Patents

Literature

51results about How to "Adjustable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

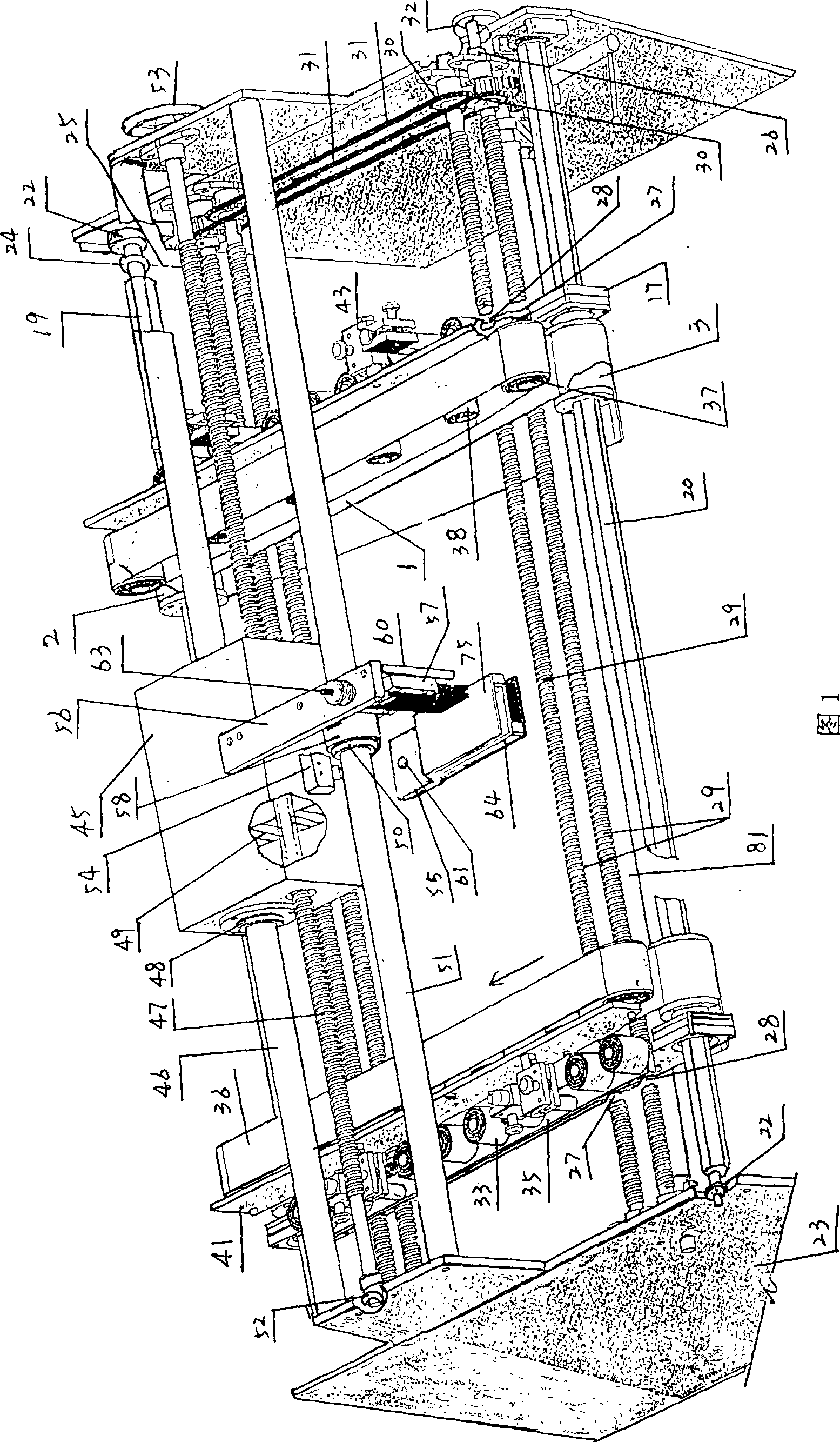

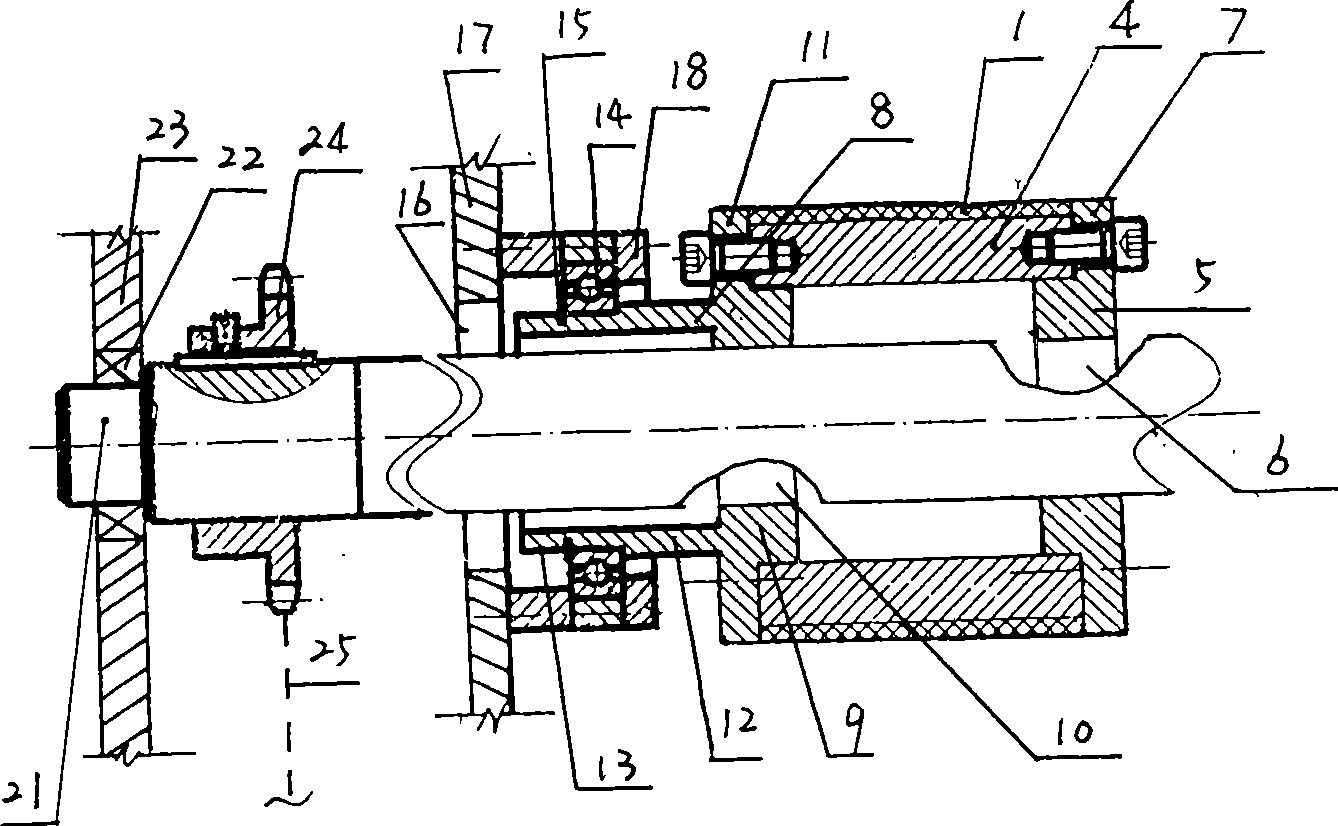

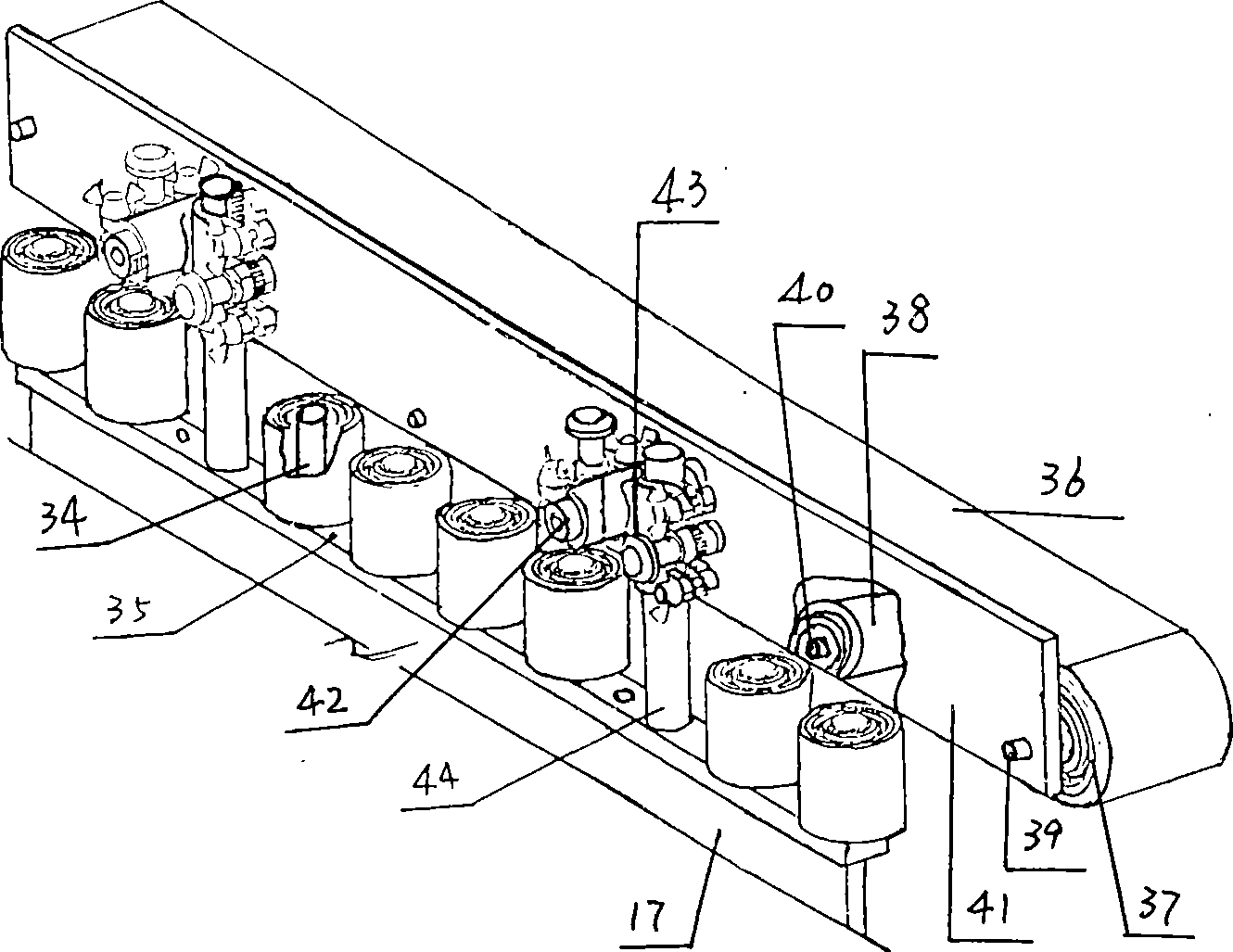

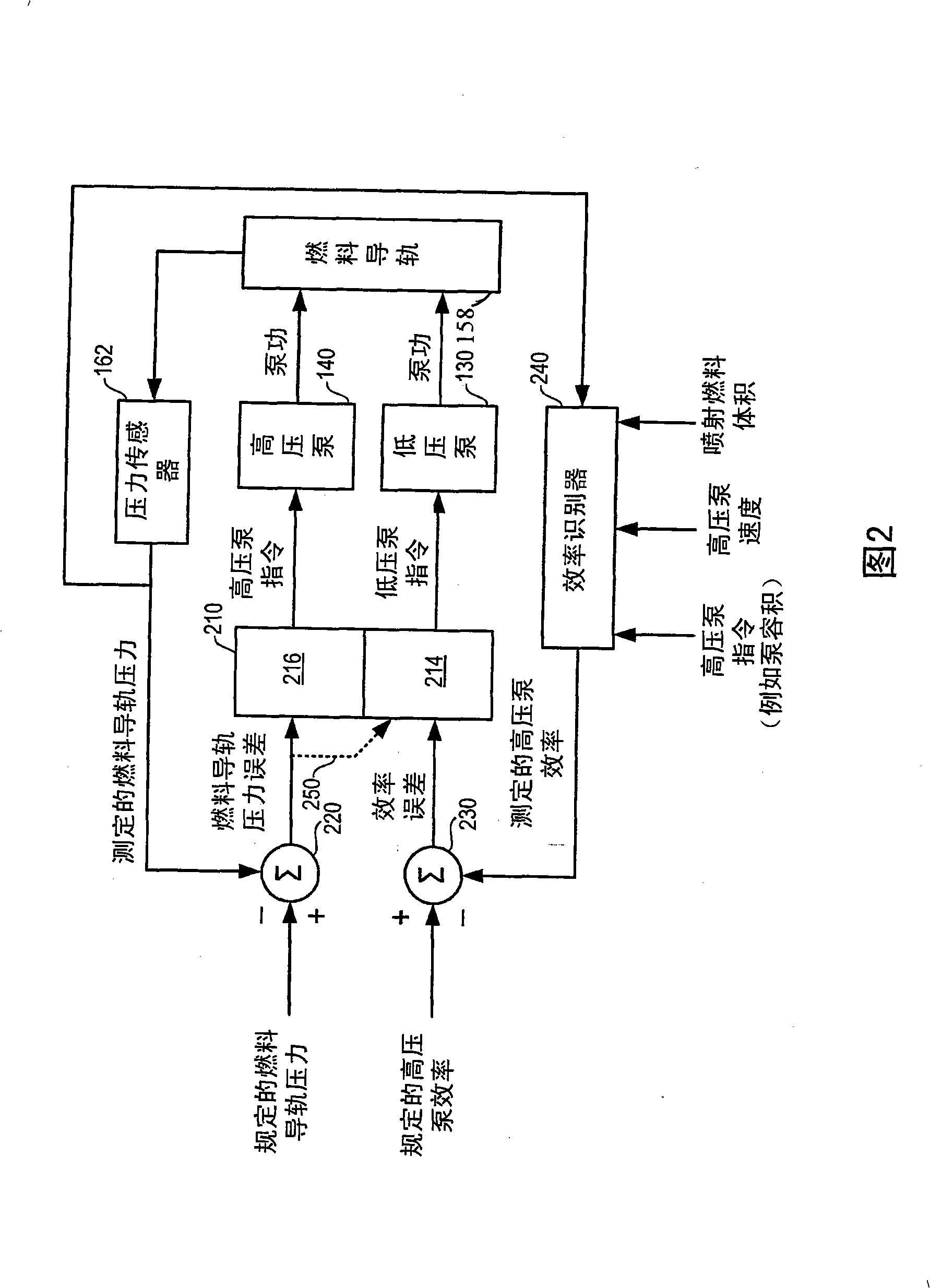

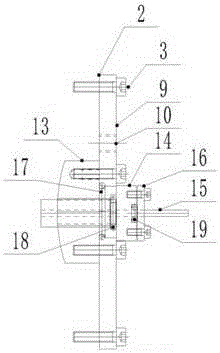

Nailing machine of corrugated case

InactiveCN101456265AQuality improvementAdjustable pressure partBox making operationsPaper-makingAxial displacementEngineering

