Flour-feeding overturning device

A technology of turning over device and feeding surface, which is applied in packaging, transportation and packaging, single object and other directions, can solve problems such as low production efficiency, and achieve the effect of improving production efficiency, good structural stability and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

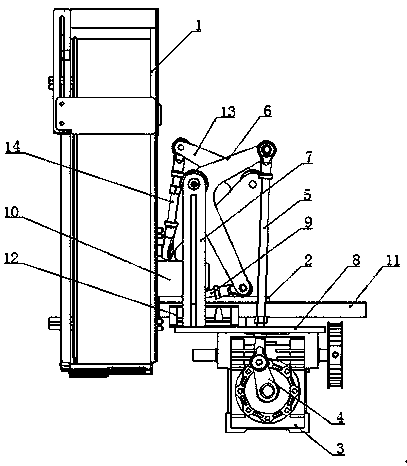

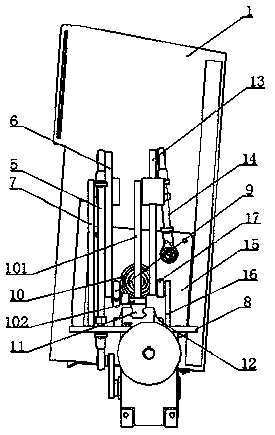

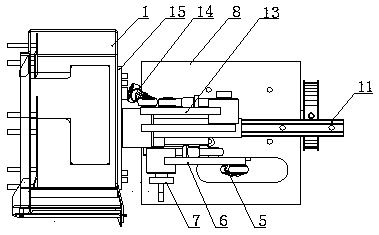

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] see Figure 1-3 , a kind of face feeding turning device of the present invention, comprises two parts of face loading box 1 and horizontal conveying rotating mechanism 2, and motor holder 8 then fixes the whole set of device on the frame of plastic bag flat bag bagging machine.

[0014] Described horizontal conveying rotation mechanism 2 comprises worm and gear reducer box 3, crank 4, first connecting rod 5, first rocker arm 6, first support plate 7, second connecting rod 9, push steady bearing seat (built-in push steady Bearing) 10, guide rail 11, slider 12, second rocker arm 13, third connecting rod 14, fixed plate 15, support plate 16 and fourth connecting rod 17, worm gear reducer 3 is fixed on the motor fixing seat 8, one end of the crank 4 is connected to the output shaft of the worm gear box 3, and the fulcrum at the corner of the L-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com