manufacturing method thereof

InactiveCN102297706AImprove protectionHigh sensitivityMeasurement apparatus housingsConverting sensor output opticallyMetal fiberGrating

The invention discloses a metal-encapsulated fiber Bragg grating sensor and a manufacturing method thereof. By encapsulating the fiber Bragg grating in a steel pipe through a specific manufacturing method, the sensor of the invention improves the strain sensitivity compared with the prior art, and Easy to install.

Owner:黄堃

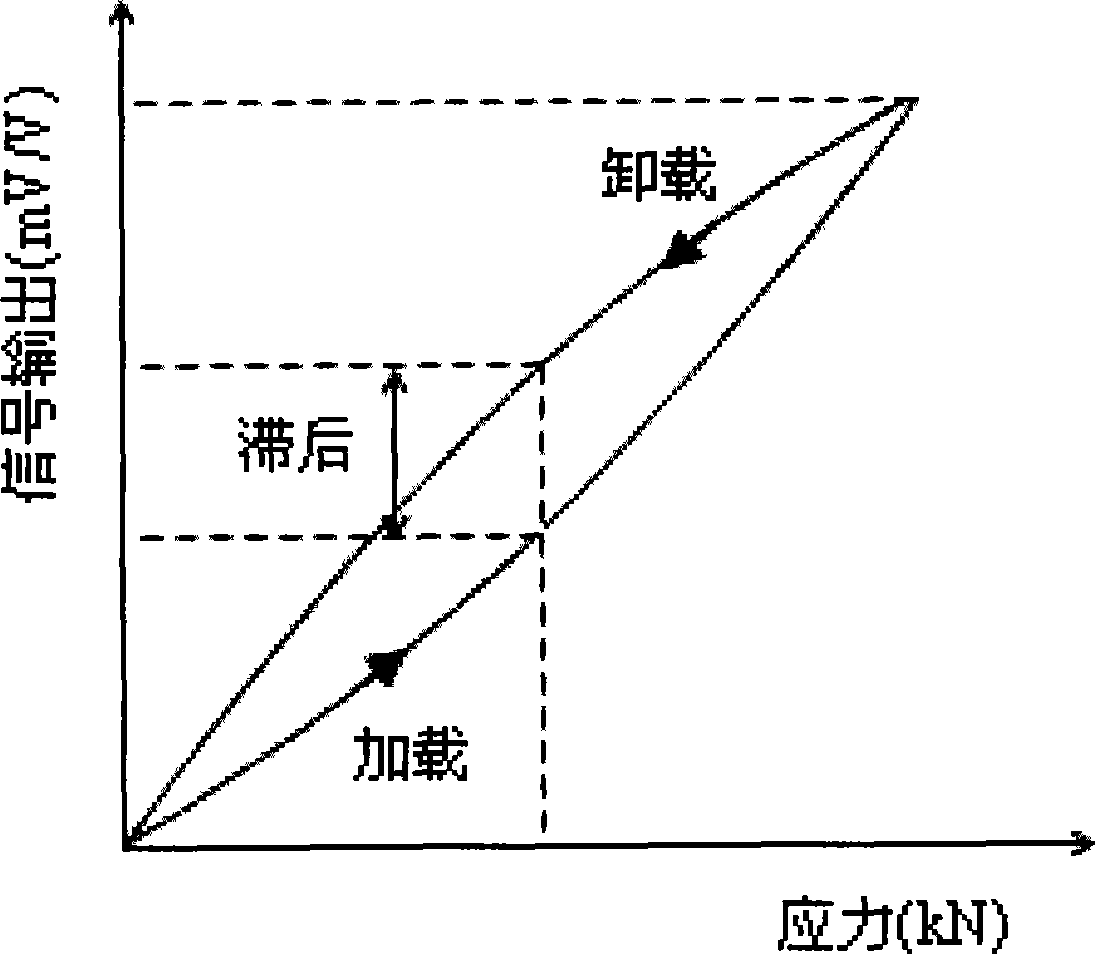

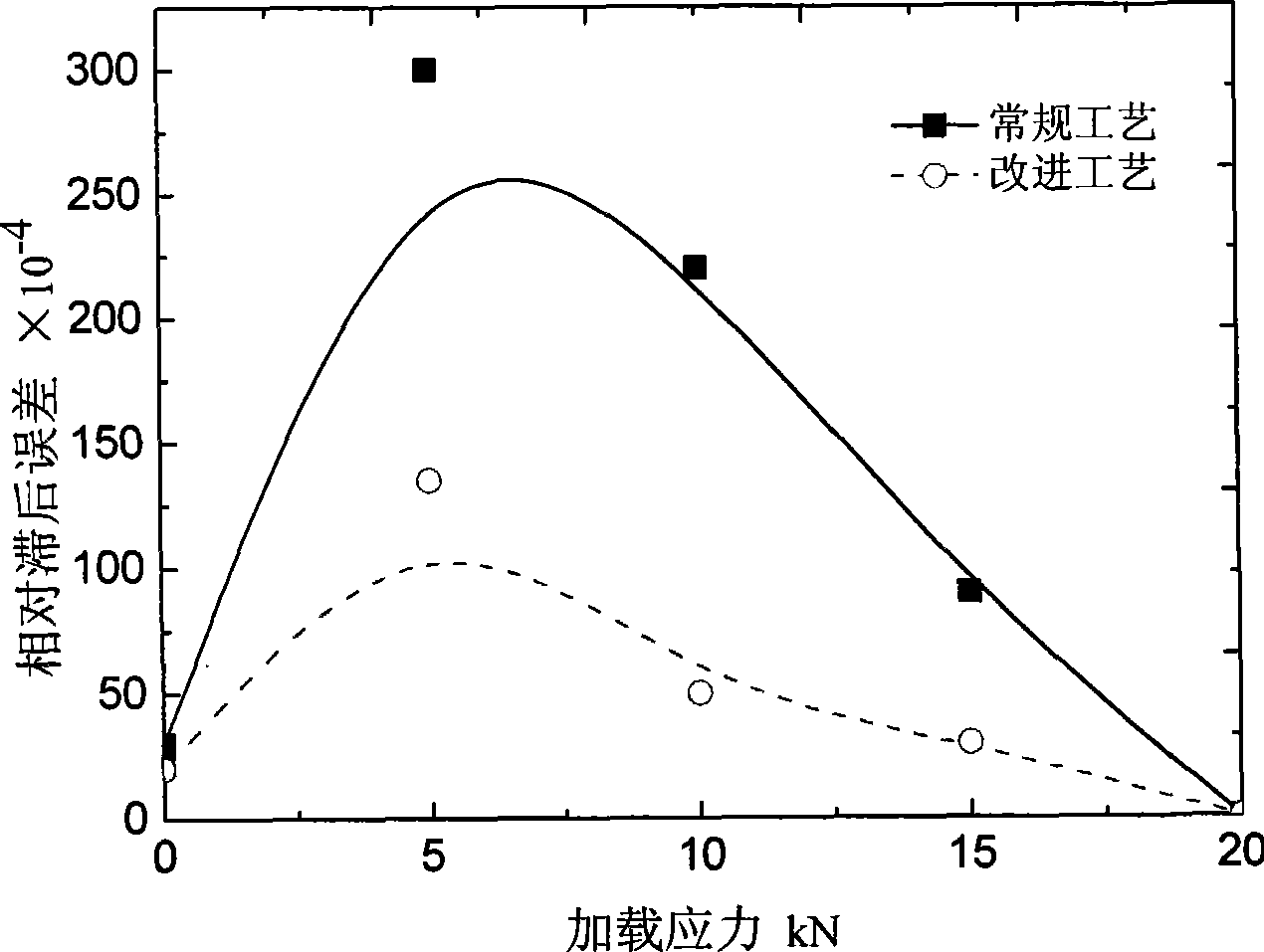

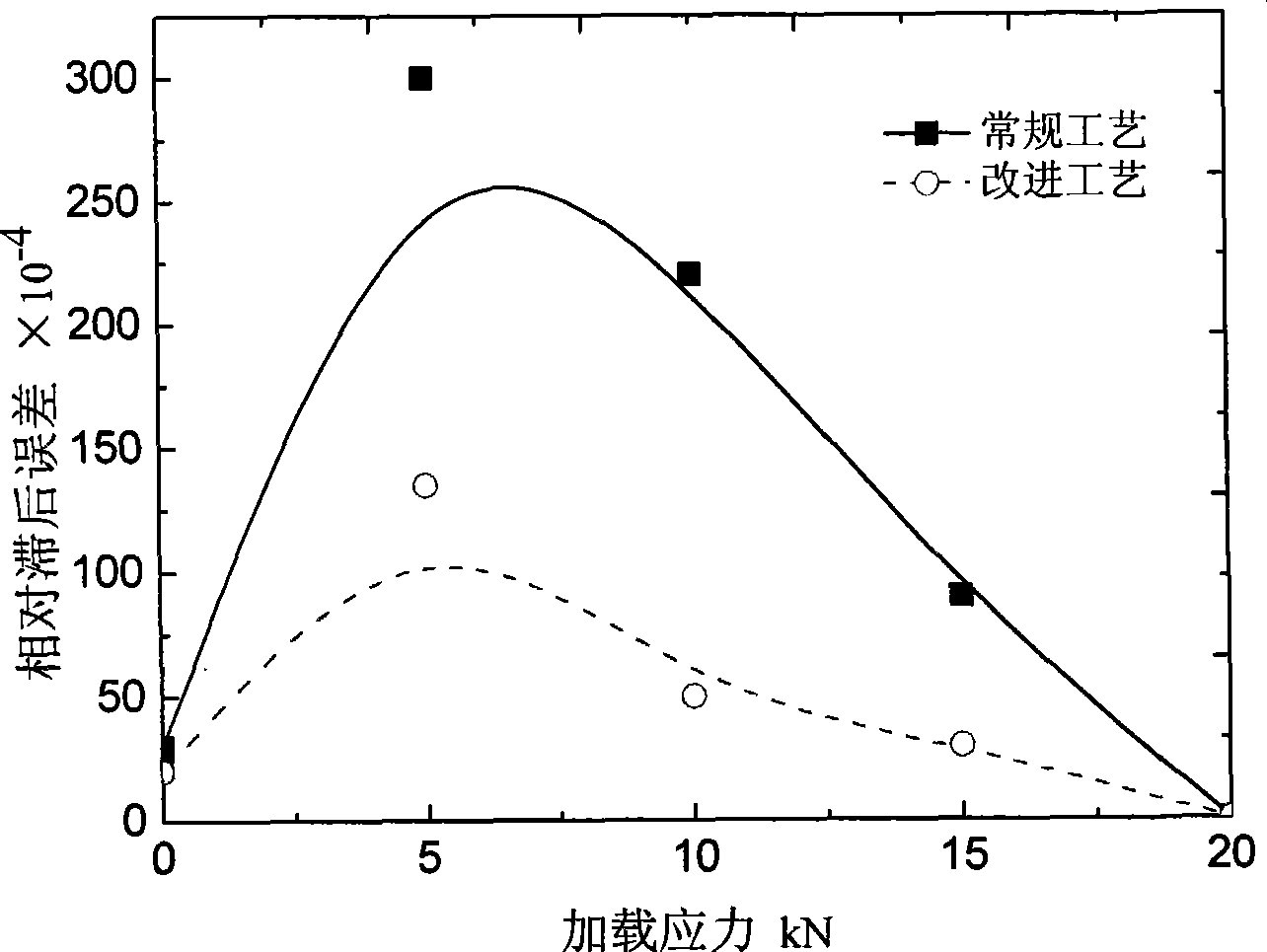

Method for reducing hysteresis error of precipitated martensitic stainless steel

ActiveCN101413048AReduce the energy required for precipitationImprove diffusivityElastomerHysteresis

The invention relates to a method for reducing the hysteresis error of out-precipitated martensitic stainless steel elastomer. The method comprises the following: a step of performing solid solution, which is to heat a bar with a furnace at a speed between 5 and 30 DEG C per minute, heat the bar to 1,040+ / -10 DEG C, preserve heat for 1 to 4 hours and compulsively cool the bar to room temperature; a step of deep cooling, which is to cool the compulsively cooled bar in liquid nitrogen at a cooling temperature between 70 and 90 DEG C below zero for 2.5 to 6 hours; a step of performing deformation processing, which is to stretch or compress the deep cooled bar at a speed less than or equal to 5 millimeters per second at normal temperature and control the elongation or compression ratio of the bar in the stretching / compressing direction between 1.0 and 5.0 percent; a step of aging, which is to put the deformed bar into a heating furnace at a temperature not higher than 200 DEG C, heat the bar with the furnace at a speed between 5 and 30 DEG C per minute, raise the temperature to 480+ / -5 DEG C and preserve the heat for 2.5 to 5 hours. The method improves the capability of out-precipitated martensitic stainless steel in resisting micro-region plastic deformation, and reduces the hysteresis error of weighting sensors.

Owner:METTLER TOLEDO CHANGZHOU PRECISION INSTR +2

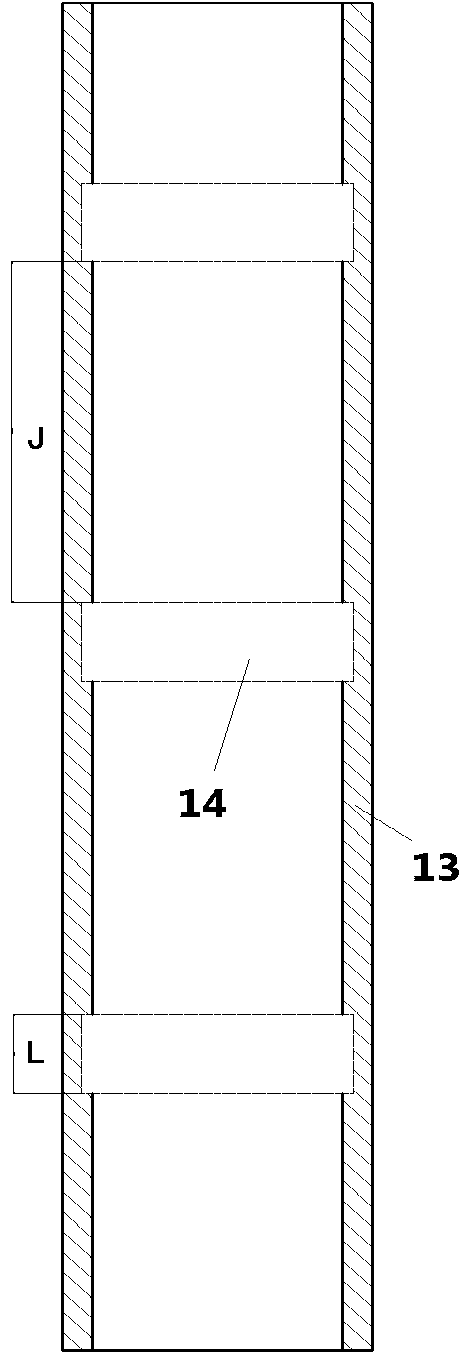

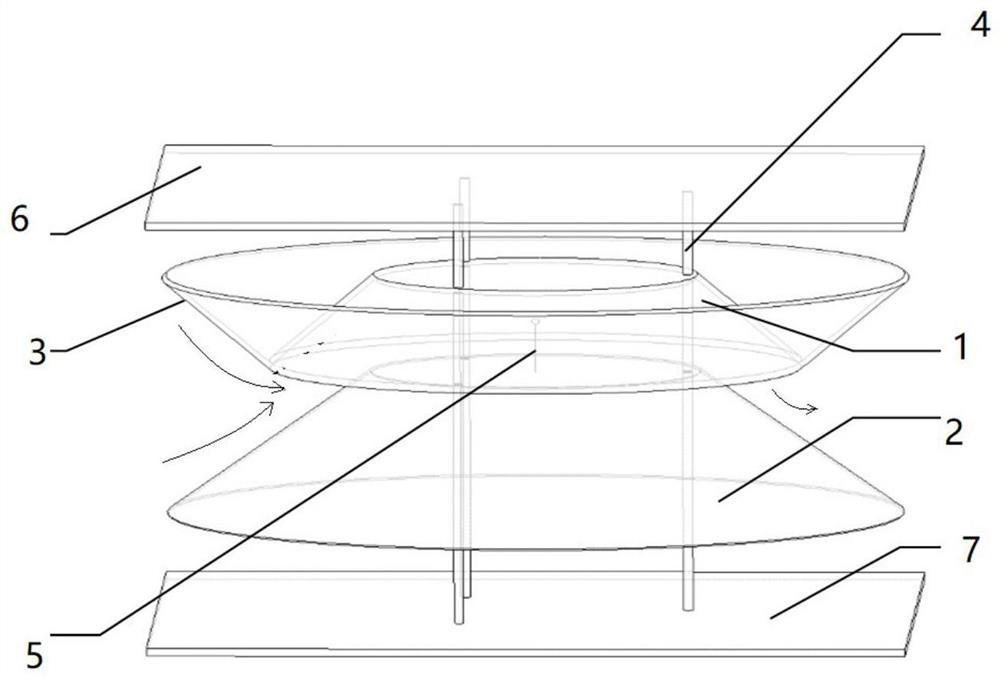

Radiation shield for meteorological measurement

InactiveCN105928630AImprove ventilationReduce hysteresis errorThermometer detailsWind runEngineering

The invention discloses a radiation shield for meteorological measurement, and belongs to the technical field of a meteorological instrument, for solving the technical problem of providing a radiation shield for meteorological measurement, capable of reducing sensor radiation errors and lag errors. The radiation shield comprises at least three guide tubes, the two ends of each guide tube is provided with an opening, each guide tube is internally at least provided with a temperature sensor probe, at least one guide tube has relative good ventilation whatever wind directions the radiation shield is disposed at, and thus solar radiation errors and lag errors of the temperature sensor probe can be reduced. Even if one guide tube is damaged, other guide tubes can still work normally, the whole radiation shield is little affected, and the reliability is quite good.

