A steam boiler system with intelligent control of blowdown time

A technology of blowdown time and boiler, applied in the control system, steam generation, boiler cleaning device, etc., can solve the problem of not blowdown control scheme, excessive emission, etc., and achieve the effect of reducing lag, stabilizing flow, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0040] In this article, if there are no special instructions, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

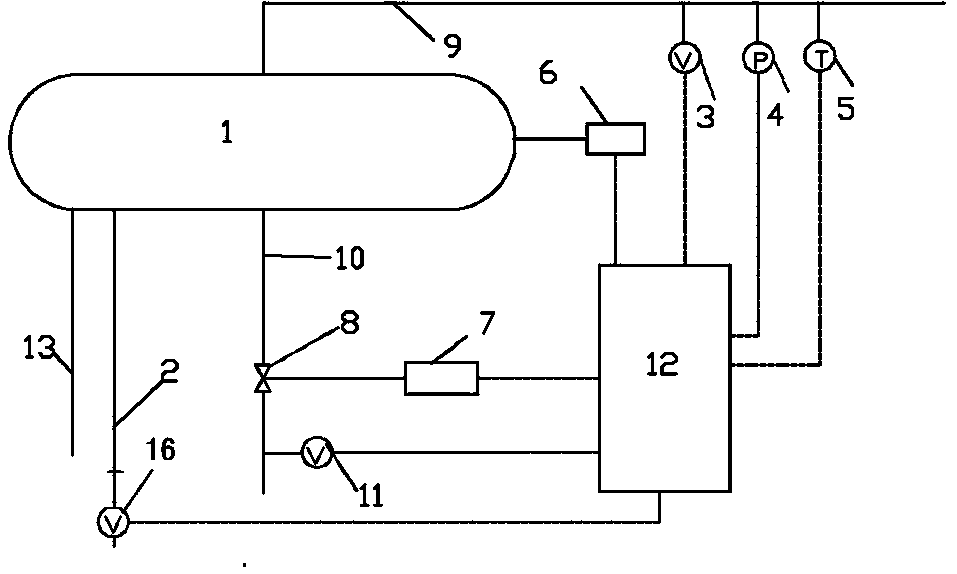

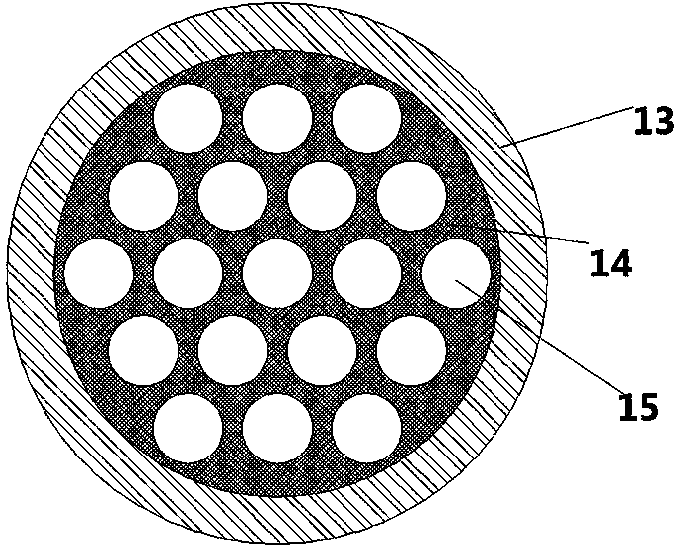

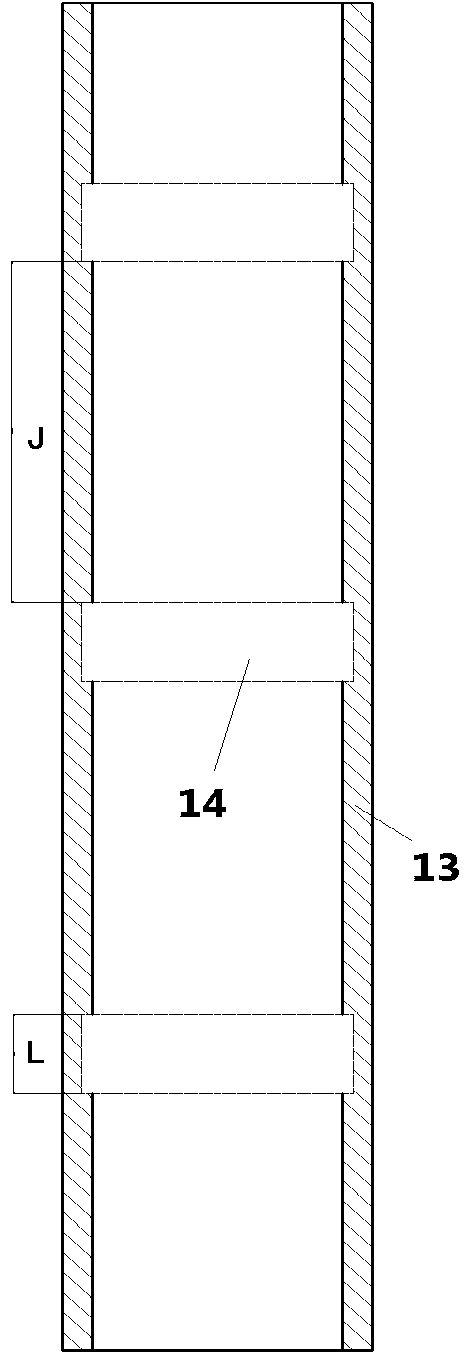

[0041] Such as figure 1 As shown, a boiler thermal system includes at least one boiler for generating steam, and the boiler is data-connected with a monitoring and diagnosis controller 12 to monitor the operation of the boiler.

[0042] Such as figure 1 As shown, the boiler includes an automatic control blowdown system, the boiler performs periodic blowdown, and the automatic control blowdown system performs automatic control according to the amount of steam produced by the boiler and the amount of water input to the boiler. The specific control system is as follows:

[0043] Such as figure 1 As shown, the boiler includes a flow meter 3, a pressure gauge 4 and a thermometer 5 arranged on the steam out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com