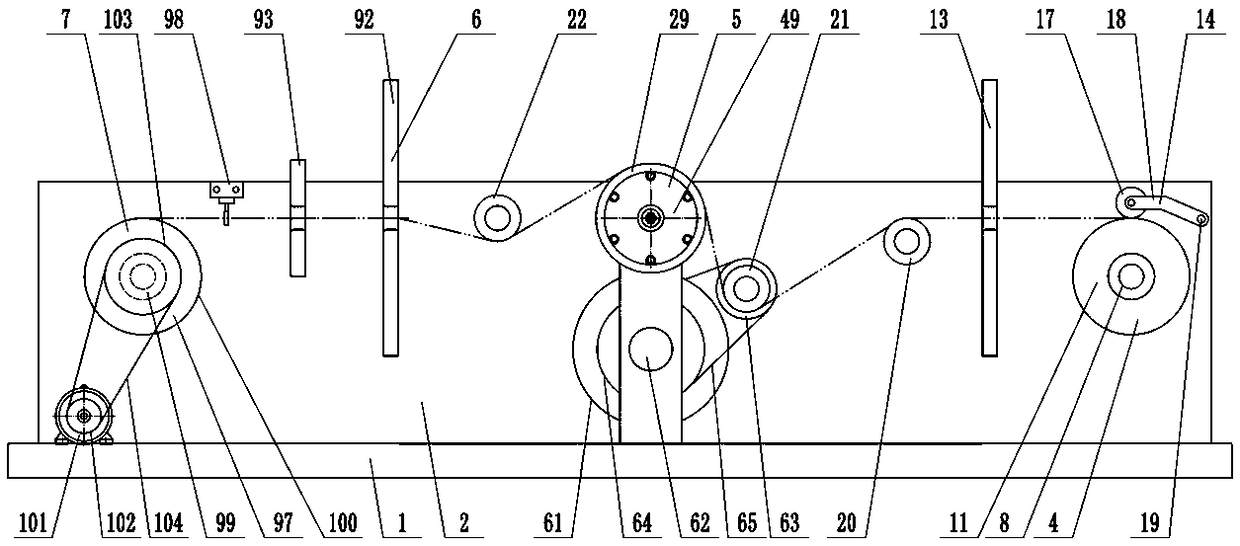

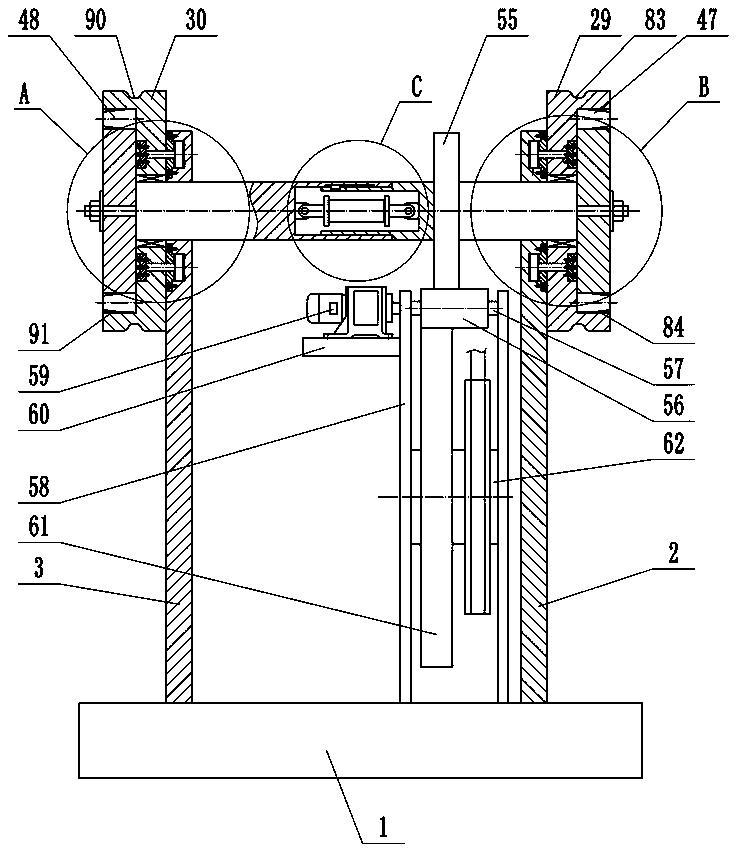

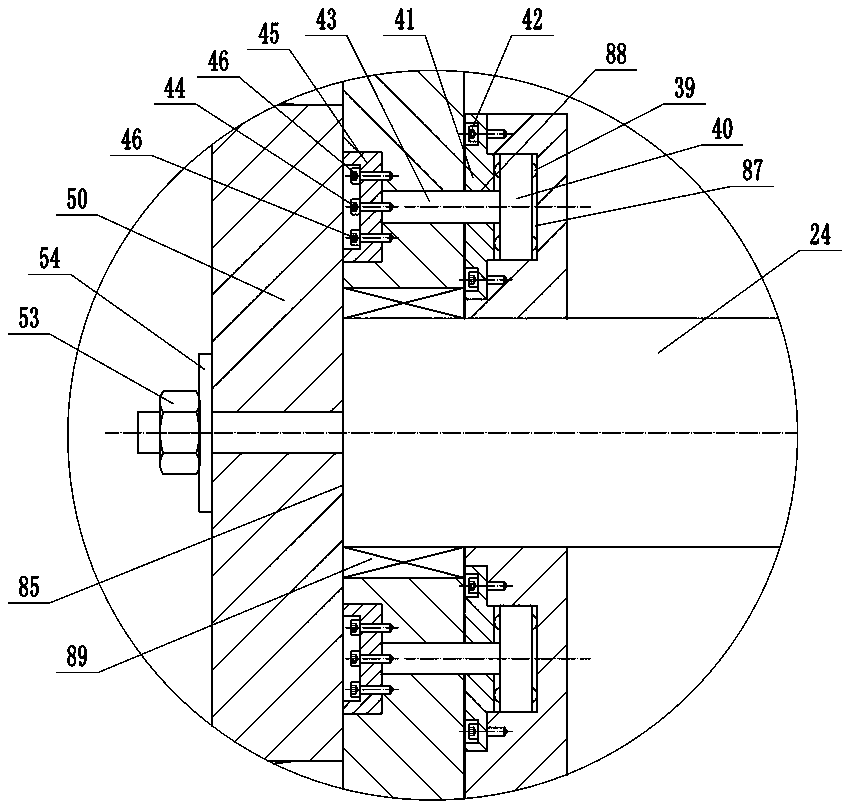

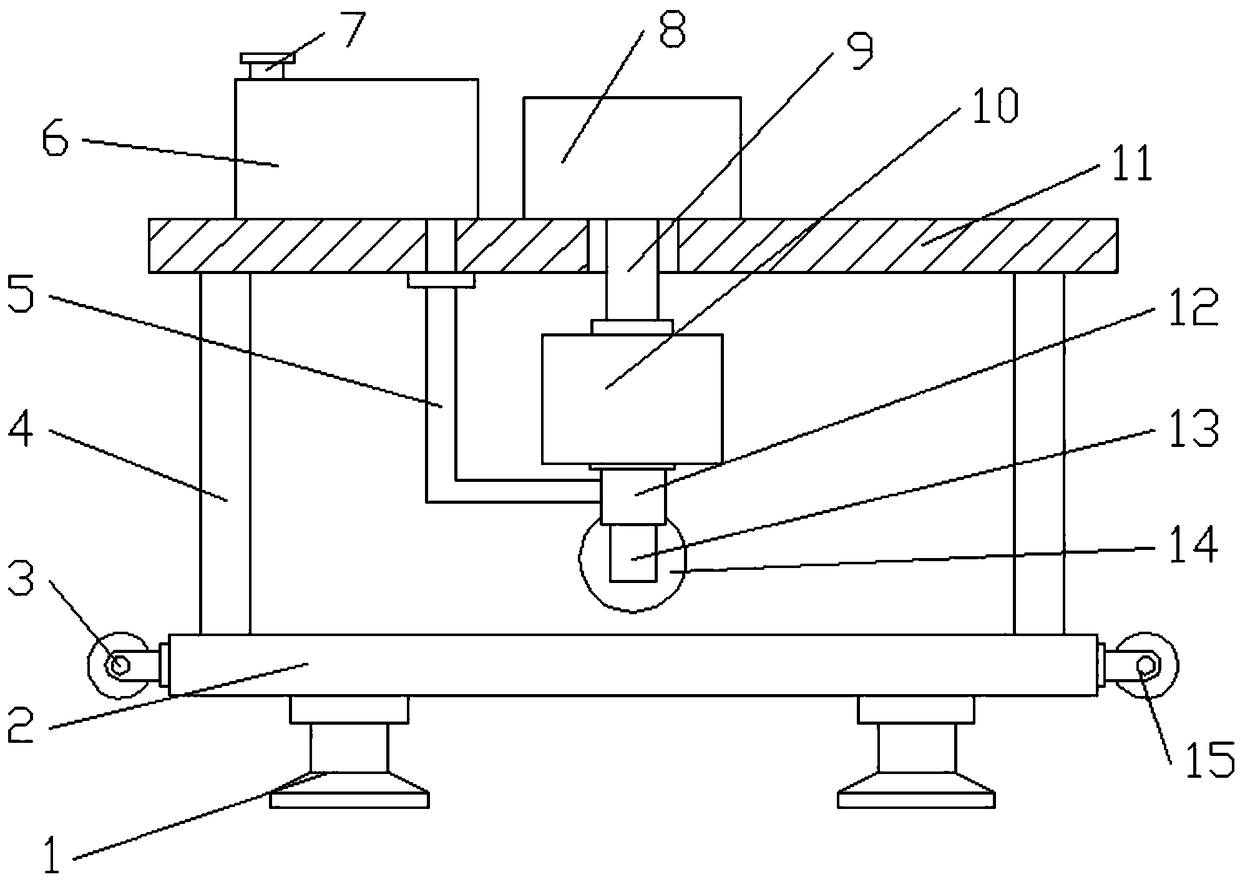

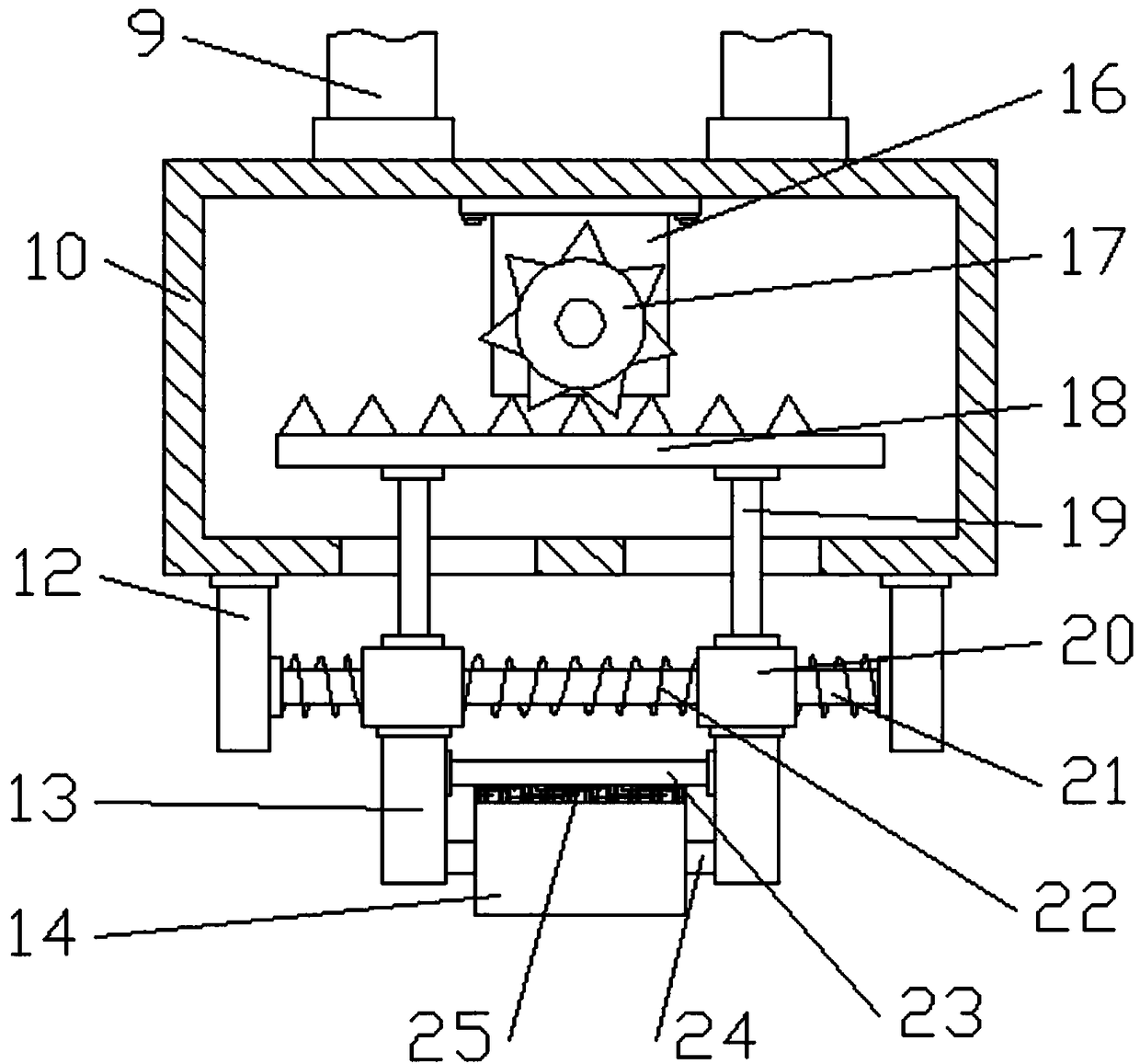

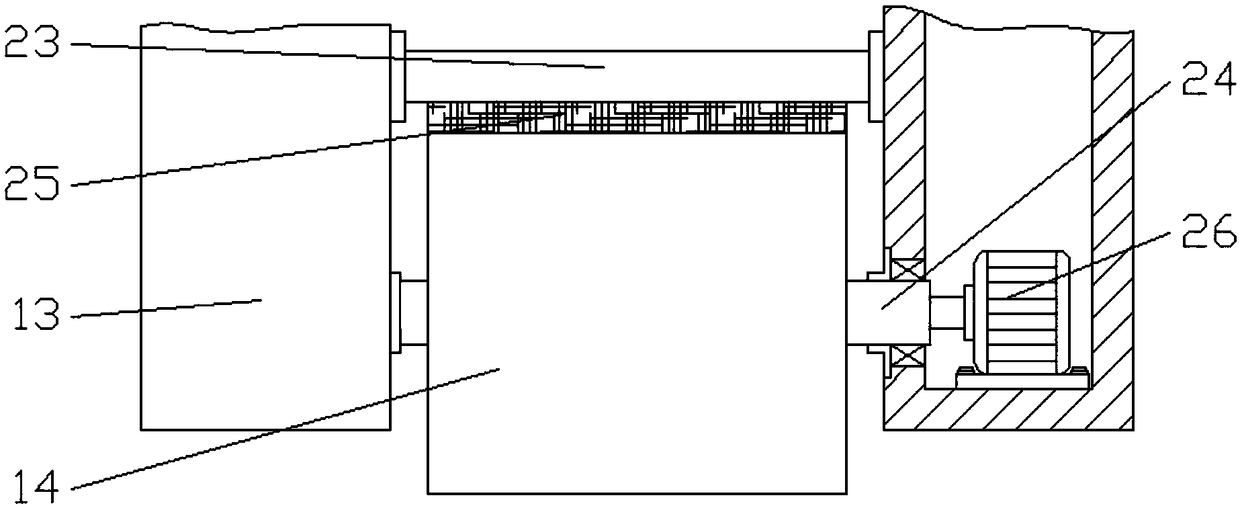

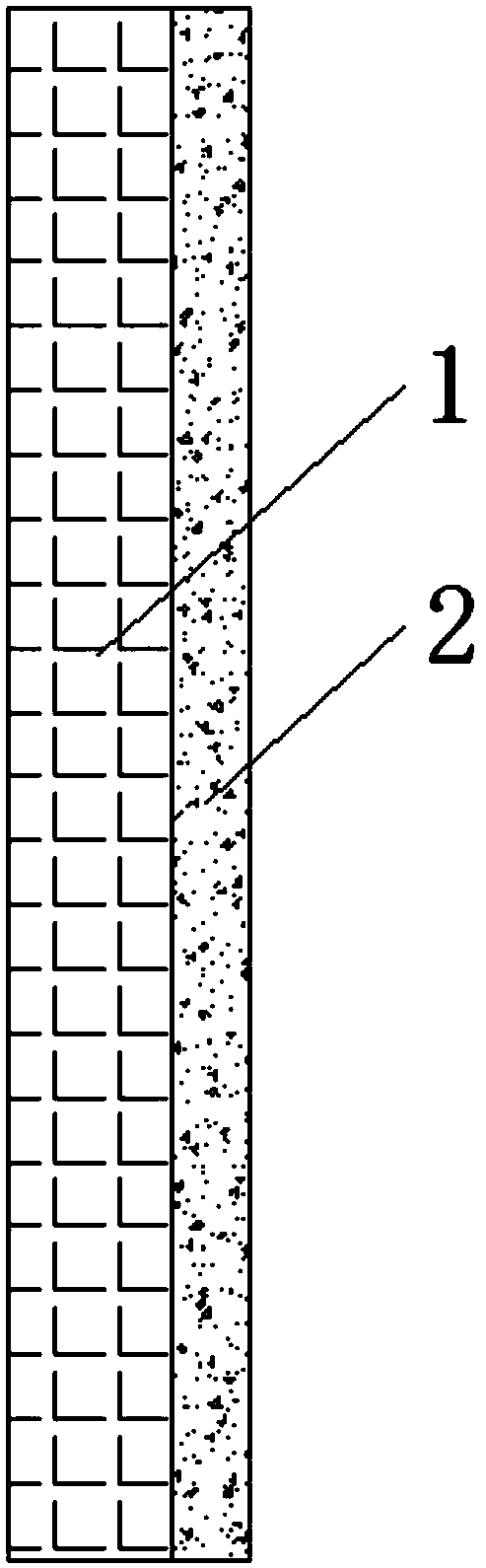

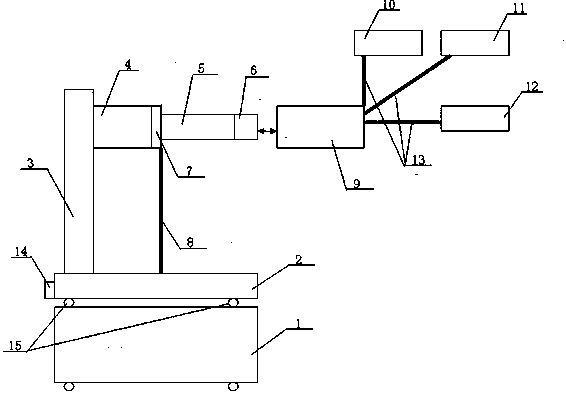

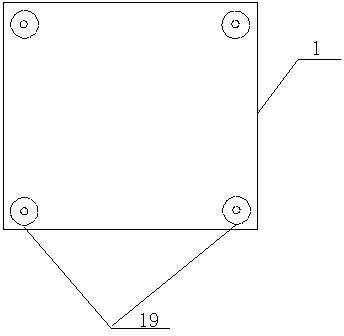

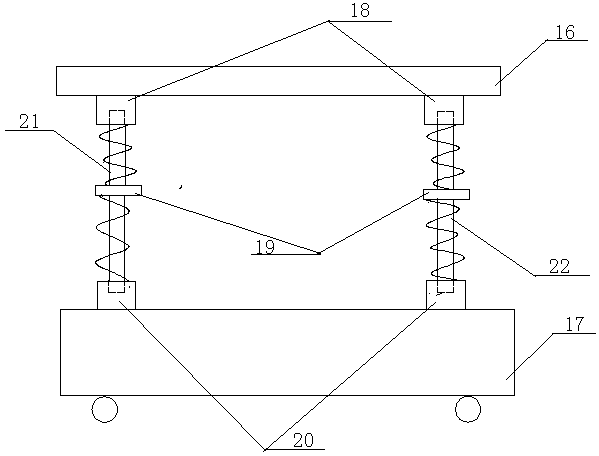

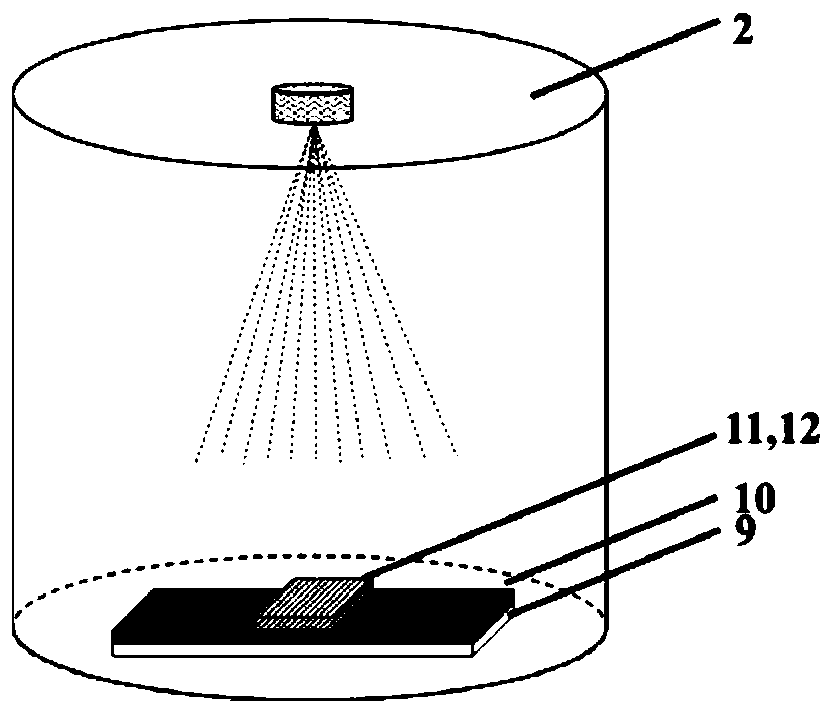

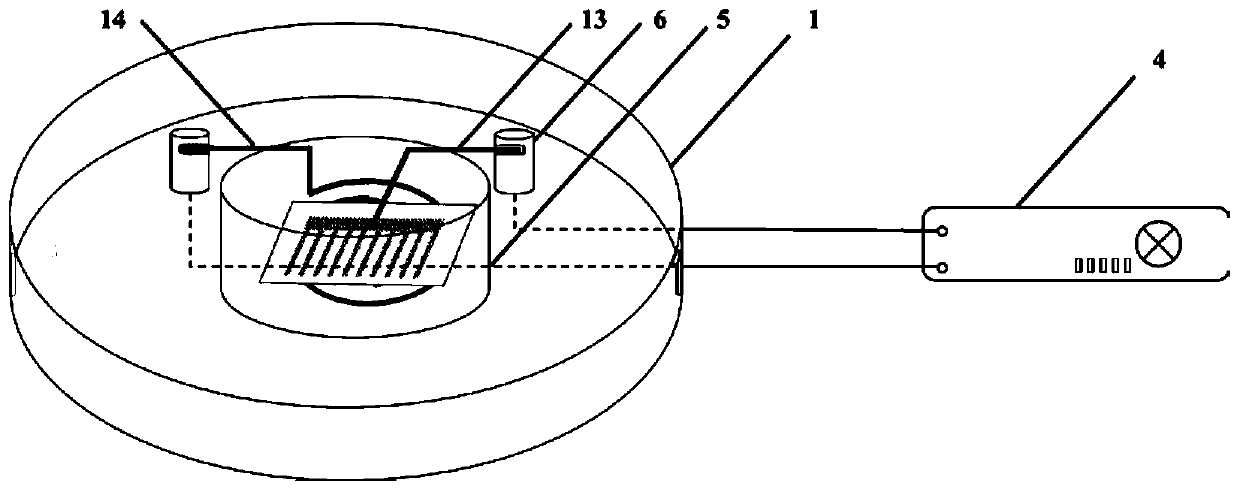

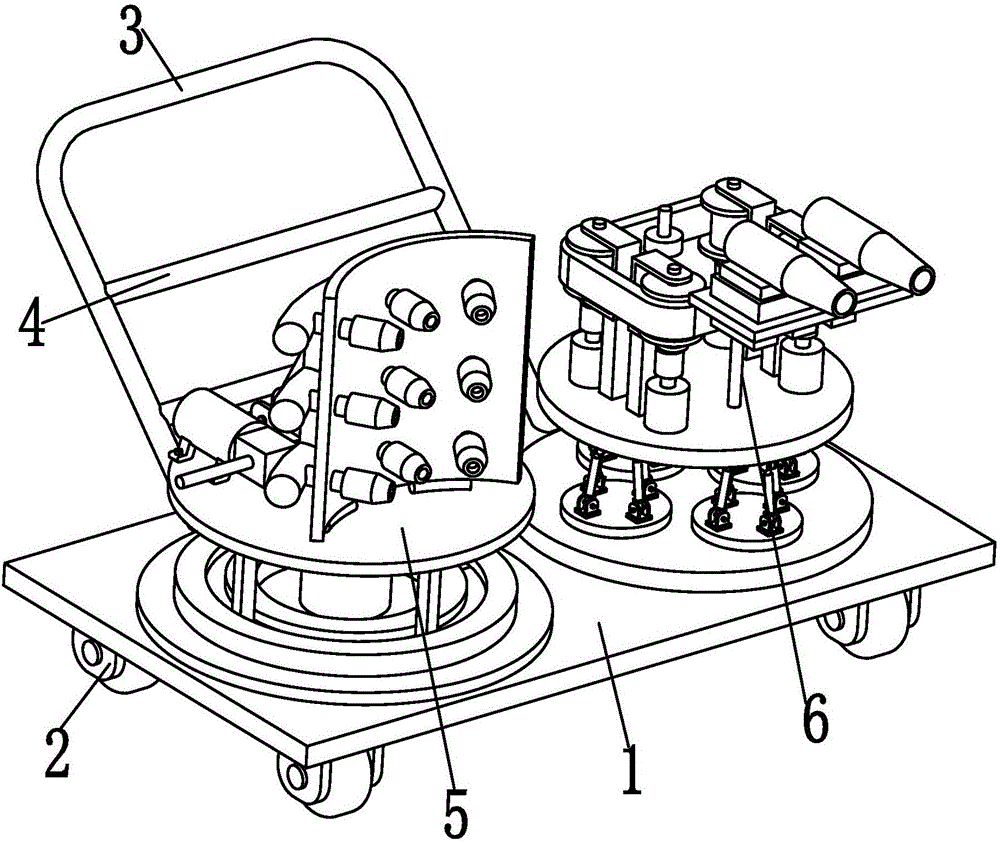

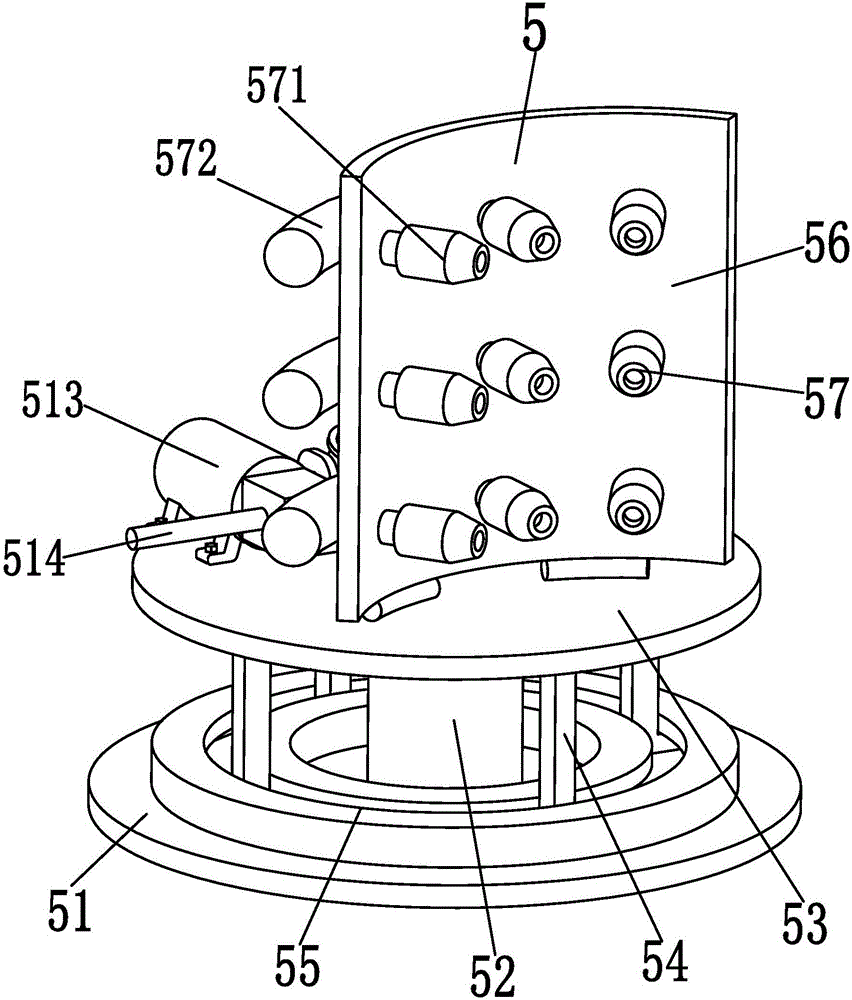

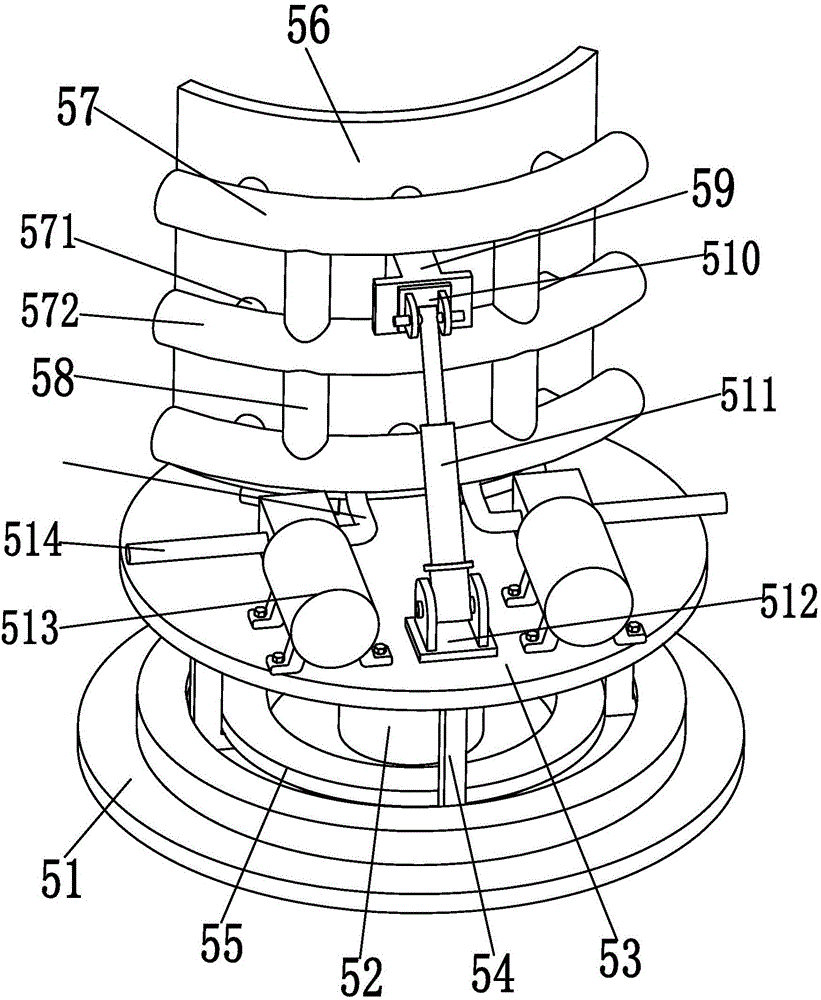

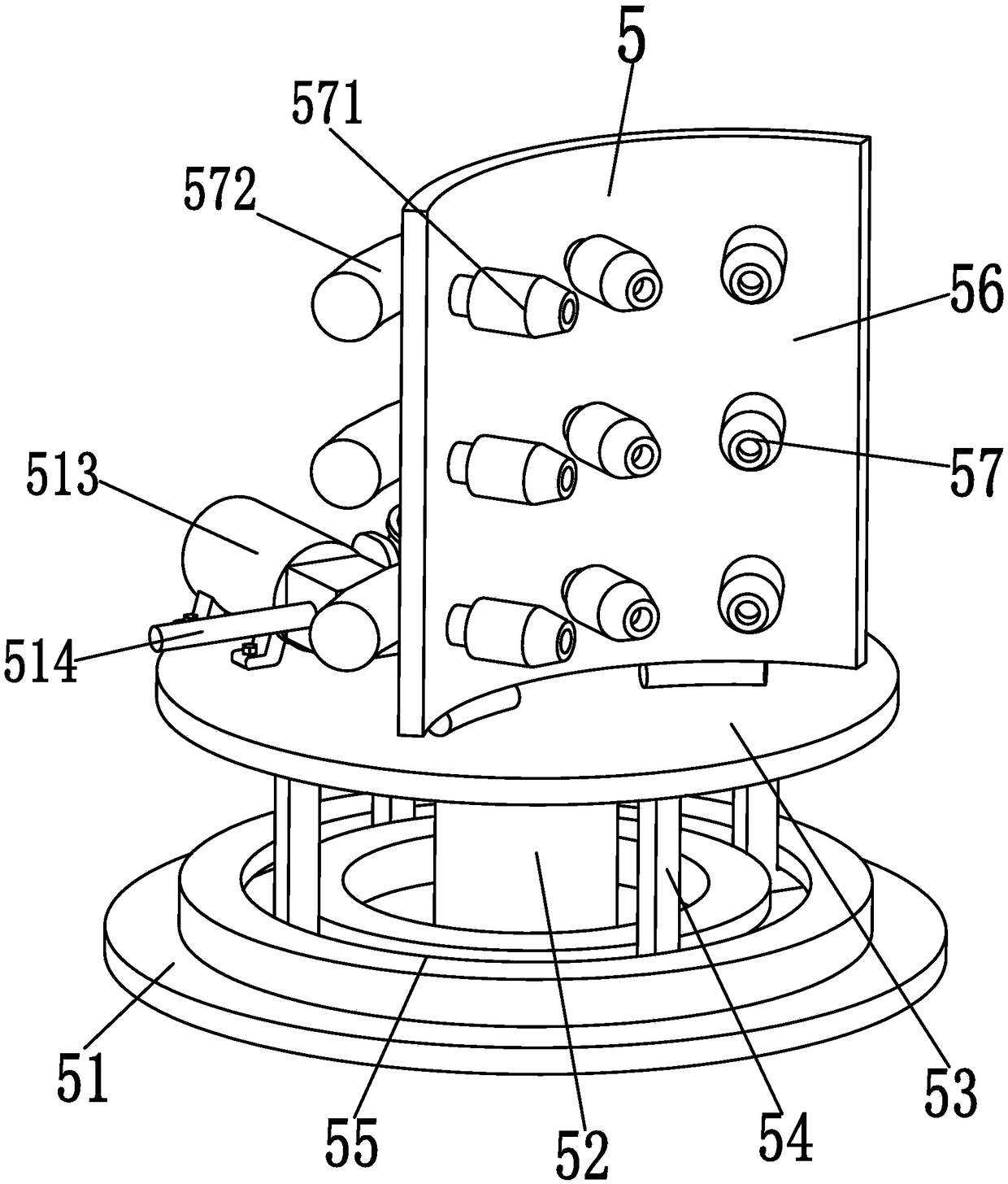

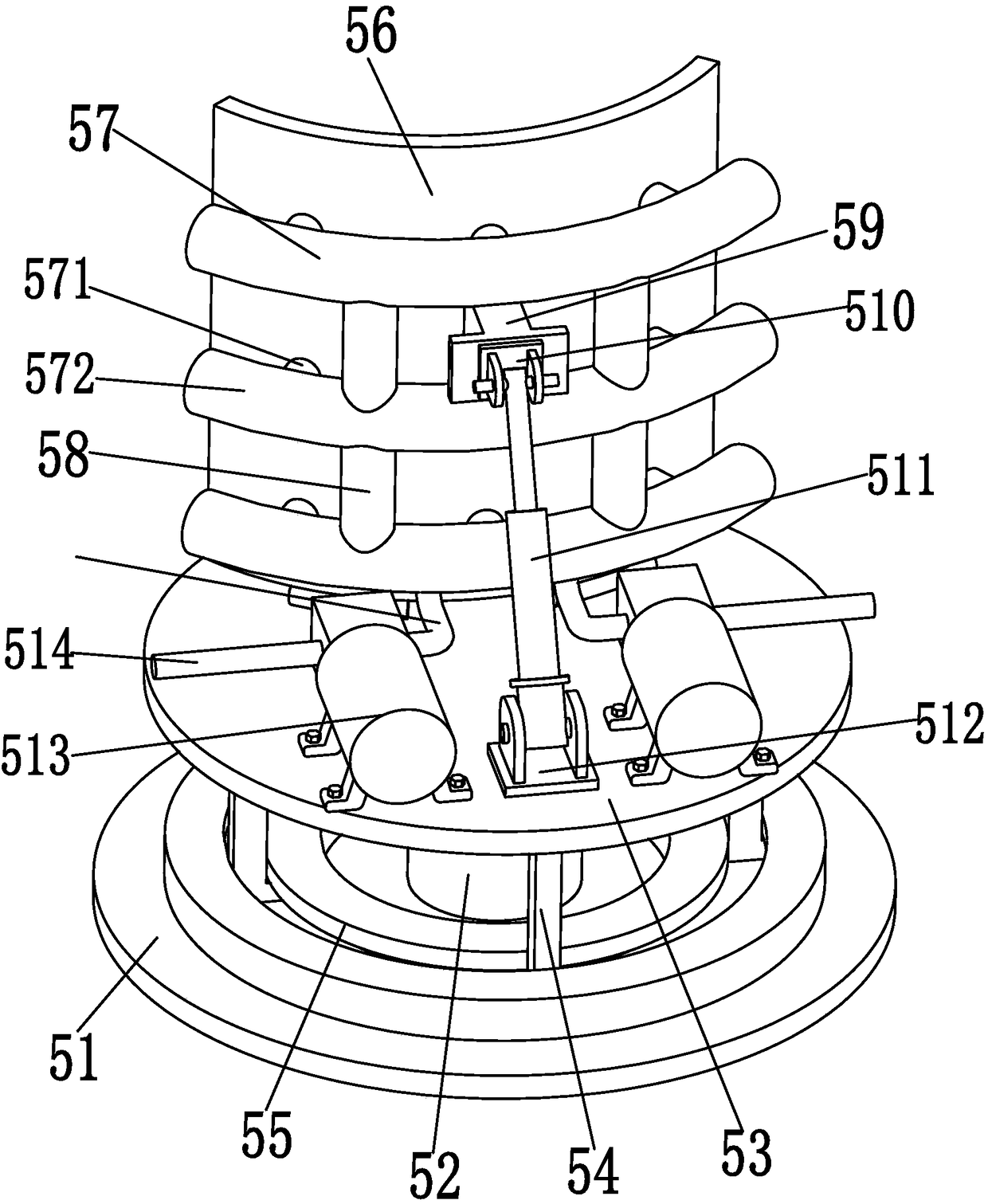

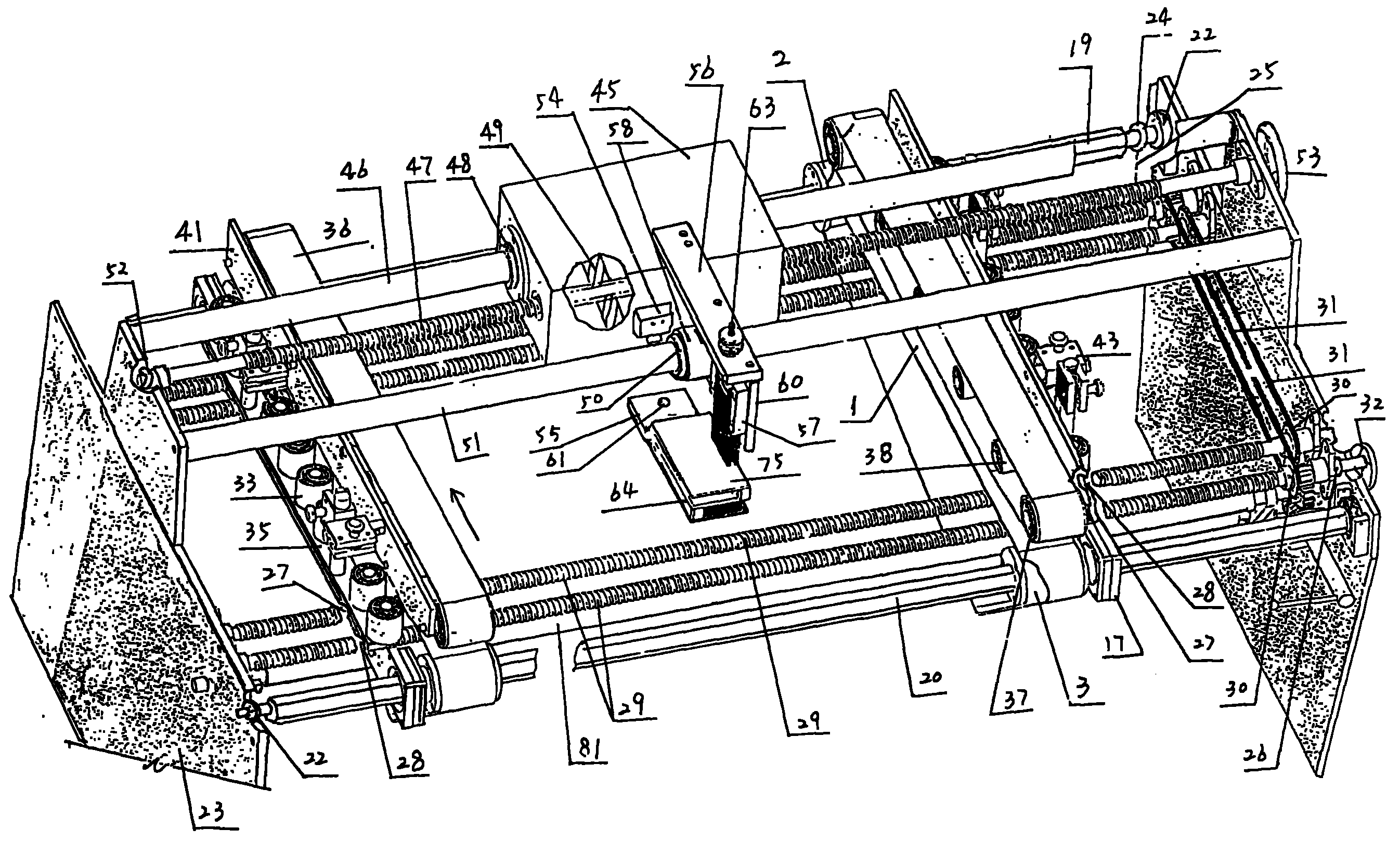

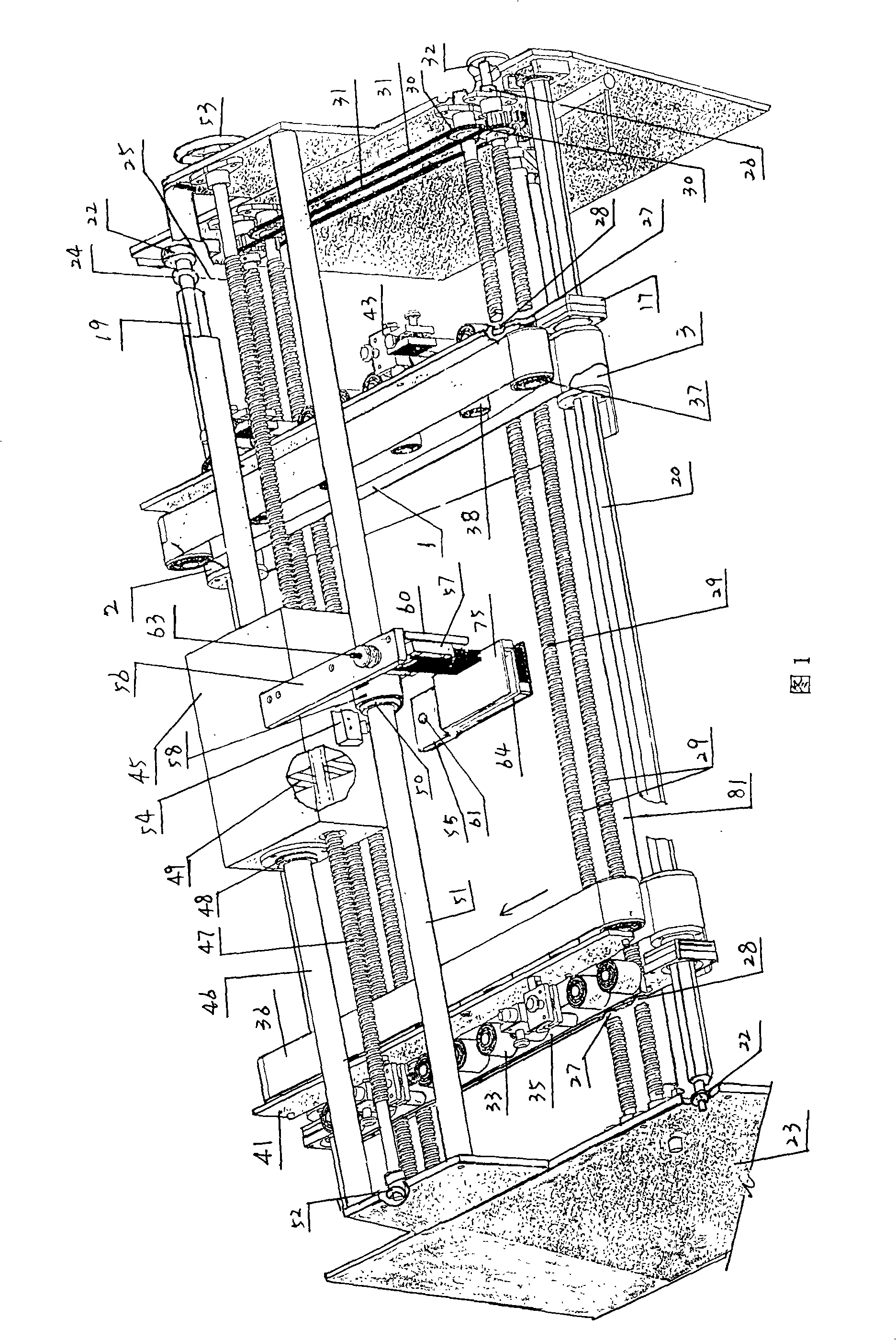

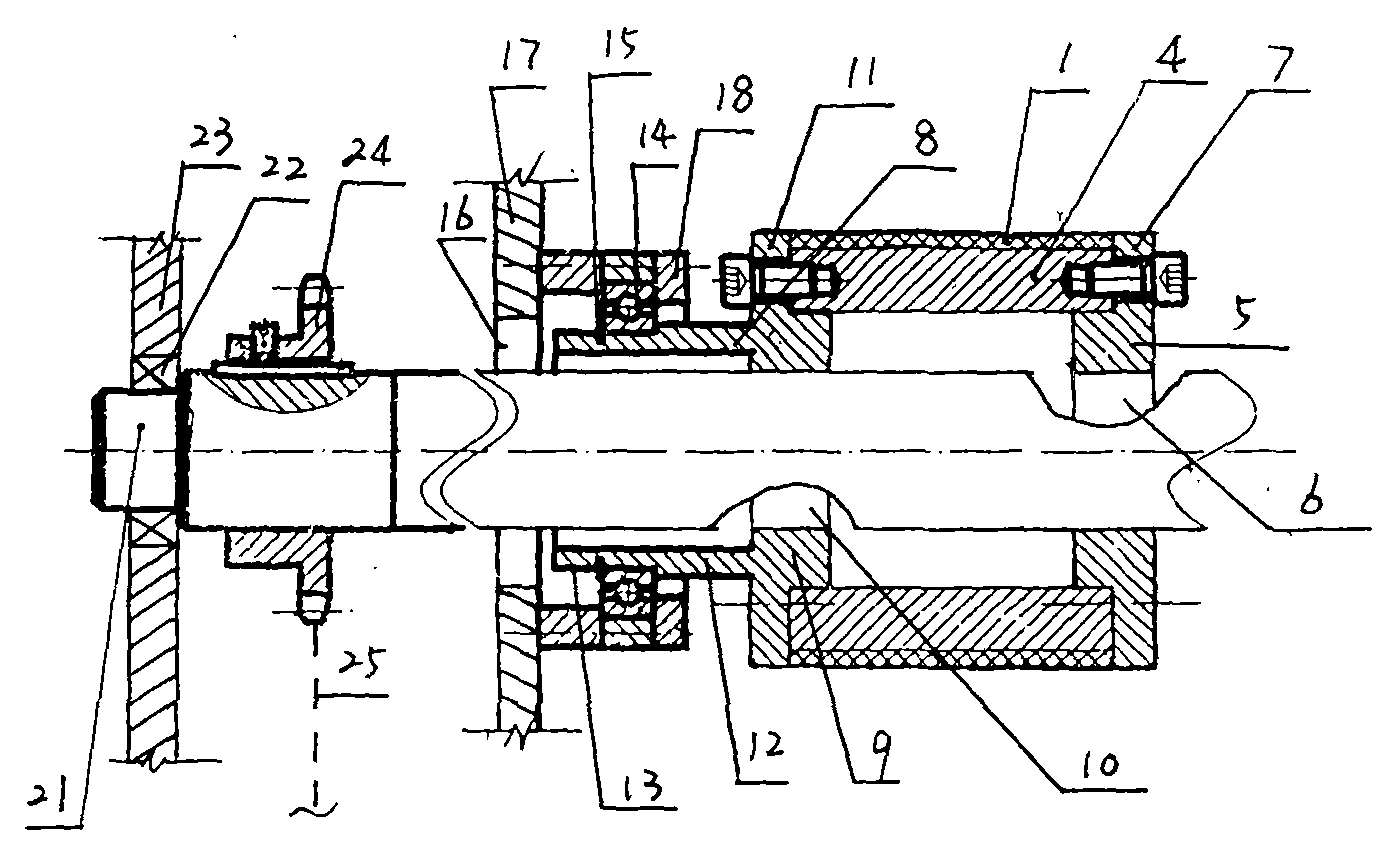

The invention carton stapler for corrugated cases and belongs to the field of corrugated case manufacturing equipment. The carton stapler adopts a paper conveying mechanism which uses a hexagonal steel type transmission shaft to drive two small belts (1). A driving roller (2) and a driven roller (3) one each side of each small belt (1) are connected together through a small wall plate (17) on the same side, and each small belt (1) is also provided with a complete manual adjustment mechanism which adjusts axial displacement by using a threaded rod threaded rod shaft as well as an array roll type transverse positioning mechanism and a paper pressing belt (36) type paper pressing mechanism with a small roll (38), wherein the manual adjustment mechanism, the array roll type transverse positioning mechanism and the paper pressing belt (36) type paper pressing mechanism are all connected with the small wall plate (17) the transverse position of which can be adjusted. The carton stapler also adopts an automatic head nailing device which has a light controlled automatic system and is matched with the continuous paper conveying device. The transverse position of the automatic head nailing device is adjustable, the vertical position of a nail head holder (57) and the size of the paper pressure are adjustable, and a nail tongue (64) of a belt base plate (55) is changeable. The rollers can be changed easily and the transverse positions of the rollers can be adjusted conveniently, the friction is small, and the paper pressure is adjustable in terms of size. The carton stapler can not damage the surface of corrugaled board and the patterns on the surface of the corrugaled board, achieves excellent nailing quality, high efficiency and low energy consumption, and is convenient in adjustment and maintenance and is suitable to nail corrugaled boards with different thicknesses.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