Owner:NANJING MICROSENSING ELECTRONICS TECH CO LTD

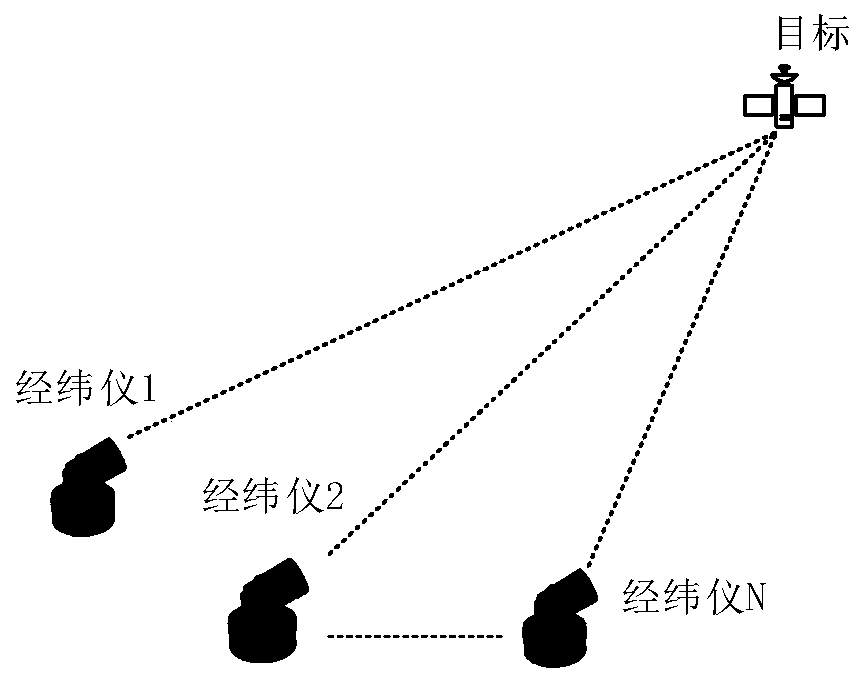

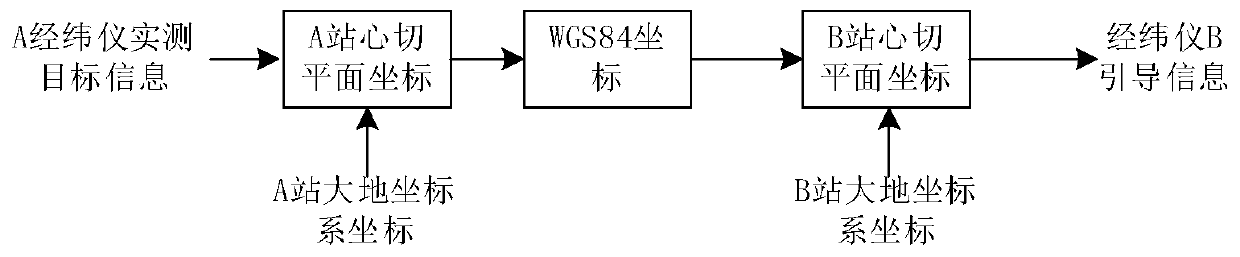

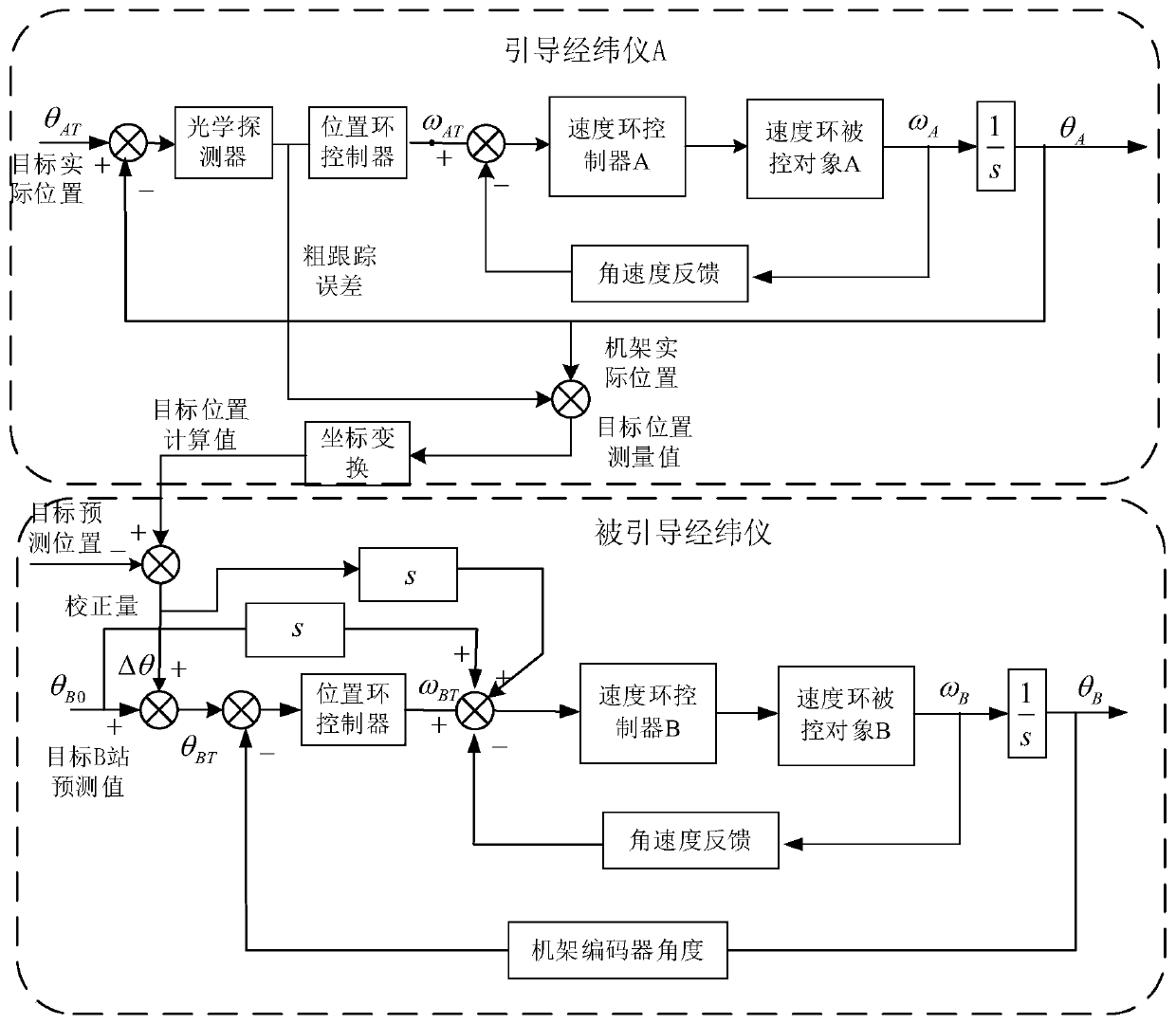

Method for improving mutual guiding precision of multiple photoelectric theodolites working together

ActiveCN109827541AHigh degree of achievabilityReduce hysteresis errorTheodolitesHysteresisTheodolite

The invention discloses a method for improving the mutual guiding precision of multiple photoelectric theodolites working together. For the requirement of high-precision guiding, the problem of the insufficient mutual guiding precision of the multiple photoelectric theodolites currently working together is solved. When the multiple photoelectric theodolites track the same target at the same time,one theodolite firstly captures the target and stabilizes the tracking target, then the theodolite emits a signal to guide other photoelectric theodolites to enter a tracking state, the factors affecting the guiding accuracy mainly include a site error, a pointing error and a dynamic hysteresis error. In order to suppress the errors, target trajectory data is transformed to coordinates of a station center tangent plane of a guided theodolite through synchronous star capture and calibration, the guided theodolite firstly moves along a predicted target trajectory, and then the mutual guidance accuracy is improved by the fine adjustment of a frame position, deviation amount feedforward control and other methods after receiving a deviation amount.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

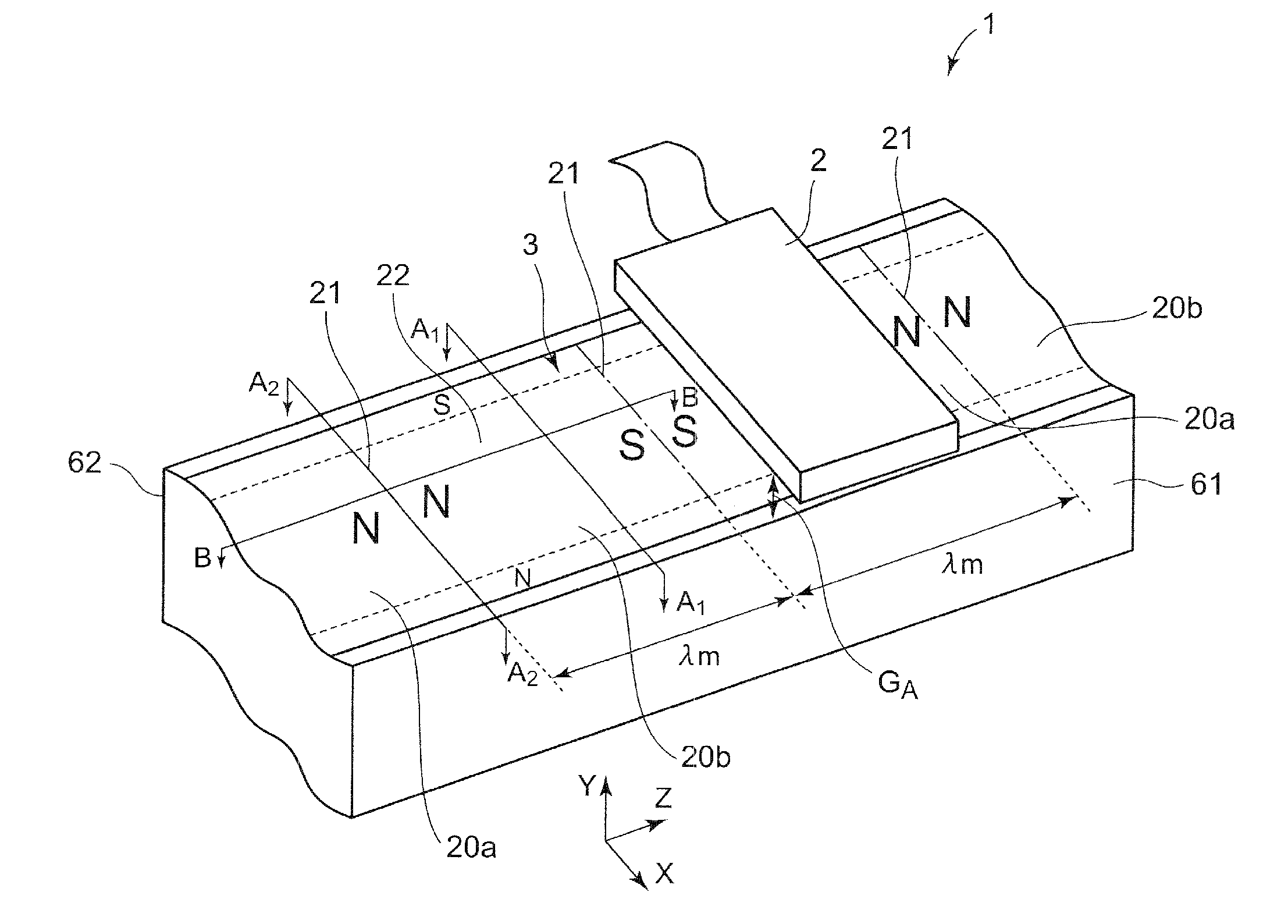

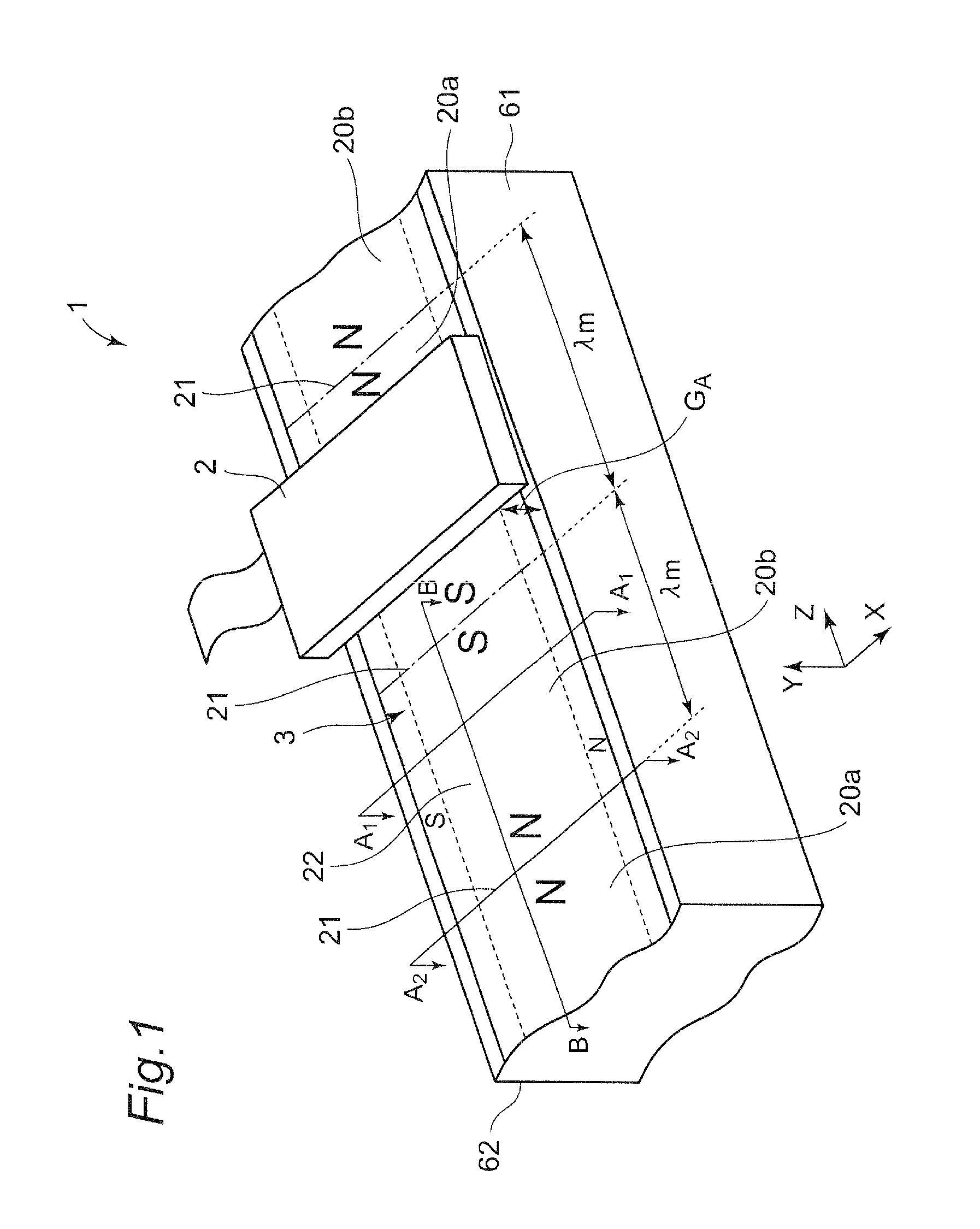

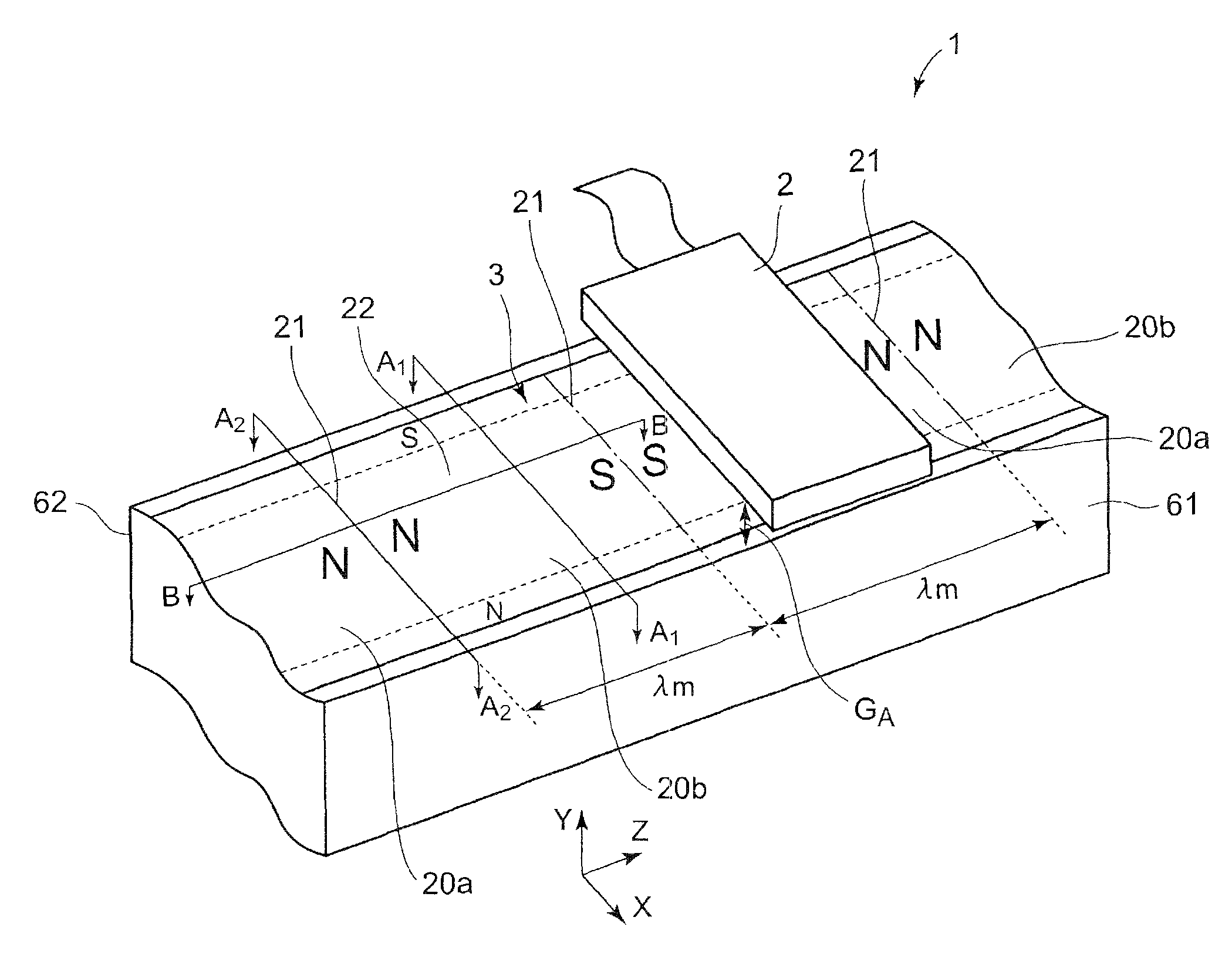

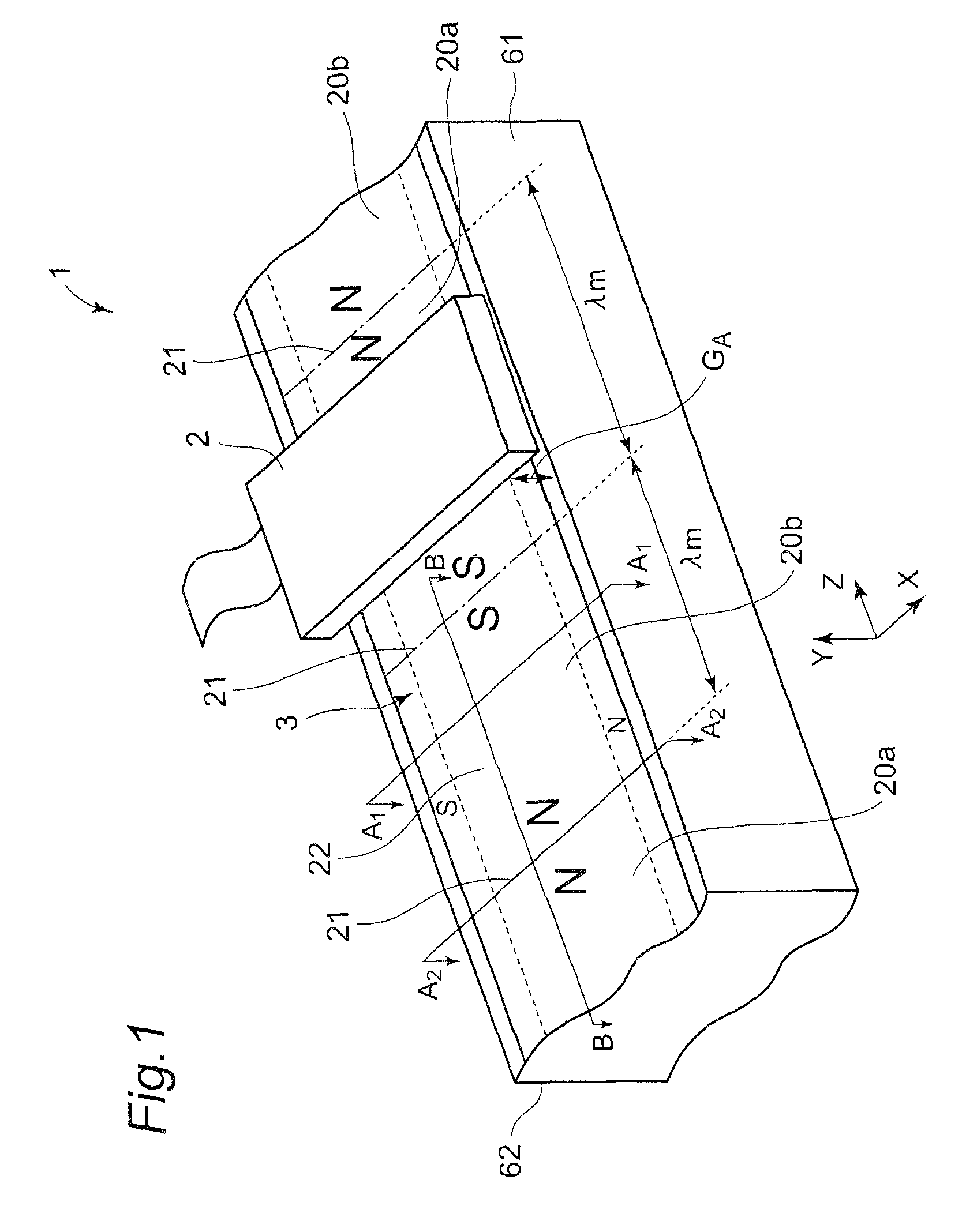

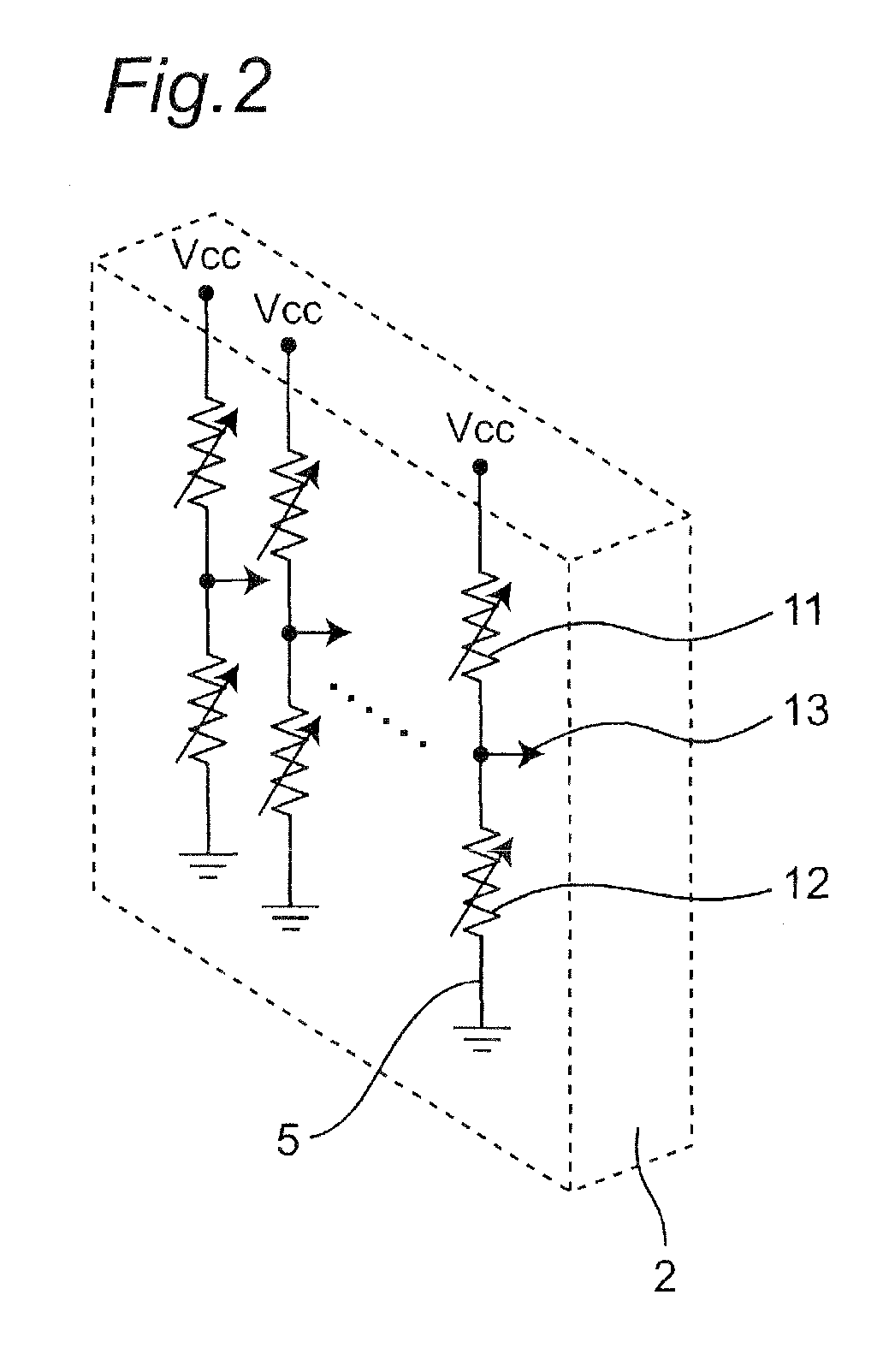

Magnetic medium for magnetic encoder, magnetic encoder and method for manufacturing magnetic medium

InactiveUS20150115939A1High reliabilityExtra signal is outputtedMagnetic-field-controlled resistorsSolid-state devicesNuclear magnetic resonanceHysteresis

The present disclosure provides a magnetic medium, a magnetic encoder, and a method for manufacturing a magnetic medium with high reliability that can obtain the sufficient signal output, while reducing the hysteresis error.Disclosed is a magnetic medium relatively movable with respect to a magnetic sensor for detecting a magnetic field in a magnetosensitive face, the magnetic medium including: a signal magnetization region including a first magnetization region magnetized in a first direction being in parallel with the magnetosensitive face and a second magnetization region magnetized in a second direction opposed to the first direction, the first magnetization region and the second magnetization region being alternately arranged along the first direction or the second direction; anda bias magnetization region magnetized in a third direction, the third direction intersecting both the first and second directions, and being in parallel with the magnetosensitive face, whereinwhile a surface of the magnetic medium opposed to the magnetic sensor is placed to face upward,the bias magnetization region is formed under the first magnetization region and the second magnetization region near an interface between the first magnetization region and the second magnetization region, and no bias magnetization regions are formed under the first magnetization region near a center of the first magnetization region and under the second magnetization region near a center of the second magnetization region.

