A fully-enclosed switch cabinet busbar grounding device and an application method

A busbar grounding and switchgear technology, which is applied to the grounding device of switchgear, switchgear, pull-out switchgear, etc., can solve the problems of inconvenient operation, achieve flexible use, good promotion and application prospects, and ensure personal safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

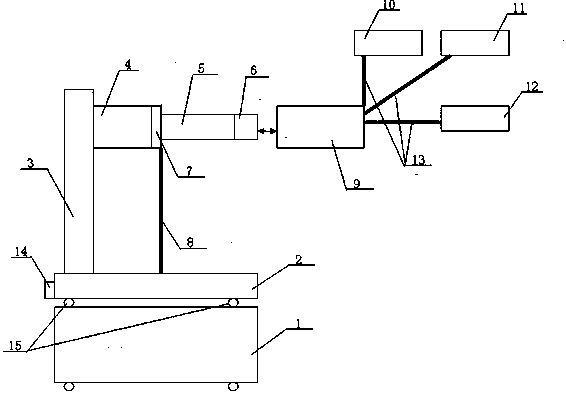

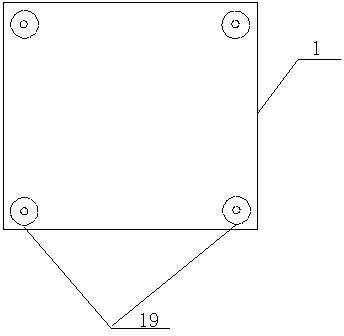

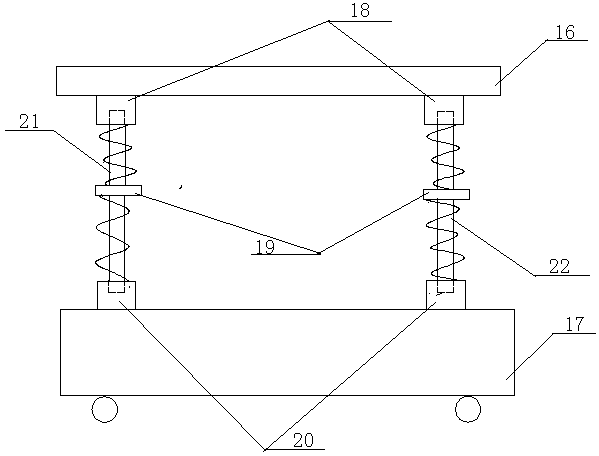

[0025] Such as figure 1 As shown, a busbar grounding device for a fully enclosed switchgear includes an operating platform mechanism 1, a chassis car 2 is arranged above the operating platform mechanism 1, and a panel 3 perpendicular to the chassis car is fixedly connected to the chassis car 2 , the panel 3 is fixedly connected with three post insulators 4 in the horizontal direction, the three post insulators 4 are perpendicular to the panel 3 in direction, and the three post insulators 4 are distributed side by side on the panel 3, the three post insulators Each post insulator of the insulator 4 is fixedly connected with a conductive arm 5 and a movable contact 6 located at the front end of the conductive arm 5, the number of the conductive arms 5 is 3, and the number of the movable contact 6 is for 3 pcs. The three conductive arms 5 are connected with the three-phase short-circuit copper bar 7 and then connected with the chassis vehicle 2 through the first grounding copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com