A Design Method of Heterogeneous Heterogeneous Cell Structure Coordinated with Principal Stress Trajectory Line

A technology of cellular structure and design method, which is applied in the field of additive manufacturing, can solve the problems of not fully considering the force flow characteristics of parts, and the structure is not efficient and reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

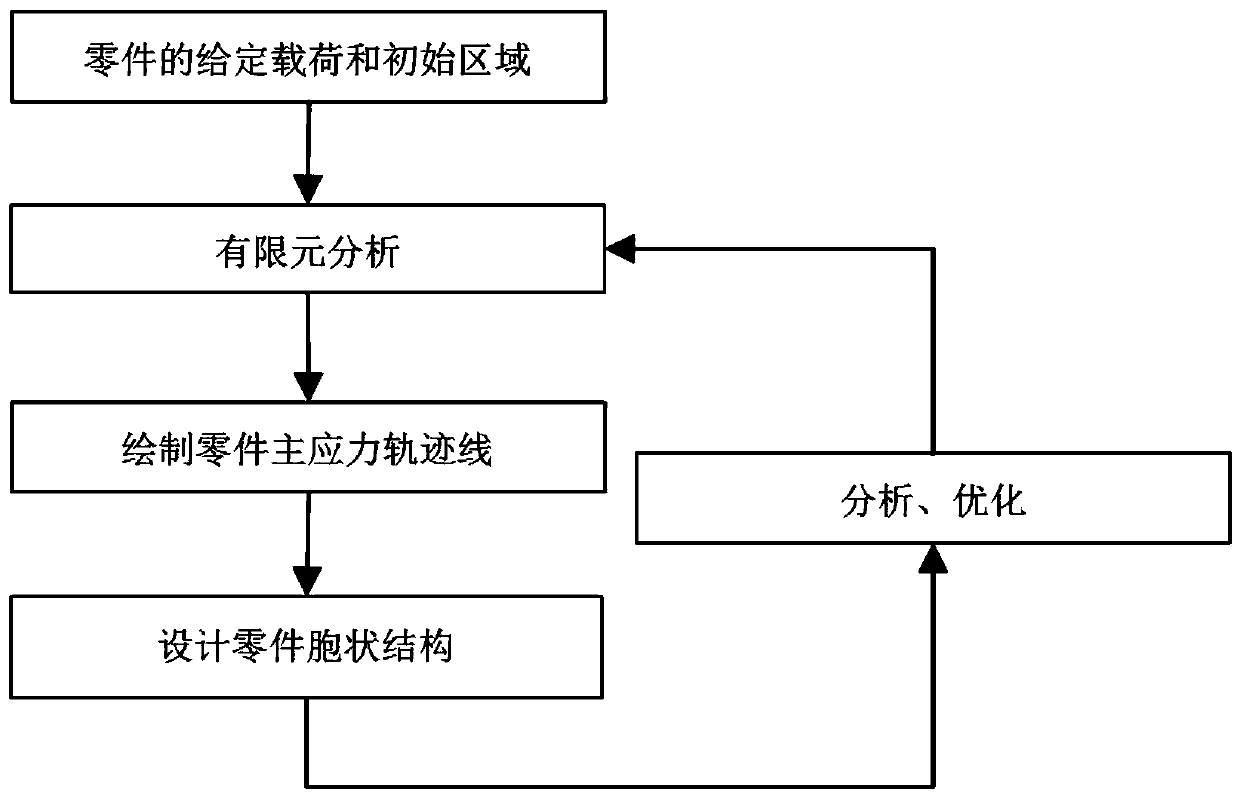

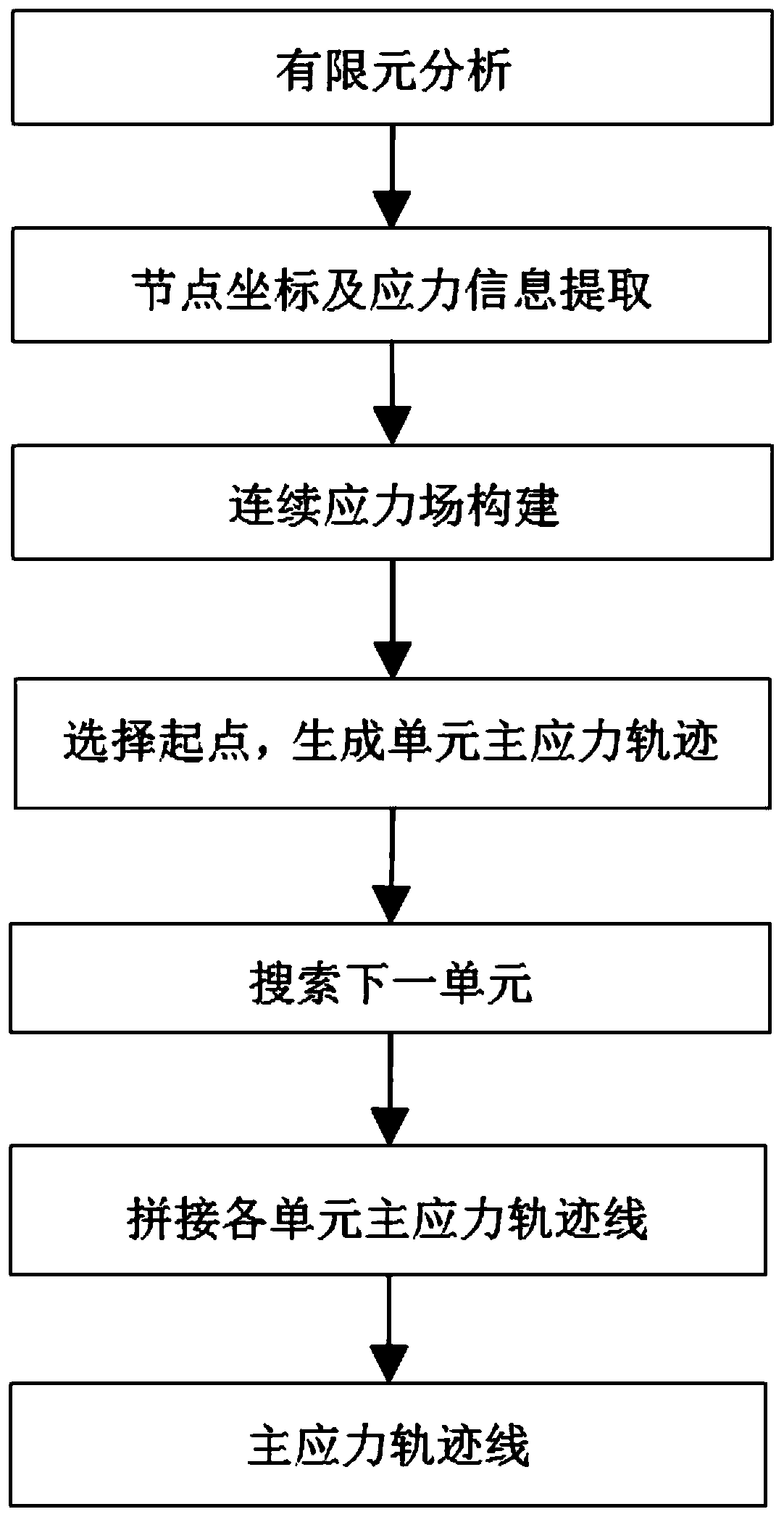

[0031] Such as figure 1 As shown, a non-uniform heterogeneous cellular structure design method coordinated with the principal stress trajectory line, the method includes the following steps:

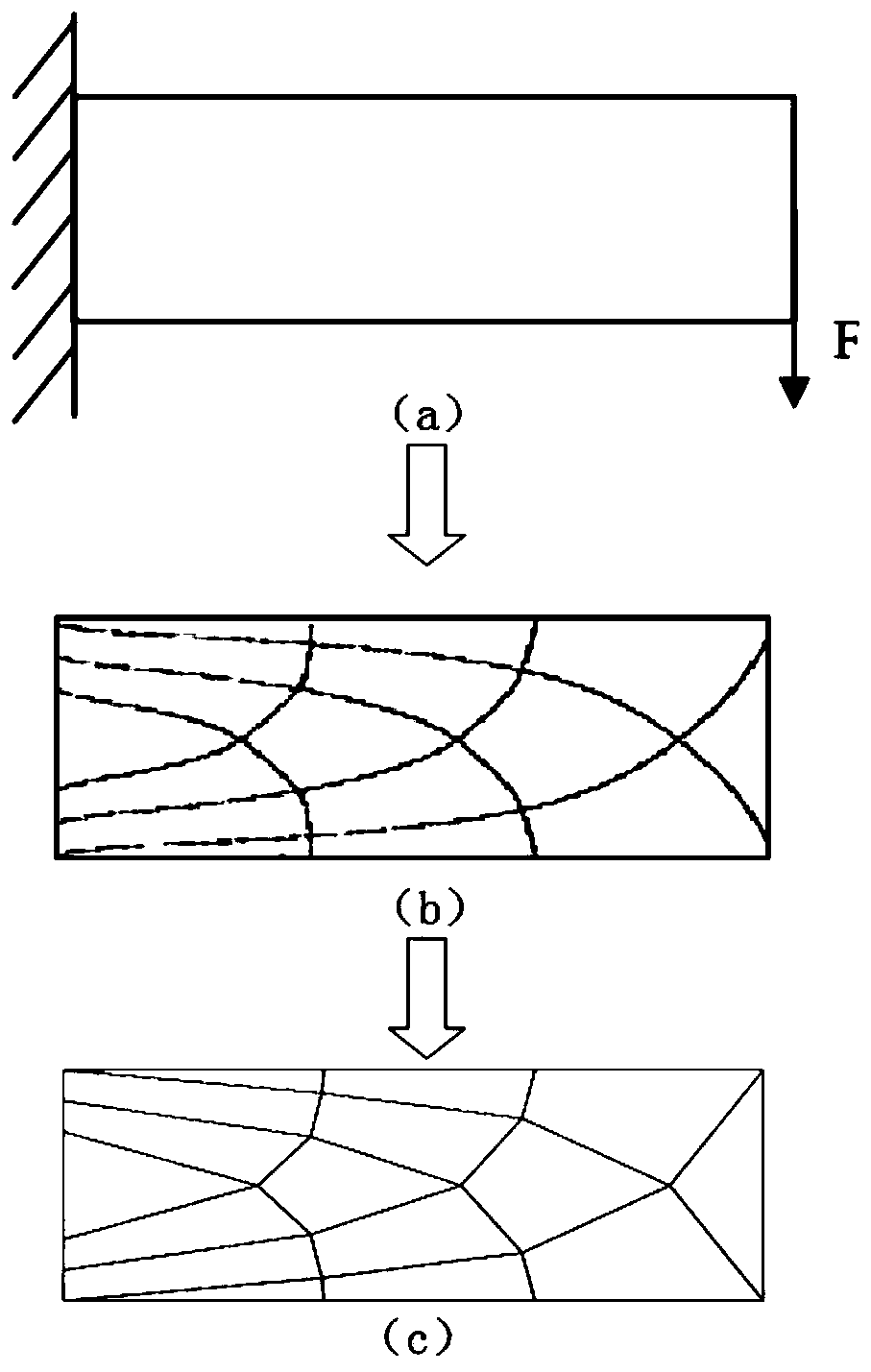

[0032] (1) Obtain the principal stress trajectory of the part according to the given load and initial area of the part. This method studies the two-dimensional structure, that is, studies the two-dimensional principal stress trajectory of the part. The corresponding principal stress trajectory is the two-dimensional principal stress trajectory . figure 2 (a) given load for the parts of this embodiment, figure 2 (b) is the principal stress trajectory of the part obtained in this embodiment.

[0033] (2) Determine the inhomogeneous heterogeneous cellular structure of the part coordinated with it according to the principal stress trajectory. The cellular structure studied by this method is a lattice structure. Specifically, the heterogeneous heterogeneous cellular structure is a bar s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com