Owner:HITACHI METALS LTD

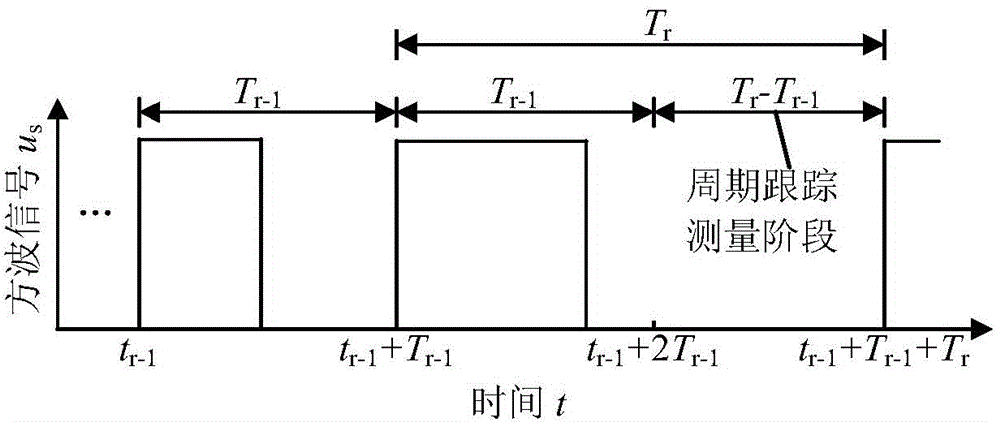

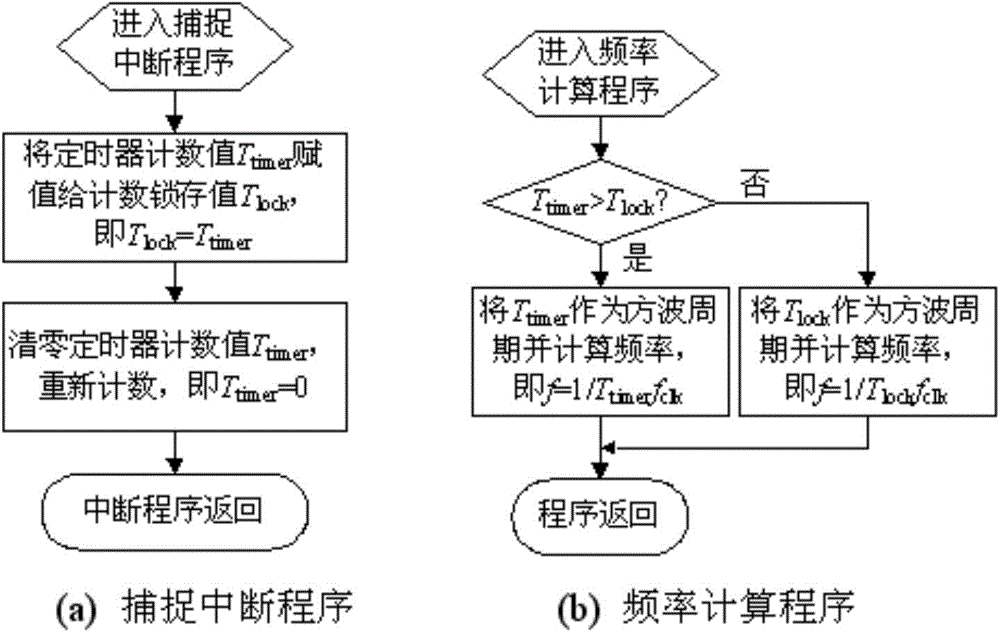

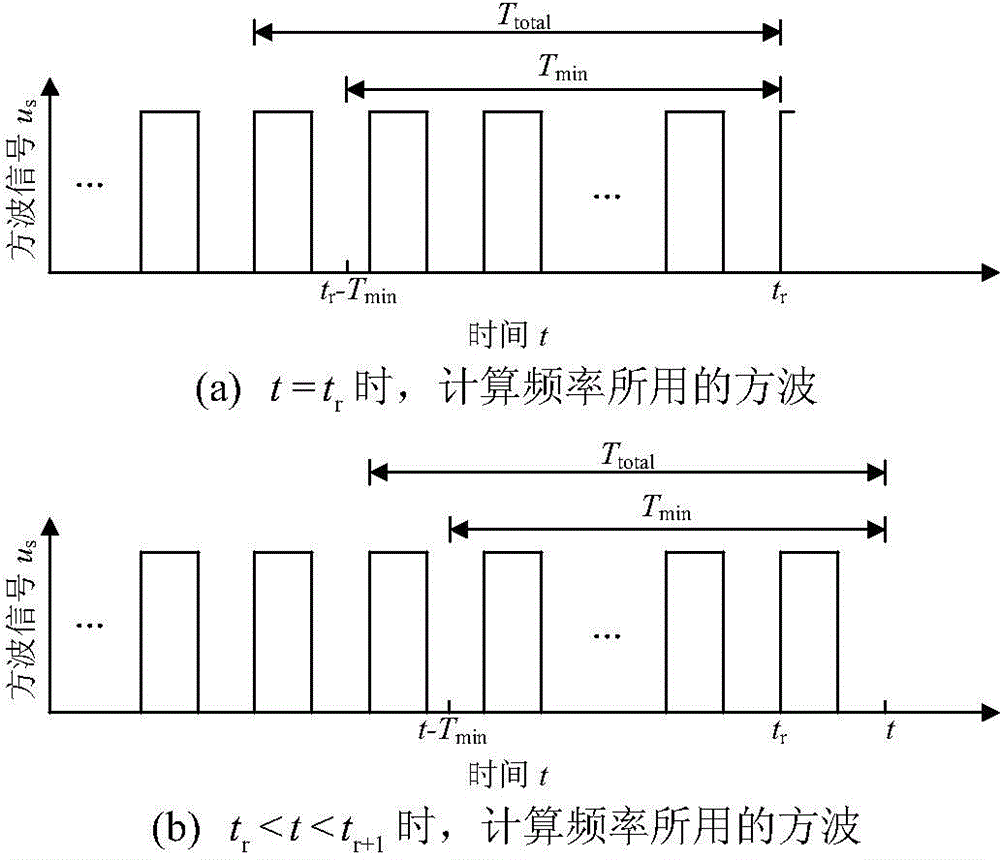

Signal frequency measuring method based on period tracking method and mobile integer period method

InactiveCN104020349AFast trackReduced Quantity RequirementsFrequency measurement arrangementHysteresisGreek letter epsilon

The invention discloses a signal frequency measuring method based on a period tracking method and a mobile integer period method. The signal frequency measuring method comprises the specific steps that first, the timer frequency f[clk] and an allowed measuring error epsilon are set; second, if the upper limit f[max] of a measured signal frequency f is unknown, the mobile integer period method is used for measuring the signal frequency, and if the upper limit f[max] of a measured signal frequency f is known, whether the f[max], the f[clk] and the epsilon meet the relational expression that f[max] is smaller than f[clk]*epsilon is judged, if yes, the period tracking method is used for measuring the signal frequency, and if not, the mobile integer period method is used for measuring the signal frequency. The period tracking method can update the measuring result in time when detecting the situation that the signal period is prolonged, and the mobile integer period method achieves the effect that the measuring result is updated at least one time in each signal period. The period tracking method and the mobile integer period method can track the changing process of the signal frequency faster, the hysteresis error is reduced, the requested number of timers is not increased, the calculation amount is small, only a small amount of memory variable needs to be added, and therefore the hardware cost of a frequency testing device cannot be increased.

Owner:SOUTHWEST UNIVERSITY

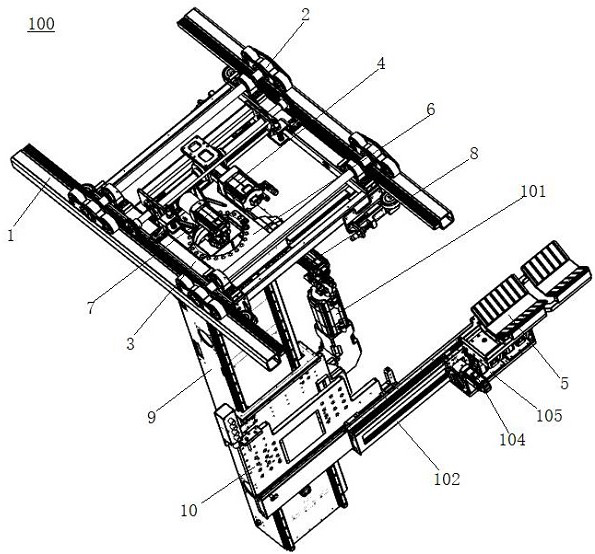

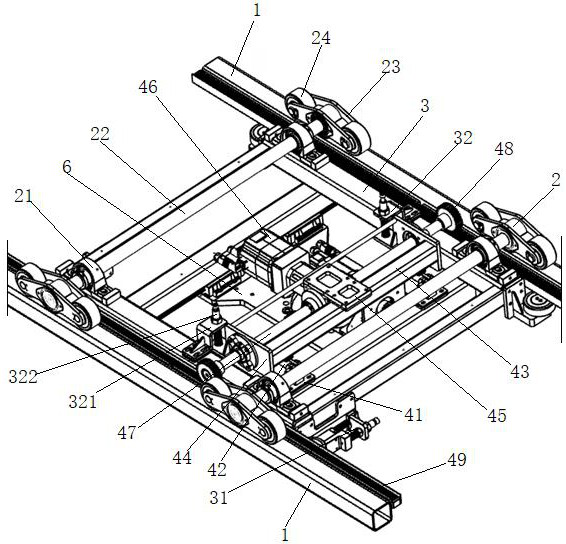

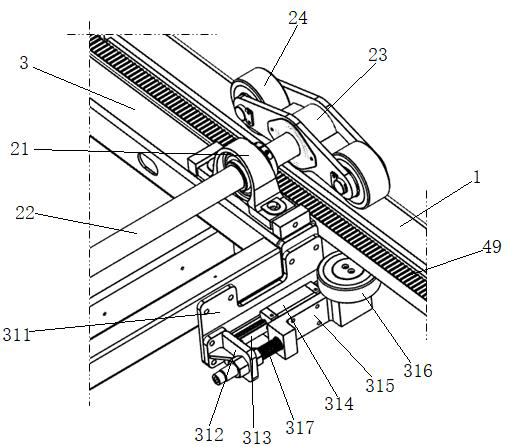

High-speed precise multi-axis material taking robot

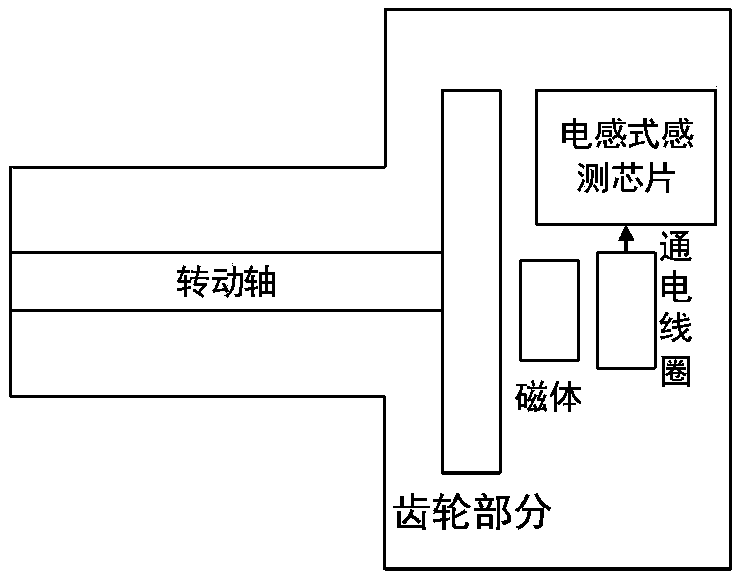

ActiveCN112276918AGuaranteed motion accuracyRealize pick and placeProgramme-controlled manipulatorGripping headsGear wheelEngineering

The invention discloses a high-speed precise multi-axis material taking robot which comprises an X-axis driving assembly, a Y-axis driving assembly, a rotary driving assembly, a Z-axis driving assembly, a first-stage extending mechanism, a second-stage extending mechanism, a jacking mechanism and material taking modules. The X-axis driving assembly, the Y-axis driving assembly, the Z-axis drivingassembly, the first-stage extending mechanism and the second-stage extending mechanism are all driven through cooperation of gears and racks and a linear rail servo motor, the rotary driving assemblyis driven by a worm and gear, an installation vertical cabinet is arranged on a rotary plate of the rotary driving assembly, and the Z-axis driving assembly is arranged on the installation vertical cabinet. All electric control components needed by the multi-axis material taking robot are arranged in the installation vertical cabinet, a man-machine operation interface is arranged outside the installation vertical cabinet, and the two material taking modules are arranged. The high-speed precise multi-axis material taking robot is high in operation stability, capable of meeting the requirementsof application scenes with high high-speed material taking and placing and position precision requirements, simple in structure and good in coordination, and the material taking and placing efficiencyis greatly improved.