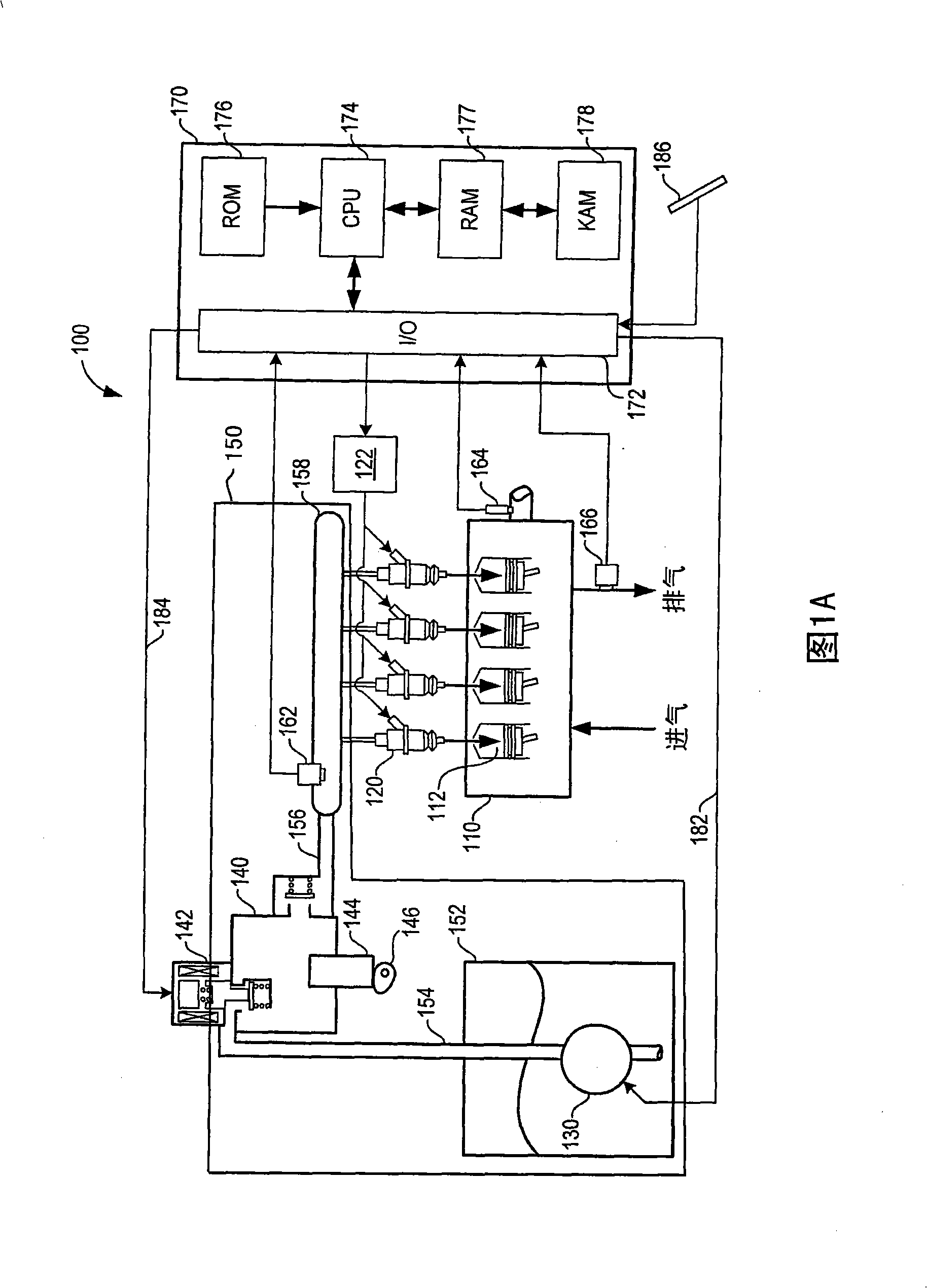

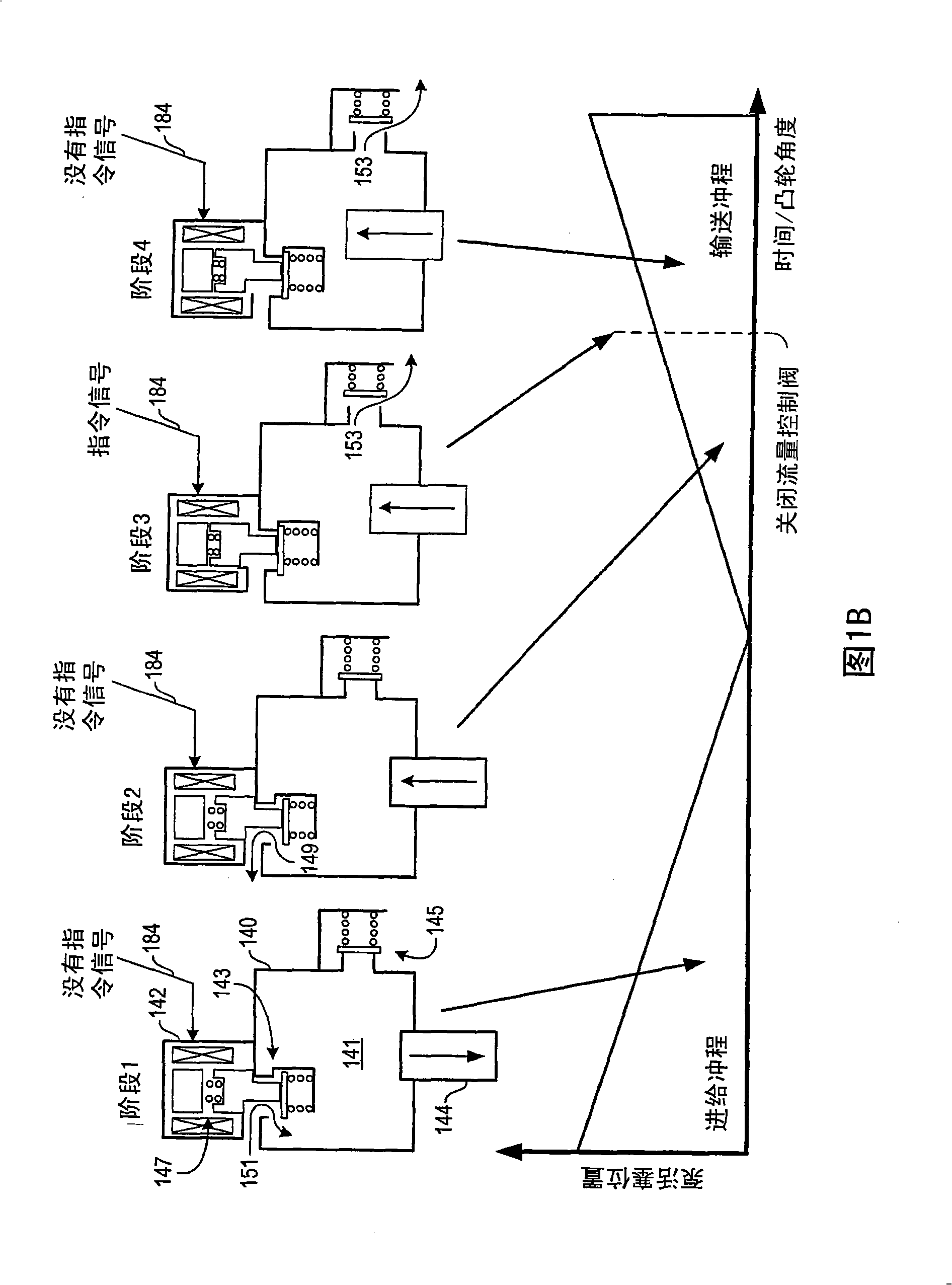

Volumetric efficiency based lift pump control

InactiveCN101403358AAdjustable operationMachines/enginesLiquid fuel feedersEngineeringInternal combustion engine

The present invention relates to a volumetric efficiency based lift pump control method. As one example, a method of operating a fuel delivery system of a directly injected internal combustion engine including a plurality of in-cylinder direct fuel injectors, a higher pressure fuel pump and a lower pressure fuel pump is provided. The method comprises operating the lower pressure fuel pump and the higher pressure fuel pump to maintain a prescribed fuel pressure at the fuel injectors; and varying an amount of pump work that is provided by the lower pressure fuel pump relative to the higher pressure fuel pump responsive to an indication of the efficiency of the higher pressure pump.

Owner:FORD GLOBAL TECH LLC

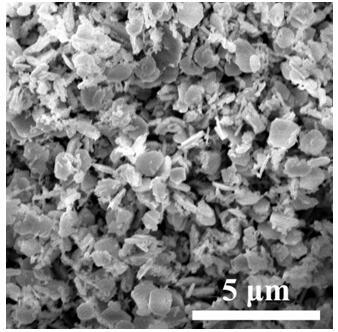

Anti-static coating for photo-curing nanometer polyaniline-epoxy acrylic resin interpenetrating network

ActiveCN102618100ASimple preparation processStable conductivityElectrically-conductive paintsChemistryNanometre

The invention relates anti-static coating for a photo-curing nanometer polyaniline-epoxy acrylic resin interpenetrating network, which is prepared by interpenetrating polyaniline and an epoxy acrylic resin system under the action of an initiator and a catalytic agent. Aniline is subjected to in-situ emulsion polymerization in epoxy acrylic resin to obtain doped nanometer polyaniline particles, and a dilute monomer, a catalytic agent, an initiator, a polymerization inhibitor and fillers are further added into the doped nanometer polyaniline particles to be stirred evenly. The anti-static coating is simple in process device, convenient to operate and quick in curing speed. The anti-static coating for the photo-curing nanometer polyaniline-epoxy acrylic resin interpenetrating network has good glossiness, stable electric conduction performance, good mechanical property, ageing-resistant performance and chemical erosion resistance performance, not only can serve as the anti-static coating, but also has the price and environment-friendly advantages. Products can be used in the inner walls of oil transmission pipelines, electronic machines, electrostatic dust preventing floors, bridges, railways and other places and have wide application range and good economic and social benefits.

Owner:HUBEI QILI NEW MATERIAL CO LTD

Air-tightness gap-adjustable type spark-gap switch operation method

ActiveCN105186293AAdjustable operationReliable triggerSpark gaps adjustmentExhaust valveThermodynamics

The present invention discloses an air-tightness gap-adjustable type spark-gap switch operation method and provides an air-tightness gap-adjustable type spark-gap switch. The switch is in the form of a spark-gap controllable switch and comprises an anode, a cathode and a trigger electrode. An air-tightness switch working space is formed by an insulated housing, an anode flange, a cathode flange, a trigger electrode insulated sheath, an anode sealing pressure plate, a trigger electrode sealing pressure plate and a sealing washer at a corresponding seam. An inflation and exhaust system is formed by an inflation valve and an exhaust valve. After that, an anode lead and a cathode lead are connected as required. Then the operation of the air-tightness gap-adjustable type spark-gap switch is enabled. The method meets the requirements of applications and changes the operating pressure of the switch and the air atmosphere of the switch. Meanwhile, the operation reliability of the switch is improved and the anti-interference capability of the switch is enhanced. Moreover, through changing the discharge distance between the cathode and the anode, the requirements of different operating voltage levels in different applications can be met. In addition, the service life of the spark-gap switch is prolonged and the environment adaptability of the switch is improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

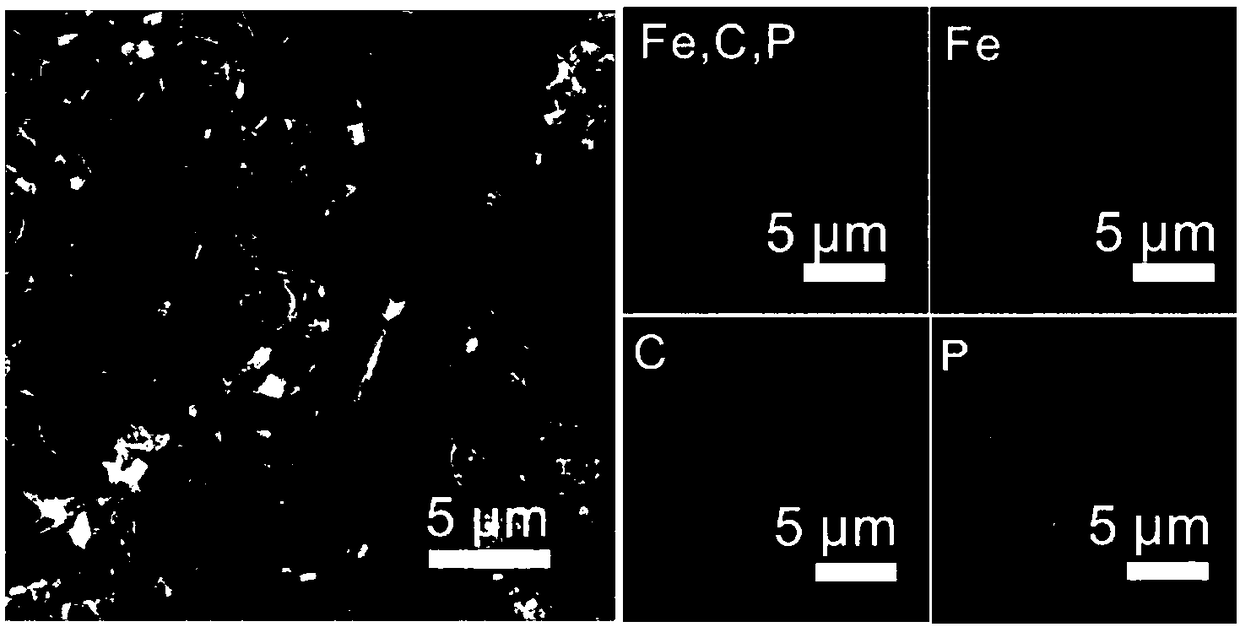

Preparation method and application of metal phosphide porous frame/graphene composite fiber

InactiveCN108360091AShape adjustableControllable structureInorganic material artificial filamentsCvd grapheneGraphite oxide

The invention discloses a preparation method and an application of a metal phosphide porous frame / graphene composite fiber. The metal phosphide porous frame / graphene composite fiber is prepared from afibrous compound as a precursor by calcining, and the fibrous compound is prepared from MOF (metal-organic framework) crystal powder and graphene oxide by compounding. The preparation method is simple to operate and mild in condition, the composite fiber is adjustable in morphology, controllable in structure and uniform in component distribution, structural integrity of graphene and a metal phosphide porous frame obtained by taking MOF crystals as the template is retained, excellent performance of graphene and excellent performance of the metal phosphide porous frame are combined, and the composite fiber can be produced in batches or industrially, has excellent performance as a lithium ion battery anode material and has good application prospect.

Owner:ZHEJIANG UNIV OF TECH

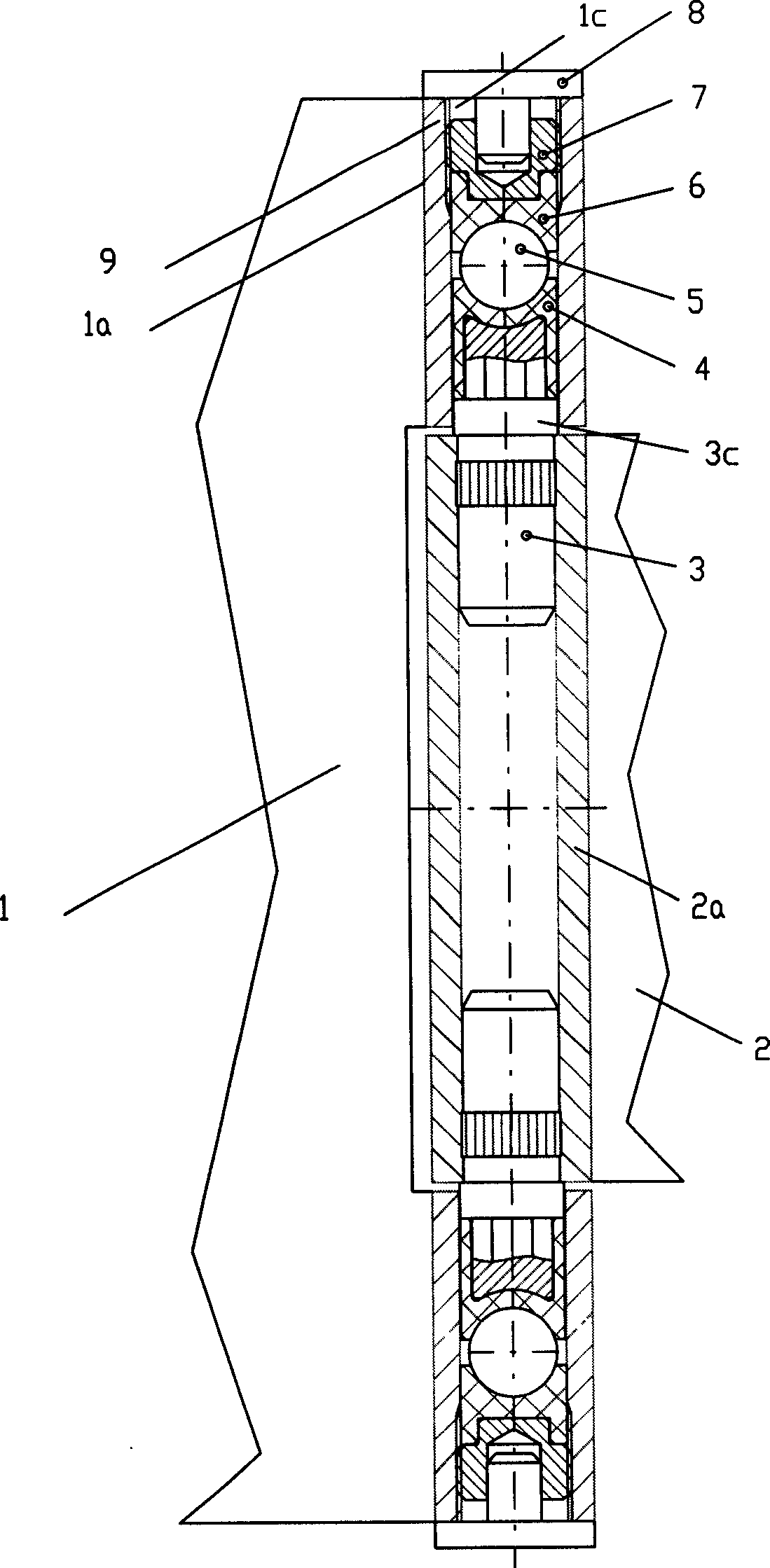

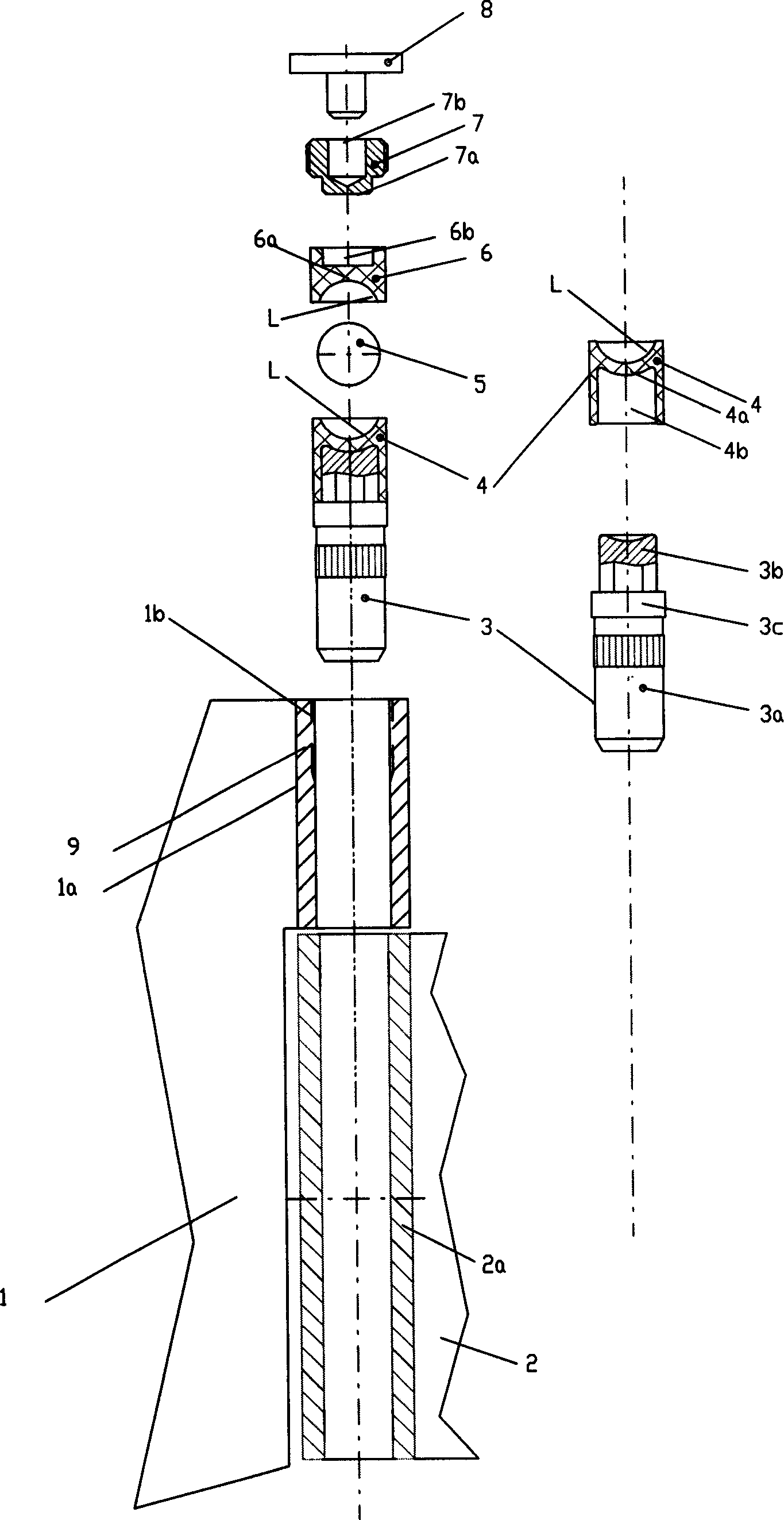

Door hinge with concealed bearing

ActiveCN1641177AImprove wear resistanceImprove performanceWing accessoriesHingesHinge angleEngineering

