Portable dragging moment measuring device and method based on PID control

A technology for dragging torque and measuring devices, applied in measuring devices, force/torque/power measuring instruments, torque measurement, etc., to avoid adverse effects and make the measurement process simple and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

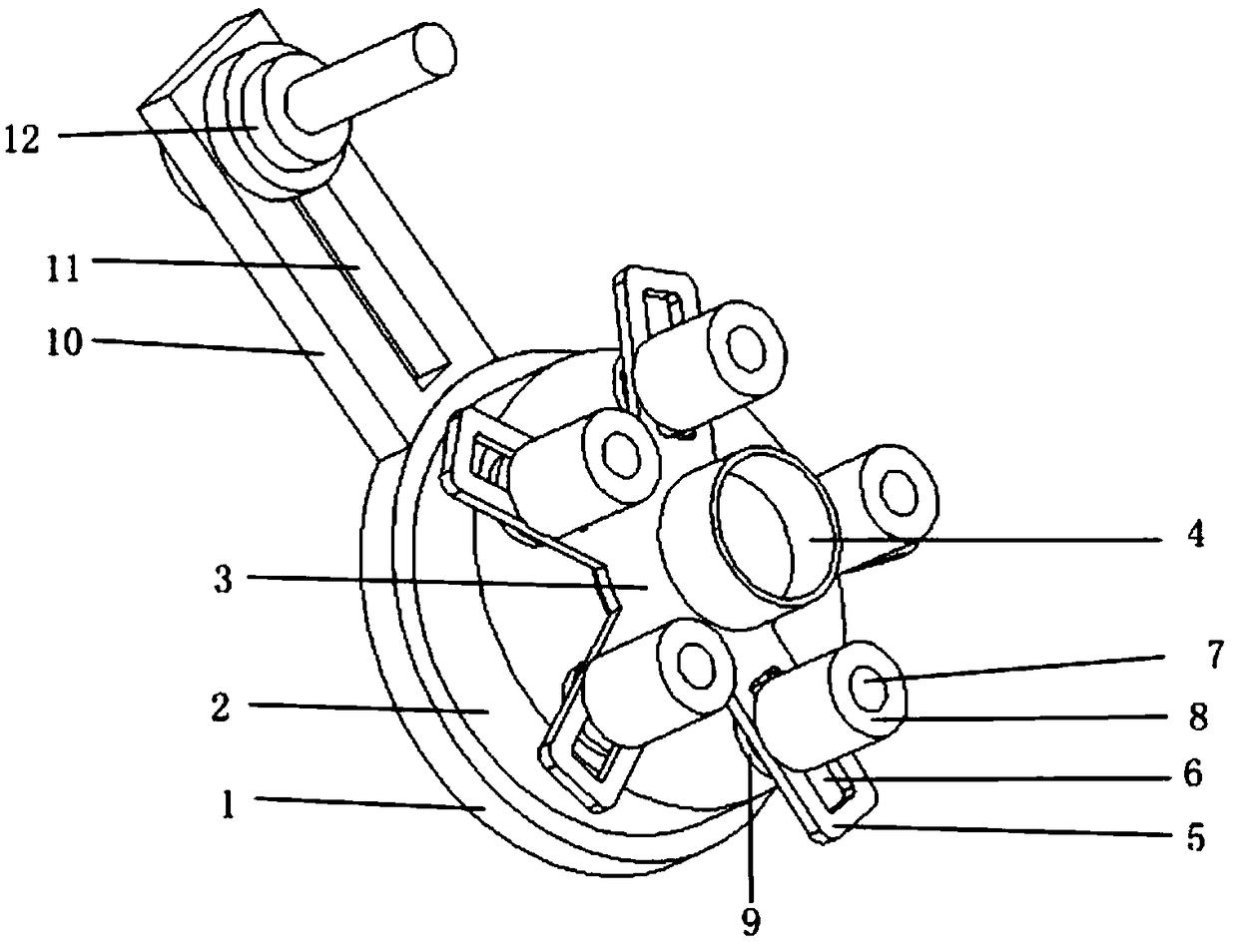

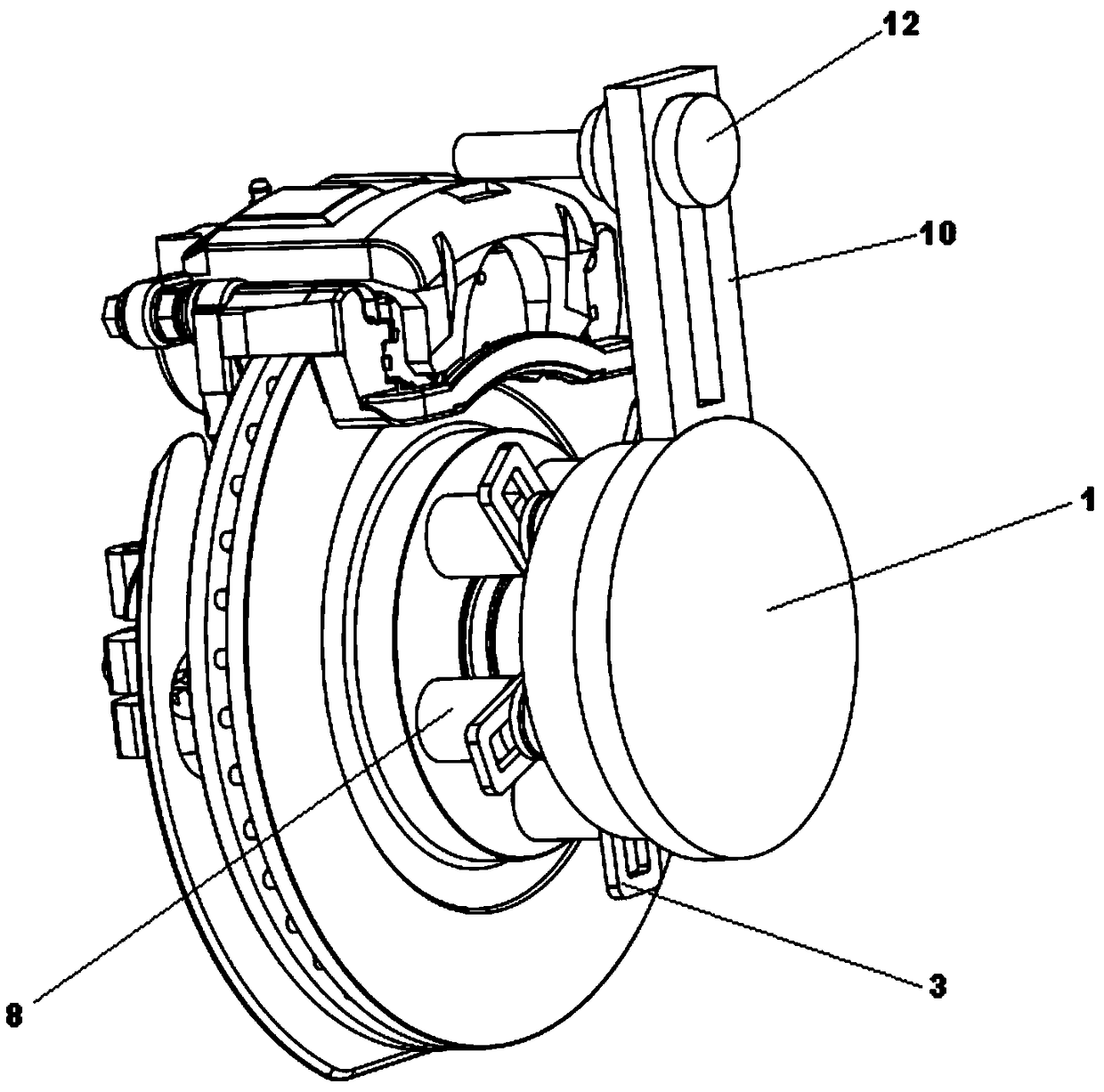

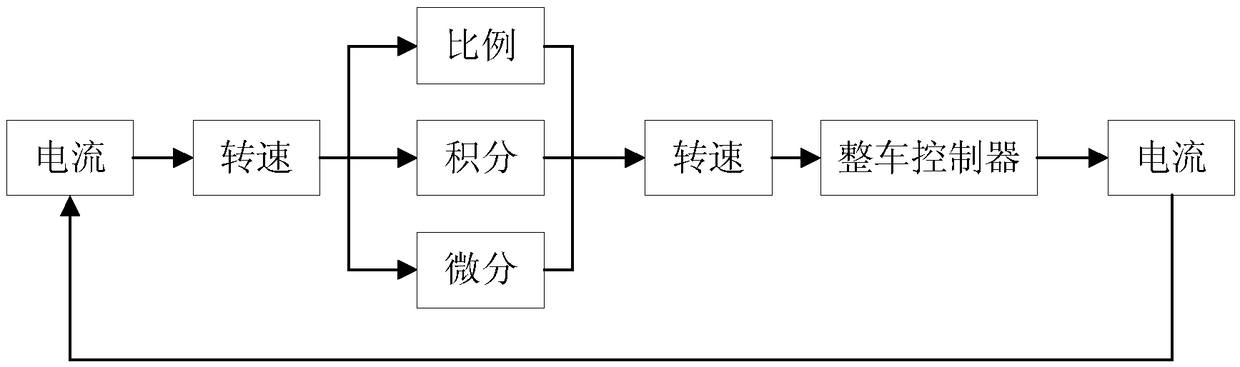

[0027] In this embodiment, a portable drag torque measurement device based on PID control, such as figure 1 As shown, it includes a torque measuring device 1, a motor 2 arranged on the torque measuring device, an adjustable mounting mechanism 3 arranged on the motor, a first adjustable mounting bracket 10 connected with the torque measuring device, and the first adjustable mounting mechanism The adjustable length locking pin 12 connected with the frame, the data display connected with the torque measuring device, the PID controller controlling the constant speed rotation of the motor and the vehicle controller arranged on the vehicle body; the PID controller is electrically connected with the motor, The PID controller is electrically connected to the vehicle controller, the data display is electrically connected to the torque measuring device, and the PID controller, the motor, the data display, the torque measuring device and the vehicle controller are all electrically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com