Owner:健芮智能科技(昆山)有限公司

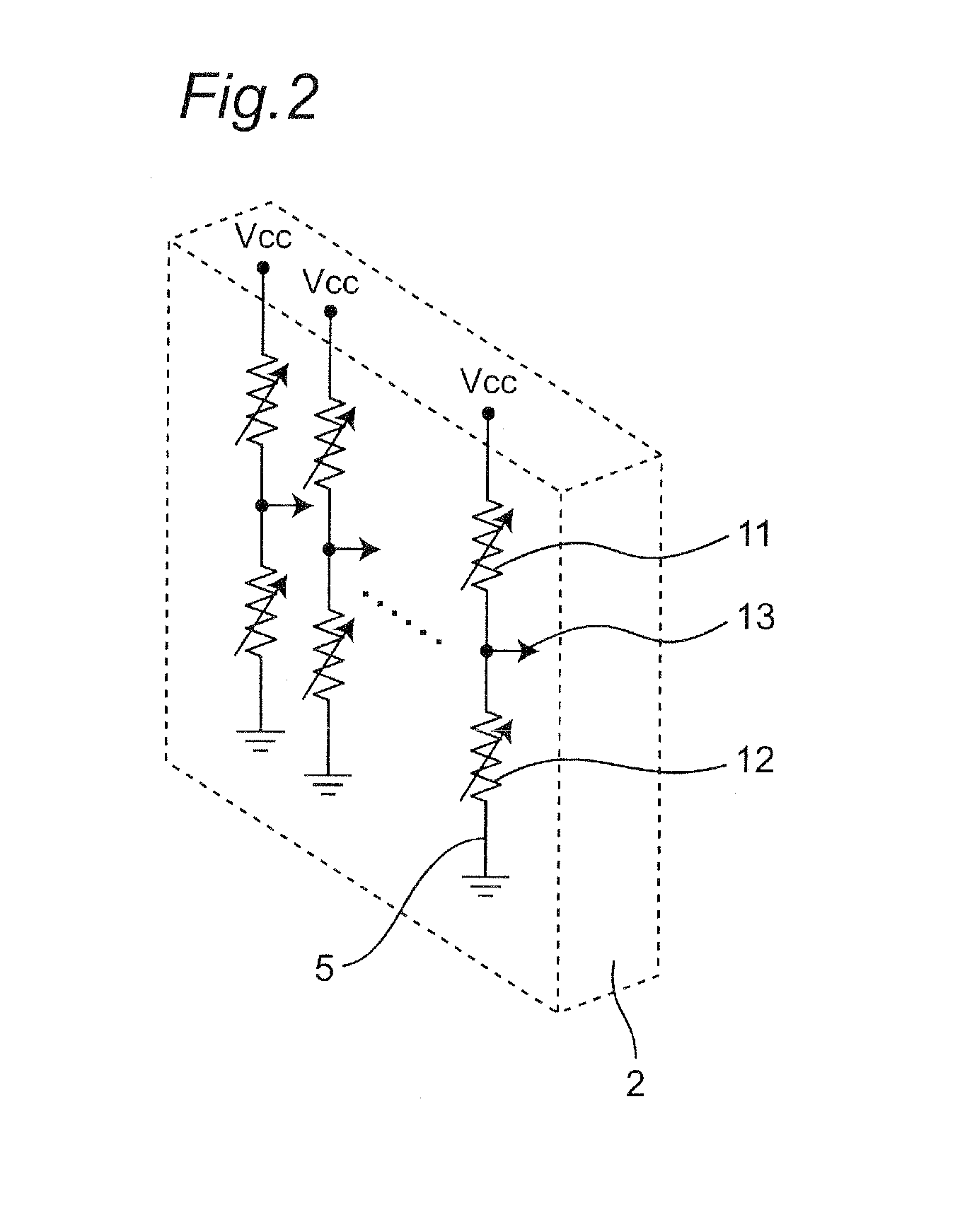

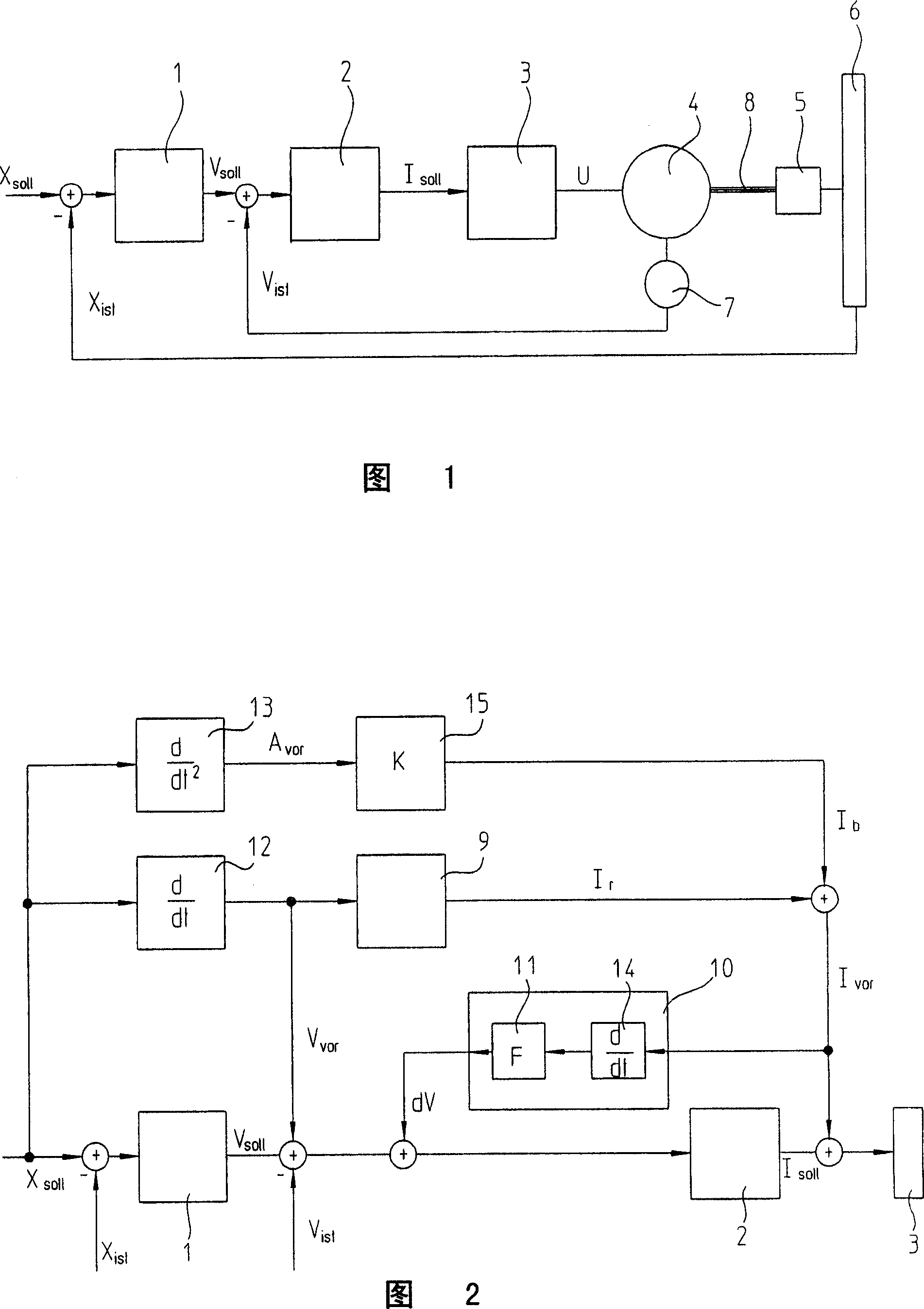

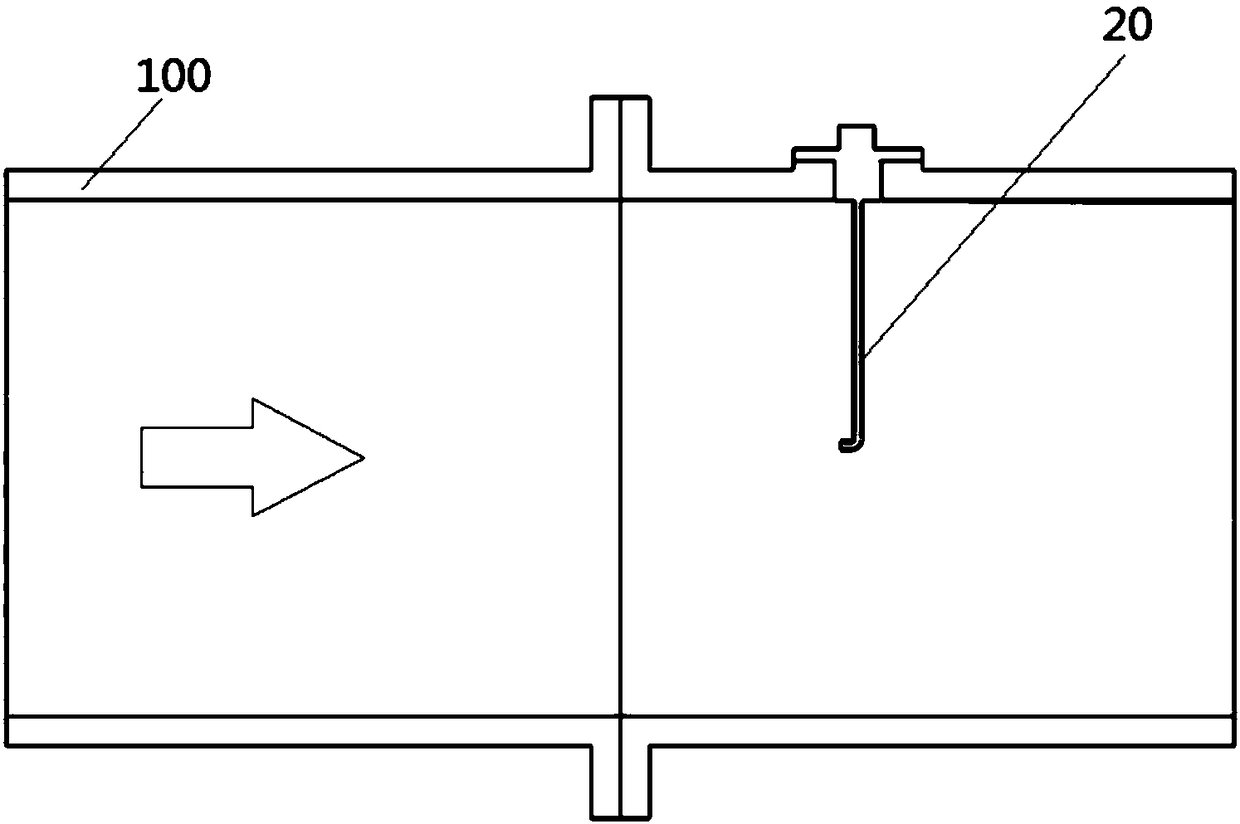

Controller structure

InactiveCN101017367AReduce hysteresis errorReduce or completely avoid hysteresis errorsSimulator controlControllers with particular characteristicsDifferentiatorReference current

The invention relates to a controller structure for controlling the position of an object (5), in which the object (5) is drived by a motor (4) through a mechanical installation (8). The controller structure has a position controller (1) for generation of a rotational speed reference value(Vsoll) from a position reference value(Xsoll) and a position actual value(Xist); a rotational speed controller (2) for generation of a reference current value (Isoll) from the rotational speed reference value and a rotational speed actual value (Vist); as well as circuits (9,12,13) for generation of a pre-control (Ivor) from the position reference value, wherein the pre-control (Ivor) is connected to the reference current value (Isoll). The pre-control current (Ivor) is provided to a module (10) for torsion pre-controlling, wherein the output signal (dV) of the module is added to the rotational speed reference value (Vsoll). The module (10) for torsion pre-controlling is composed by a differentiator (14) of the first derivative for forming the pre-control current (Ivor), and a second multiplier (11), in which the first derivative of the pre-control current multiplies a factor (F).

Owner:DR JOHANNES HEIDENHAIN GMBH

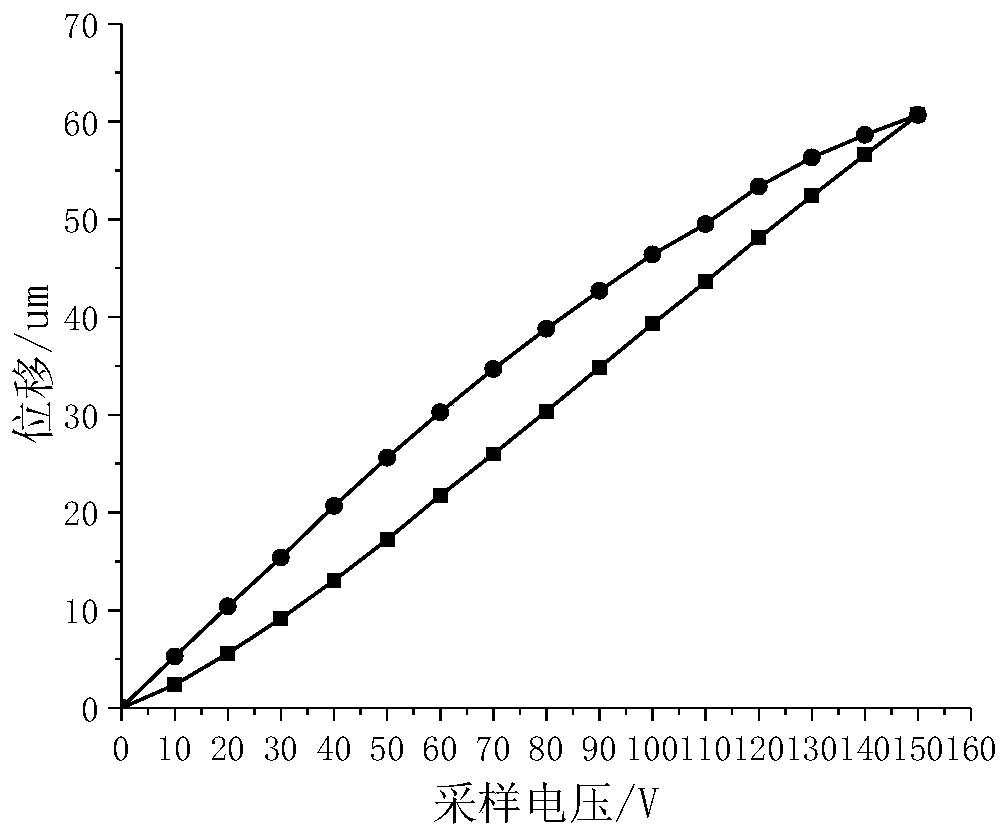

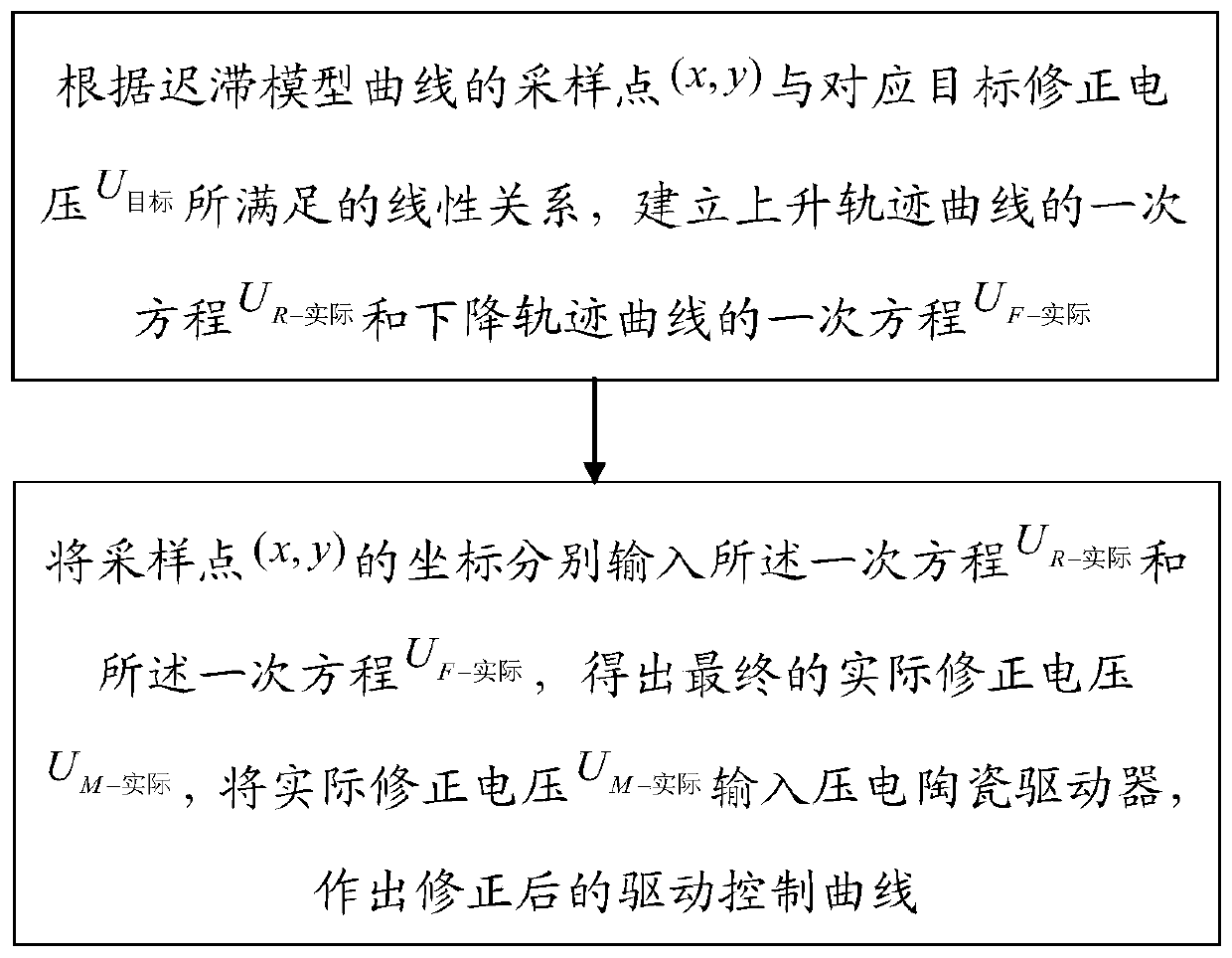

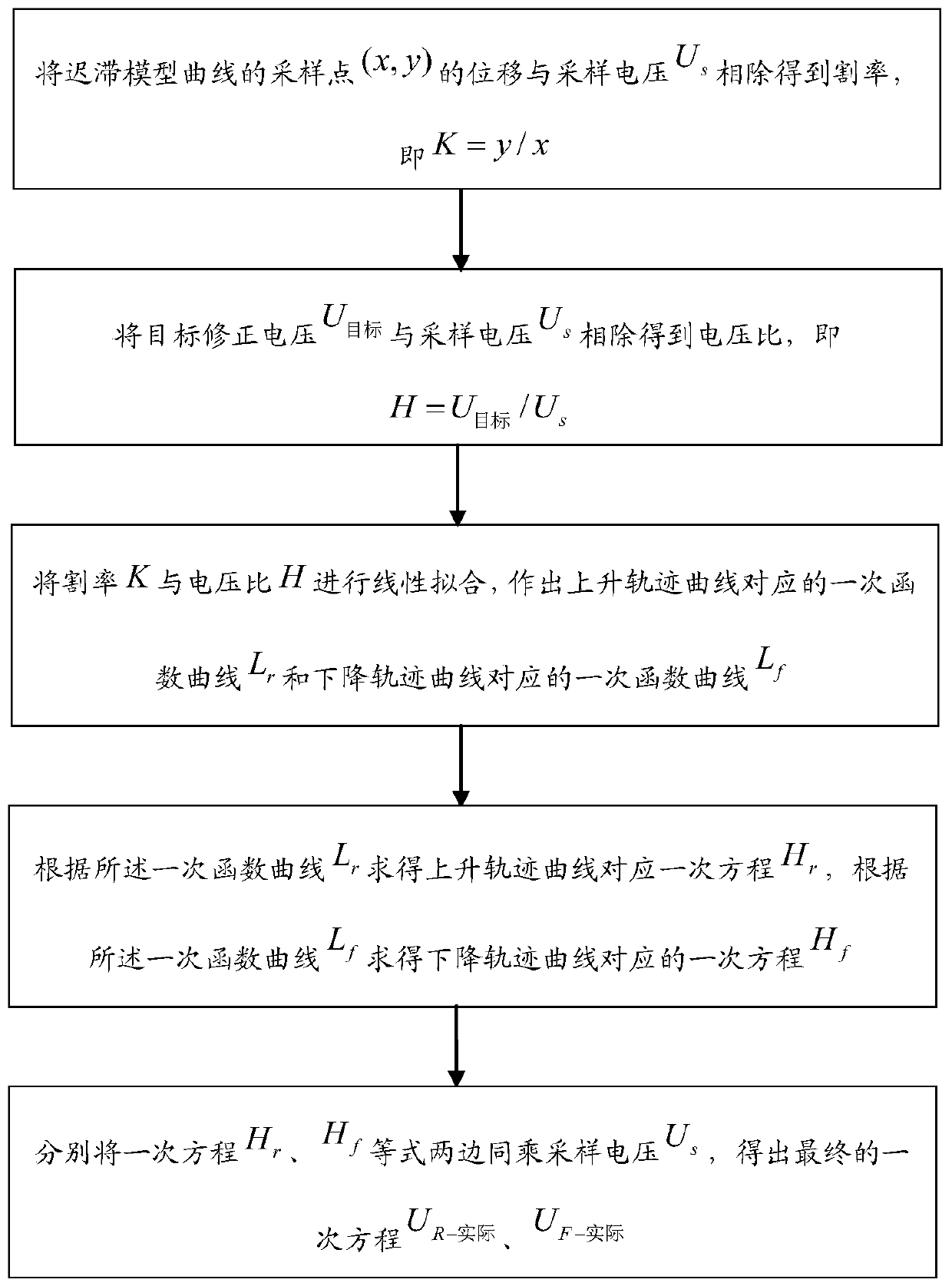

Anti-hysteresis method and device for piezoelectric ceramic, equipment and medium

ActiveCN111030503AGood repeatabilityImprove universalityPiezoelectric/electrostriction/magnetostriction machinesLinear relationshipEngineering

The invention provides an anti-hysteresis method and device for piezoelectric ceramics, equipment and a medium, and the method comprises the steps: S1, building a linear equation UR-shiji of a risingtrack curve and a linear equation UF-shiji of a falling track curve according to the linear relation between a sampling point (x, y) of a hysteresis model curve and a corresponding target correction voltage U target; and S2, finally, respectively inputting the coordinates of the sampling point (x, y) into the linear equation UR-shiji of the rising track curve and the linear equation UF-shiji of the falling track curve to obtain a final actual correction voltage UM-shiji, and actually inputting the actual correction voltage UM-shiji into a piezoelectric ceramic driver to draw a corrected driving control curve. Through the two linear equations, the anti-hysteresis method and device are higher in feasibility and operability, and provide a scientific reference basis for the further improvementof the positioning and control precision of the piezoelectric ceramic driver.

Owner:HUAQIAO UNIVERSITY

Magnetic medium for magnetic encoder, magnetic encoder and method for manufacturing magnetic medium

InactiveUS9574906B2Reduce hysteresis errorIncrease in sizeMagnetic bodiesInductances/transformers/magnets manufactureHysteresisMagnetic media

The present disclosure provides a magnetic medium, a magnetic encoder, and a method for manufacturing a magnetic medium with high reliability that can obtain the sufficient signal output, while reducing the hysteresis error. The magnetic medium is relatively movable with respect to a magnetic sensor for detecting a magnetic field in a magnetosensitive face.

Owner:HITACHI METALS LTD

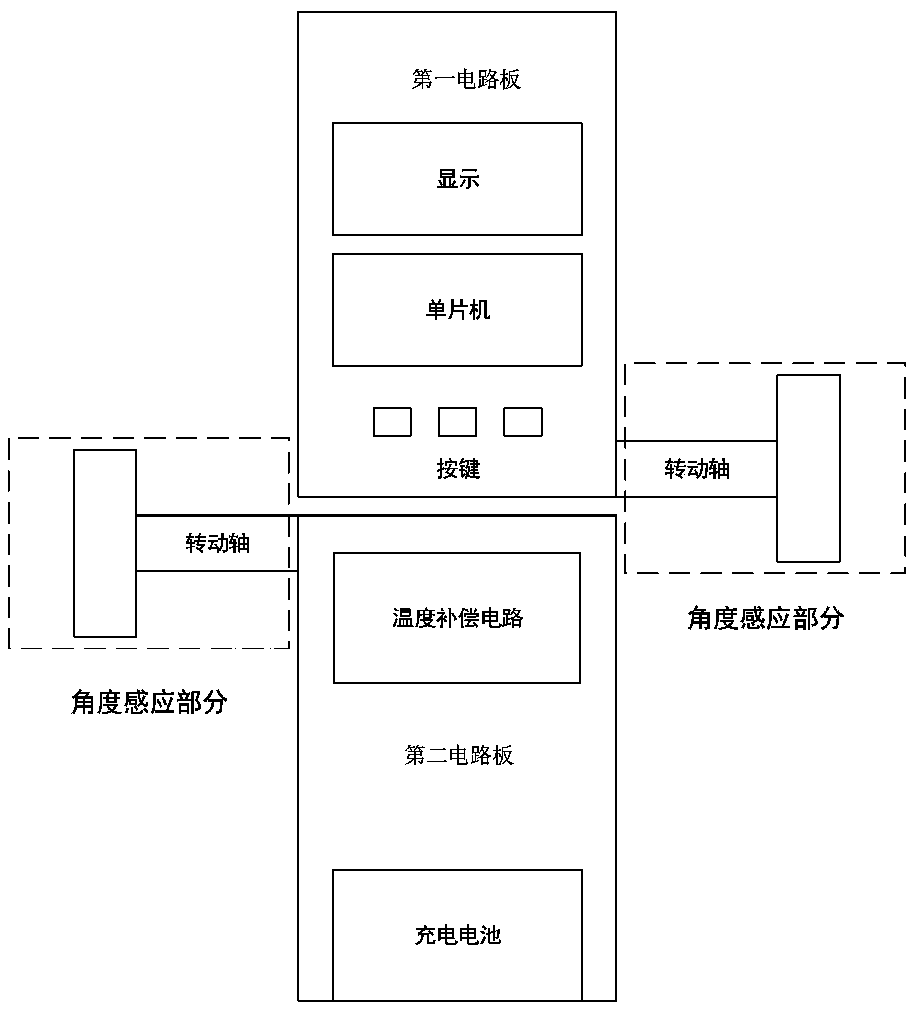

Angle sensor for leg angle measurement

InactiveCN109259769AConvenient and effective for training and rehabilitationHigh precisionDiagnostic recording/measuringSensorsThigh musculatureMicrocomputer

An angle sensor for leg angle measurement is disclosed and belongs to the field of an angle sensor. The angle sensor includes a first circuit board for generating a first angle signal and a first temperature signal at the thigh and transmitting the first angle signal and the first temperature signal to the single chip microcomputer, a second circuit board for generating a second angle signal and asecond temperature signal at the lower leg and transmitting the second angle signal and the second temperature signal to a single chip microcomputer, and the single chip microcomputer for processingthe first angle signal, the second angle signal, the first temperature signal and the second temperature signal to obtain a final angle value of the single chip microcomputer. It solves the problems of inaccurate observation of angle change of leg shape by naked eyes, interference of ambient temperature and strong magnetic field in leg shape correction, dance training and rehabilitation treatment,and can be used in leg shape correction, dance training and rehabilitation treatment.