The plate has outer and inner parts (1, 2) with a fastening unit for mounting the plate on a door frame. The inner part is placed between two cylindrical supporting sections (1a), which are placed on the outer part. Two supporting parts (4, 6) made up of rugged plastic such as Teflon, are placed between the sections. A ball (5) made of steel is arranged between the parts (4, 6), and a set screw (7) is screwed into the sections. - The support part (6) exerts pressure against the ball (5) using the set screw, where the ball exerts the pressure against the support part (4).

Owner:ECO SCHULTE

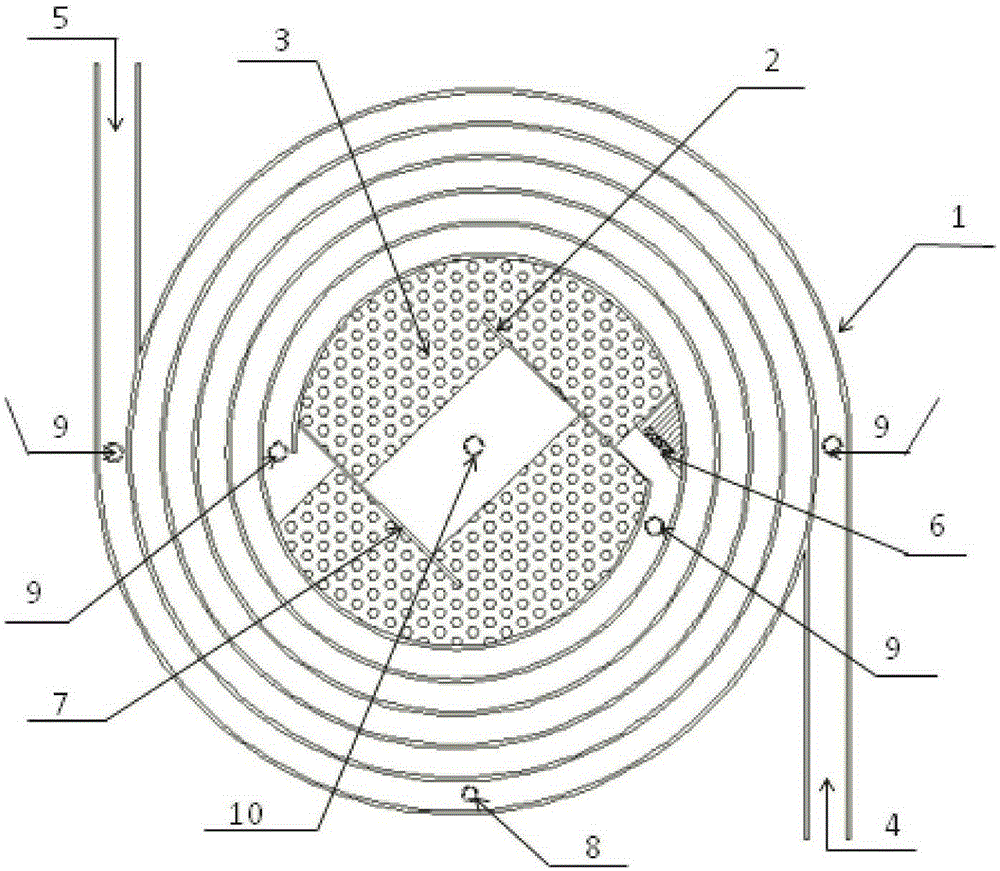

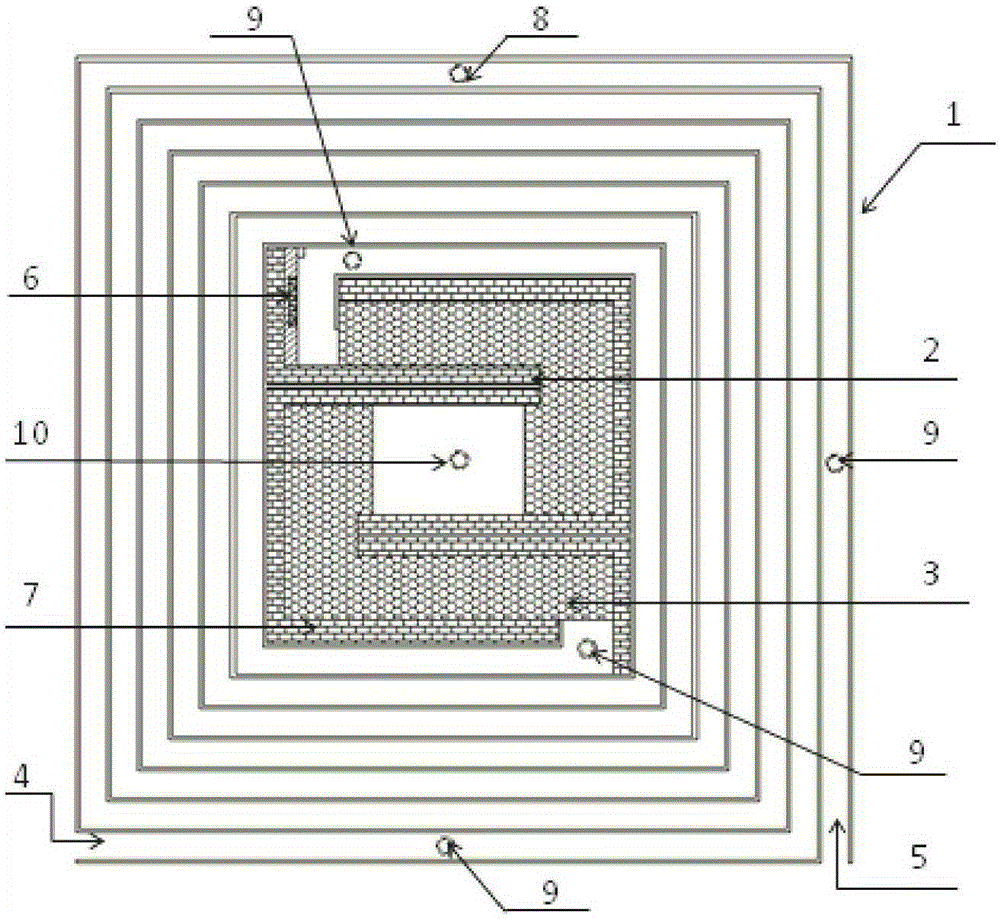

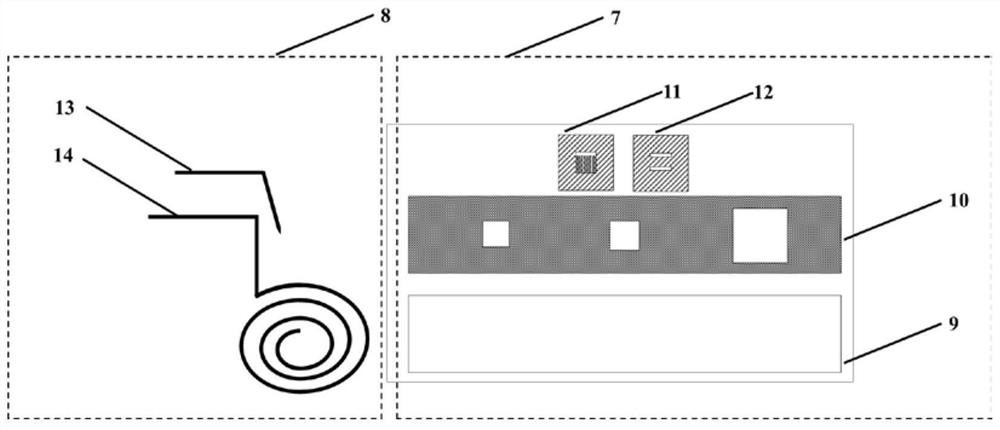

Plasma combustion-supporting Swiss roll combustor

InactiveCN105180183AReduce pollutionSolving the problem of smooth ignition and maintaining combustionIncinerator apparatusCombustion chamberPorous medium

The invention provides a plasma combustion-supporting Swiss roll combustor and belongs to the technical field of low-heating-value gas utilization. The combustor comprises a combustion chamber and a spiral plate type channel. The combustor specifically comprises a combustor shell, a flow guide plate, a porous medium, a gas inflow channel, a gas outflow channel, a discharge device, an ozone addition opening, a thermometer hole, an ignition hole, an observation hole, a metal high-voltage electrode plate, an electrode leading-out wire and an exhaust chimney. The combustor is round or square. The upper end and the lower end of the combustor are sealed through sealing plates. The gas inflow channel and the gas outflow channel are formed in the two ends of the spiral plate type channel. The porous medium is located in the center of the combustion chamber. The inner wall of the combustion chamber is coated with a heat-resisting material. The combustion chamber is wrapped by a heat insulating material. The discharge device and the flow guide plate are located in an inlet of the combustion chamber. The ozone addition opening is formed in the outermost ring of the spiral plate type channel. According to the combustor, the plasma discharge device or an ozone generator and the porous medium material are combined, and the purposes of reducing energy consumption, eliminating poison and the like can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

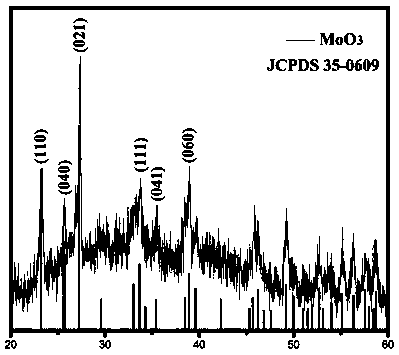

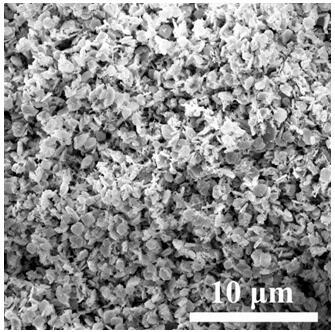

Electrospinning synthesis method of MoO3 sheet structure

ActiveCN109205676AConcentration controllableEasy to control the fiberizing processMolybdenum oxides/hydroxidesFiberSynthesis methods

The invention discloses an electrospinning synthesis method of a MoO3 sheet structure, and the electrospinning synthesis method comprises the steps of: adding a molybdenum salt, hydroxylamine hydrochloride, dopamine hydrochloride and PVP into a mixed solvent of ethanol, DMF and 1,5-pentanediol, stirring to obtain a spinning solution, and forming precursor fiber by an electrospinning method; calcining the obtained precursor fiber to obtain a product. The method designs a novel precursor reaction system, has the advantages such as wide sources of raw materials, low price, simple operation and equipment, controllable parameters, uniform product size, good repeatability and dispersibility, and has broad application prospects in gas sensing, adsorption, and other fields.

Owner:UNIV OF JINAN +1

Yarn drafting and mixing device

ActiveCN108914273AGuaranteed stabilityPrevent axial movementDrafting machinesContinuous wound-up machinesYarnEngineering

The invention provides a yarn drafting and mixing device, and belongs to the technical field of textile machinery. The device comprises a yarn reversal mechanism, a drafting mechanism, a mixing mechanism and a yarn collecting mechanism. A front drafting spindle connecting ring of a front drafting spindle and a rear drafting spindle connecting ring of a rear drafting spindle of the drafting mechanism are in sliding connection through a rotation preventing guide sliding block and a rotation preventing guide sliding slot. Six front synchronous notches are evenly distributed in the outside of a front synchronous sheave, and front synchronous columns are uniformly disposed in front notches of a front drafting wheel in equal circumference. Six rear synchronous notches are evenly distributed in the outside of a rear synchronous sheave, and rear synchronous columns are uniformly disposed in rear notches of a rear drafting wheel in equal circumference. A mixing guide frame of the mixing mechanism is provided with a first mixing guide hole and a second mixing guide hole. The mixing frame is provided with a mixing hole, and the yarn collecting mechanism is disposed on the left side of the mixing mechanism. The yarn drafting and mixing device can achieve synchronous drawing and mixing of two yarns of different colors of the same material for yarn collecting.

Owner:浙江常山康辉纺织有限公司

Textile fabric printing device capable of automatically adjusting printing position

InactiveCN108909156AAdjustable positionAvoid offsetRotary pressesHydraulic cylinderControl engineering

The invention provides a textile fabric printing device capable of automatically adjusting a printing position. The device comprises an operation table, a supporting rod is fixed to the upper side ofthe operation table, a top plate is fixed to the upper side of the supporting rod, a pigment box is fixed to the upper side of the top plate, a hydraulic cylinder is arranged on the right of the pigment box, a hydraulic rod is connected to the lower side of the hydraulic cylinder, a protection box is fixed to the lower side of the hydraulic rod, a first motor is arranged on the inner wall of the top of the protection box, the output end of the first motor is connected and fixed with a gear, the lower side of the gear is in engaged connection with a rack, the lower side of the rack is fixedly connected with a connecting rod, the lower side of the connecting rod is fixedly connected with a connecting sleeve, the lower side of the connecting sleeve is fixedly connected with a mounting frame,a second motor is arranged on the inner wall of the bottom of the mounting frame, the output end of the second motor is fixedly connected with a rotating shaft, and a printing roller is fixedly connected to the rotating shaft. The textile fabric printing device is reasonable in structural design, convenient to operate, capable of adjusting the printing position and suitable for being used and popularized.

Owner:宛兴友

Novel two-component waterproof and decorative integrated paint and construction method thereof

InactiveCN109651905AReduced risk of efflorescence and chromatic aberrationReduce material and construction costsAntifouling/underwater paintsCovering/liningsEmulsionControllability

The invention discloses novel two-component waterproof and decorative integrated paint and a construction method thereof. The paint includes a base layer; the outer layer of the base layer is sprayedwith a mortar layer; and the mortar layer consists of an acrylic emulsion, a special inorganic cementing material, a filling material and a plurality of functional additives. The paint consists of theacrylic emulsion, the special inorganic cementing material, the filling material and a plurality of the functional additives; the paint is unique in formula, and therefore, risks of the crystalline bloom and chromatic aberration of colored decorative mortar can be greatly reduced; the paint can be applied to leakage maintenance of external walls, refurbishment of exterior wall tiles, flat painting and renovation of the exterior walls, waterproof and decorative integration of new exterior walls, waterproof maintenance of old exterior walls and reconstruction of the exterior walls; the paint can adopt brushing, roll coating, spraying and batch painting; and compared with traditional paint construction modes, the paint can have waterproof performance without performing water repellent treatment, a putty layer spraying process, priming paint making and overlay varnishing are not needed, all painting processes can be simplified to a waterproof and decorative integrated paint process, so that materials and construction costs can be reduced, and the controllability of construction quality can be enhanced.

Owner:浙江厦光涂料有限公司

A fully-enclosed switch cabinet busbar grounding device and an application method

PendingCN109004569ASolve the problem of unreliable groundingEnsure personal safetySwitchgear earthing arrangementsBusbarEngineering

The invention relates to a fully-enclosed switch cabinet busbar grounding device and an application method, belonging to the technical field of electric power overhaul, the busbar grounding device comprises an operation platform mechanism, A chassis truck is arranged above the operation platform mechanism, A panel is fixedly connected to the chassis truck, the panel is fixedly connected with threepillar insulators, each of the three post insulators is fixedly connected with a conductive arm and a movable contact, the three conductive arms are connected with the chassis car by a three-phase short-circuit copper bar and connected with the chassis car by a first grounding copper bar, the three movable contacts are correspondingly connected with the three upper static contacts inside the switch cabinet, The three-phase busbar of the busbar room is in corresponding contact connection with three upper static contacts through branch down leads, and the busbar grounding device effectively solves the problem of incapability of reliable grounding in maintenance of a switch cabinet busbar, effectively solves the personal safety of operating personnel in the maintenance process of a fully-enclosed switch cabinet busbar, and has very good popularization and application prospects.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER +1

