Controller structure

A regulator and differentiator technology, applied in control/regulation systems, instruments, simulators, etc., to solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

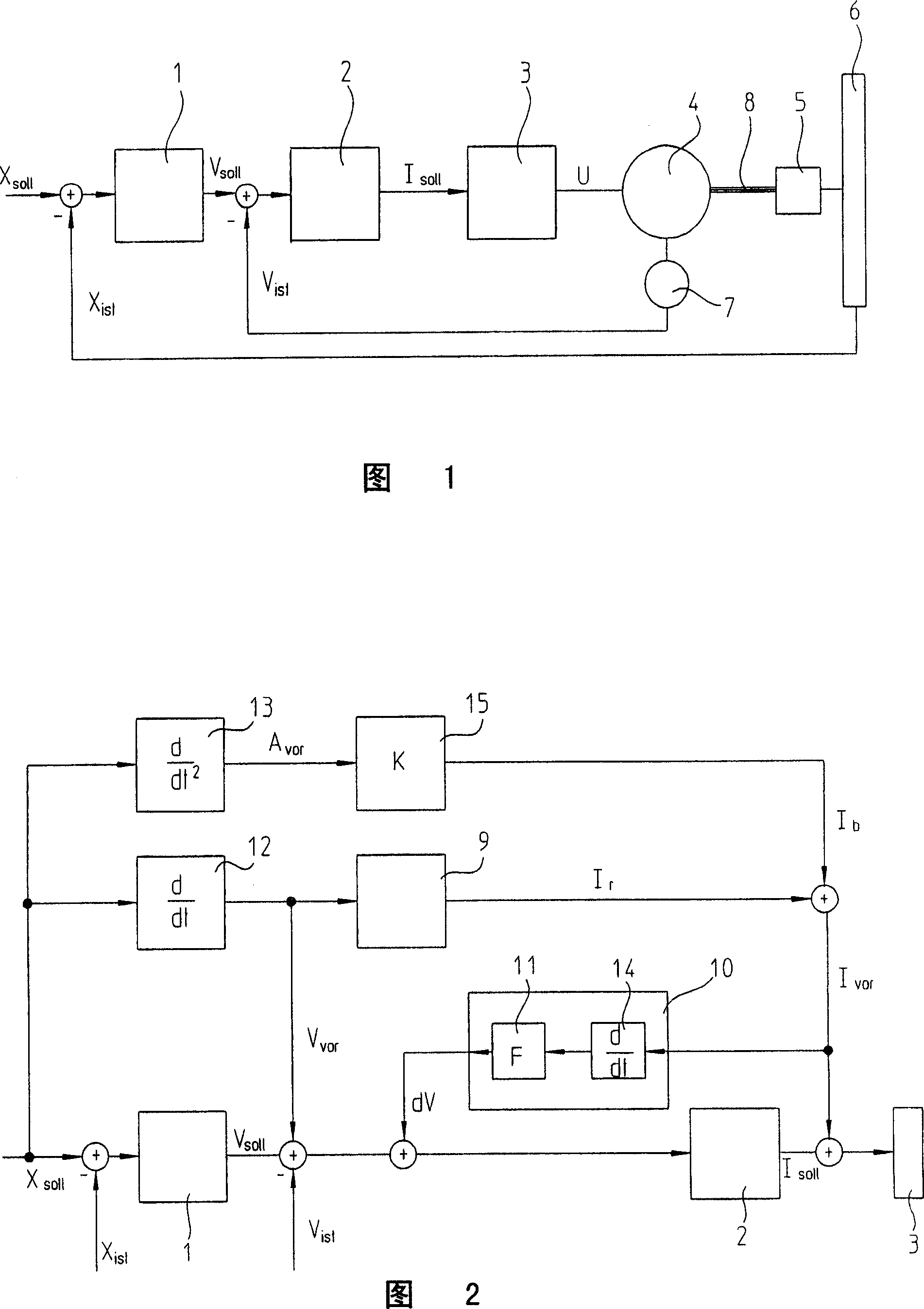

[0014] FIG. 1 shows a simplified structure of a controller according to the prior art. The difference resulting from a position setpoint value Xsoll and an actual position value Xist is fed to a position controller 1 . The position setpoint Xsoll can be obtained, for example, from a part program of a numerical control device, according to which programmed tool path is to be carried out to machine the workpiece. In this case, the actual position value Xist is acquired by means of a length measuring device 6 which detects the position of an object 5 in the direction of the axis to be adjusted. The longitudinal movement of the body 5 to be regulated is here effected by a drive or electric motor 4 , which is connected to the body 5 via a mechanical device 8 . The mechanism has a certain elasticity, so that the speed and position of the motor 4 and the object 5 do not always have to correspond to each other.

[0015] The position controller 1 produces a signal corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com