A ventilation slot dust removal trolley

A technology of ventilation slots and trolleys, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of recoil dust, fast dust speed, flying out, etc., and achieve the effect of increasing service life, changing length, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

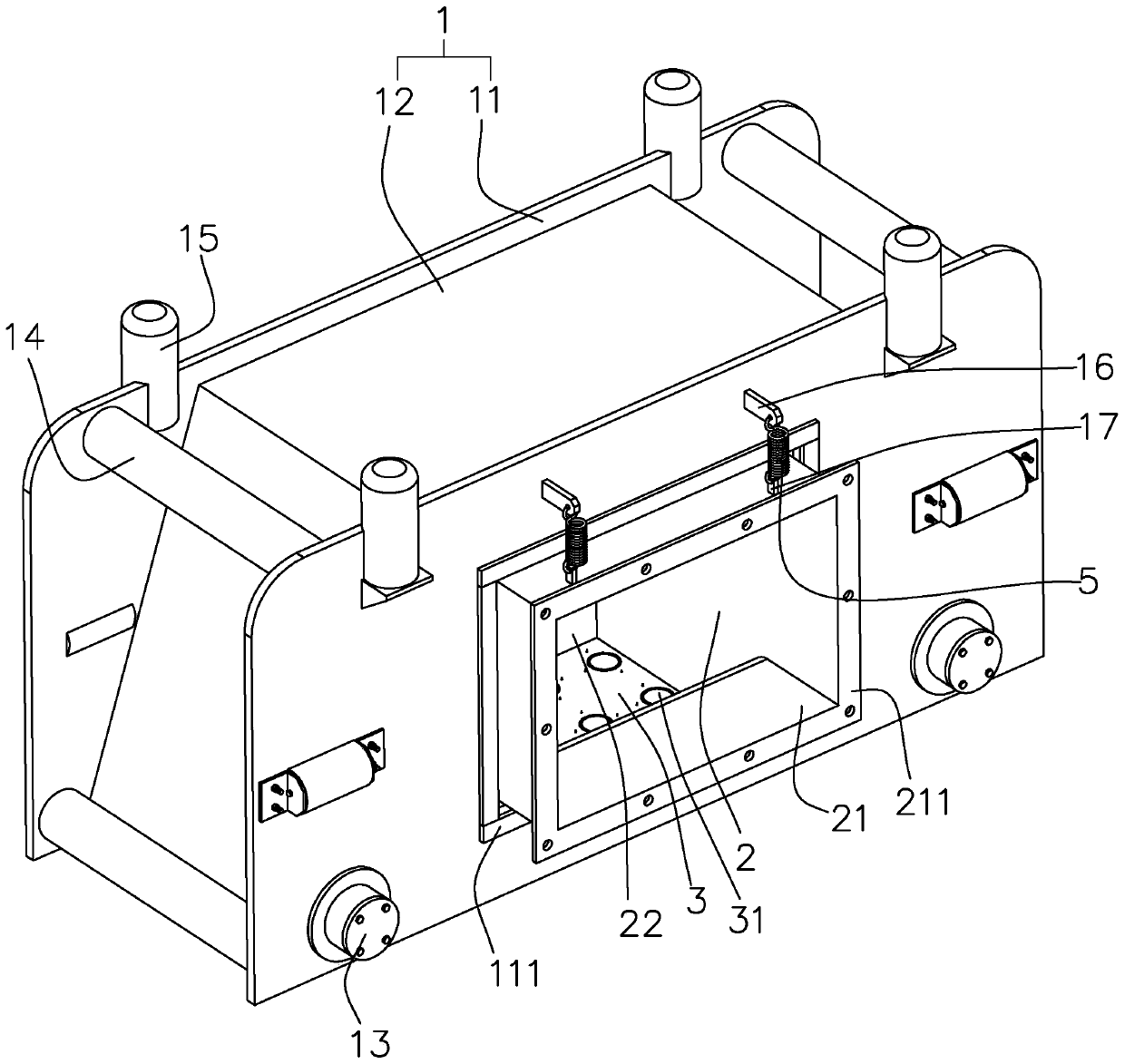

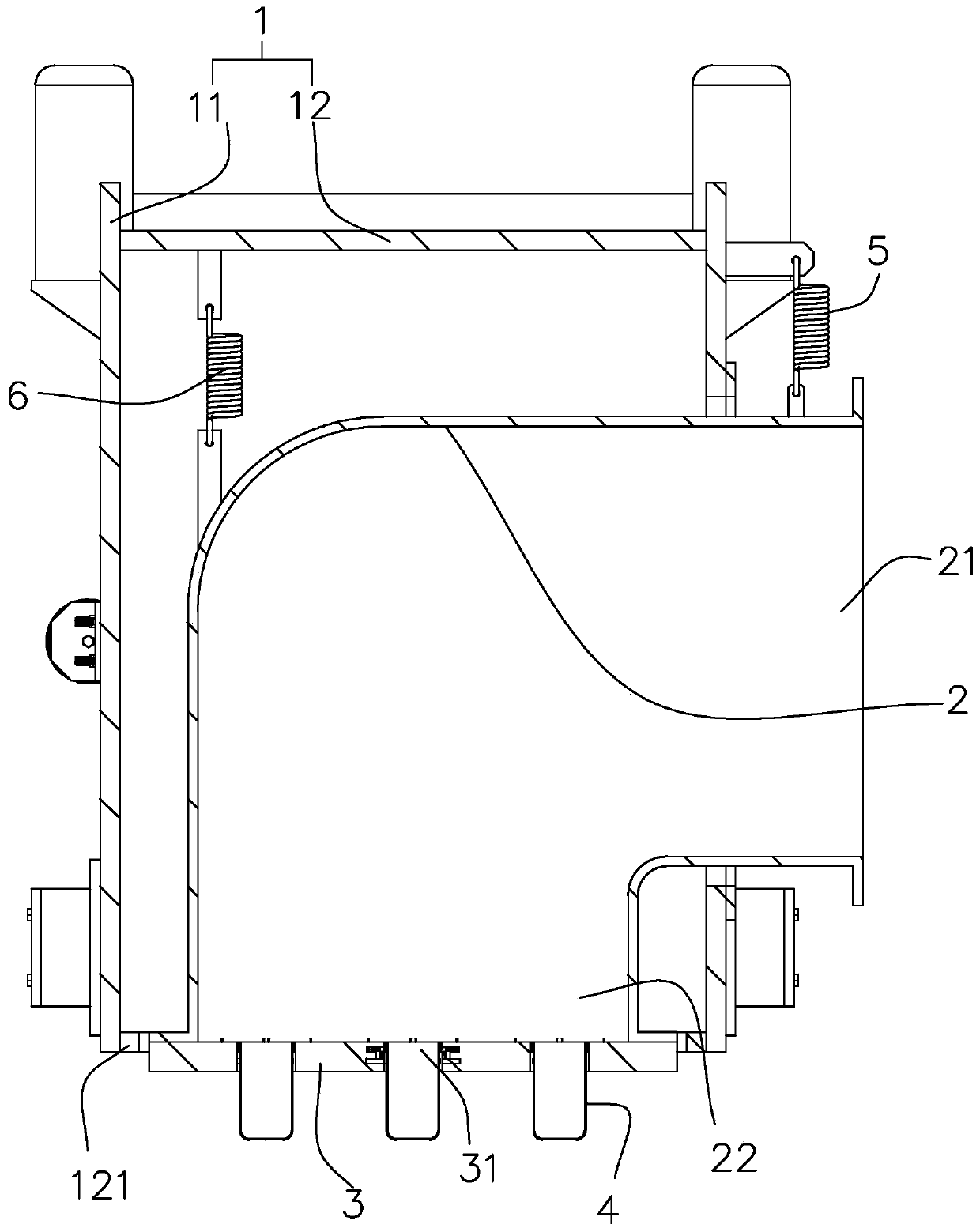

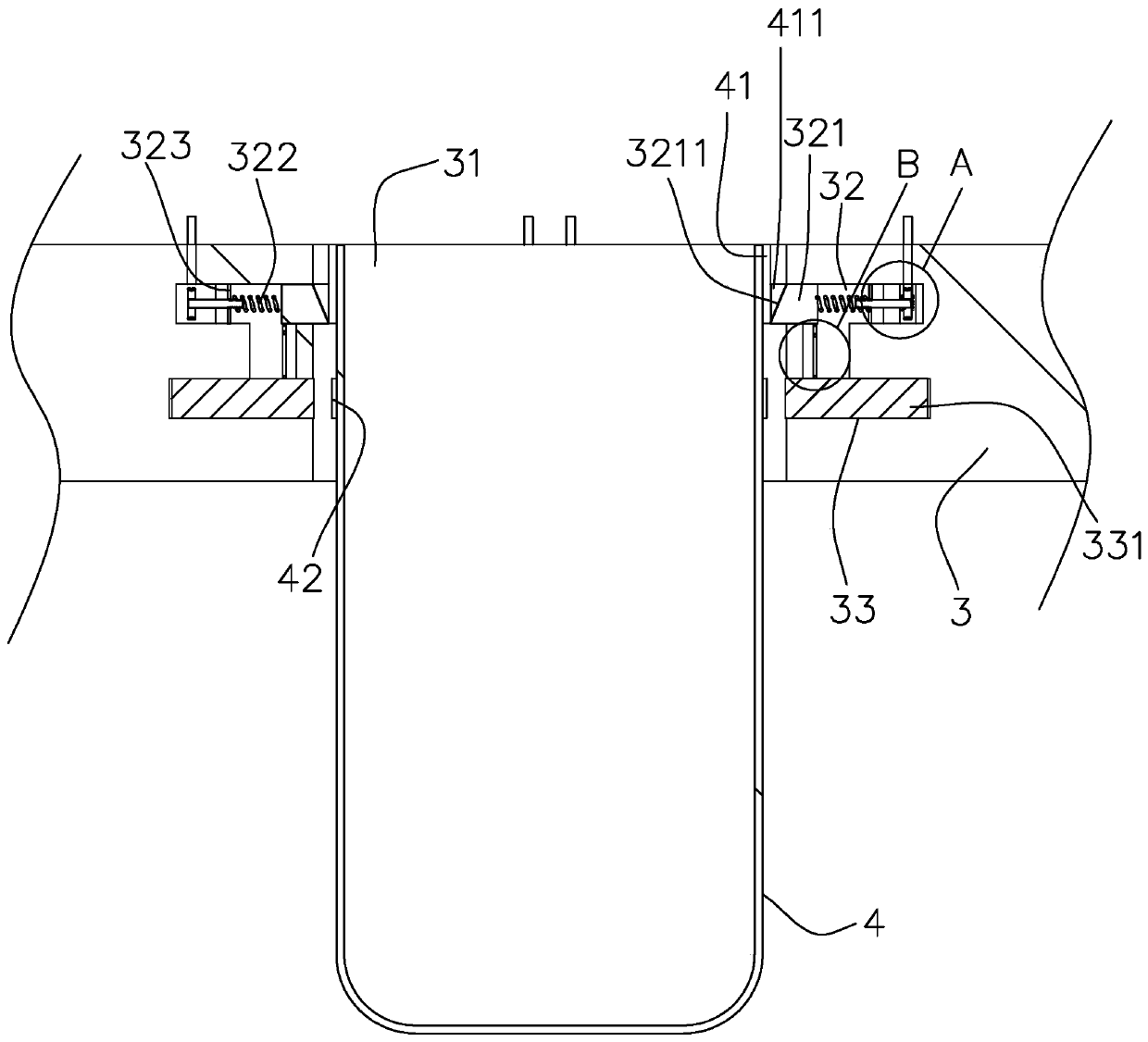

[0041] A ventilation slot dust removal trolley, such as figure 1 and figure 2 , comprising a hollow car body 1, the side of the car body 1 is provided with an installation opening 111, the bottom of the car body 1 is provided with a dust removal port 121, and the car body 1 is movably connected with an inverted L-shaped air inlet elbow 2. The air inlet elbow 2 includes an air inlet end 21 and an air outlet end 22 , the air inlet end 21 protrudes from the installation opening 111 , and the air outlet end 22 points to the dust removal opening 121 . Dust enters the air inlet elbow 2 from the air inlet end 21 and is discharged from the air outlet end 22 .

[0042] Such as figure 1 The car body 1 includes a side plate 11 and a shell 12, the side plate 11 is provided with two pieces, and the shell 12 is set as a trapezoid and is located between the two side plates 11. The installation opening 111 is located on one of the side panels 11 , and the dust removal opening 121 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com