Injection mold release mechanism

A demoulding mechanism and injection mold technology, applied in the field of injection molds, can solve problems such as bayonet jamming, product or mold damage, and failure to demould normally, so as to avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

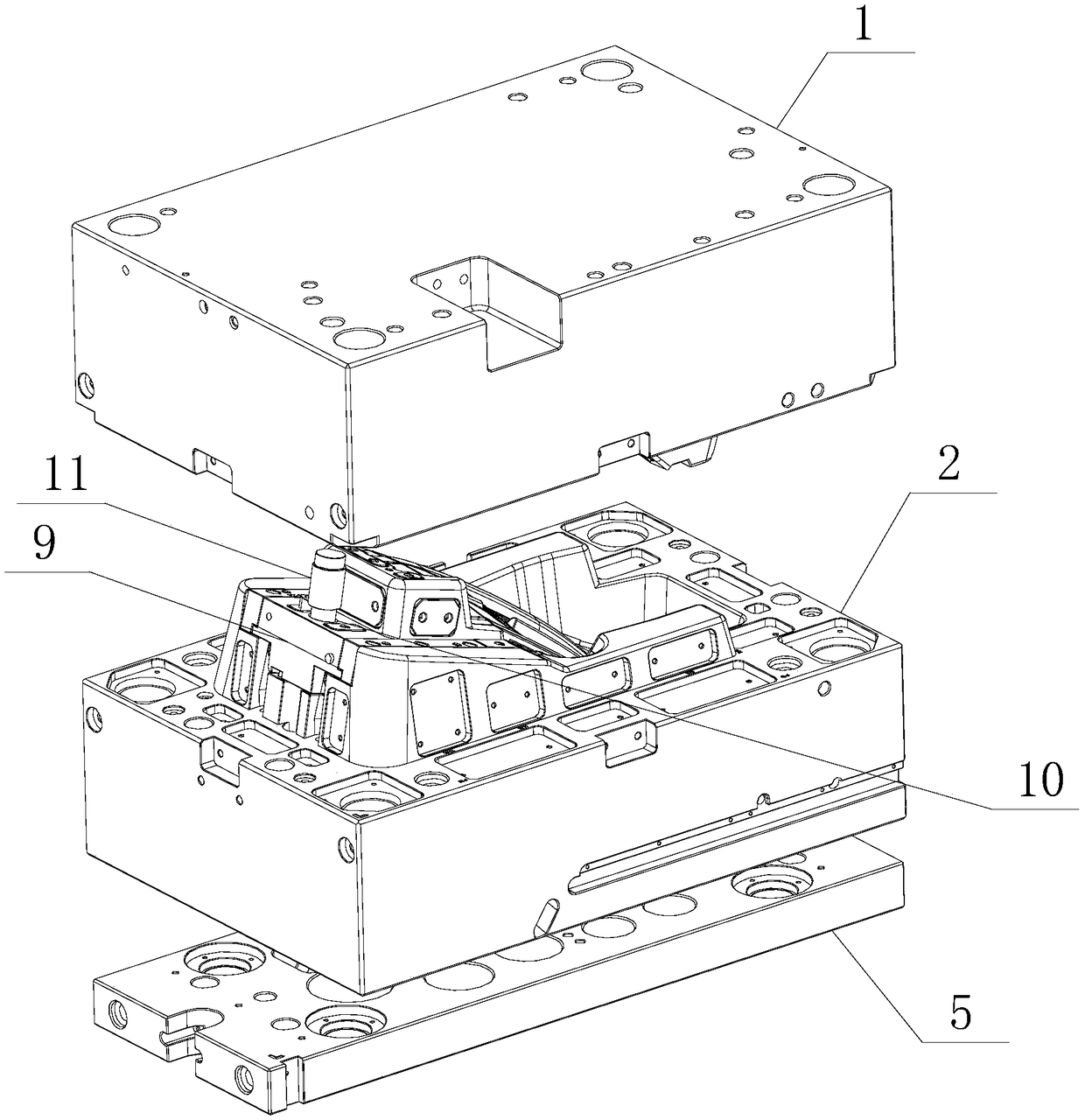

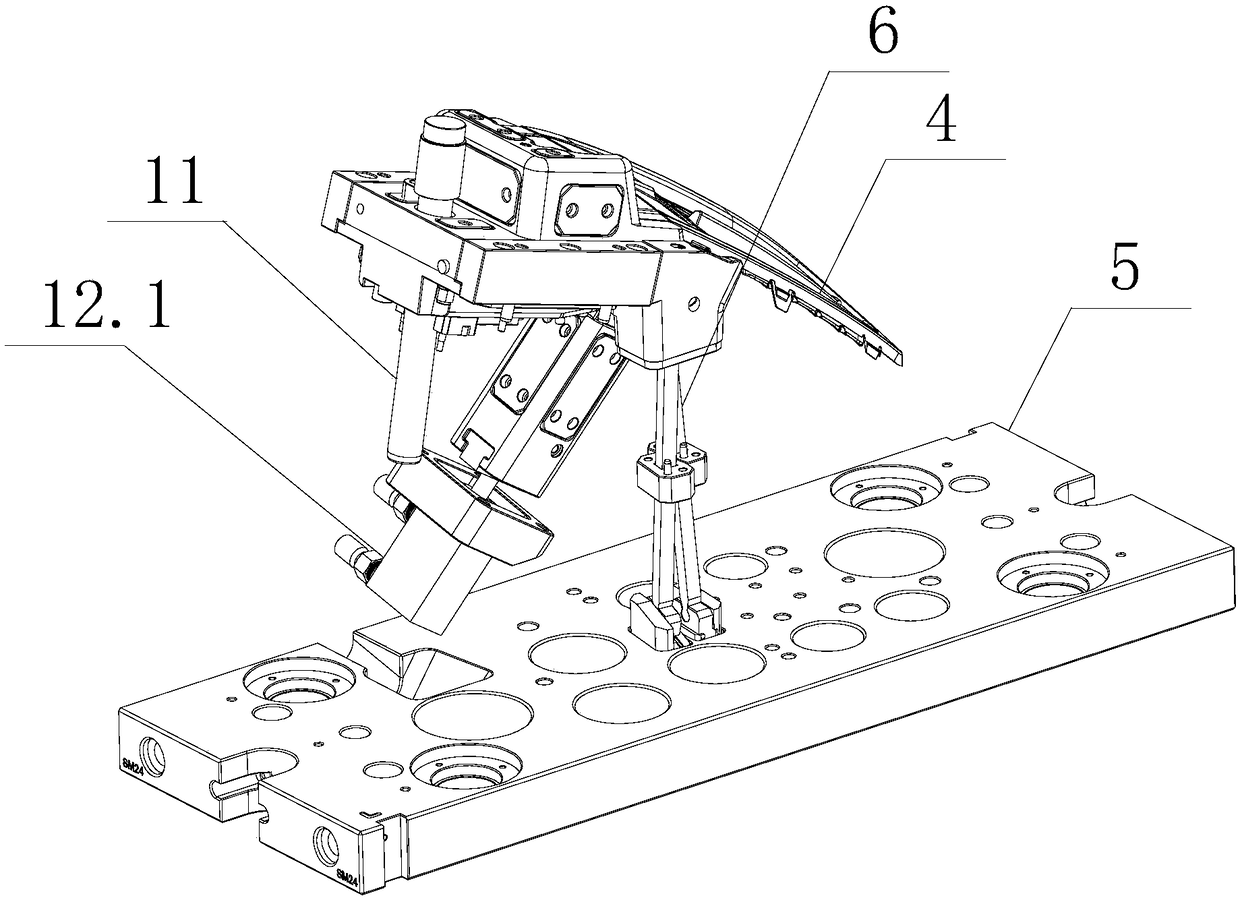

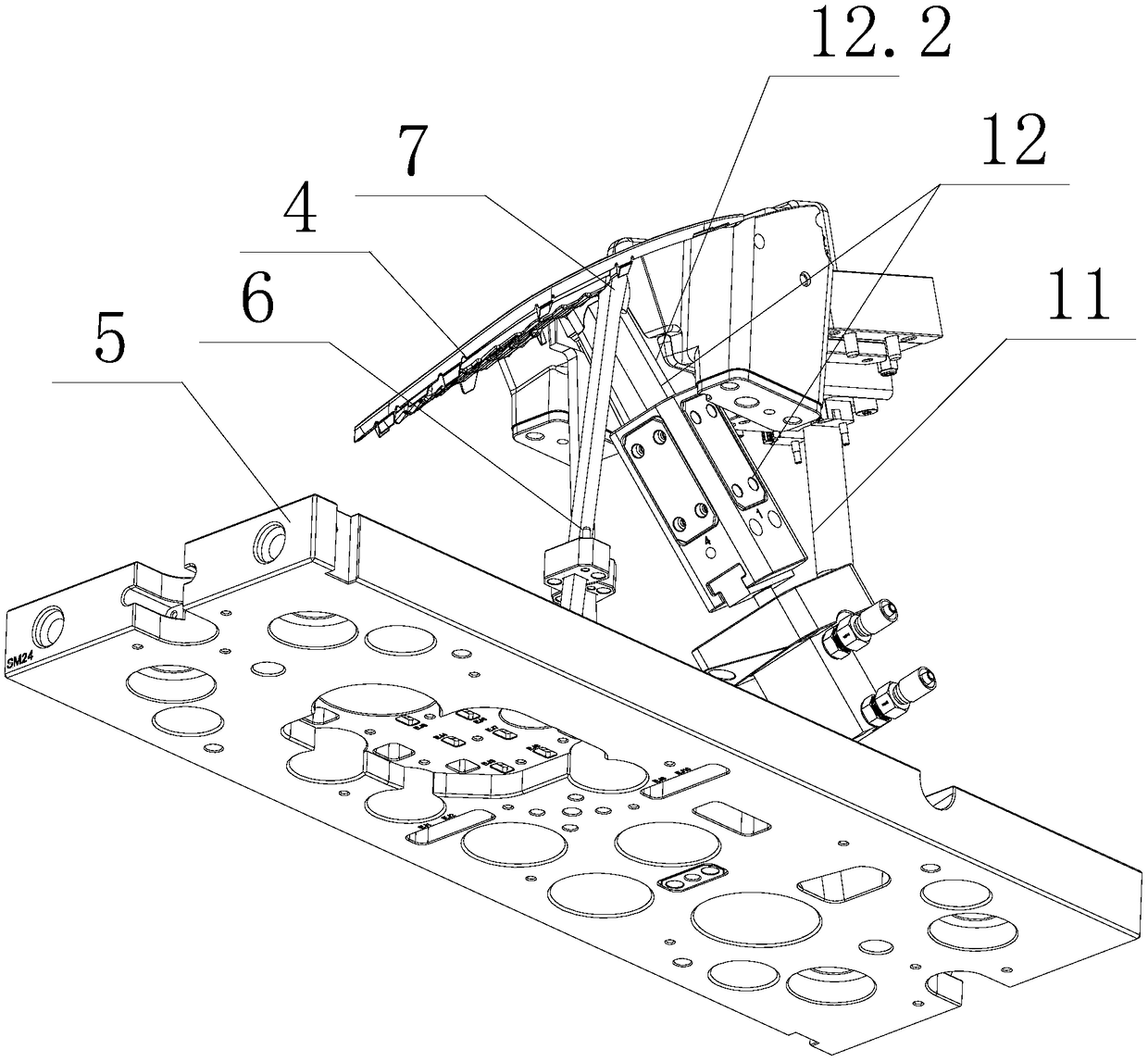

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an injection mold demoulding mechanism of the present invention includes an upper mold 1 and a lower mold 2, the upper mold 1 is slidingly fitted on the lower mold 2, and the upper mold 1 and the lower mold 2 are connected by guide posts; The lower mold 2 is provided with a demoulding mechanism and a product bracket 3, and the demoulding mechanism is connected with the product bracket 3;

[0017] The demoulding mechanism includes a first auxiliary demoulding mechanism for assisting the product 4 in forming the bottom shape, a second auxiliary demoulding mechanism for assisting the product 4 in forming the bottom shape, and a second auxiliary demoulding mechanism for assisting the product 4 in forming the bottom shape and for The third auxiliary demoulding mechanism release...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap