Automatic stretching head

A drawing head, automatic technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency and slow speed, and achieve the effect of high preloading operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

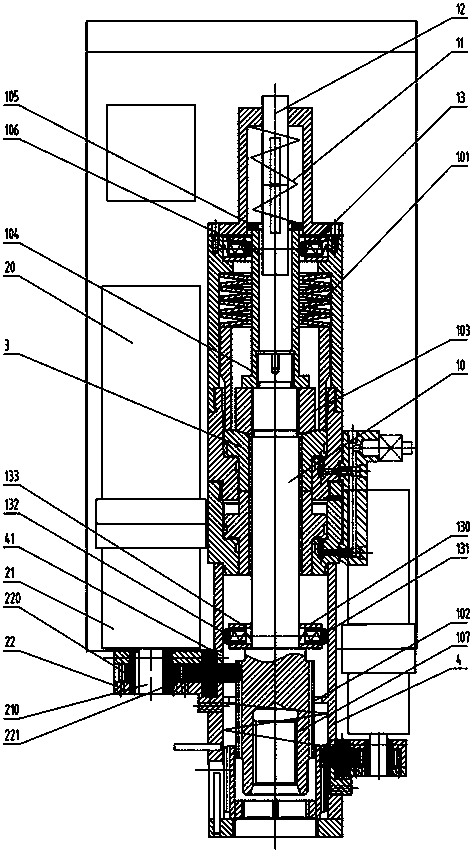

[0008] An automatic stretching head is composed of a stretching head and a driving device. The stretching head is composed of a stretching head body 10 , a compression spring 11 , a detection sensor 12 and a retaining device 13 . The upper part of the stretching head body 10 is a pull rod 101 , and the lower part is a spur gear 102 . The pull rod 101 is arranged in the middle of the piston 3, the middle part of the pull rod 101 is provided with a retention nut 103 at the upper end of the piston 3, the upper end of the retention nut 103 is provided with a pull rod sleeve 104, and the top of the pull rod sleeve 104 is provided with a washer 105, and the compression spring 11 Set on the washer 105, the detection sensor 12 is set in the top hole 106 of the pull rod 101, the retaining device 13 is set on the upper end of the pull rod sleeve 104 and the lower end of the pull rod 101, and the inside of the spur gear 102 is provided with a pre-tightening bolt Matching thread 107; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com