Owner:华蓥市铜堡初级中学

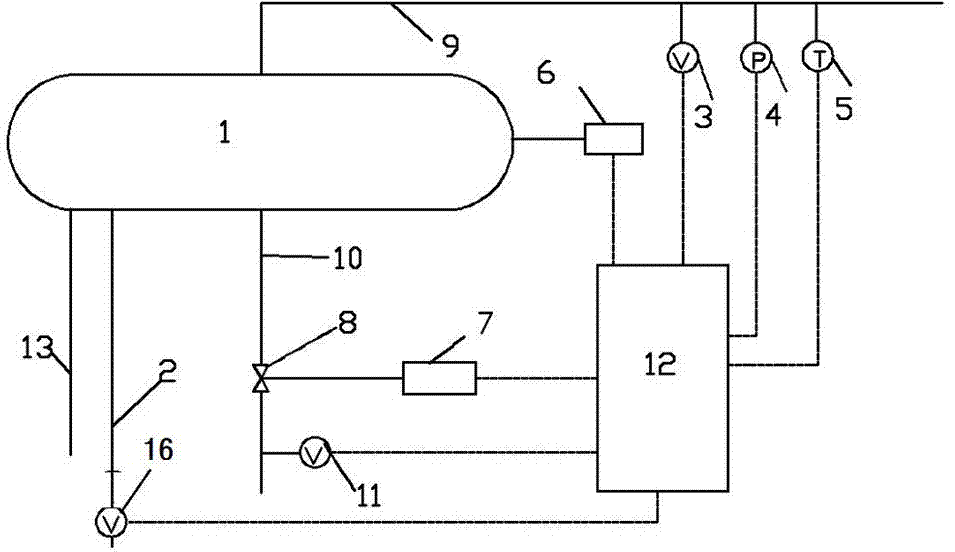

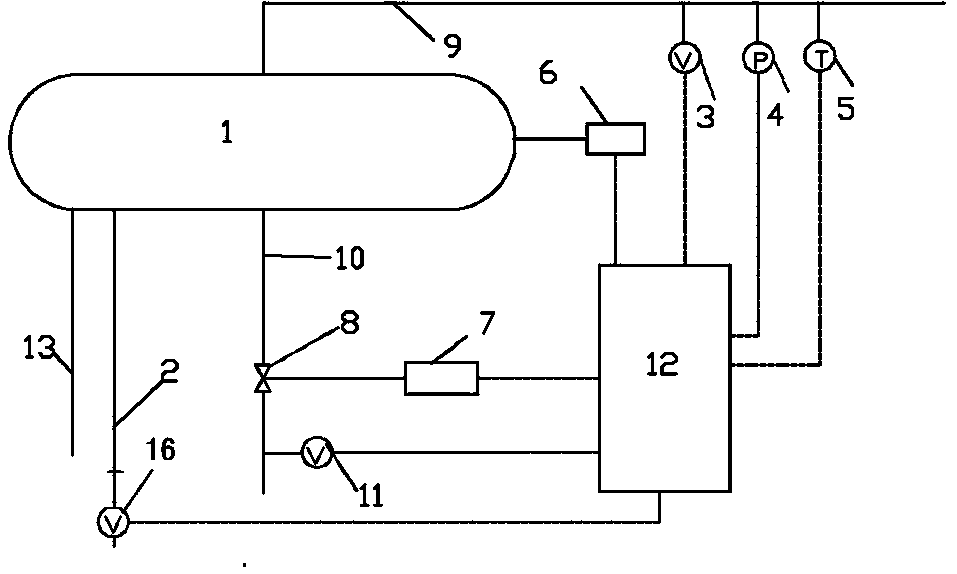

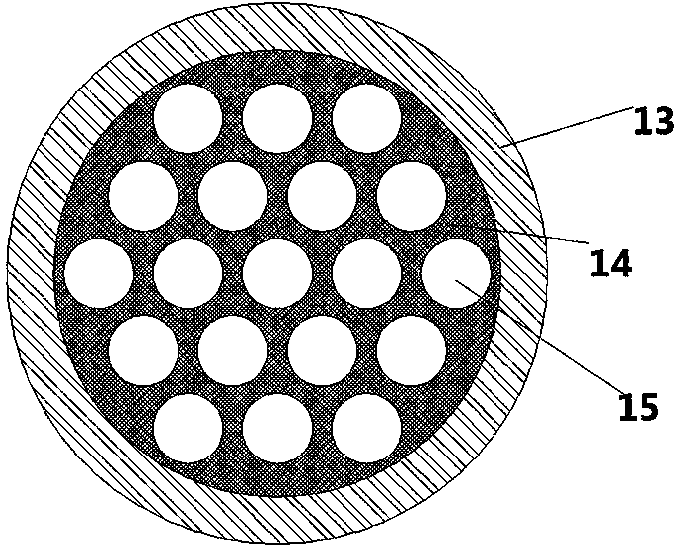

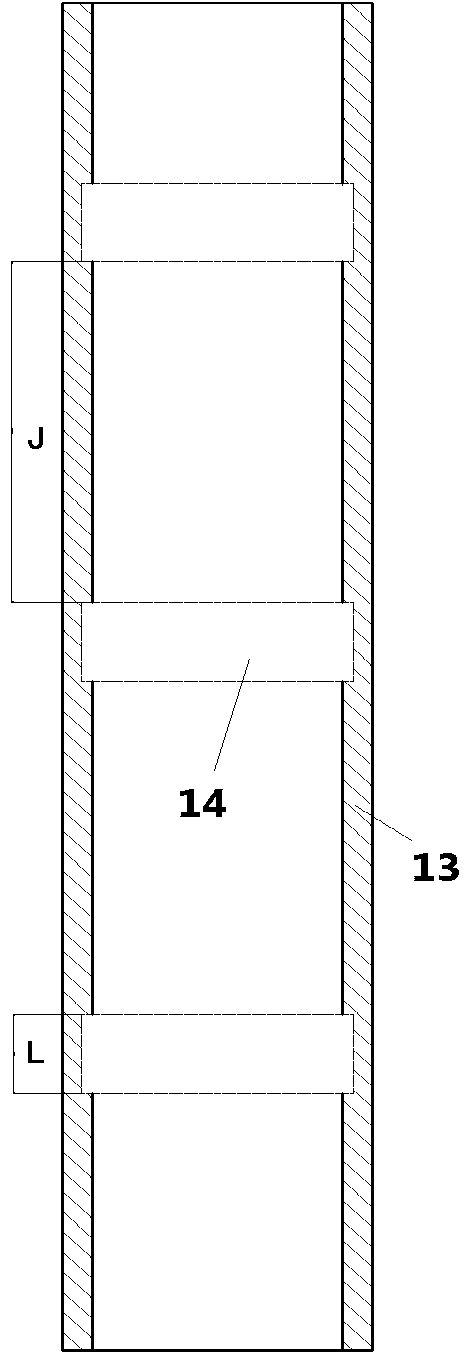

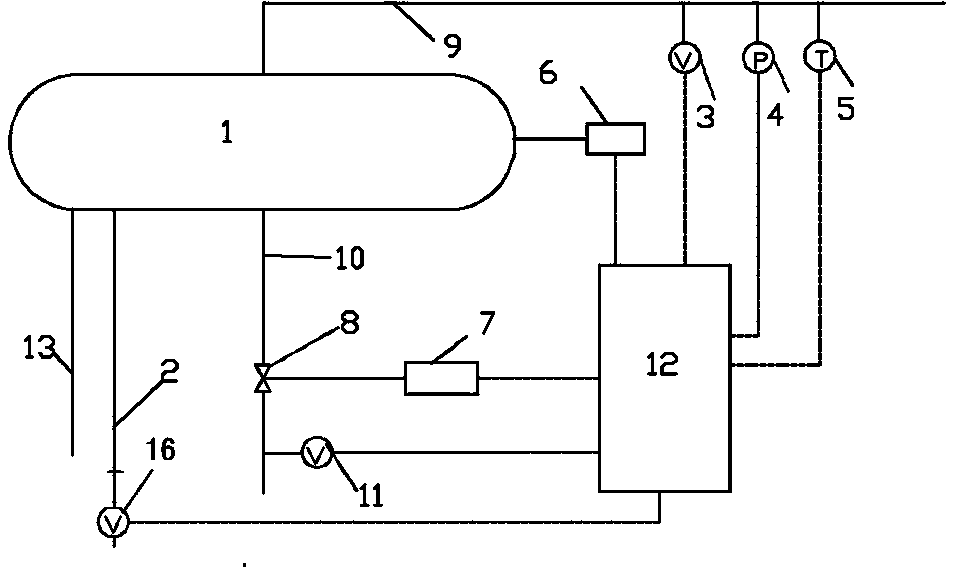

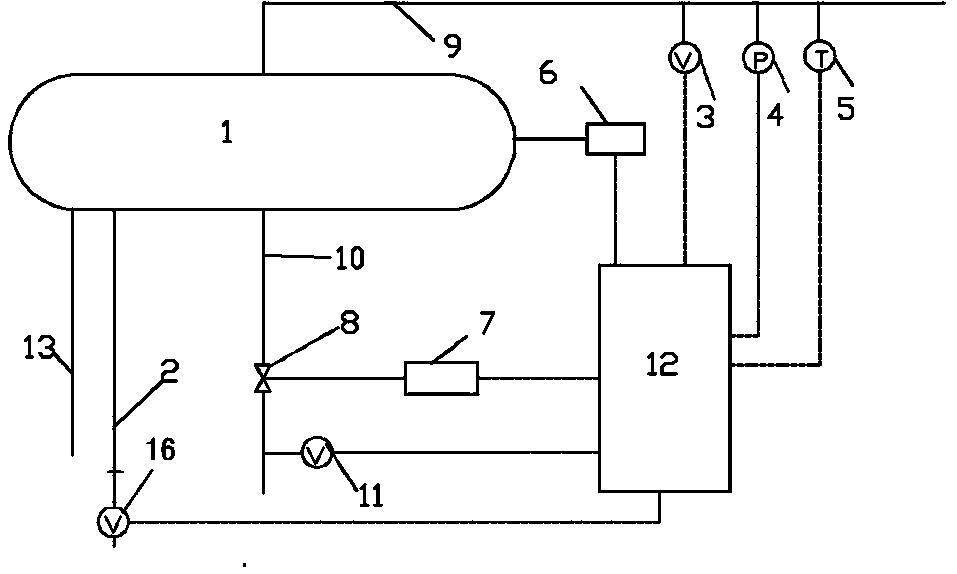

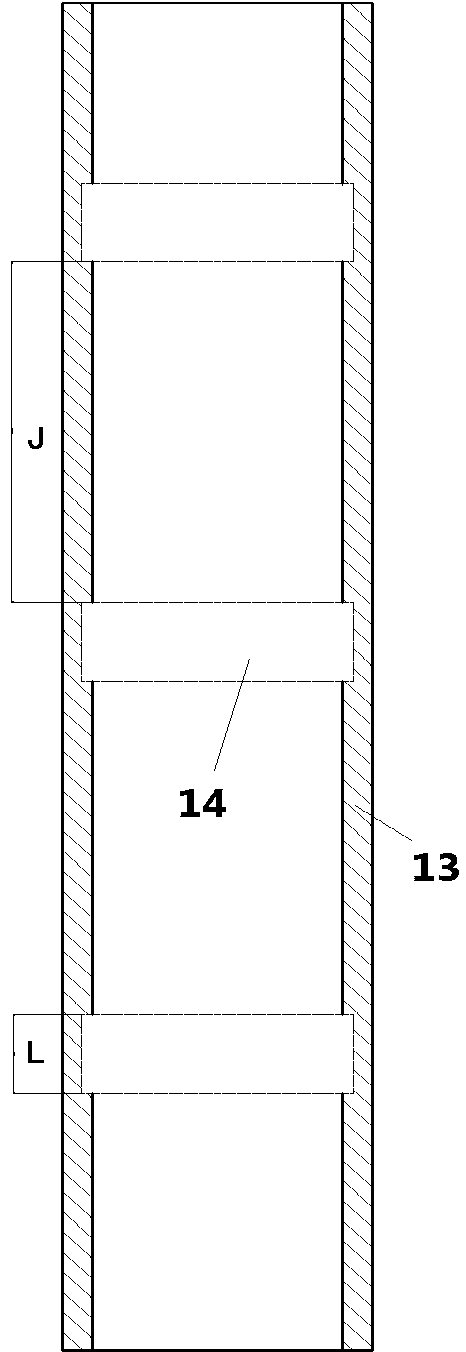

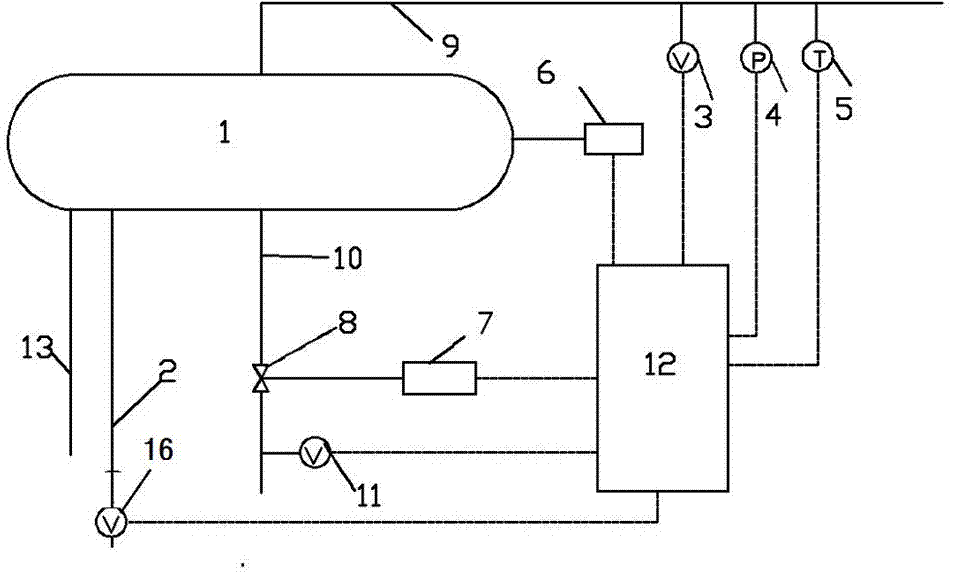

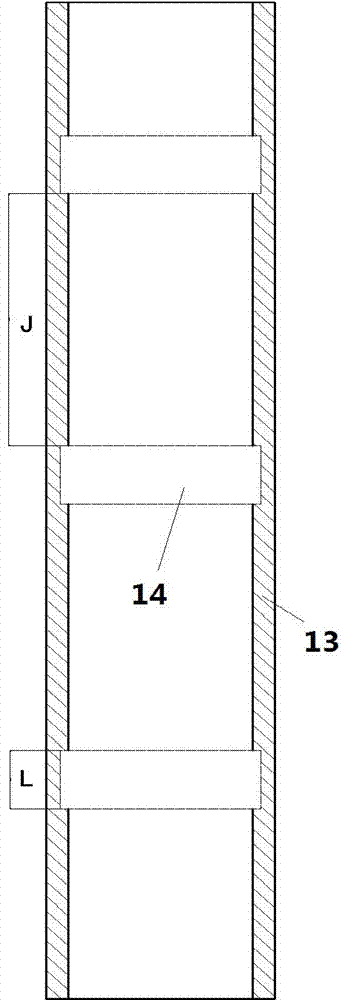

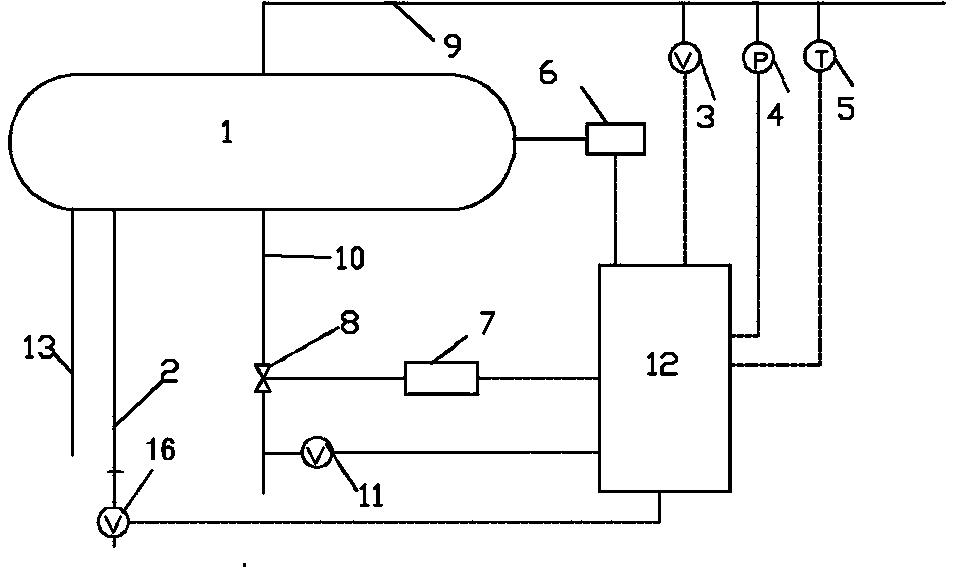

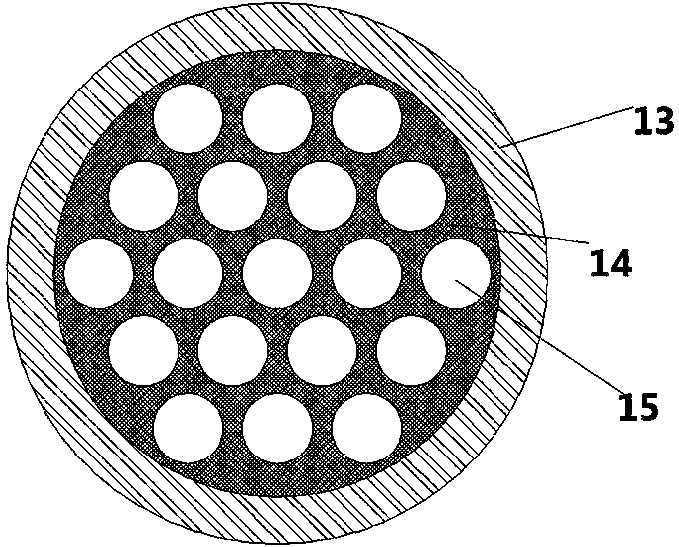

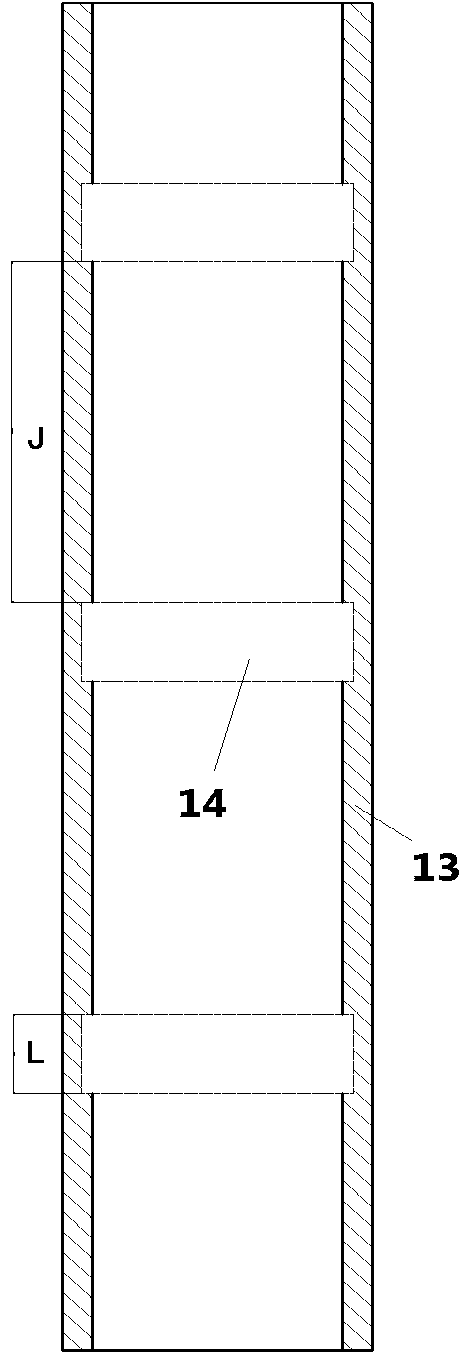

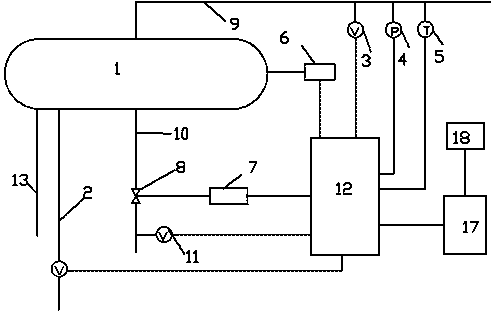

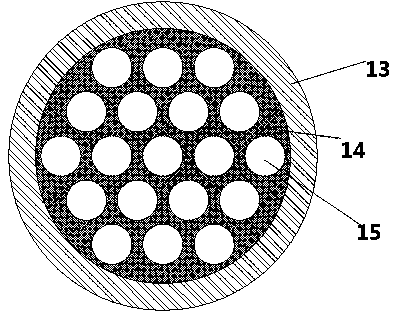

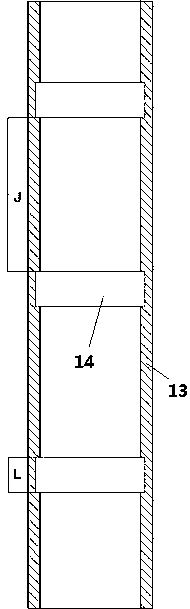

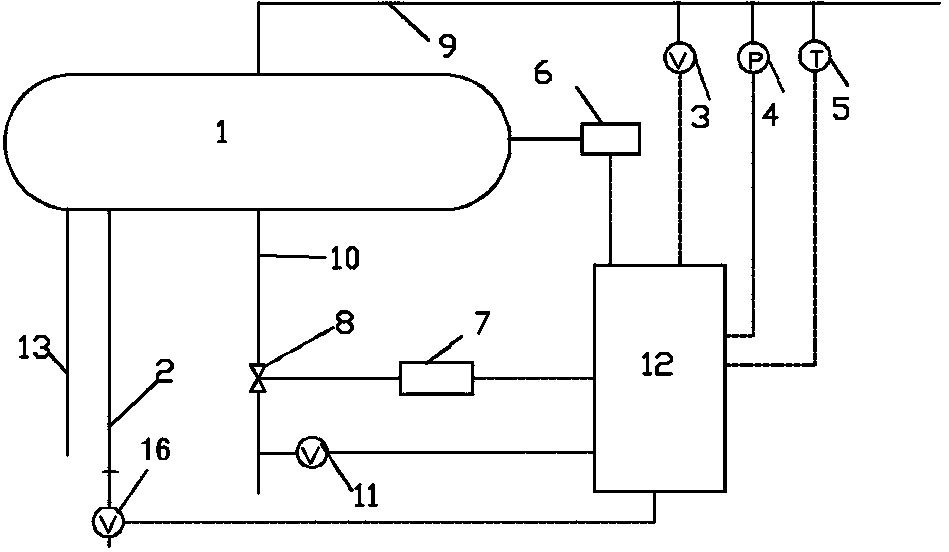

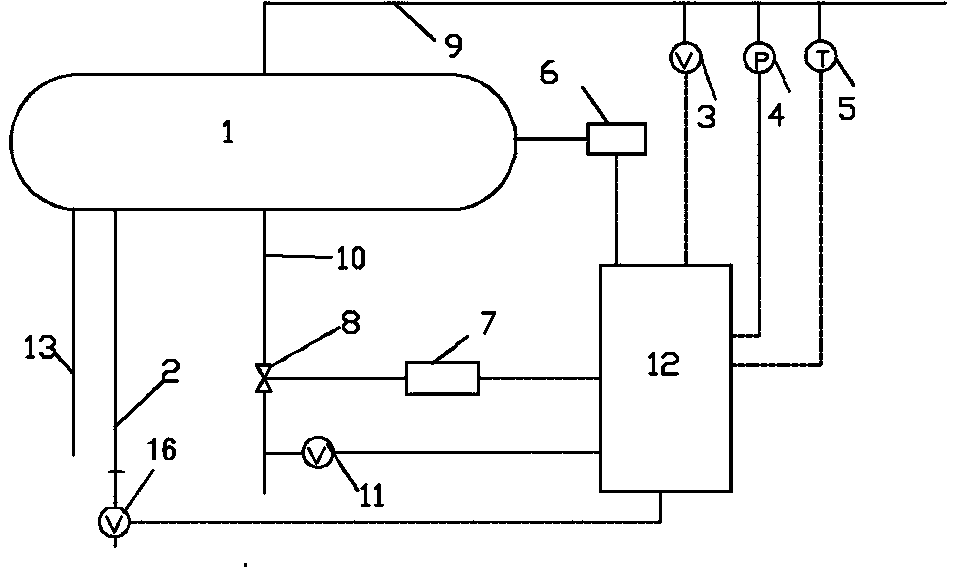

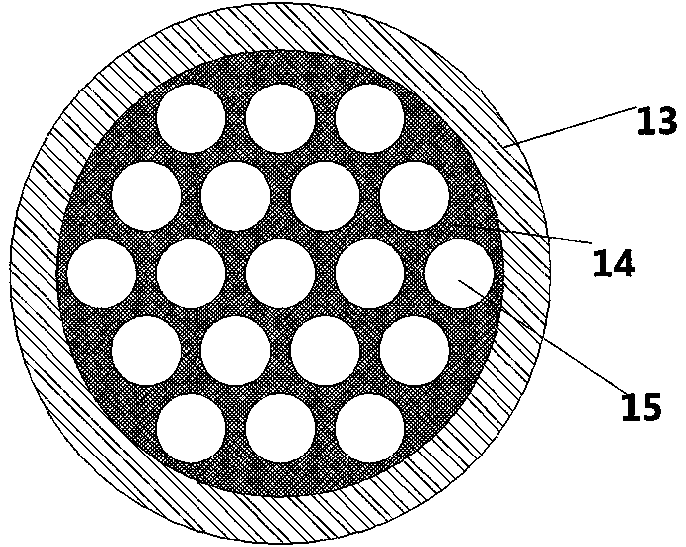

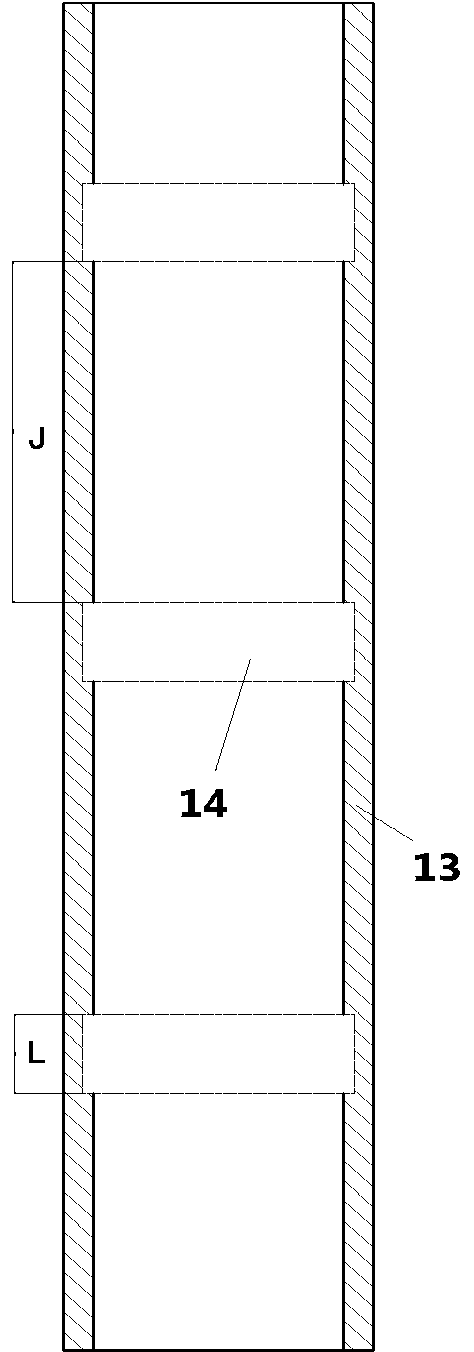

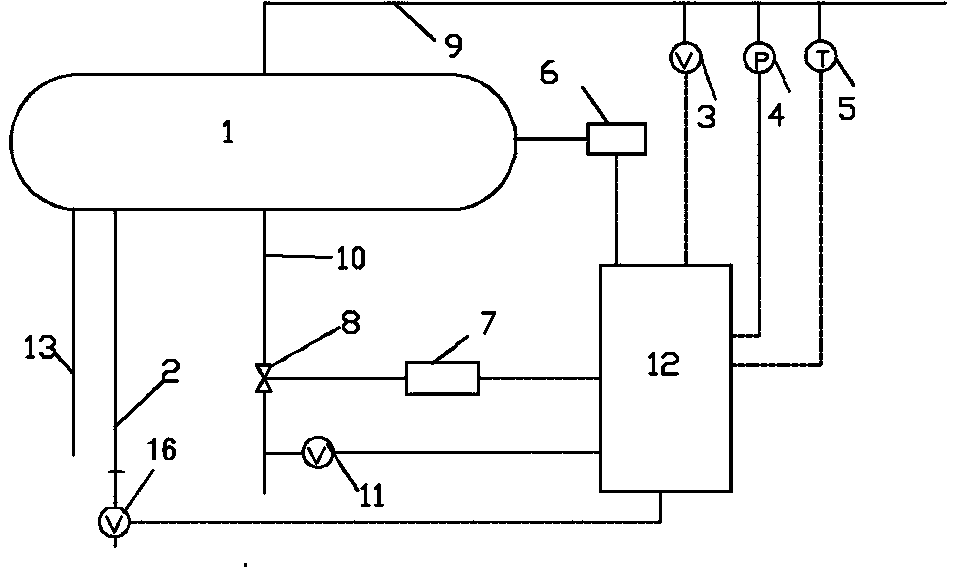

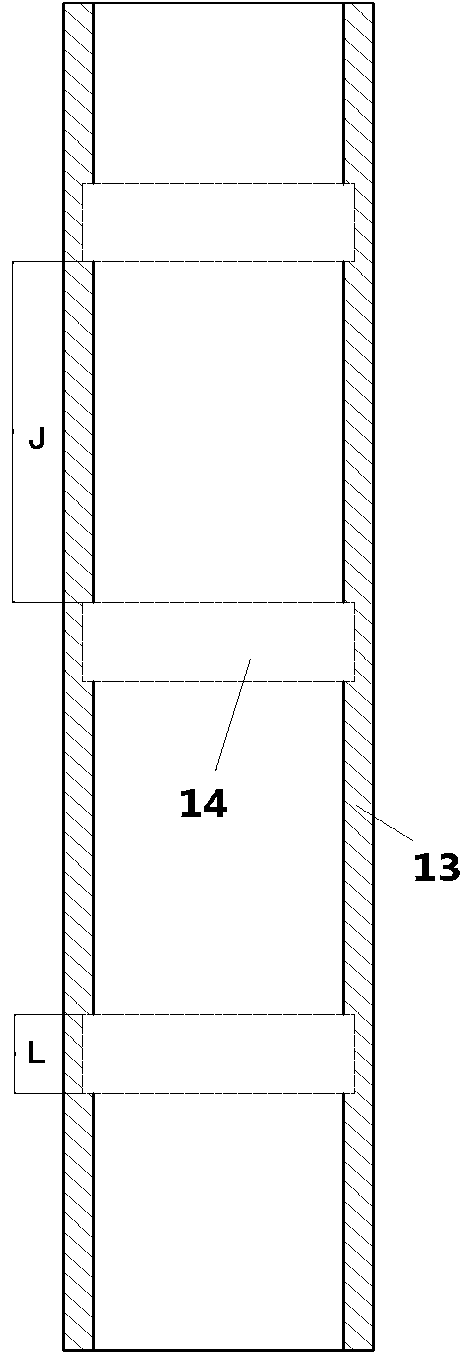

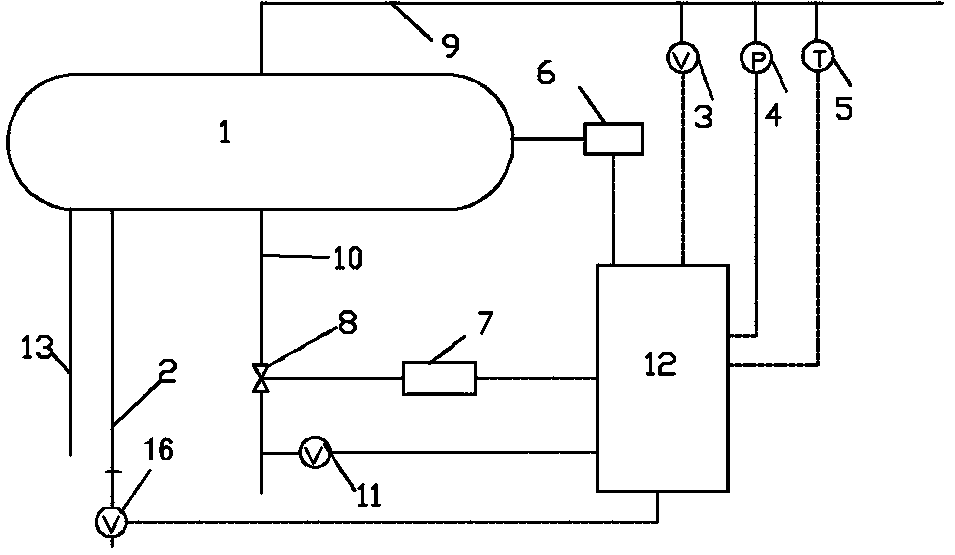

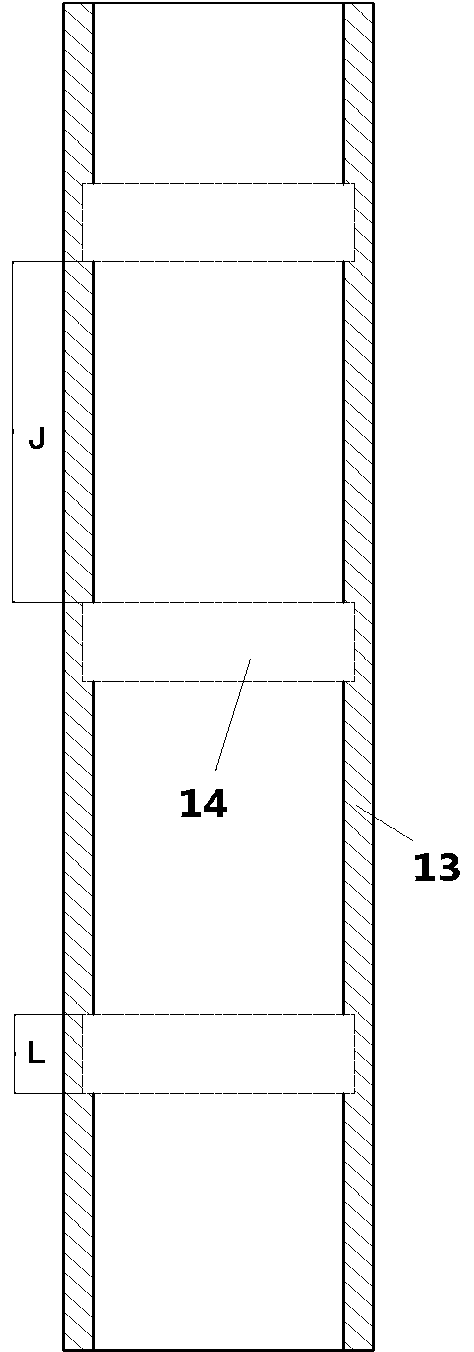

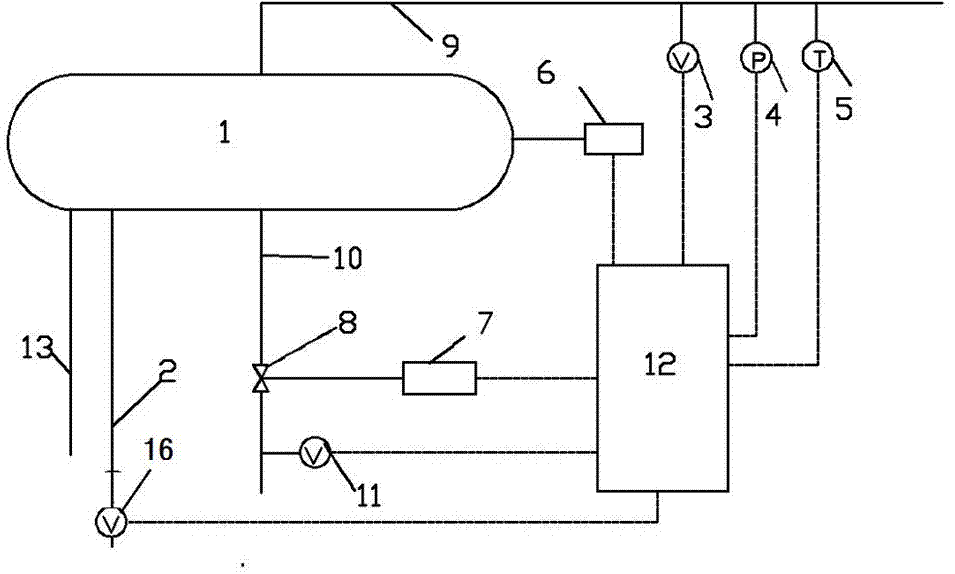

Cloud-computing boiler blow-off system

InactiveCN107101191AKeep abreast of the operation status in timeAvoid wastingBoiler cleaning apparatusBoiler controlData connectionAutomatic control

The invention provides a cloud-computing boiler blow-off system. According to the cloud-computing boiler blow-off system, automatic control is carried out according to the amount of steam generated by boilers and the amount of water input to the boilers, the boilers are periodically subjected to blow-off operation, and a central diagnosis monitor automatically sets the blow-off amount according to the ratio of the mass of the steam to the mass of the water input to the boilers; and the monitoring diagnosis controller is in data connection with a cloud server so that the monitored data can be transmitted to the cloud server conveniently, the cloud server is connected to a client side, and the client side can obtain the monitored data through the cloud server. According to the cloud-computing boiler blow-off system, the amount of the input water and the amount of the generated steam of each boiler are monitored in real time so that the dynamic ratio relation of the amount of the input water and the amount of the generated steam can be obtained, the blow-off amount of the boilers can be automatically calculated according to the dynamic ratio relation, the blow-off time and the blow-off speed can be adjusted according to the blow-off amount, the operation condition of the boiler blow-off system can be timely mastered by the client side, the blow-off parameters can be adjusted timely through the client side, and therefore a large amount of heat energy waste caused by faults of the boiler blow-off system can be prevented.

Owner:ZHONGBEI UNIV

A steam boiler system with intelligent control of blowdown time

