Packaging mold and semiconductor packaging process

A semiconductor and mold technology, applied in the field of semiconductor packaging process, can solve the problem that the mold flow of the colloid cannot completely cover the upper and lower surfaces of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

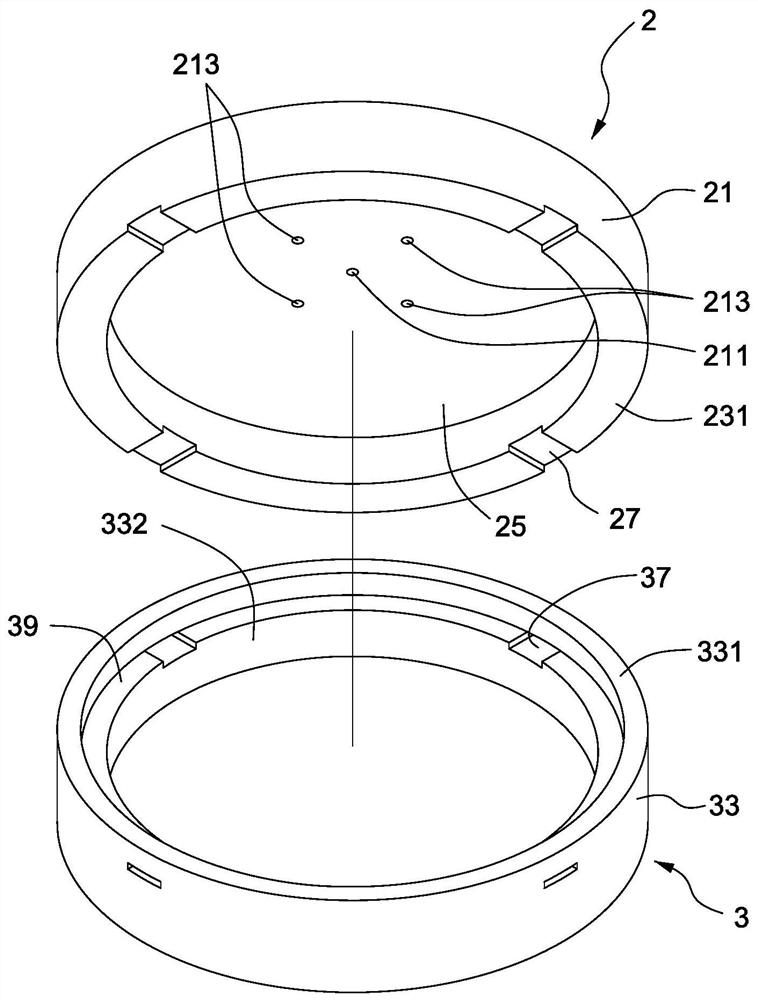

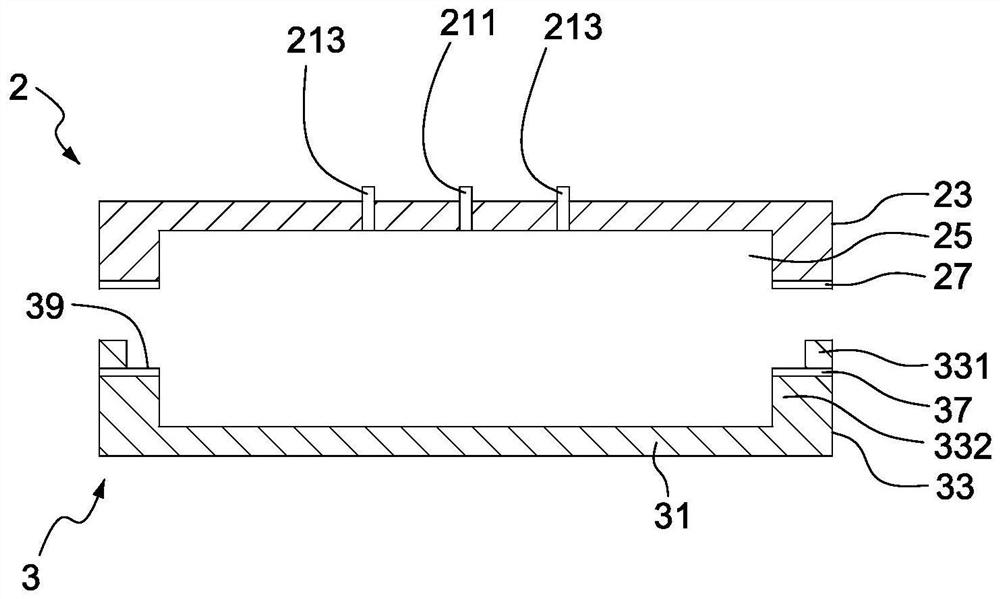

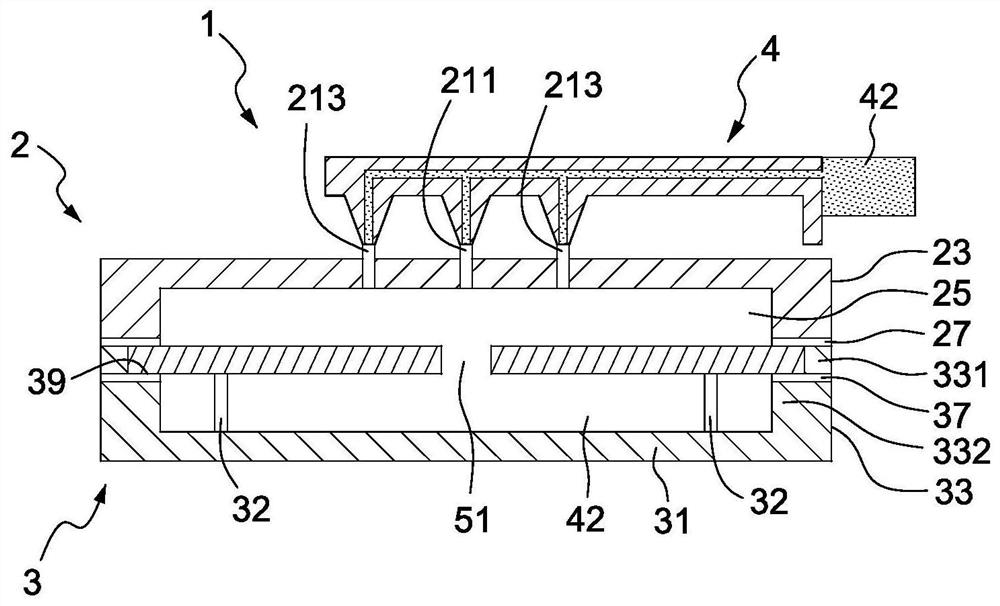

[0015] figure 1 A schematic exploded perspective view of an embodiment of the packaging mold of the present disclosure, and figure 2 It is a schematic exploded cross-sectional view of an embodiment of the packaging mold of the present disclosure. see figure 1 and figure 2 , the packaging mold 1 has an upper mold 2 and a lower mold 3 that can be separated and combined with each other, the user can separate the upper mold 2 and the lower mold 3, and place the object to be packaged in them, and then put the upper mold 2 Combined with the lower mold 3 to carry out the packaging process of the object.

[0016] like figure 1 and figure 2 As shown, the upper mold 2 has an upper part 21 and an upper side part 23 combined with the upper part 21 , and a space that the upper part 21 and the upper side part 23 of the upper mold 2 can jointly define is an upper mold cavity 25 . The upper part 21 of the upper mold cavity 2 has a main glue injection port 211 and a plurality of secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com