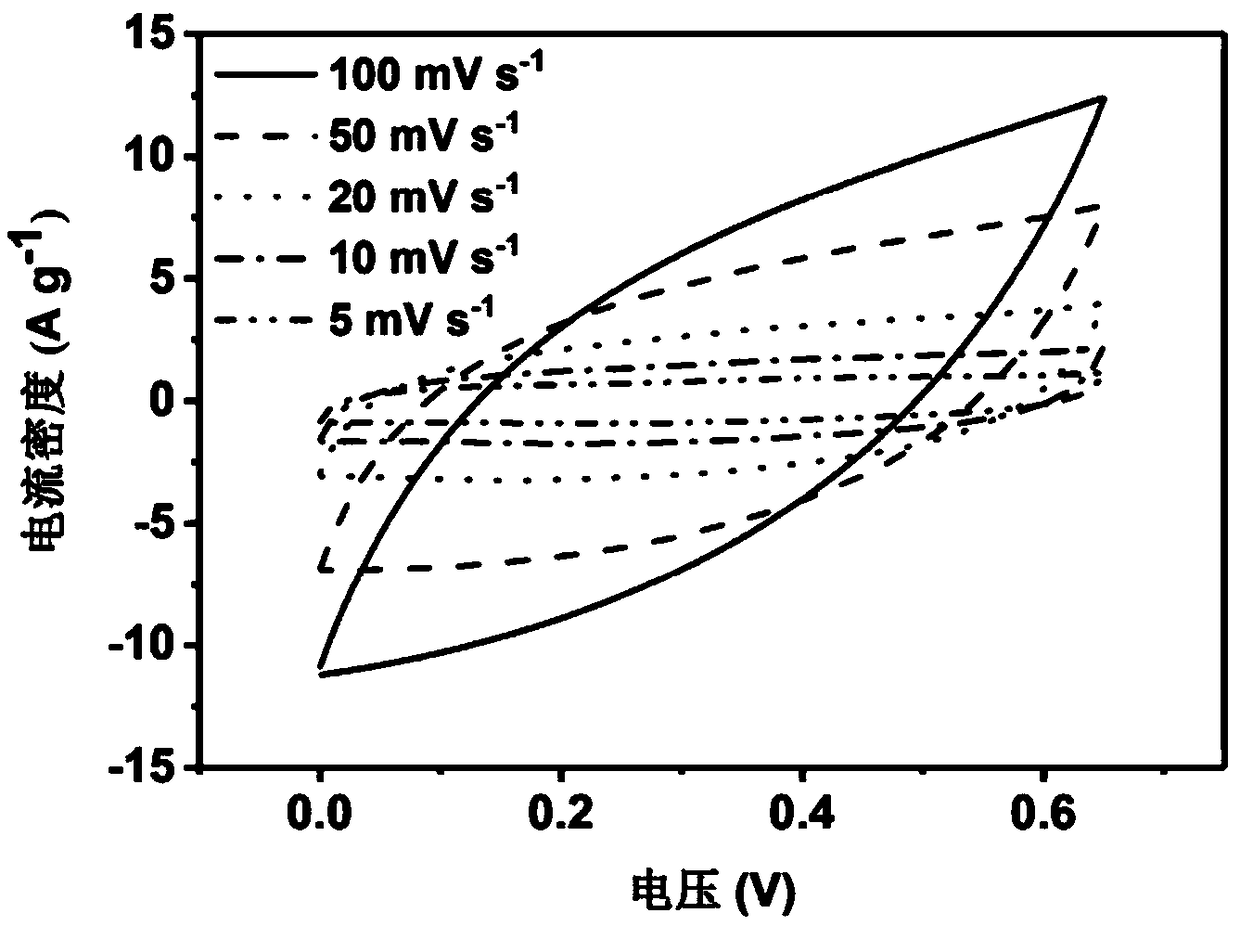

Flexible and solid supercapacitor, preparation method and application thereof

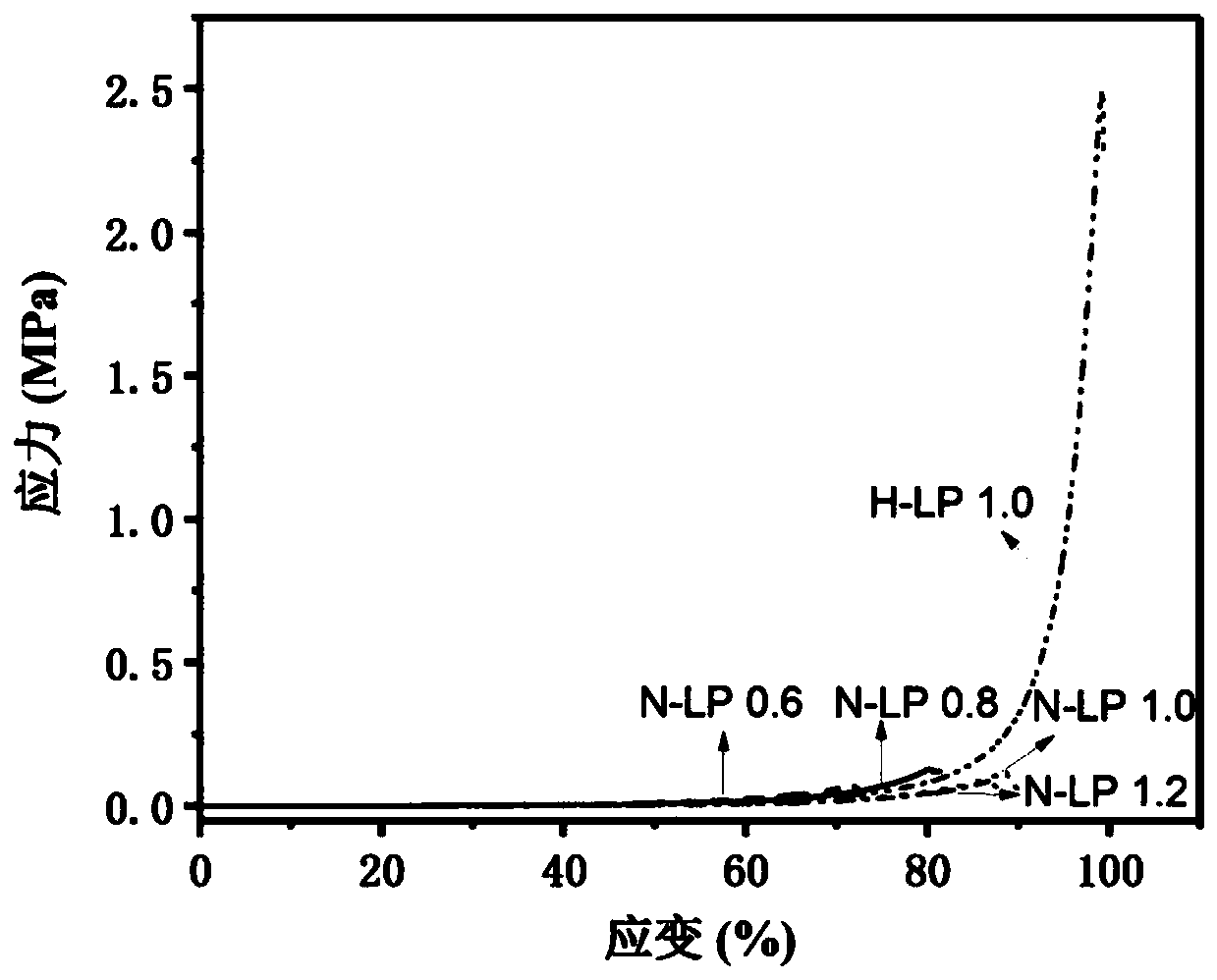

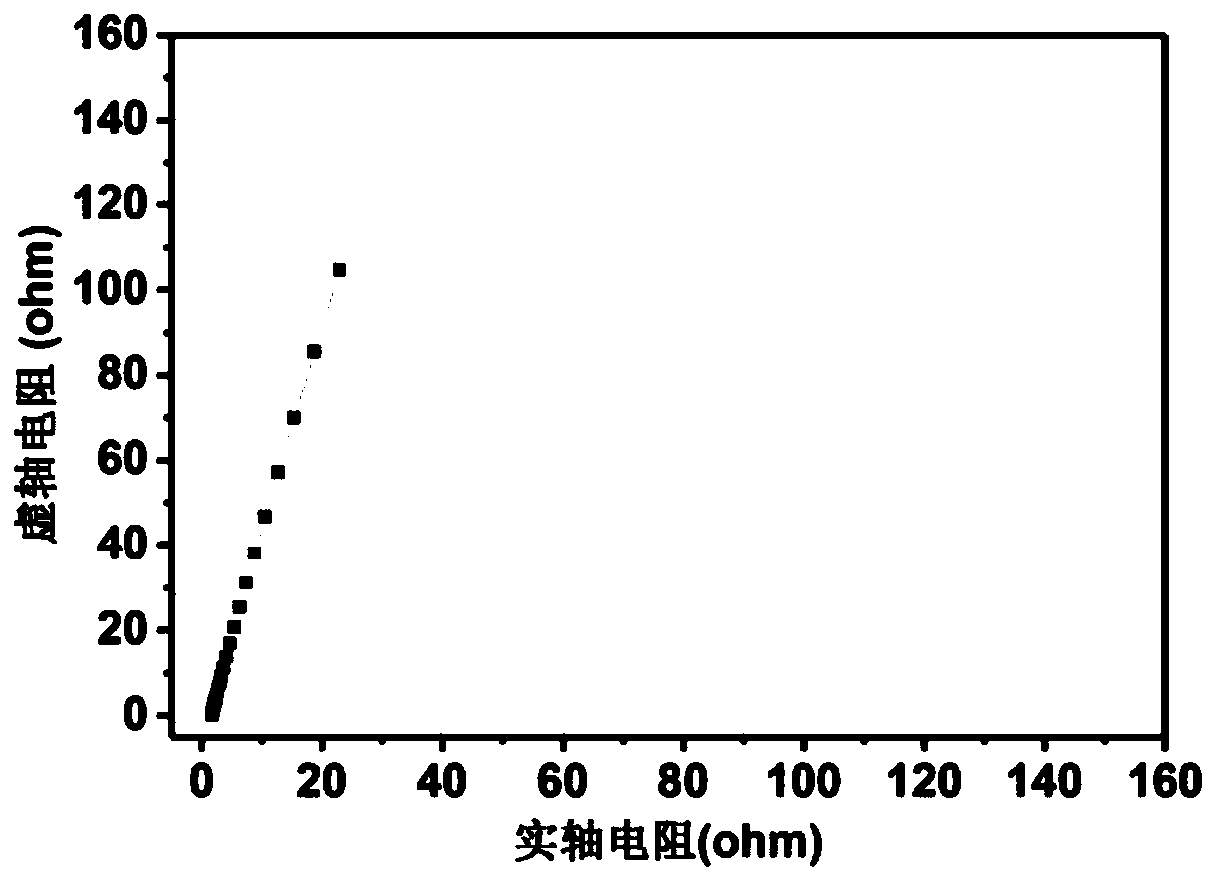

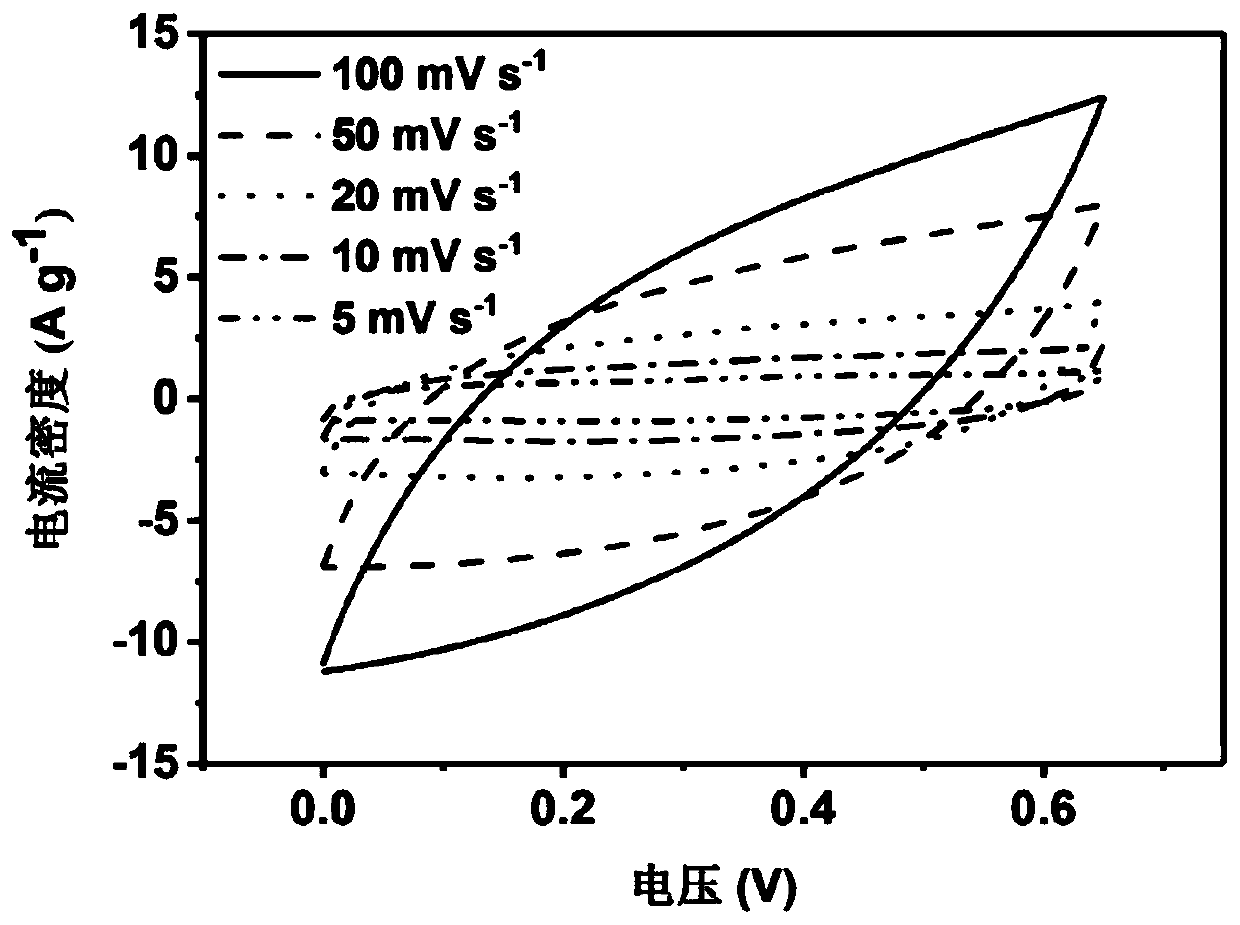

ActiveCN109473294AEasy to prepareRaw materials are non-toxic and renewableHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceDouble network

The invention belongs to the field of supercapacitors and discloses a flexible and solid supercapacitor, a preparation method and application thereof. The supercapacitor comprises a positive electrode, a negative electrode and an electrolyte interposed therebetween, wherein the electrolyte is double-network lignin hydrogel, and both the positive and negative electrodes are conductive electrodes. The double-network lignin hydrogel as the electrolyte in the present invention not only has high mechanical strength property, but also has a simple preparation method, low raw material cost, renewability, green environmental protection, and high ionic conductivity; when the hydrogel is used as the electrolyte to assemble the supercapacitor, additional soaking of an ionic solution is not required and additional use of a diaphragm is not needed, thereby effectively reducing the thickness and weight of the supercapacitor. The obtained capacitor specific capacitance value is higher than the current hydrogel electrolyte type flexible supercapacitor specific capacitance value. In addition, the supercapacitor has very good charging and discharging cycle stability, compression resistance and bending resistance.

Owner:SOUTH CHINA AGRI UNIV

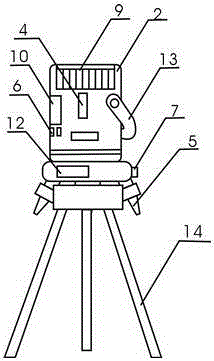

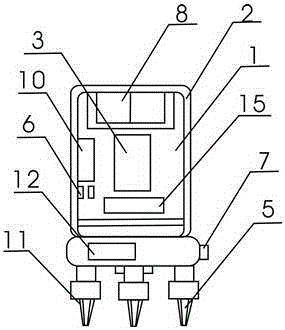

Novel laser level meter

The invention provides a novel laser level meter, which comprises a level meter body, a housing, an infrared transmitter, a laser emission window, an adjustable bracket, a control button and an adjusting knob. The novel laser level meter is characterized by comprising a storage battery, a solar panel, a controller, a wrap angle, an alarm, a hand strap, an elevator foot rest and a balance inductor. The outer side of the level meter body is provided with the housing. The level meter body is provided with the infrared transmitter. The level meter body is installed onto the elevator foot rest when the novel laser level meter needs to be used at a higher position, so that the operation is simple and convenient. The balance inductor is connected with the controller. When the novel laser level meter is inclined, the balance inductor receives a signal and transmits the signal to the controller. After that, the controller sends an instruction to the alarm, and the alarm gives an alarm to remind the working personnel. Therefore, the accuracy of measurement results is ensured.

Owner:TIANJIN SENRAN ENG COST CONSULTING

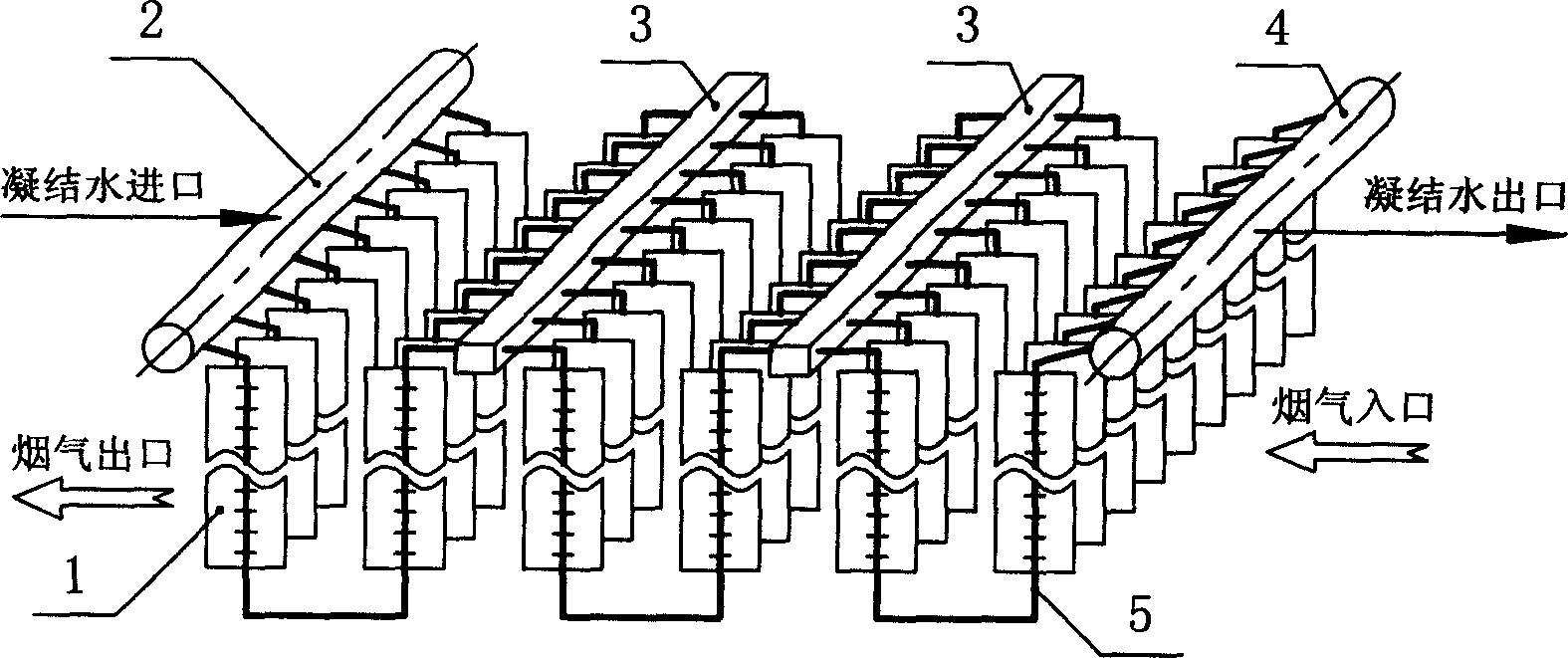

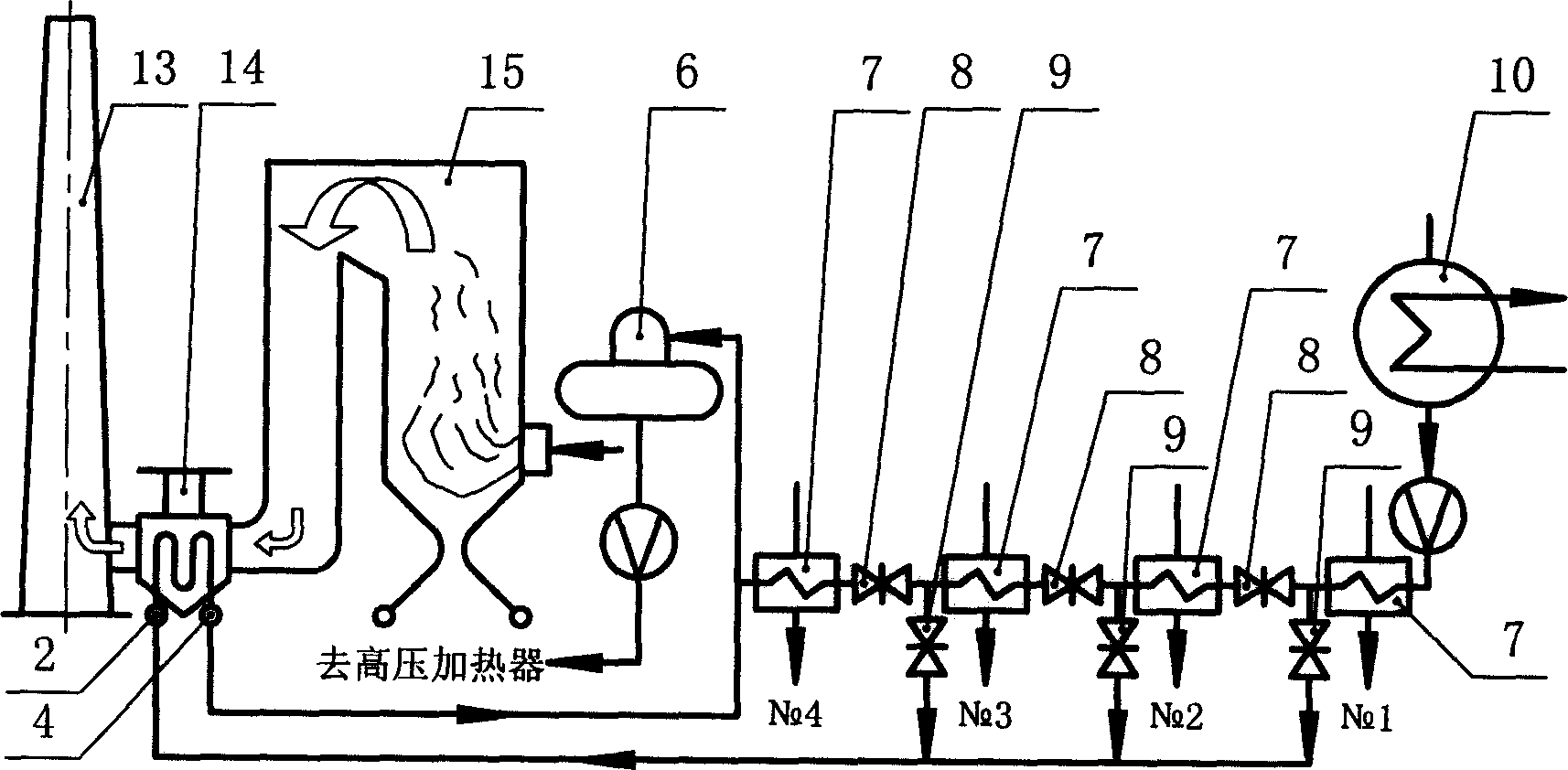

Residual-heat used type electric dust separator and its application system

InactiveCN1623673AIncrease the heat exchange areaSignificant energy saving benefitsIncreasing energy efficiencyDirect contact heat exchangersHigh energyEngineering

A afterheat utilization type electric dust separator for the steam electric power plant is disclosed. It is installed between the smoke outlet of boiler and chimney and features that it has an afterheat exchanger instead of conventional metallic plate anode for absorbing the afterheat of fume to heat the water needed by production procedure. Its advantages are low cost and high energy saving effect.

