Hypersonic inlet starting method and starting device

A hypersonic, air intake technology, applied in the ignition of the turbine/propulsion device, the starting of the turbine/propulsion device, the starting of the engine, etc., can solve the overall performance decline of the engine, poor anti-back pressure performance of the intake port, Complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

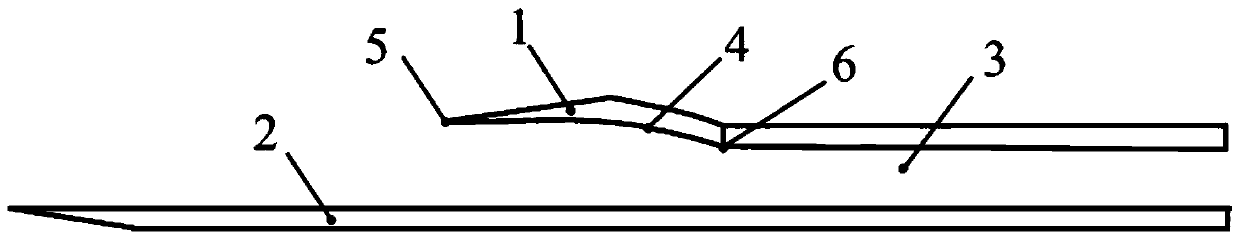

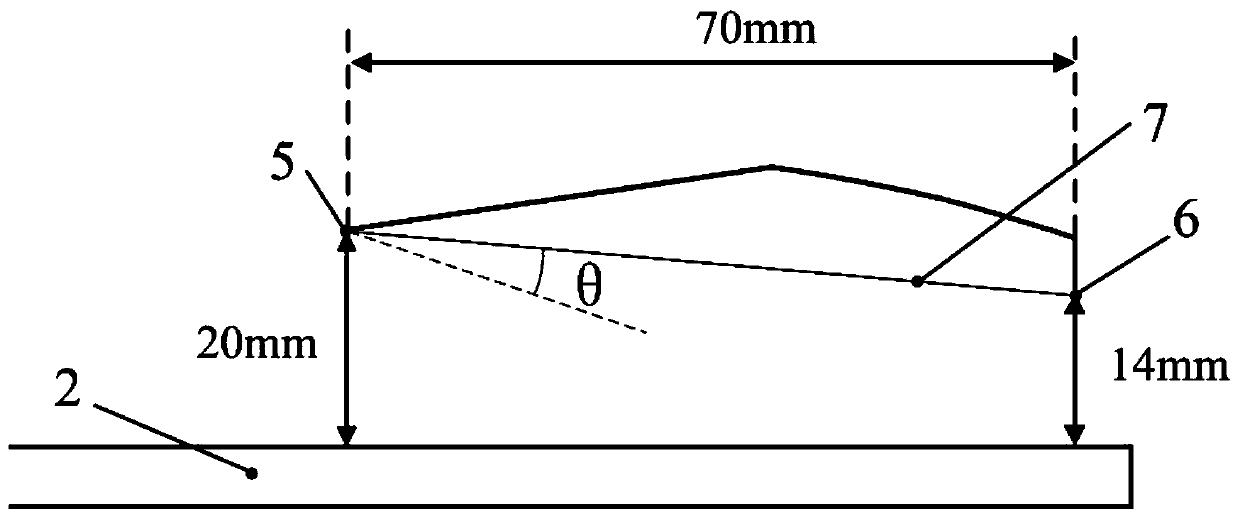

[0023] Please refer to Figure 1 to Figure 3 , the present invention provides a hypersonic inlet start control method, comprising:

[0024] Step S1, obtaining the best starting profile inside the lip cover according to the known performance parameters of the air inlet, the design profile inside the lip cover and the Mach number for starting control;

[0025] In order to fully illustrate the control method of auxiliary starting used in the present invention, firstly, a two-dimensional inlet as shown in the figure is given, and the self-starting Mach number Ma of the inlet is given ss , Restart Mach number Ma rs and design Mach number Ma d and other performance parameters, and the inner profile of the lower lip cover at the design Mach number is also given, which is called the design profile in the present invention. It should be noted that, for the convenience of expressing the content of the present invention, the air intake precursor and the isolation section that are not ...

Embodiment 2

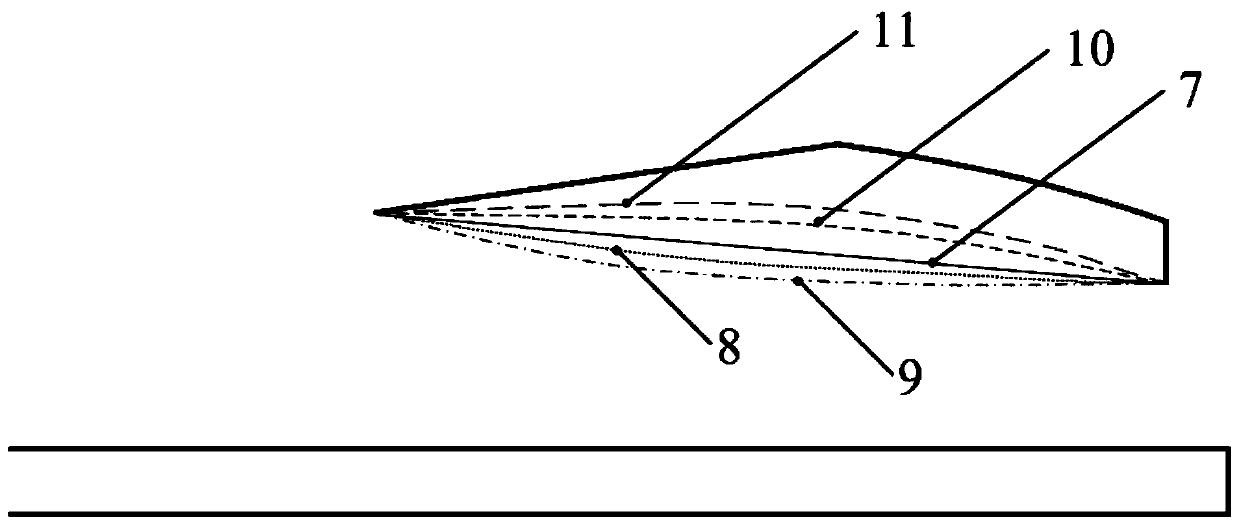

[0070] A lip cover elastic auxiliary panel is arranged around the edge of the inner top wall of the lip cover top plate, and the lip cover top plate and the lip cover elastic auxiliary panel are jointly arranged to form a cavity, and there is a gaseous medium or a liquid medium in the cavity. In order to reduce the weight of the aircraft itself, air is selected as the medium here, and the step 2 includes:

[0071] When the flight state of the aircraft reaches the control Mach number, control the air pressure change in the cavity formed by the lip cover top plate and the lip cover elastic auxiliary panel, so that the deformed shape of the lip cover elastic auxiliary panel tends to the above-mentioned The best starting line on the inner side of the lip cover;

[0072] Specifically, the amount of air input into the cavity can be controlled through the air intake equipment and the air intake valve installed on the air intake pipe. When the air pressure value reaches the starting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com