InactiveCN106989379BReduce lagExcellent pollution controlBoiler cleaning apparatusBoiler controlHysteresisAutomatic control

The invention provides an intelligently-controlled boiler system. The system is controlled automatically according to the steam quantity generated by boilers and the water quantity input into the boilers, the boilers are subjected to regular sewage discharging, the sewage discharging speed maintains unchanged, a central diagnosis monitor sets the sewage discharging time automatically according to the specific value between the steam mass and the mass of the water input into the boilers, and thus the discharge capacity is controlled automatically. The input water quantity and the generated steam quantity of each boiler are monitored in real time, the dynamic ratio relation between the input water quantity and the generated steam quantity is obtained, the discharge capacity of the boilers is calculated automatically according to the dynamic proportion relation, and the sewage discharging time is adjusted according to the discharge capacity. Compared with the prior art, hysteresis quality is reduced due to the fact that the sewage discharging time is calculated automatically, and the optimal sewage discharging control can be achieved.

Owner:ZHONGBEI UNIV

A boiler system that intelligently stores sewage data through cloud computing

InactiveCN107289441BKeep abreast of the operation status in timeAvoid wastingBoiler cleaning control devicesSteam boilersData connectionAutomatic control

The invention provides an automatic control boiler system. The system performs automatic control according to the quantity of steam generated by a boiler and the quantity of water input into the boiler; the boiler termly discharges pollutions; a steam drum comprises a water quality analyzer for measuring the quality of the water in the steam drum; the water quality analyzer is in data connection with a monitoring diagnosis controller for receiving measured data; the boiler termly discharges pollutions; a central diagnosis monitor stores a reference data PH value J, the pollution discharge time T and the pollution discharge speed V; the reference data is the pollution discharge quantity V*T satisfying the demand when the PH value of water in the steam drum is J; and the boiler achieves a function of automatically correcting the reference data according to the measured PH data in the steam drum. The boiler also achieves the function of automatically correcting the reference data; the reference data is automatically corrected according to the detected water quality pollution discharge conditions to guarantee the control accuracy; a client can timely master the operation conditions of a boiler pollution discharge system; and pollution discharge parameters are adjusted timely through the client to prevent a lot of heat energy wastes caused by faults of the boiler pollution discharge system.

