High-speed precise multi-axis material taking robot

A robot and precision technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of inability to meet the requirements of high precision, high speed and high stability, occupy a large space, and high equipment costs, and achieve accurate pick and place, saving The effect of high space and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

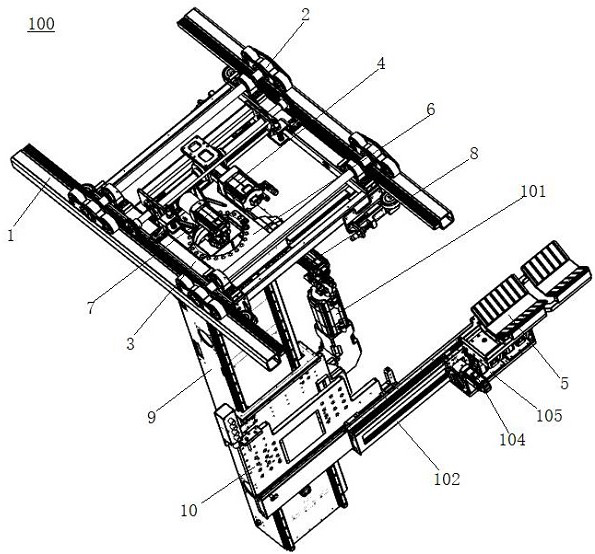

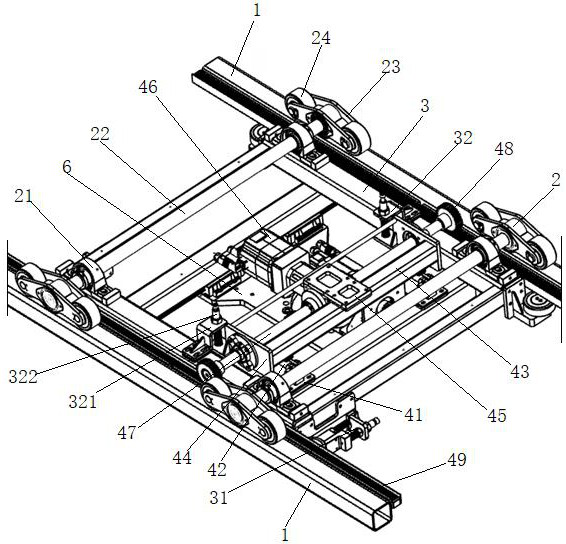

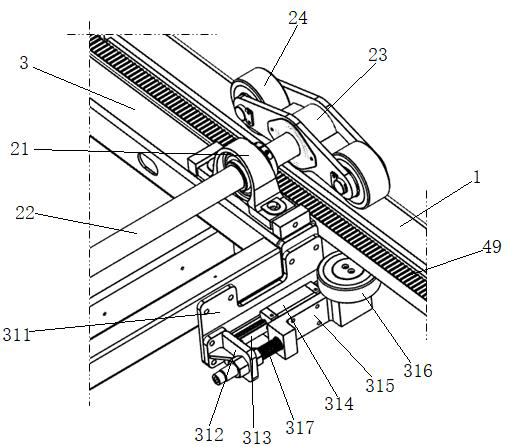

[0043] Please refer to Figure 1-Figure 9 , the present embodiment is a high-speed precision multi-axis retrieving robot 100, which includes a pair of hollow rectangular pipe rails 1 arranged in parallel, located between the two hollow rectangular pipe rails 1 and passing through two pairs of walking components 2 on the hollow rectangular pipe rails 1 Rectangular support frame 3 walking on top, X-axis driving assembly fixed on the rectangular support frame 3 and driving the rectangular support frame 3 to move horizontally through rack and pinion cooperation 4, slidably suspended on the rectangular support frame through slider slide rails The first support plate 6 on the frame 3, the Y-axis drive assembly 7 fixed on the first support plate 6 and driving the first support plate 6 to move horizontally through rack and pinion cooperation, and the rotation drive assembly fixed on the first support plate 6 Component 8, the installation vertical cabinet 9 that is driven to rotate by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com