Owner:XI AN JIAOTONG UNIV

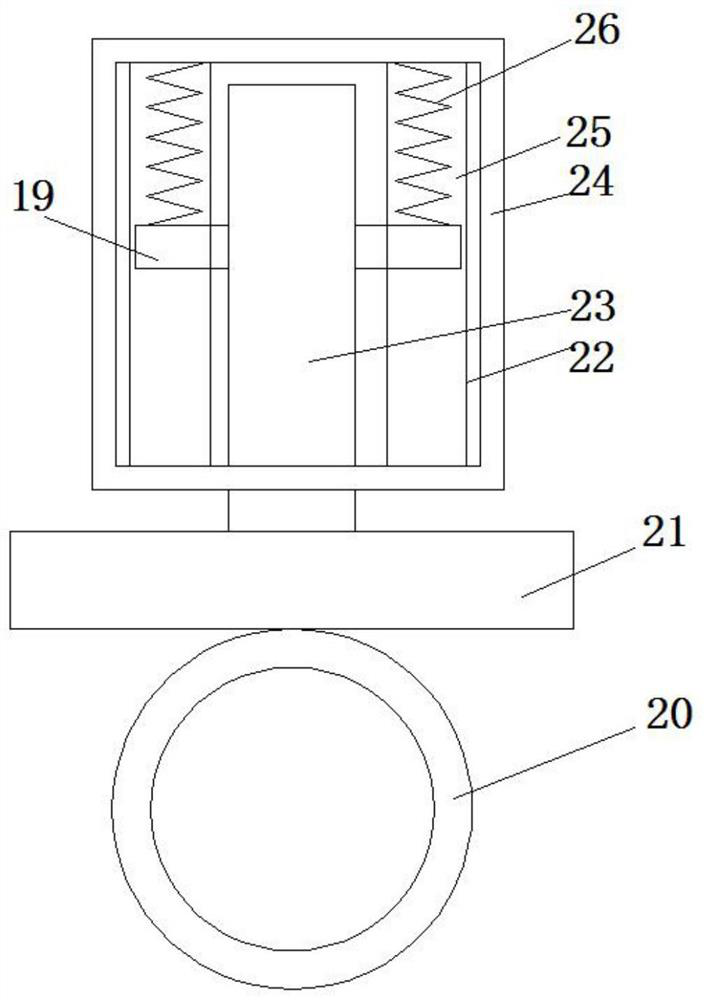

Live pig breeding excrement cleaning device

InactiveCN112335553AAdjustable operationReasonable structureAnimal housingAnimal scienceWater storage tank

The invention discloses a live pig breeding excrement cleaning device. The device comprises a moving mechanism, a bottom plate, a water storage tank, a handrail and a cleaning wheel. The front end face of the bottom plate is obliquely arranged, a driving motor is installed in the bottom plate, and fixing blocks are arranged on the oblique face of the front end of the bottom plate and obliquely arranged along the front end face of the bottom plate; and two sets of fixing blocks are symmetrically distributed, a mud guard is arranged between the two sets of fixing blocks in a sliding manner, sliding blocks are arranged at the two ends of the mud guard in a protruding manner, the sliding blocks extend into sliding grooves formed in the fixing blocks, the sliding grooves are formed in the length direction of the fixing blocks, and second bolts are further arranged in the fixing blocks. The second bolts slide longitudinally along the sliding grooves, one ends of the second bolts penetrate through the sliding grooves to extend into the sliding blocks and are in threaded connection with the sliding blocks, and the mud guard slides in the length direction of the fixing blocks. The live pigbreeding excrement cleaning device is reasonable in structure, has the characteristics of convenience in operation, convenience in use and the like, and can be widely popularized.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

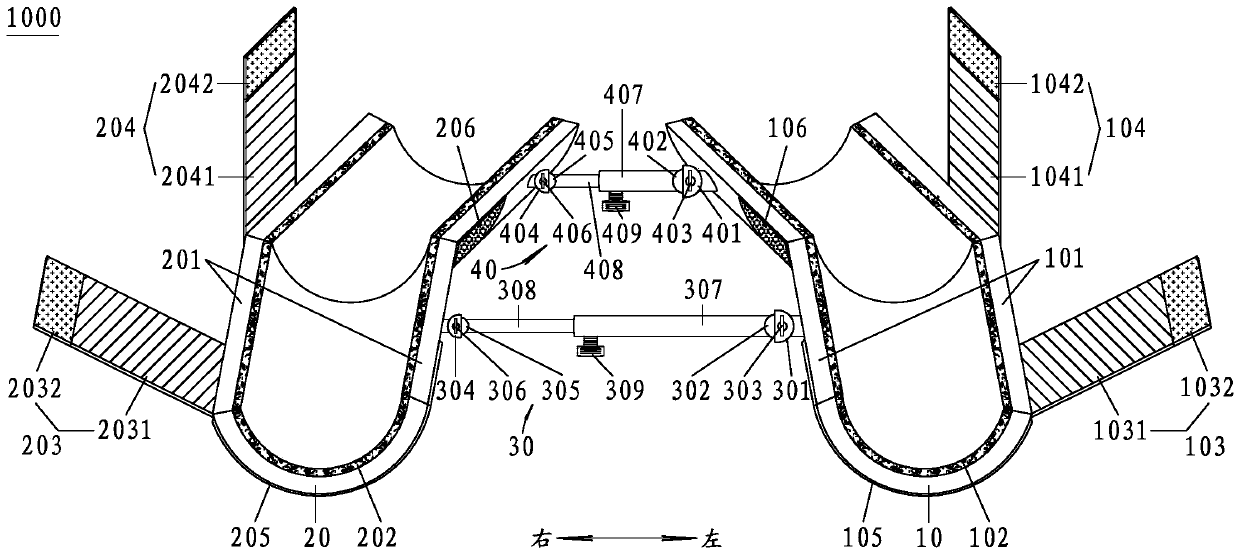

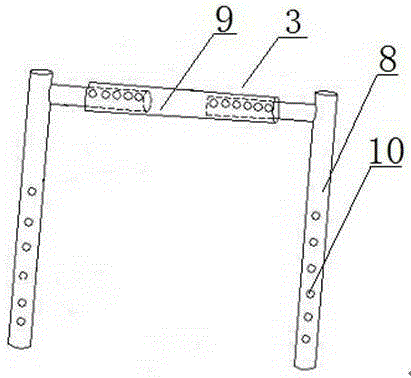

Correction device for pediatric developmental dysplasia of hip

The invention discloses a correction device for pediatric developmental dysplasia of hip. The device comprises a first inverted V-shaped wrist rest suitable for supporting a left knee wrist of a child, a second inverted V-shaped wrist rest suitable for supporting a right knee wrist of the child, and a telescopic adjusting part for adjusting the distance between the first inverted V-shaped wrist rest and the second inverted V-shaped wrist rest to expand a left leg and a right leg of the child. The device provided by the invention has the following effects: two legs of the child can be expandedto abduction to be fixed, so that the corrective treatment of developmental dysplasia of the hip is facilitated; two legs of the child are only supported by the first inverted V-shaped wrist rest andthe second inverted V-shaped wrist rest, so that the child feels comfortable when uses the device; the telescopic adjusting part has an adjustable telescopic length, so that the distance between the first inverted V-shaped wrist rest and the second inverted V-shaped wrist rest can be adjusted, and the distance of the first inverted V-shaped wrist rest and the second inverted V-shaped wrist is conveniently and adaptively adjusted to be suitable for use according to the size and the like of the lower part of a child body; therefore, the device has a good use effect.

Owner:SHENZHEN CHILDRENS HOSPITAL

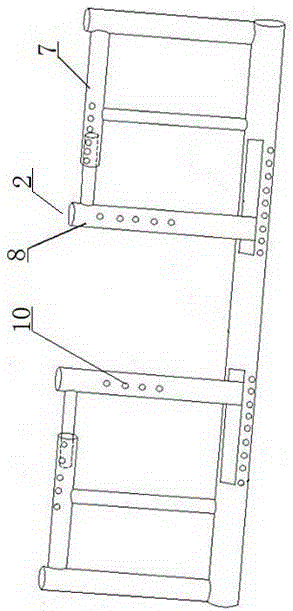

Sheep special-purposed mobile shearing device

InactiveCN105284658AAdjustable widthHeight adjustableOther apparatusGrooming devicesEngineeringInverted u

The invention discloses a sheep special-purposed mobile shearing device. The device comprises a mobile frame body, a standing support, a device rack surface, and wheels. The mobile frame body is provided with a neck-fixing mechanism and limb-fixing devices. The neck-fixing mechanism comprises a U-shaped notched frame and an inverted-U-shaped notched frame. The notch of the U-shaped notched frame is oriented upward. The bottom end of the U-shaped notched frame is connected to the standing support of the mobile frame body. Positioning pins are arranged on the U-shaped notched frame and the inverted-U-shaped notched frame. The upper opening of the U-shaped notched frame can be engaged with the inverted-U-shaped notched frame. The limb-fixing devices are arranged on the four corners of the device rack surface. With the device, a sheep can be fixed. Height and width are adjustable. The device is suitable for mobile use. A humane design of an anti-hurting arc is formed by a soft pad and 1 / 2 pipe, such that sheering is facilitated.

Owner:天祝藏族自治县三洋盛生物工程有限公司

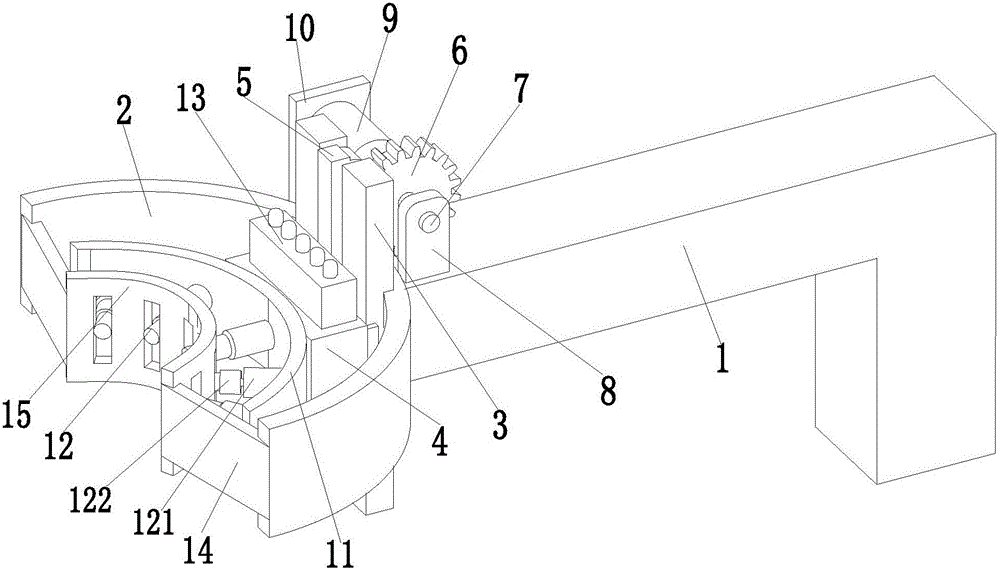

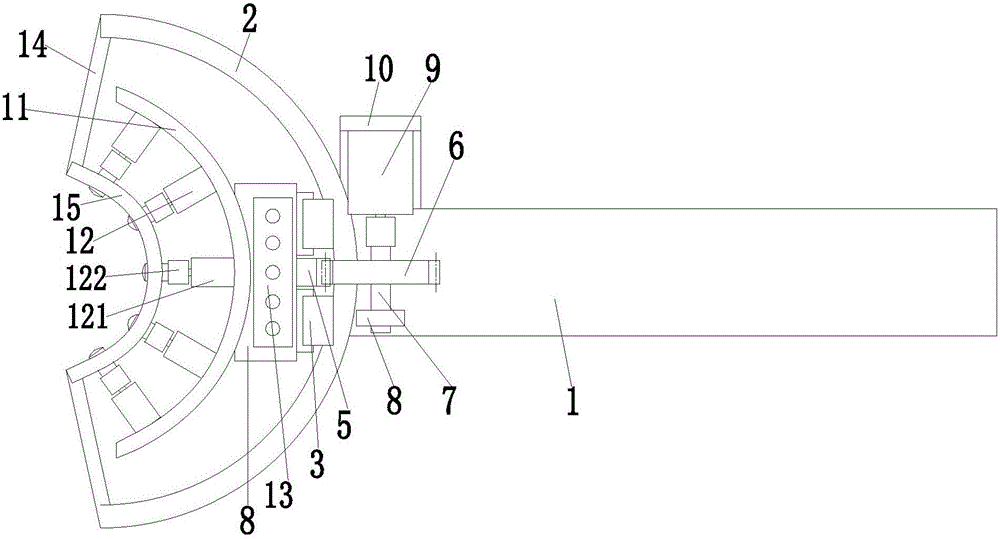

Special massage mechanical hand for orthopaedic cervical spondylosis

InactiveCN105943342AUniform massage forceWith comfort levelVibration massageRobot handPhysical medicine and rehabilitation

The invention relates to a special massage mechanical hand for orthopaedic cervical spondylosis. The special massage mechanical hand comprises an L-shaped support post, wherein an installing wall is welded at the tail end of the L-shaped support post; two linear slide rails are symmetrically arranged at the middle part of the inner side of the installing wall; an ascending and descending block is arranged on the two linear slide rails; a rack is welded on the right end surface of the ascending and descending block, and is positioned between the two linear slide rails; the rack is engaged with a rotating gear; the middle part of the rotating gear is arranged at a rotating shaft through a key; the front end of the rotating shaft is arranged on a fixing block through a bearing; the fixing block is welded at the upper end surface of the L-shaped support post; the back end of the rotating shaft is connected with a rotating motor through a shaft coupler; and the rotating motor is arranged on an L-shaped fixing plate through a motor seat. The special massage mechanical hand has the advantages that the ultrasonic automatic massage function can be realized; the comfort degree of manual massage is realized; the the advantages of simplicity and convenience in operation, good massage effect, uniform massage force, adjustable massage force strength, high work efficiency and the like are also realized; and a new path for automatic cervical vertebra massage is provided.

Owner:刘栋

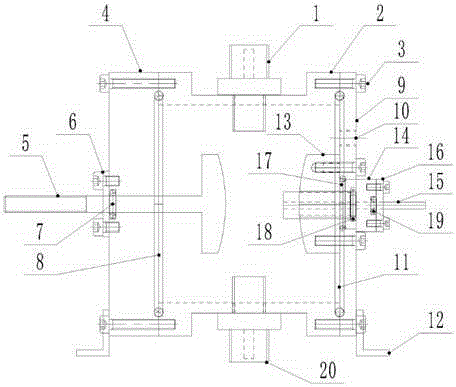

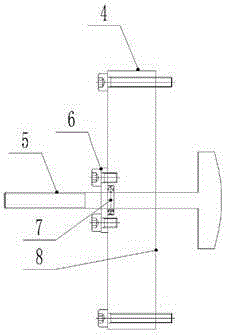

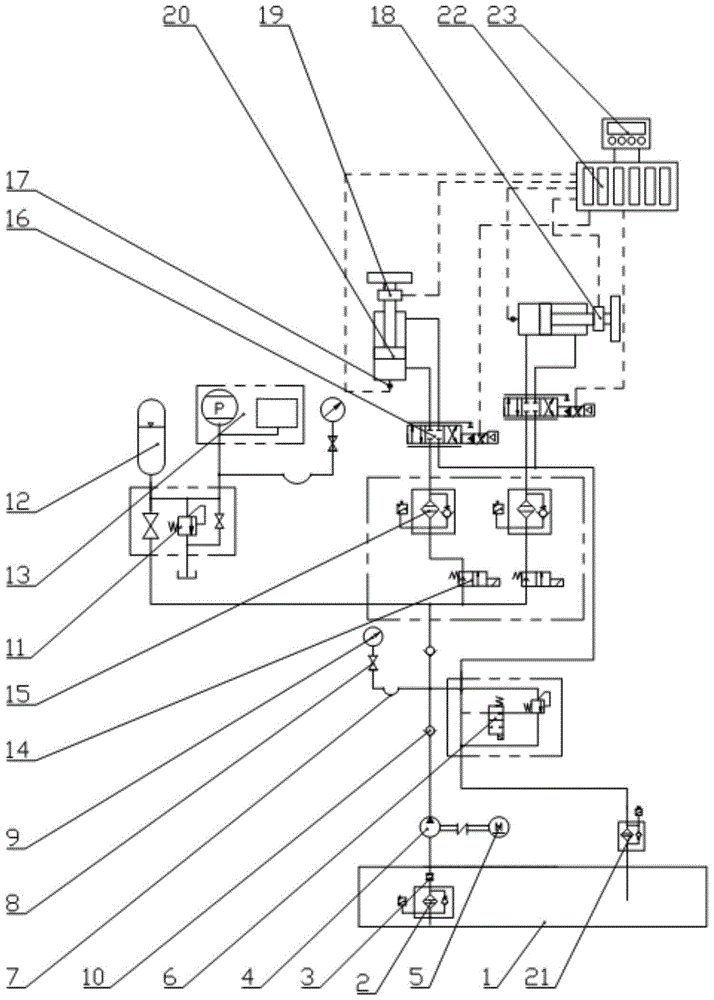

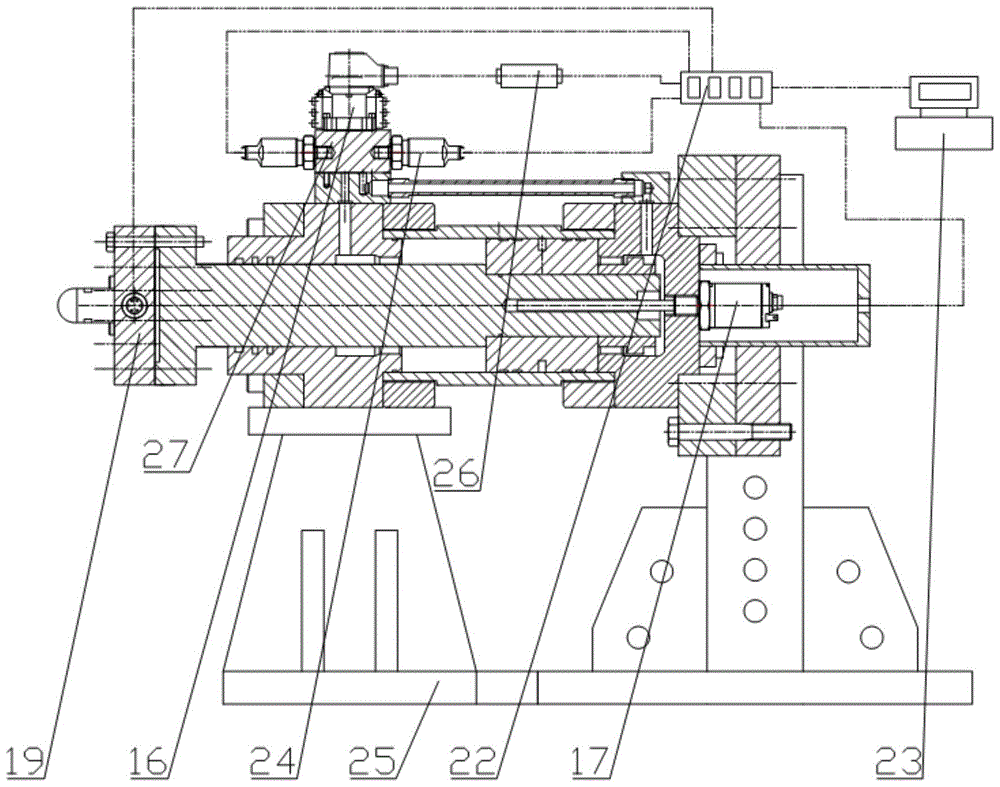

Hydraulic servo variable load loading test bench

ActiveCN104006034BNice appearanceCompact structureFluid-pressure actuator testingFatigue loadingClosed loop

The invention discloses a hydraulic servo variable-load loading test bench, belongs to the field of mechanical hydraulic pressure, and relates to a fatigue test bench using an electro hydraulic servo system and being capable of realizing pressure and displacement feedback double closed loop control. The test bench consists of a control system and four loading mechanisms in parallel connection, wherein two of the four loading mechanisms in parallel connection are used for loading in the axial direction, and the other two of the four loading mechanisms in parallel connection are used for loading in the radial direction. In the control system, an industrial personal computer and a controller are connected through a data wire; and a displacement sensor and large and small force sensors are connected to the controller through data transmission wires. The loading test bench is fixed on the ground; the large force sensor for loading in the axial direction is mounted at the front end of one servo hydraulic cylinder; and the small force sensor for loading in the radial direction is mounted at the front end of the other servo hydraulic cylinder. Four control channels of the hydraulic servo variable-load loading test bench can work together; and the test bench has the advantages of simple structure, clear principle, low cost, stable long-term operation and high efficiency, and can synchronously carry out the fatigue loading for a plurality of samples.