Owner:ZHONGBEI UNIV

A cloud computing boiler sewage system

InactiveCN107101191BKeep abreast of the operation status in timeAvoid wastingBoiler cleaning apparatusBoiler controlData connectionAutomatic control

The invention provides a cloud-computing boiler blow-off system. According to the cloud-computing boiler blow-off system, automatic control is carried out according to the amount of steam generated by boilers and the amount of water input to the boilers, the boilers are periodically subjected to blow-off operation, and a central diagnosis monitor automatically sets the blow-off amount according to the ratio of the mass of the steam to the mass of the water input to the boilers; and the monitoring diagnosis controller is in data connection with a cloud server so that the monitored data can be transmitted to the cloud server conveniently, the cloud server is connected to a client side, and the client side can obtain the monitored data through the cloud server. According to the cloud-computing boiler blow-off system, the amount of the input water and the amount of the generated steam of each boiler are monitored in real time so that the dynamic ratio relation of the amount of the input water and the amount of the generated steam can be obtained, the blow-off amount of the boilers can be automatically calculated according to the dynamic ratio relation, the blow-off time and the blow-off speed can be adjusted according to the blow-off amount, the operation condition of the boiler blow-off system can be timely mastered by the client side, the blow-off parameters can be adjusted timely through the client side, and therefore a large amount of heat energy waste caused by faults of the boiler blow-off system can be prevented.

Owner:ZHONGBEI UNIV

Intelligent acid-base control boiler blowdown system

InactiveCN107120634AReduce lagReduce hysteresis errorBoiler cleaning apparatusBoiler cleaning control devicesIntelligent control systemAutomatic control

The invention provides an intelligent control system which comprises a monitoring and diagnosing controller and a boiler. The boiler comprises a blowdown pipe arranged at the lower end of a boiler steam pocket, a blowdown valve is arranged on the blowdown pipe, one end of the blowdown valve is connected with a valve adjusting device, the valve adjusting device is in data connection with the monitoring and diagnosing controller, and therefore valve aperture data can be transmitted to the monitoring and diagnosing controller; meanwhile, a command is received from the monitoring and diagnosing controller, and the aperture of the blowdown valve is adjusted; the steam pocket further comprises a water quality analyzer which comprises a PH value testing unit so as to measure the PH value of water in the steam pocket, and the water quality analyzer is in data conenction with the monitoring and diagnosing controller, and therefore measured PH data are conveniently received; and the boiler is subject to blowdown, the blowdown time and blowdown speed are automatically set by the central monitoring and diagnosing controller according to the measured PH value, and therefore the blowdown amount is automatically controlled. According to the intelligent control system, the blowdown amount is automatically calculated; and compared with the prior art, the hysteretic nature caused by automatic control in the prior art is reduced, and the optimal blowdown control can be achieved.

Owner:ZHONGBEI UNIV

A Steam Boiler System with Intelligent Control of Blowdown Base Data

InactiveCN107143840BGuaranteed accuracyReduce regulation errorBoiler water tubesBoiler cleaning apparatusData connectionAutomatic control

Owner:ZHONGBEI UNIV

Method for reducing hysteresis error of precipitated martensitic stainless steel

ActiveCN101413048BReduce the energy required for precipitationImprove diffusivityHysteresisElastomer

The invention relates to a method for reducing the hysteresis error of out-precipitated martensitic stainless steel elastomer. The method comprises the following: a step of performing solid solution, which is to heat a bar with a furnace at a speed between 5 and 30 DEG C per minute, heat the bar to 1,040+ / -10 DEG C, preserve heat for 1 to 4 hours and compulsively cool the bar to room temperature;a step of deep cooling, which is to cool the compulsively cooled bar in liquid nitrogen at a cooling temperature between 70 and 90 DEG C below zero for 2.5 to 6 hours; a step of performing deformation processing, which is to stretch or compress the deep cooled bar at a speed less than or equal to 5 millimeters per second at normal temperature and control the elongation or compression ratio of thebar in the stretching / compressing direction between 1.0 and 5.0 percent; a step of aging, which is to put the deformed bar into a heating furnace at a temperature not higher than 200 DEG C, heat the bar with the furnace at a speed between 5 and 30 DEG C per minute, raise the temperature to 480+ / -5 DEG C and preserve the heat for 2.5 to 5 hours. The method improves the capability of out-precipitated martensitic stainless steel in resisting micro-region plastic deformation, and reduces the hysteresis error of weighting sensors.

Owner:METTLER TOLEDO (CHANGZHOU) PRECISION INSTR CO LTD +2

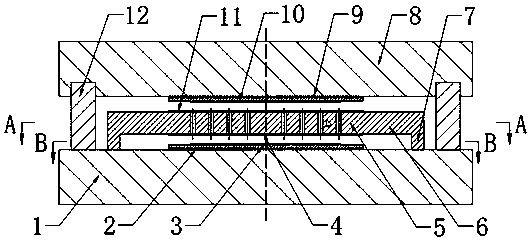

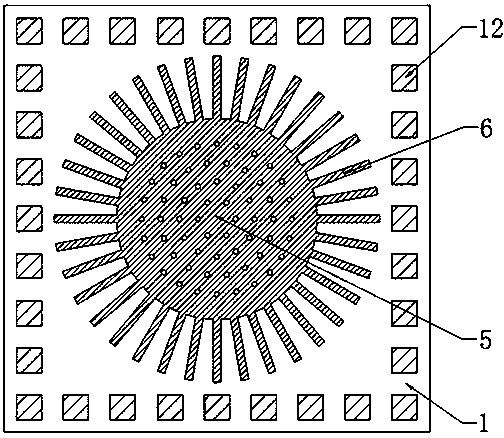

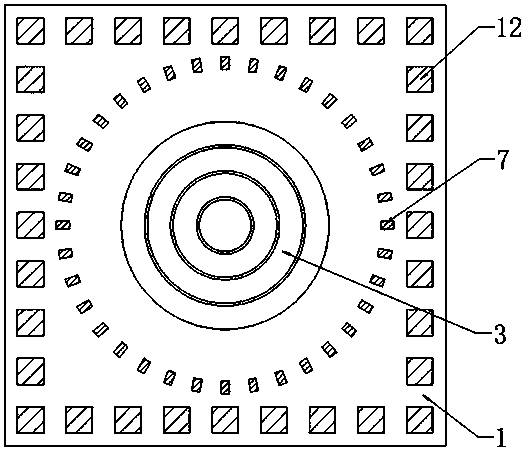

Contact mode micro accelerometer

ActiveCN108490217AAvoid short circuitInhibit Capacitor SaturationAcceleration measurementCapacitanceAccelerometer

The invention provides a contact mode micro accelerometer which comprises a lower substrate and an upper substrate. A supporting column, a thin plate, a plurality of supporting beams and anchor pointsof the beams are arranged between the lower substrate and the upper substrate. The lower substrate and the upper substrate are provided with lower and upper fixed electrodes. The surfaces of the fixed electrodes are covered with insulating layers. The upper and lower surfaces of the thin plate are provided with upper and lower moving electrodes. The micro accelerometer has a first working state in which the thin plate and the moving electrodes are deformed by force but are not in contact with the insulating layer and a second working state in which the thin plate and the moving electrodes aredeformed by force and are in contact with the insulating layers. According to the contact mode micro accelerometer, a principle that the accelerometer causes the deformation of the moving electrodesand thus the capacitance between the fixed electrodes is changed is used to work. Through the insulating layers on the fixed electrodes, the short circuit of the moving and fixed electrodes is prevented, the insulating layers provide support for a movable structure, thus the measurement of the high acceleration can be realized, and the capacitance saturation of the sensor can be effectively suppressed by a combined structure of the beams and the round thin plate.

Owner:WENZHOU UNIVERSITY

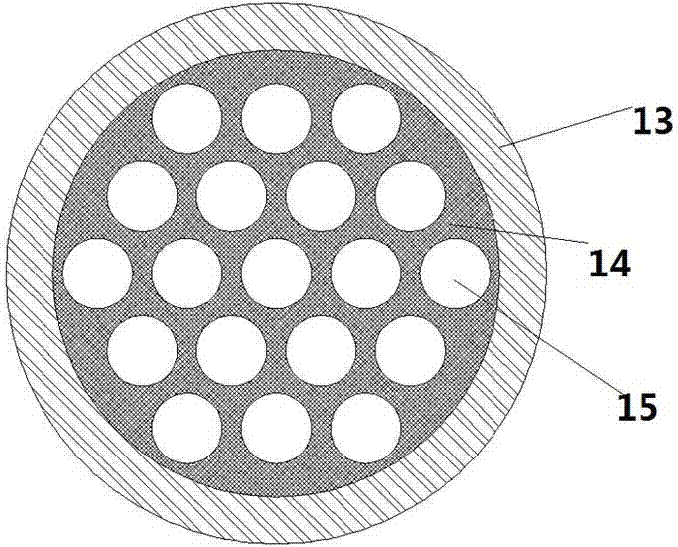

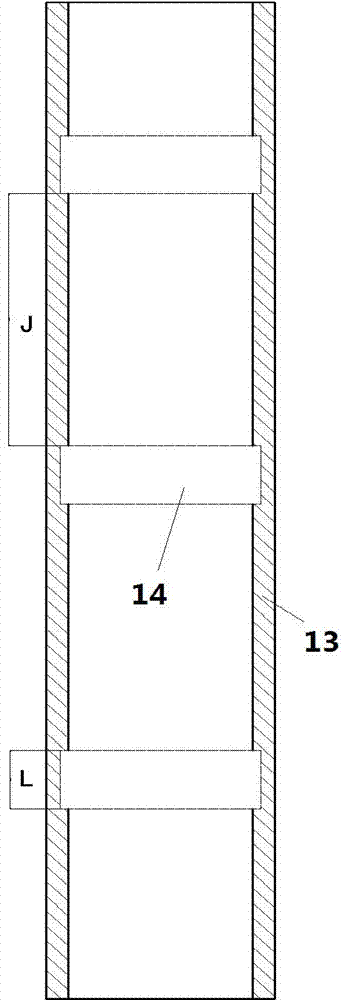

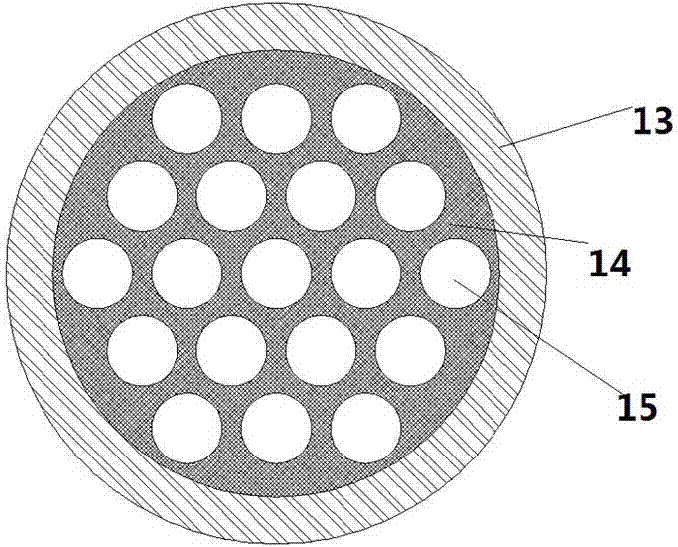

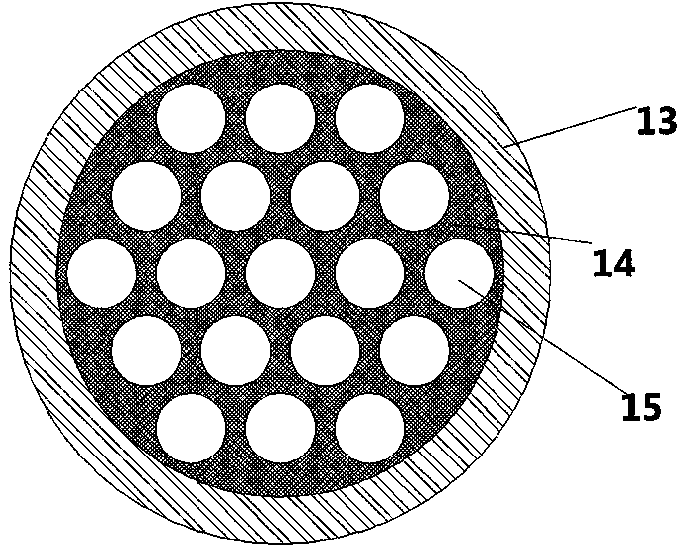

Cloud computing steam boiler system capable of controlling current stabilization of steam and liquid

InactiveCN108954287AKeep abreast of the operation status in timeAvoid wastingBoiler controlBoiler cleaning control devicesThermal energyAutomatic control

The invention provides a boiler system. The boiler system performs automatic control according to the amount of steam generated by a boiler and the amount of water fed into the boiler; sewage is discharged from the boiler at regular intervals; a steam pocket comprises a water quality analyzer which is used for measuring the quality of water in the steam pocket; the steam pocket is connected to anascending pipe and a descending pipe; a plurality of cutting heat exchange parts are arranged in the ascending pipe at intervals and extend in the height direction of the ascending pipe; and a plurality of holes are formed in the cutting heat exchange parts and run through the cutting heat exchange parts in the height direction of the ascending pipe. The boiler has the effects of flow rate stabilization, vibration absorption and noise reduction and avoids the wasting of lots of energy sources caused by the failure of the boiler sewage discharge system.

Owner:ZHONGBEI UNIV

Boiler system with intelligent control of blowdown time by cloud computing

InactiveCN107289439BKeep abreast of the operation status in timeAvoid wastingBoiler cleaning control devicesSteam boilersData connectionAutomatic control

The invention provides an automatic control boiler system. The system comprises a monitoring diagnosis controller and a boiler; a steam drum comprises a water quality analyzer; the water quality analyzer comprises a PH value testing unit for measuring the PH value of water in the steam drum; the water quality analyzer is in data connection with the monitoring diagnosis controller to receive measured PH data; the boiler termly discharges pollutions; the pollution discharge speed is kept invariable; a central diagnosis monitor automatically sets a pollution discharge time according to the measured PH value to automatically control the pollution discharge quantity; the monitoring diagnosis controller is in data connection with a cloud server for transferring monitored data to the cloud server; the cloud server is connected with a client; and the client can obtain the monitored data through the cloud server. Through real-time monitoring of the PH data of each boiler, the pollution discharge time is automatically adjusted according to a dynamic proportional relation; the client can timely master the operation conditions of a boiler pollution discharge system; and pollution discharge parameters are adjusted timely through the client to prevent a lot of heat energy wastes caused by faults of the boiler pollution discharge system.

Owner:ZHONGBEI UNIV

A steam boiler system with intelligent control of sewage discharge speed

InactiveCN107166365BReduce lagExcellent pollution controlBoiler cleaning control devicesSteam boilersHysteresisAutomatic control

The invention provides an intelligent boiler control system. The system conducts automatic control according to the amount of steam generated by boilers and the amount of water input into the boilers, the boilers regularly discharge dirt, the dirt discharging speed is kept unchangeable, a center diagnosis monitor automatically sets the dirt discharging speed according to the specific value between the steam mass and the mass of water input into the boilers, and accordingly the dirt discharging amount is automatically controlled. According to the system, through real-time monitoring of the input water amount and the generated steam amount of each boiler, the dynamic proportion relation between the input water amount and the generated steam amount is obtained, the dirt discharging amount of the boilers is automatically calculated according to the dynamic proportion relation, and the dirt discharging speed is adjusted according to the dirt discharging amount. According to the intelligent boiler control system, due to the fact that the dirt discharging time is automatically calculated, compared with the prior art, hysteresis quality is reduced, and optimal dirt discharging control can be achieved.

