Anti-hysteresis method and device for piezoelectric ceramic, equipment and medium

A piezoelectric ceramic and hysteresis technology, applied in the field of slope-based linear equation anti-hysteresis, can solve problems such as difficult applications, and achieve the effects of improving positioning and control accuracy, high implementability and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

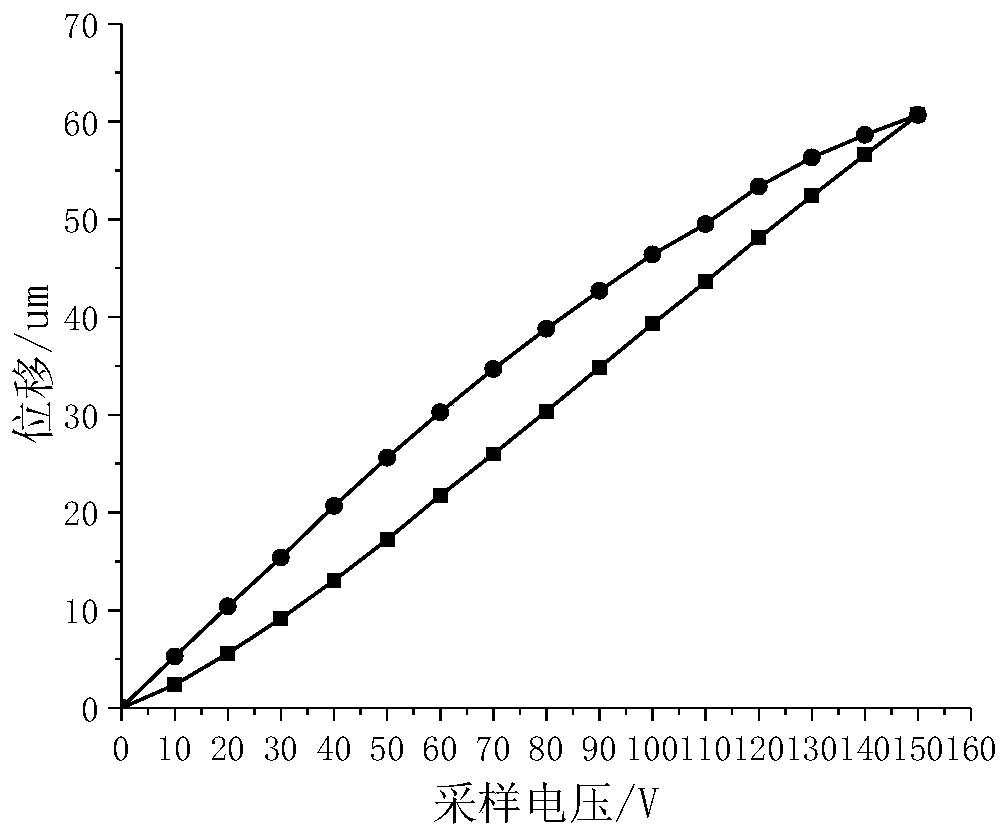

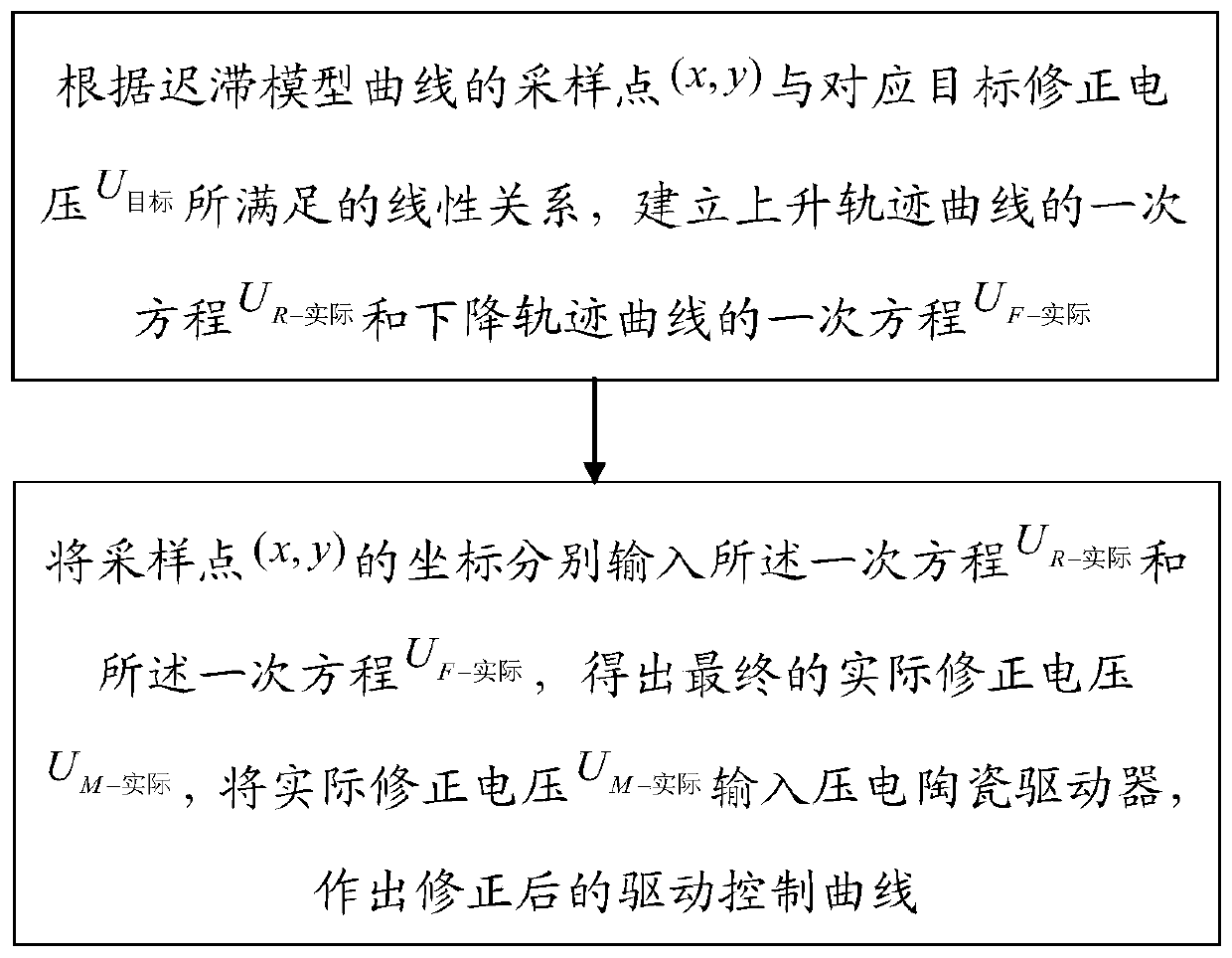

[0037] This embodiment provides an anti-hysteresis method for piezoelectric ceramics, such as figure 2 shown, including the following steps:

[0038] S1. According to the sampling point (x, y) of the hysteresis model curve and the corresponding target correction voltage U 目标 Satisfied linear relationship, establish the first-order equation U of the rising trajectory curve R-实际 and the linear equation U of the descending trajectory curve F-实际 ;Such as Figure 2a As shown, specifically include the direct steps:

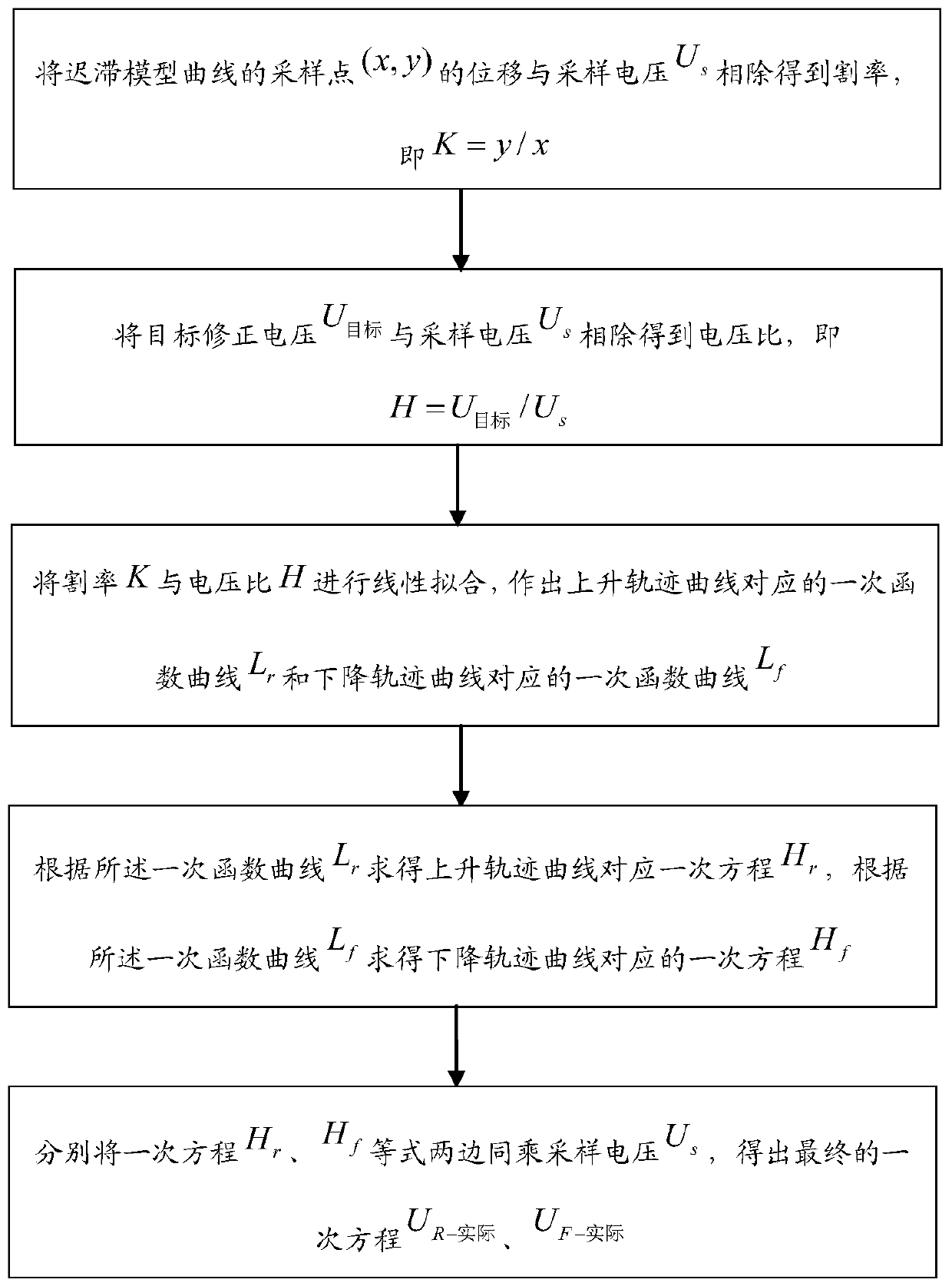

[0039] S11, the displacement F of the sampling point (x, y) of the hysteresis model curve s and sampling voltage U s Divide to get the cut rate, that is, K=y / x=F s / U s ;Such as Figure 2b As shown, the calculation process of cut rate is as follows:

[0040](1) Connect the first and last two points of the hysteresis model curve to make a corrected straight line;

[0041] (2) Find the hysteresis nonlinear law curves of the rising trajectory and the falling tra...

Embodiment 2

[0068] In this embodiment, a piezoelectric ceramic anti-hysteresis device is provided, such as Figure 10 shown, including:

[0069] The equation building module is used to correct the voltage U according to the sampling point (x, y) of the hysteresis model curve and the corresponding target 目标 Satisfied linear relationship, establish the first-order equation U of the rising trajectory curve R-实际 and the linear equation U of the descending trajectory curve F-实际 ;

[0070] A correction module for inputting the coordinates of the sampling points (x, y) into the primary equation U respectively R-实际 and the linear equation U F-实际 , to obtain the final actual correction voltage U M-实际 , will actually correct the voltage U M-实际 Input the piezoelectric ceramic drive and make the corrected drive control curve.

[0071] Wherein, the equation building module specifically includes:

[0072] The cutting rate calculation module is used to convert the displacement F of the sampling ...

Embodiment 3

[0085] This embodiment provides an electronic device, such as Figure 11 As shown, it includes a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the computer program, any implementation manner in Embodiment 1 can be realized.

[0086] Since the electronic device introduced in this embodiment is the device used to implement the method in Embodiment 1 of this application, based on the method described in Embodiment 1 of this application, those skilled in the art can understand the electronic device of this embodiment. Specific implementation methods and various variations thereof, so how the electronic device implements the method in the embodiment of the present application will not be described in detail here. As long as a person skilled in the art implements the equipment used by the method in the embodiment of the present application, it all belongs to the protection scope of the present application....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com