Silo clearing device

A technology of clearing and conveying devices, which is applied in the directions of packaging, transportation and packaging, loading/unloading, etc., and can solve the problem of low efficiency of residual material clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

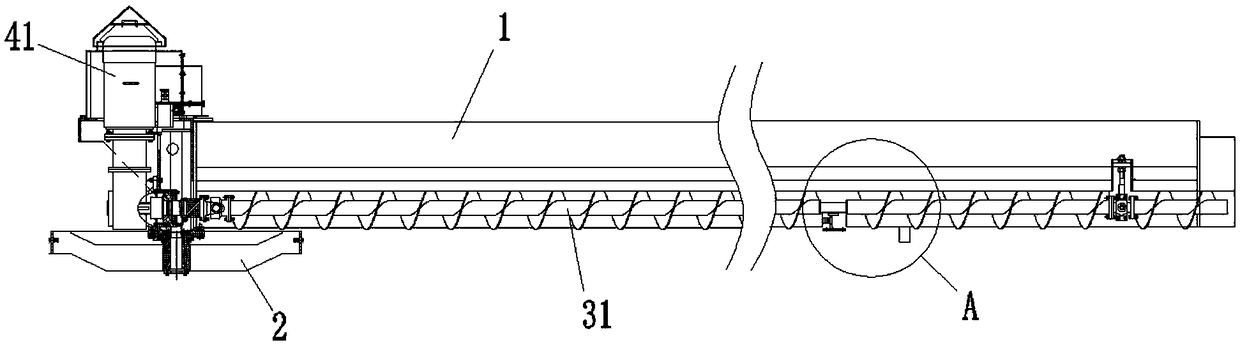

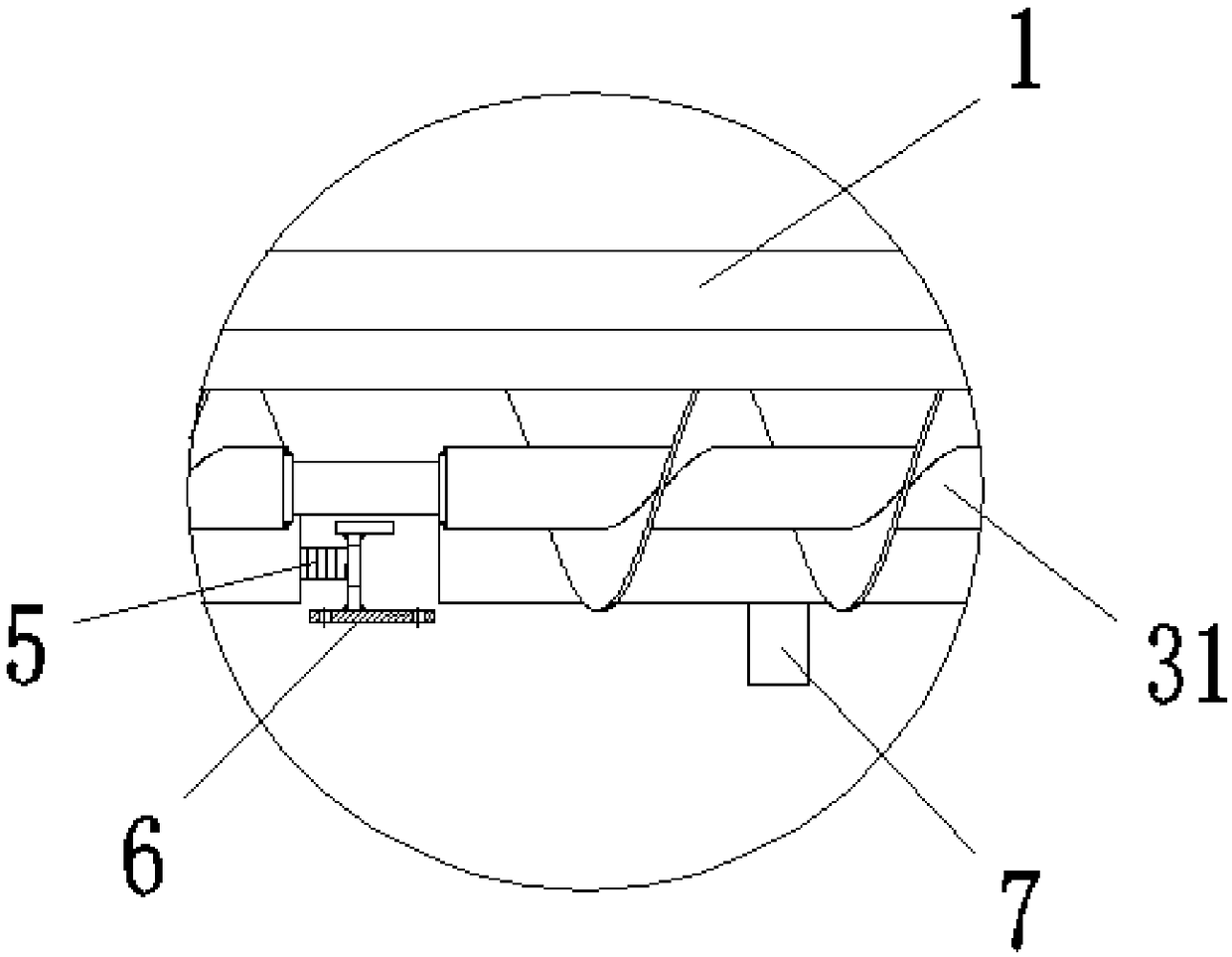

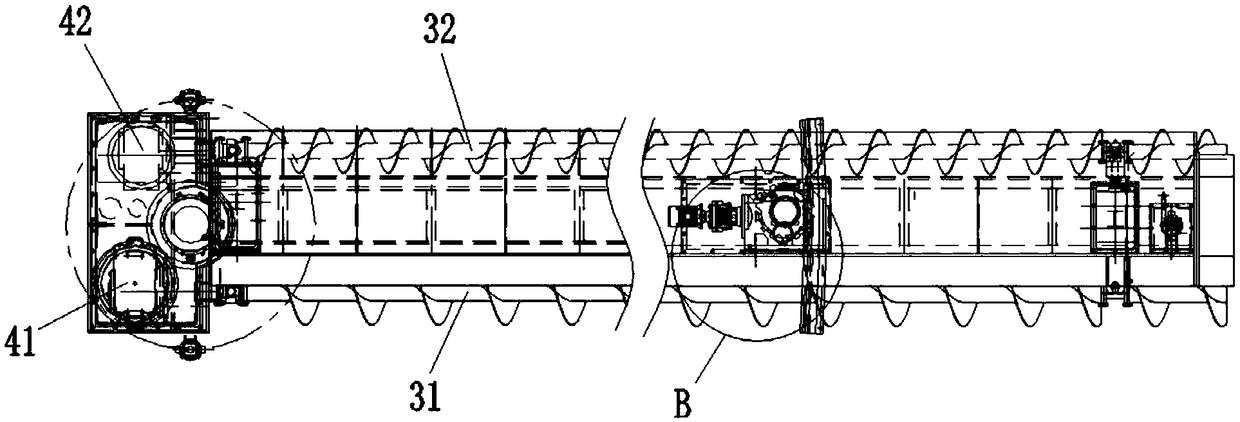

[0031] A clearing device such as Figure 1-5 As shown, it includes a frame 1 and a rotation centering device 2, the rotation centering device 2 is arranged at the end of the frame 1, and the frame 1 is also provided with a conveying device for conveying materials and for controlling the movement of the frame 1 The driving device; the conveying device includes a first auger 31 and a second auger 32, and the first auger 31 and the second auger 32 are respectively arranged on the front and rear sides of the frame 1.

[0032] Through a clearing device with the above-mentioned structure, during the clearing process, if the hardened material collapses and buries the device, causing the first auger 31 to fail to work normally, or unable to start with a load, the staff can start the second auger 32, so that The second auger 32 can clean up the material behind the clearing device, so that the clearing device can unload the load on the first auger 31 by retreating, so that the first aug...

Embodiment 2

[0044] Such as Figure 1-5 As shown, as a further optimization of the above embodiment, the clearing device also includes a control system, the control system includes a controller and a sensor, the controller is connected to the sensor, and the controller is connected to the electrical control device of the second drive motor 42 and the third drive motor 42 respectively. The electric control device of driving motor 43 is connected; Wherein, the effect of sensor is to be used for detecting the working condition of the first driving motor 41, promptly when the staff starts this clearing device, the first auger 31 can rotate normally, and sensor can the second A signal that the first auger 31 is rotating is sent to the controller; when the load on the first auger 31 increases, causing the first auger 31 to fail to work normally, that is, the first auger 31 cannot rotate during the working process At this time, the sensor will send the signal that the first auger 31 cannot work n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com