Blow-away type shell fabric expansion device

A technology for expanding devices and fabrics, applied in washing devices, ironing machines, textiles and papermaking, etc., can solve the problems of low cost and efficiency, and achieve the effects of improving tiling efficiency, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

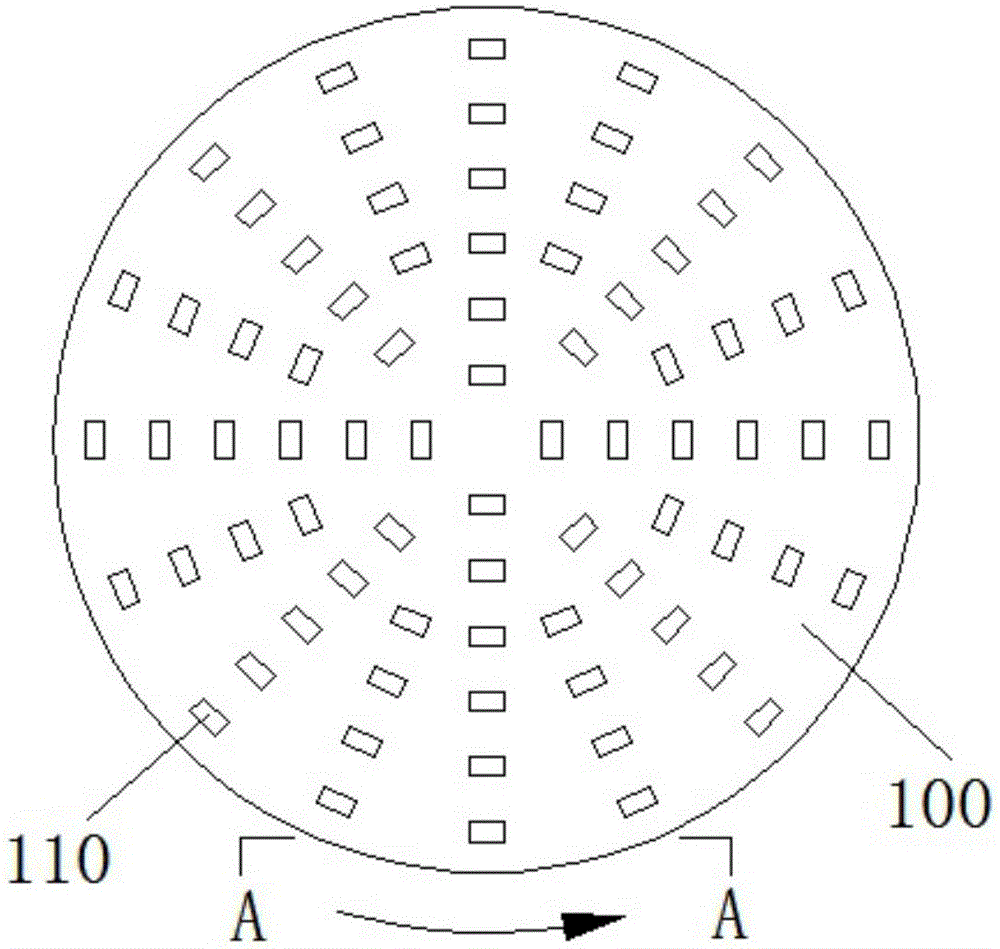

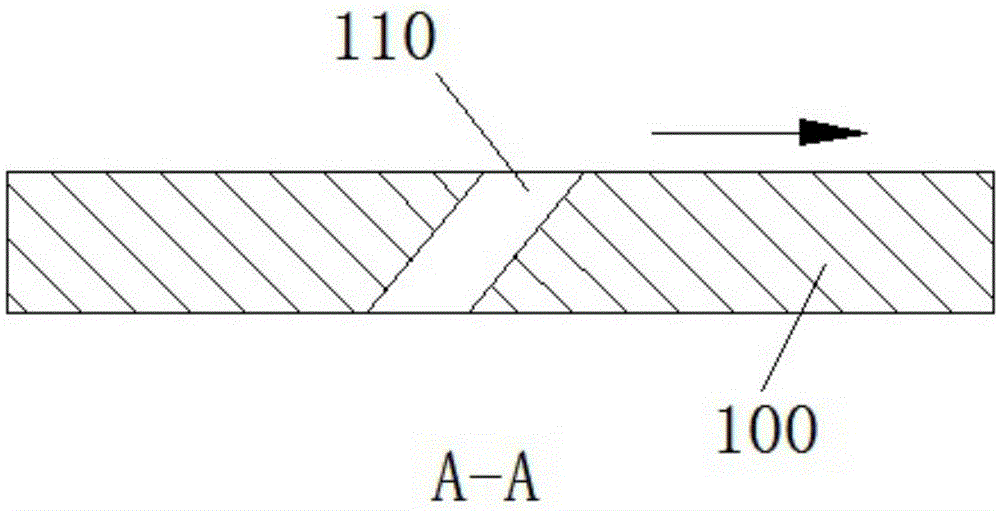

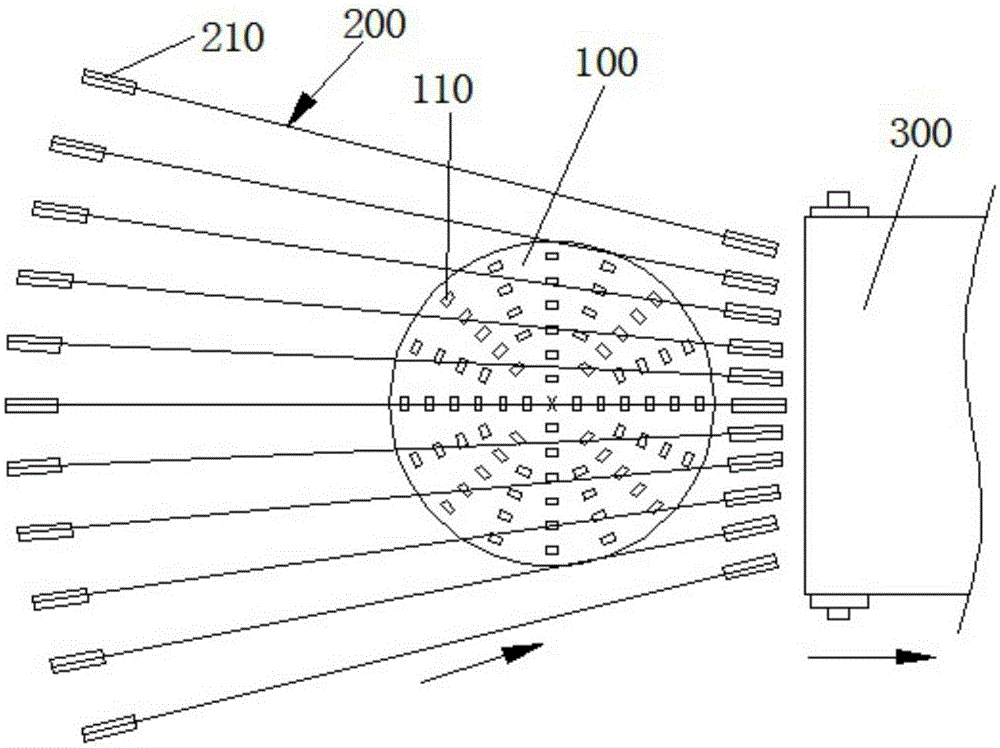

[0018] In this example, see figure 1 and figure 2 , the blow-off type fabric expansion device includes a turntable 100 uniformly distributed with oblique air outlets 110, and the air outlets 110 are deflected along the rotation direction of the turntable 100, see Figure 4 and Figure 5 A rotatable transfer disc 500 is arranged above the turntable 100, and at least two centrifugal balls 510 that can rotate freely are arranged on the bottom of the transfer disc 500, and the centrifugal balls 510 pass directly above the turntable 100 .

[0019] refer to image 3 , the turntable 100 is provided with a conveying silk path 200 for conveying the cloth to the center of the turntable, the conveying thread path 200 is formed by a radial arrangement of filamentary loops driven by guide wheel pairs 210, and the combination of radial filamentary loops The narrow side is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com