Owner:ZHONGBEI UNIV

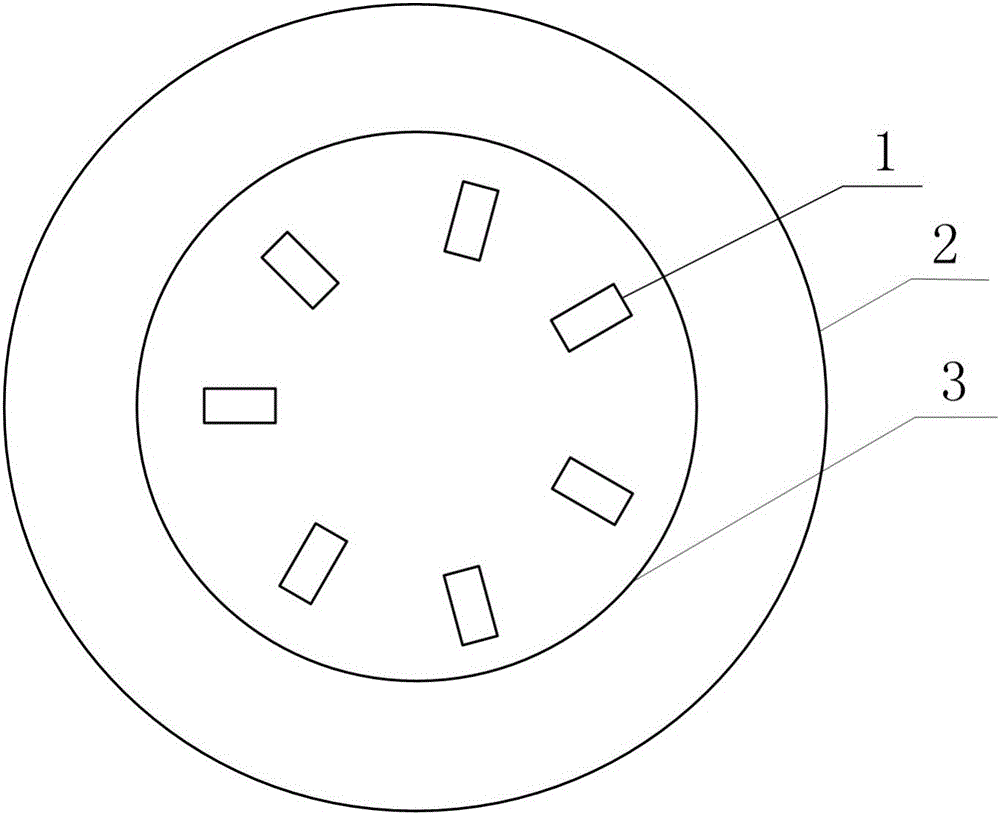

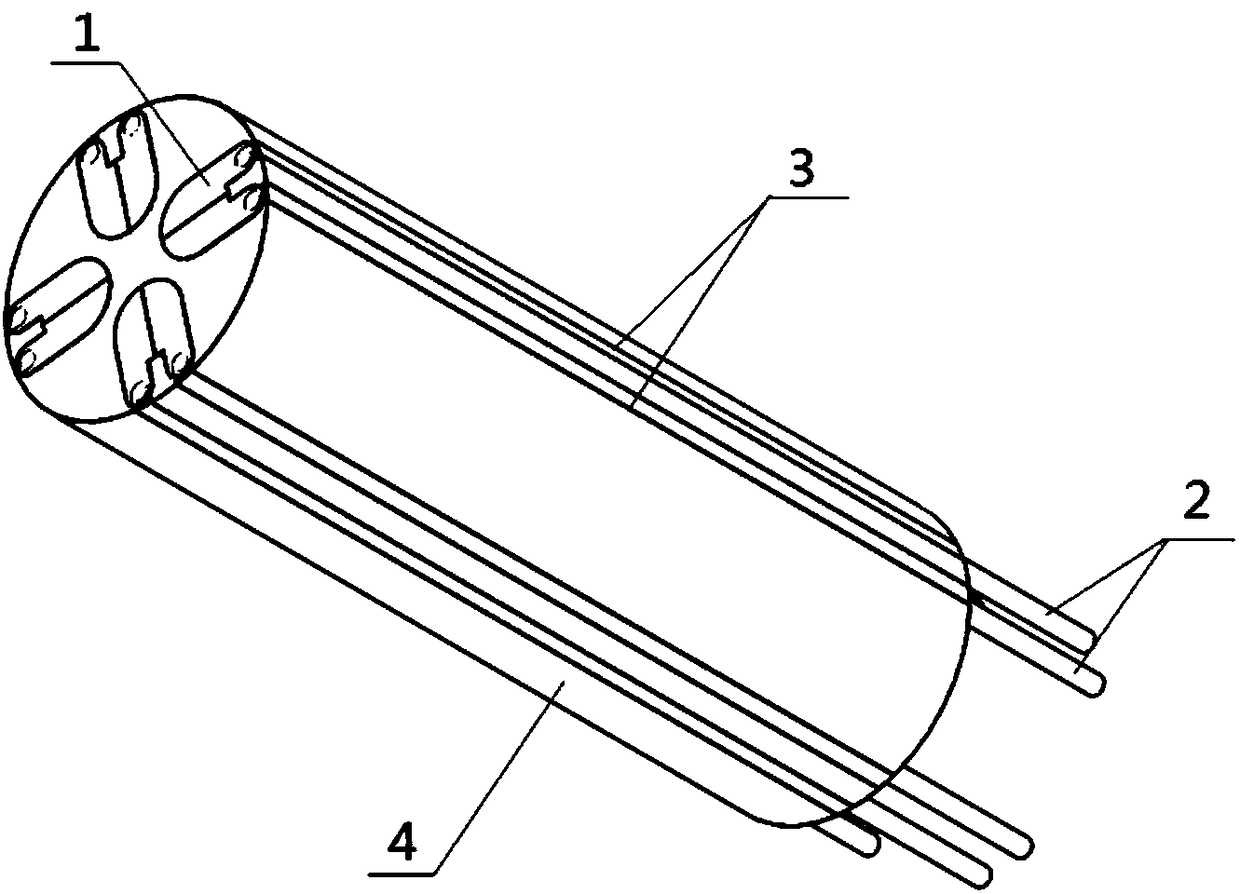

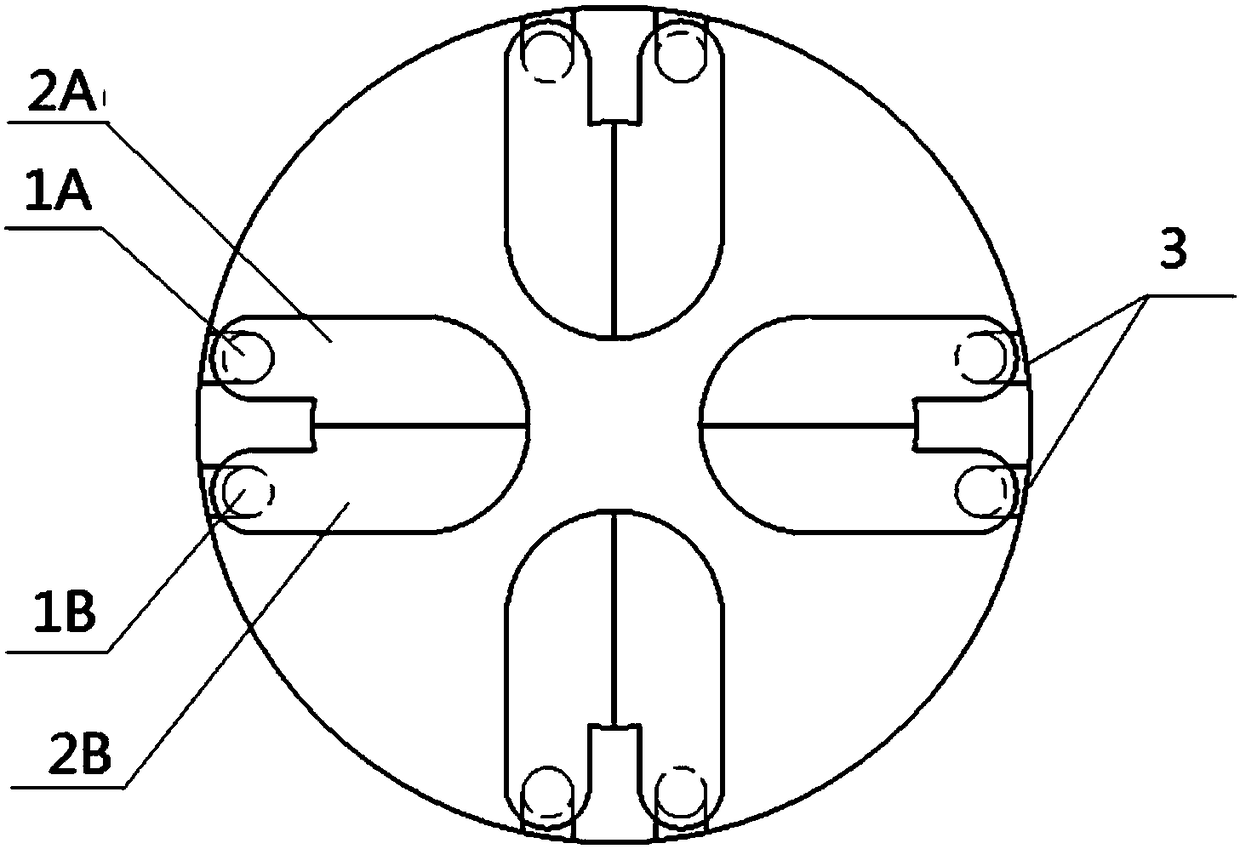

A multi-point film thermocouple structure for fluid dynamic temperature measurement

ActiveCN105806503BReduce hysteresis errorImprove measurement accuracyThermometers using electric/magnetic elementsUsing electrical meansThin film thermocouplesThin membrane

The invention relates to a thin-film thermocouple temperature measurement sensor structure for fluid dynamic temperature measurement, which is composed of several single-point thin-film thermocouples evenly distributed in the circumferential direction, and each thin-film thermocouple is composed of thermocouple wires and wires embedded in a columnar main structure. The composition of the coating layer exposed on the surface of the main structure. Each single-point thermocouple has exactly the same structure and material, but the thickness of the coating layer is different. The multi-point thin-film thermocouple of the present invention can be used to measure the dynamic temperature of the fluid, and multiple different measured values can be obtained due to the different response speeds of each point. The compensation algorithm matched with the multi-point thin-film thermocouple can save a lot of numerical calculation and calibration experiments, and effectively improve the measurement accuracy of dynamic temperature.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

PH value-based boiler system with pollution discharge time rule change intelligently controlled

InactiveCN109373303AAvoid lostImprove sewage efficiencyBoiler cleaning apparatusBoiler controlDischarge efficiencyAutomatic control

Owner:ZHONGBEI UNIV

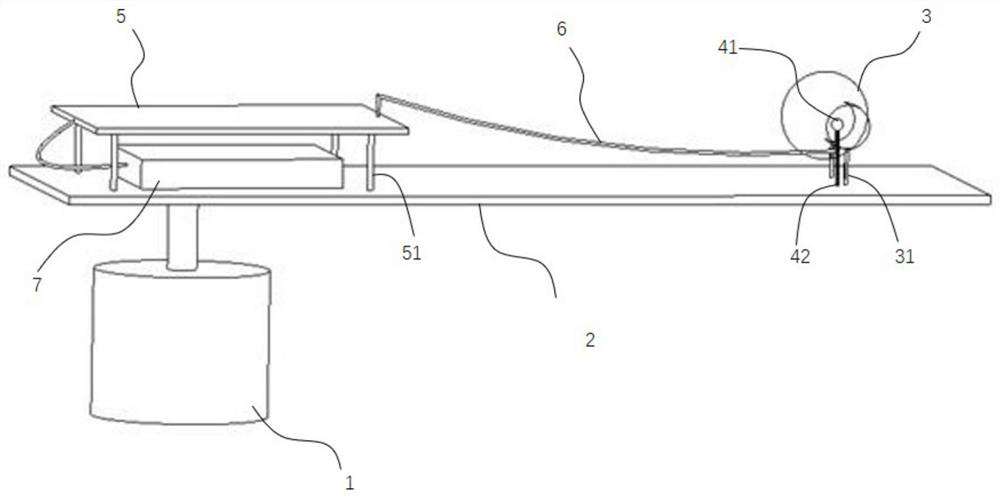

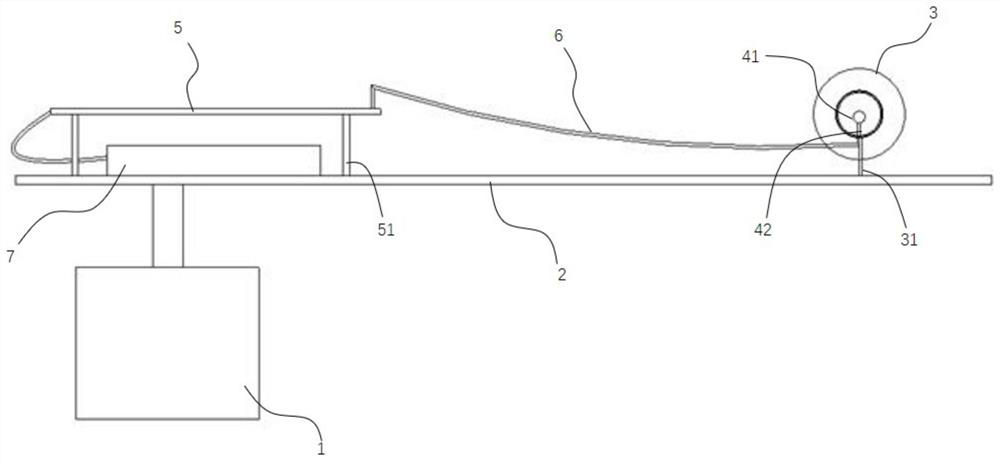

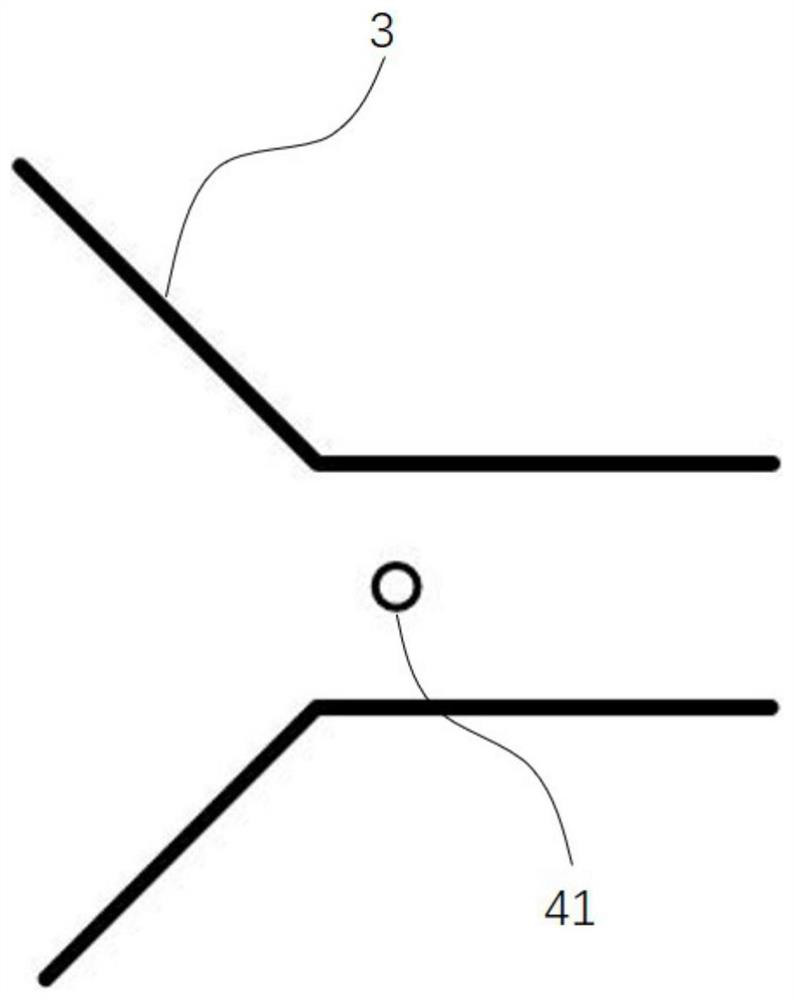

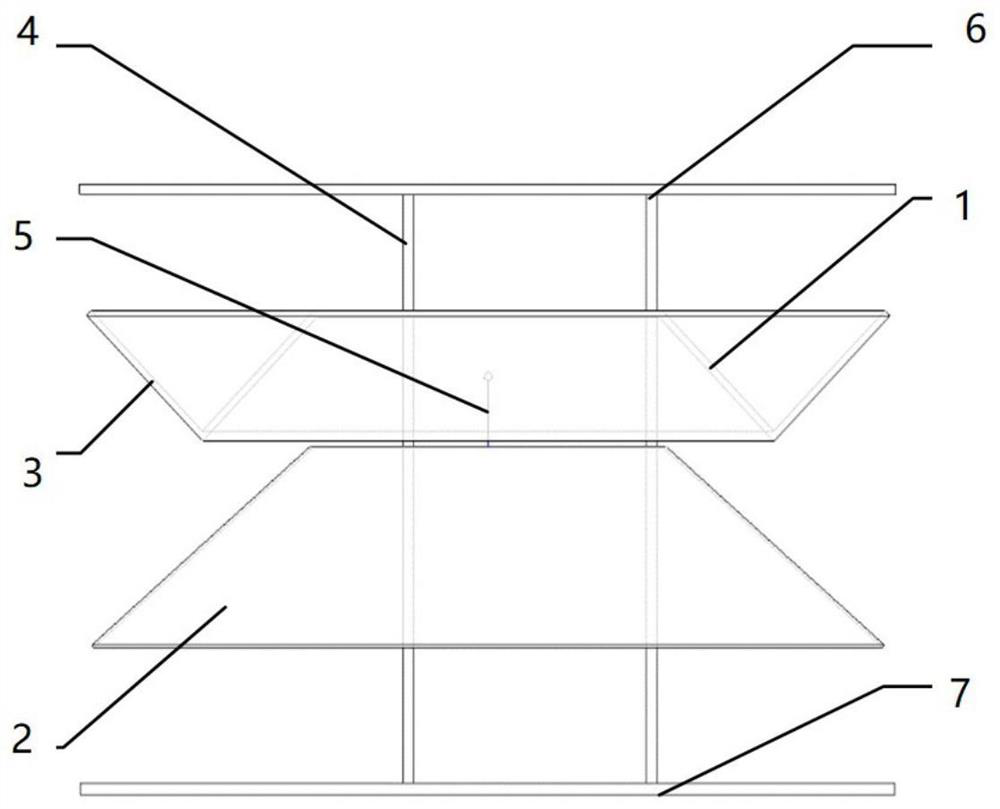

A kind of forced ventilation radiation shield with flow guide device

ActiveCN111521294BStrong ventilationScientific and reasonable structureThermometer detailsTemperature measurement of flowing materialsDrive shaftElectric machinery

The invention discloses a forced ventilation radiation shield with a deflector, which comprises a motor, a support plate, a deflector, a support column and a temperature sensor probe; Rotation; the support plate is set horizontally, one end is fixed on the drive shaft of the motor, and the motor can drive the support plate to rotate in the horizontal plane; the shroud is a trumpet-shaped structure with both ends penetrated; the shroud is fixed on the other end of the support plate through the support column The upper surface of the support plate rotates with the support plate, and the shroud is arranged in a direction perpendicular to the radius of rotation; the temperature sensor probe is fixed in the middle of the shroud; the motor drives the support plate to rotate, and the shroud located at the outer end of the support plate and the inside of the shroud The temperature sensor probe moves accordingly. The invention has the advantages of scientific and reasonable structure, strong ventilation, small temperature measurement error and the like.

Owner:江苏佐都数字科技有限公司

A boiler system with cloud computing sewage discharge speed

InactiveCN107166362BKeep abreast of the operation status in timeAvoid wastingBoiler controlBoiler cleaning control devicesData connectionAutomatic control

The invention provides a boiler system. According to the system, automatic control can be performed according to the amount of steam generated by a boiler and the amount of water input to the boiler, the boiler is subjected to sewage discharge periodically, the sewage discharge speed is kept unchanged, a central diagnosis monitor automatically sets the sewage discharge speed according to the ratio of the mass of the steam to the mass of the water input to the boiler and is in data connection with a cloud server so as to transmit monitored data to the cloud server, the cloud server is connected to a client side, and the client side can obtain the monitored data through the cloud server, manually inputs the sewage discharge speed according to the obtained data, transmits the data to a monitoring and diagnosing controller through the cloud server and manually adjusts the sewage discharge amount through the monitoring the diagnosing controller. The system has the advantages that the input water quantity and the generated steam quantity of each boiler are monitored in real time, the dynamic ratio relation of the input water quantity and the generated steam quantity is obtained, the sewage discharge amount of the boiler can be automatically calculated according to the dynamic ratio relation, the sewage discharge speed can be adjusted according to the sewage discharge amount, the operation condition of a boiler sewage discharge system can be timely mastered by the client side, the sewage discharge parameters can be adjusted timely through the client side, and a large amount of heat energy waste caused by faults of the boiler sewage discharge system can be prevented.

Owner:ZHONGBEI UNIV

A boiler system with cloud computing intelligent control of sewage discharge speed

InactiveCN107289440BKeep abreast of the operation status in timeAvoid wastingBoiler cleaning control devicesSteam boilersData connectionAutomatic control

The invention provides an automatic control boiler system. The system comprises a monitoring diagnosis controller and a boiler; a steam drum comprises a water quality analyzer; the water quality analyzer comprises a PH value testing unit for measuring the PH value of water in the steam drum; the water quality analyzer is in data connection with the monitoring diagnosis controller to receive measured PH data; the boiler termly discharges pollutions; the pollution discharge time is kept invariable; and a central diagnosis monitor automatically sets a pollution discharge speed according to the measured PH value to automatically control the pollution discharge quantity. Through real-time monitoring of the PH data of each boiler, the pollution discharge quantity of the boiler is automatically calculated according to a dynamic proportional relation; the pollution discharge speed and the pollution discharge time are adjusted according to the pollution discharge quantity; a client can timely master the operation conditions of a boiler pollution discharge system; and pollution discharge parameters are adjusted timely through the client to prevent a lot of heat energy wastes caused by faults of the boiler pollution discharge system.

Owner:ZHONGBEI UNIV

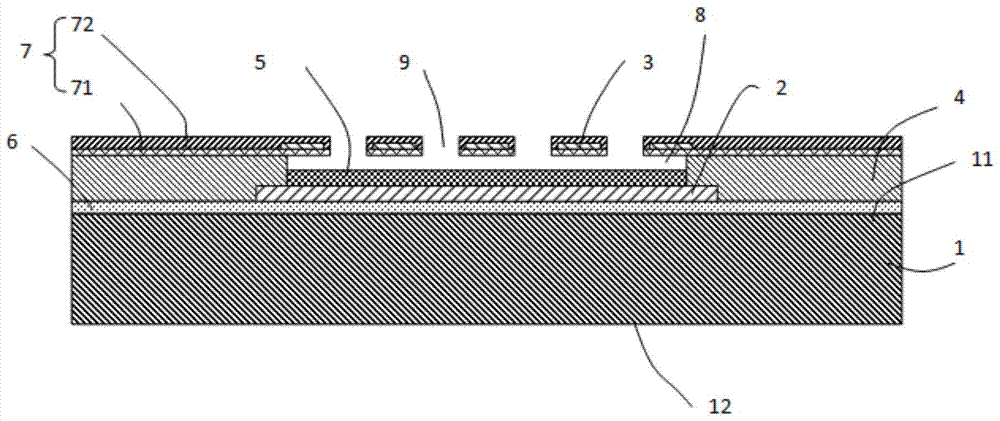

mems capacitive relative humidity sensor and preparation method thereof

ActiveCN104634833BReduce distanceDiffusion distance is shortDecorative surface effectsChemical vapor deposition coatingHysteresisCapacitance

The invention relates to a MEMS capacitive relative humidity sensor and a preparation method thereof, which belong to semiconductor chip technology. Since the MEMS capacitive relative humidity sensor supports the upper plate of the capacitor through an insulating support body, the upper plate of the capacitor and the humidity sensitive layer are reduced. The distance between the upper pole plate of the capacitor and the humidity sensitive layer is formed with an air gap, and on the upper pole plate of the capacitor, a number of through holes are opened to communicate the air gap with the outside, so that the upper surface of the humidity sensitive layer is completely In contact with air, the diffusion distance of water vapor molecules is short. Therefore, the humidity sensitive layer dehumidifies evenly and quickly, which can effectively reduce the hysteresis error generated during natural dehumidification. The MEMS capacitive relative humidity produced by this preparation method The humidity sensitive layer of the sensor dehumidifies evenly and quickly, which can effectively reduce the hysteresis error generated during natural dehumidification.

Owner:苏州工业园区纳米产业技术研究院有限公司

A temperature sensor for surface air temperature observation

ActiveCN111290047BStrong timelinessLittle effect of radiant heat pollutionThermometer detailsTemperature measurement of flowing materialsVentilation volumeEngineering

The invention discloses a temperature sensor for observation of surface air temperature, which comprises a first deflector and a second deflector arranged below the first deflector, both of which are horizontally placed, with a small top and a large bottom circular platform structure , and both are hollow structures with open bottoms, and also include guide rings, which are hollow circular platform structures with large upper and lower bottoms and open bottom surfaces. The bottom edges are overlapped and spliced; the first deflector and the second deflector are connected and penetrated through the heat insulation column, and the upper and lower extension ends are respectively connected with the first reflector and the second reflector. The bottom is equipped with a temperature sensor probe. First of all, this design increases the area of the air inlet to form a wind-gathering slope on the side, which can guide the horizontal airflow higher than the guide ring to enter, so that the measured temperature has good timeliness and increases the ventilation volume, thereby reducing the hysteresis error and enabling The structure has a relatively good ventilation environment and reduces radiation errors.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Steam boiler system for intelligently controlling sewage discharging time

InactiveCN106989379AReduce lagReduce hysteresis errorBoiler cleaning apparatusBoiler controlAutomatic controlProcess engineering

The invention provides an intelligently-controlled boiler system. The system is controlled automatically according to the steam quantity generated by boilers and the water quantity input into the boilers, the boilers are subjected to regular sewage discharging, the sewage discharging speed maintains unchanged, a central diagnosis monitor sets the sewage discharging time automatically according to the specific value between the steam mass and the mass of the water input into the boilers, and thus the discharge capacity is controlled automatically. The input water quantity and the generated steam quantity of each boiler are monitored in real time, the dynamic ratio relation between the input water quantity and the generated steam quantity is obtained, the discharge capacity of the boilers is calculated automatically according to the dynamic proportion relation, and the sewage discharging time is adjusted according to the discharge capacity. Compared with the prior art, hysteresis quality is reduced due to the fact that the sewage discharging time is calculated automatically, and the optimal sewage discharging control can be achieved.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com