Owner:DALIAN UNIV OF TECH

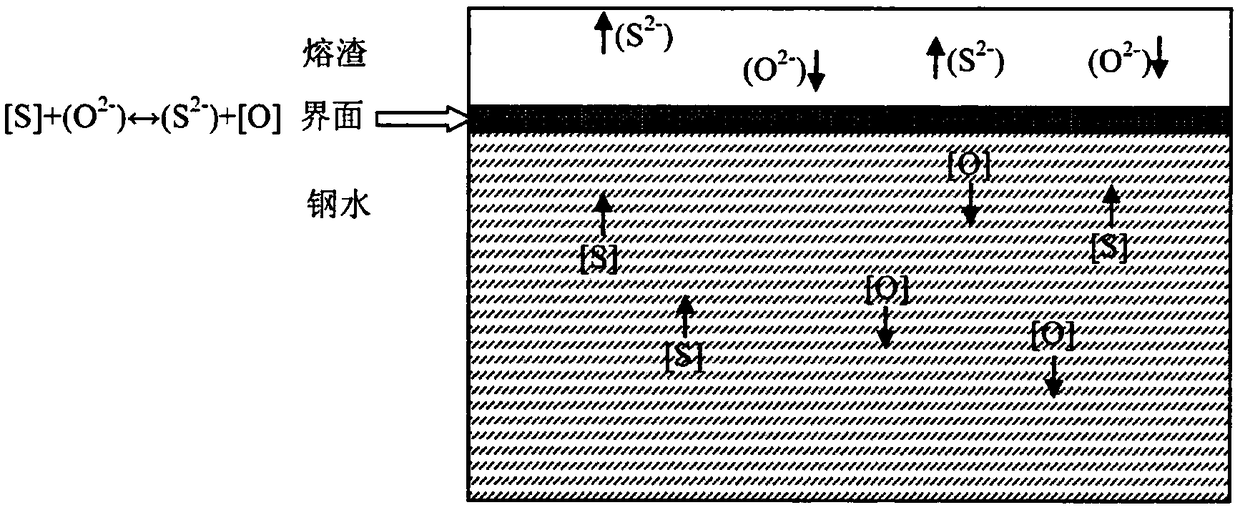

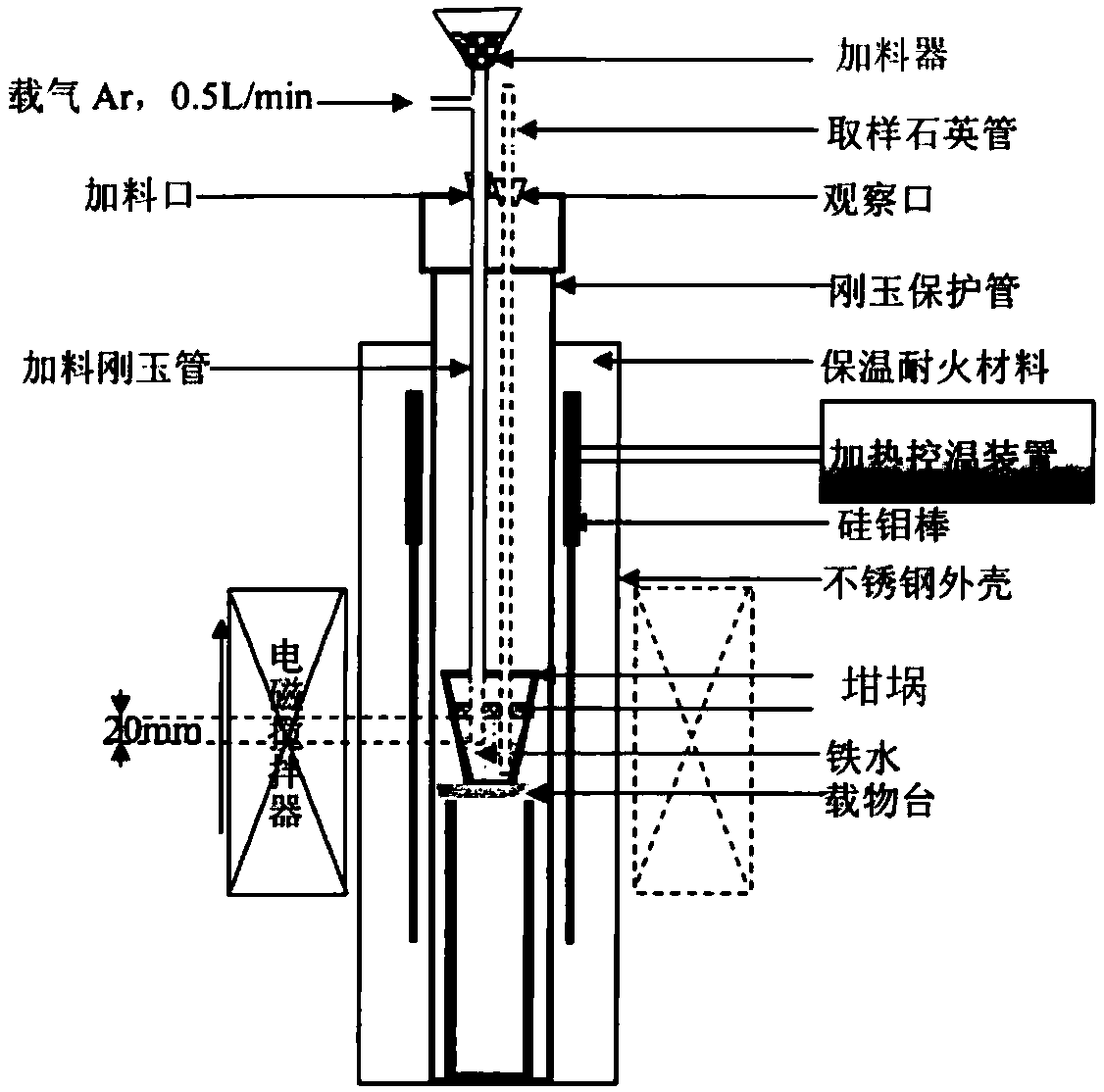

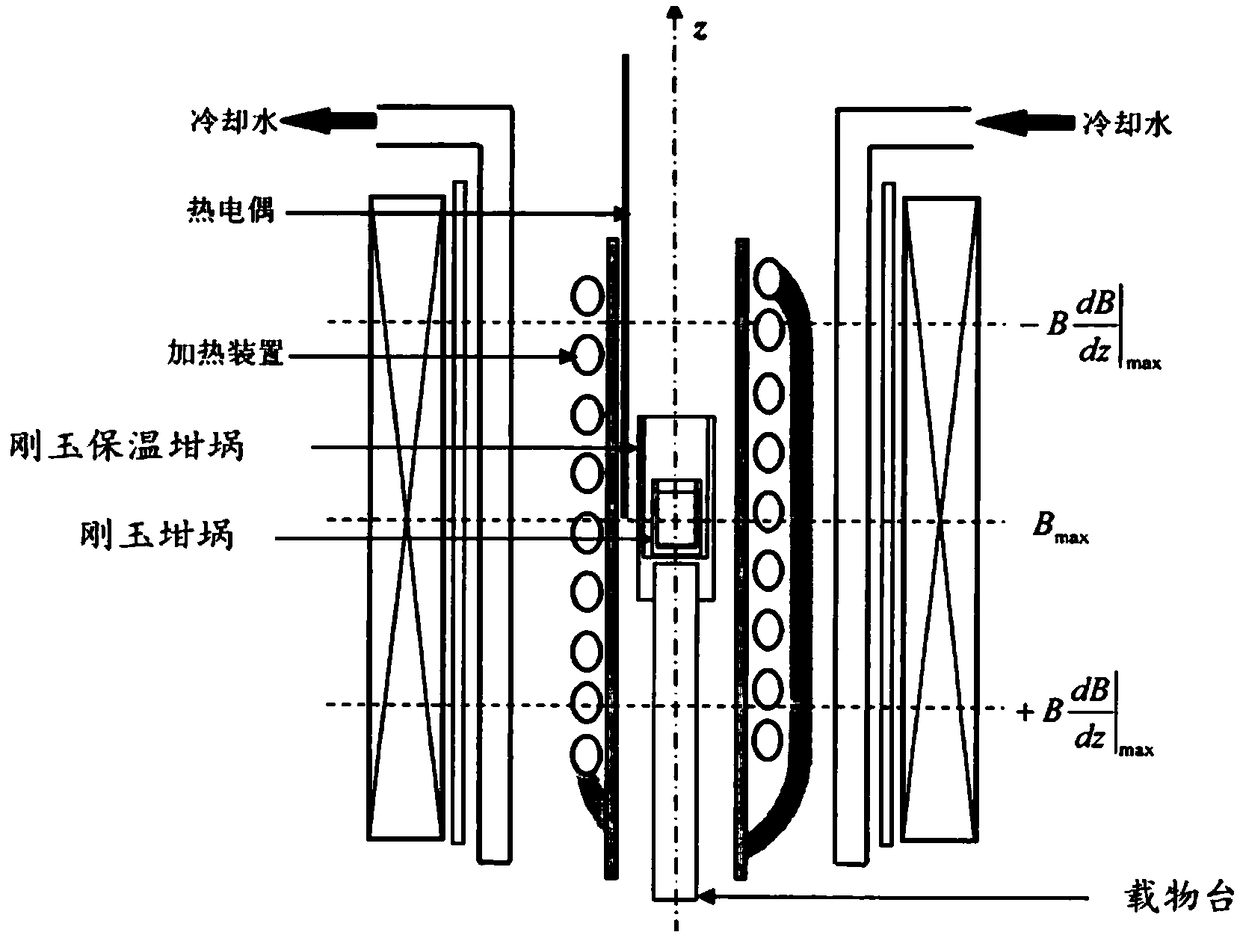

Control method for metal-slag reaction in sponge iron steelmaking process and device thereof

InactiveCN109055658ASimple process conditionsLow costProcess efficiency improvementElectric furnaceSteelmakingBall mill

The invention relates to the field of metallurgy and material heat treatment experiments, in particular to a control method for a metal-slag reaction in the sponge iron steelmaking process and a device thereof. Particularly, the control method comprises the steps that sponge iron is crushed and milled into powder with a planetary ball mill, then sponge iron powder is added into a feeder, and the sponge iron powder is added into a crucible through the feeder; the crucible is put on a carrying platform located at the magnetic field center of an electromagnetic stirrer; and the crucible containing the sponge iron powder is alternately heated and subjected to electromagnetic stirring treatment, the crucible is gradually separated from a silicon-molybdenum bar heat radiation area by pulling down the carrying platform located at the magnetic field and heat field center, and molten liquid is gradually cooled and solidified from the bottom of the crucible to the top. In addition, the inventiondiscloses a specific structure for a direct sponge iron steelmaking device. According to the control method for the metal-slag reaction in the sponge iron steelmaking process and the device thereof,the technological conditions are simple, the cost is low, energy consumption is relatively low, the yield is high, the smelting time is short, and the production scale is adjustable; and in addition,the cost is reduced, operation is easy and convenient, and environmental friendliness is achieved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

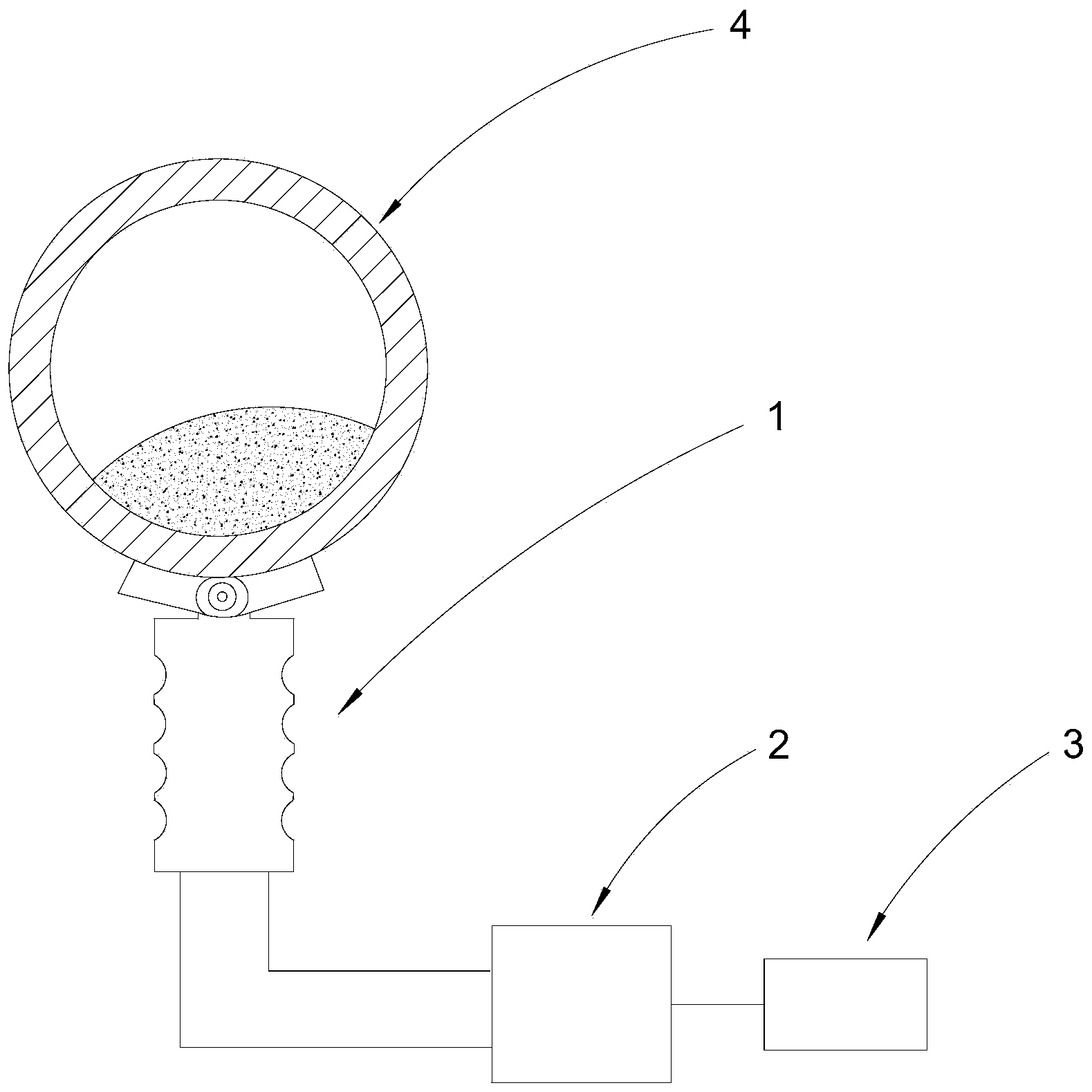

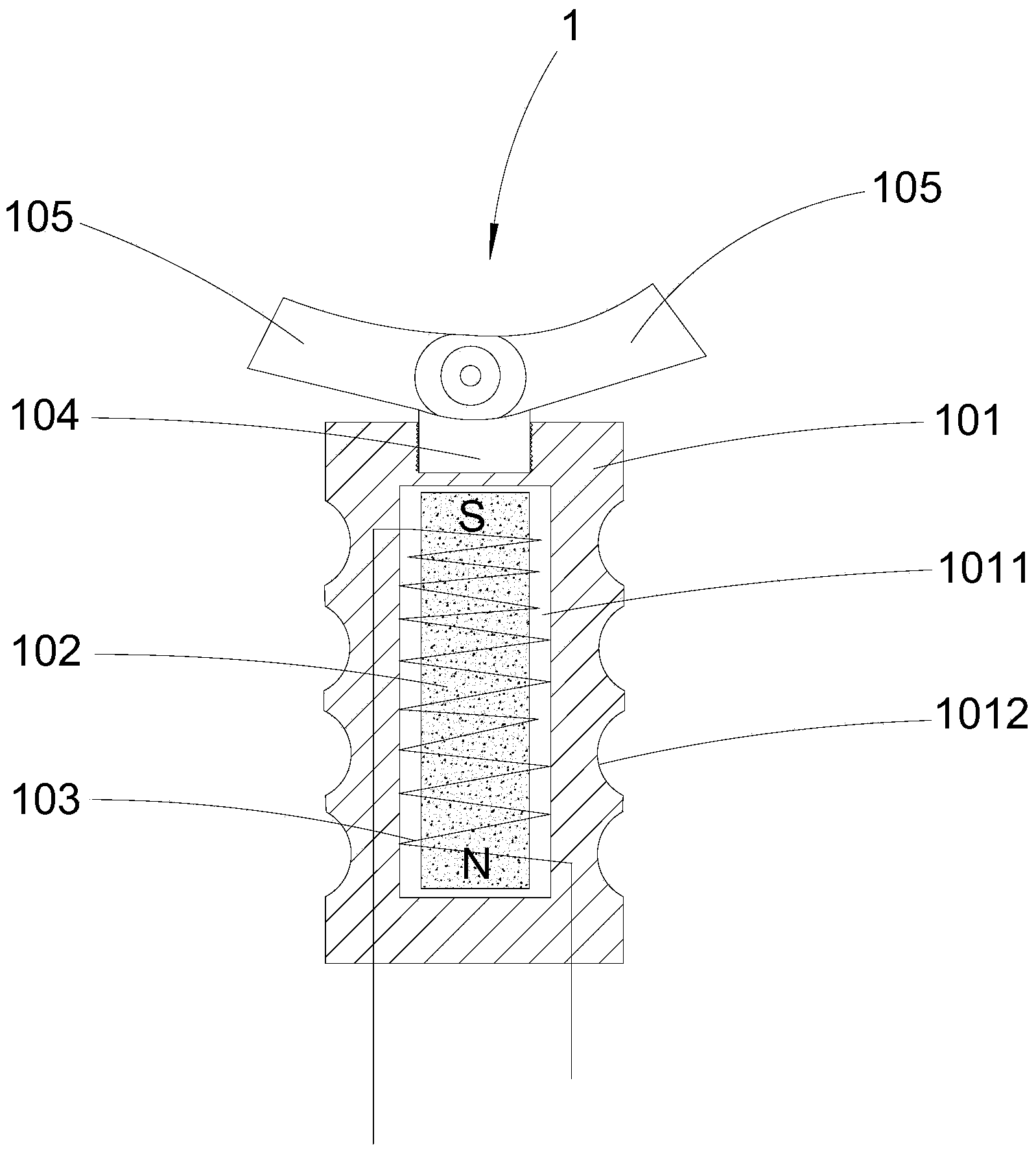

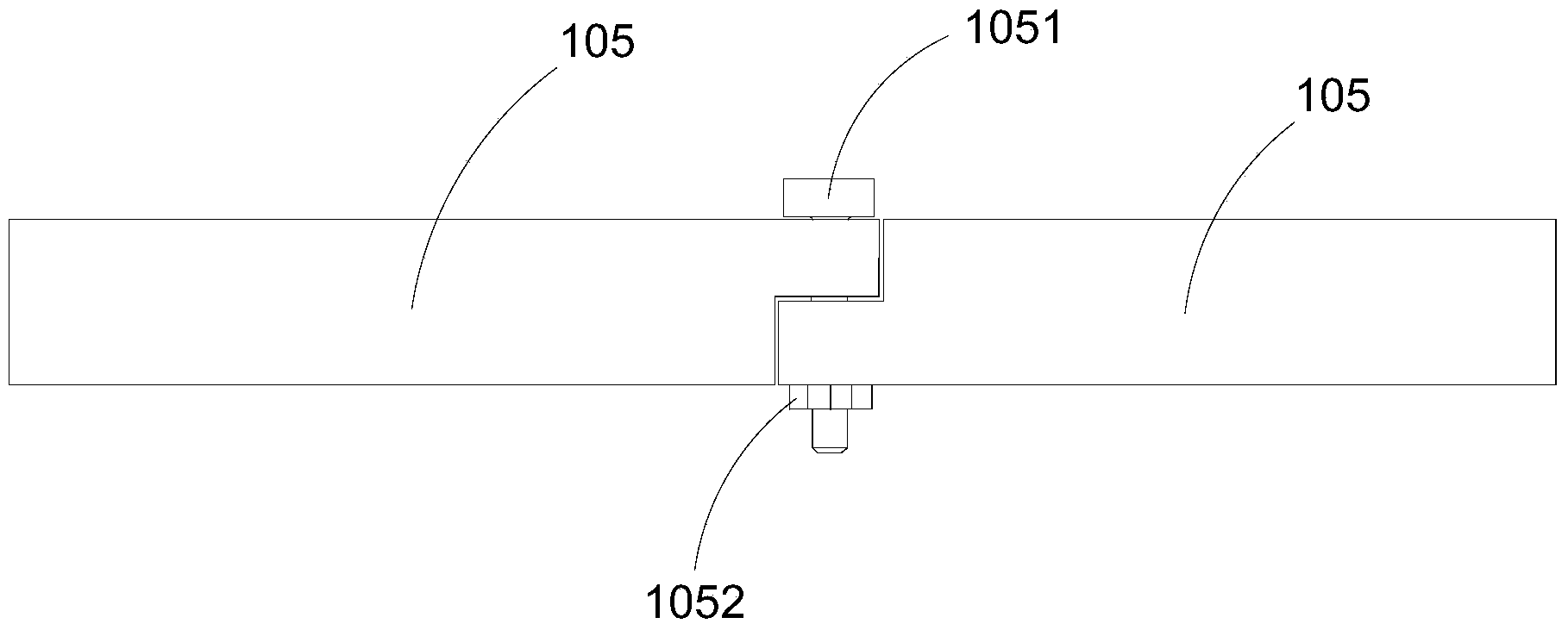

Austenitic stainless pipe inner wall oxide skin nondestructive testing device

InactiveCN104251879ACompact structureThe principle is simpleMaterial magnetic variablesAustenitic stainless steelNondestructive testing

The present invention discloses an austenitic stainless pipe inner wall oxide skin nondestructive testing device comprising a probe, an electromagnetic detector and a data processor which are sequentially electrically connected; the probe comprises a casing, a permanent magnet, an induction coil, an installation part and two scan parts, induction coil winds the permanent magnet and is installed in the casing together with the permanent magnet, the installation part is embedded in the casing, one ends of the two scan parts are respectively movably connected with the same end of the installation part, when the probe works, an included angle between the two scan parts is adjusted to detect pipes with different specifications. Compared with the prior art, the detection device has the advantages of compact structure, fast detection speed and accurate and reliable detection result, the probe scans a to-be-detected pipe by the scan parts, and does not contact with the to-be-detected pipe, the probe abrasion in the long term detection can be avoided, the service life of the probe is improved, the use cost is reduced, the included angle between the two scan parts is adjustable, the austenitic stainless pipe inner wall oxide skin nondestructive testing device is flexible in use, and is suitable for various specifications of pipelines; therefore, the application prospect is very wide.

Owner:XIANGTAN HONGYUAN ELECTRONICS SCI & TECH CO LTD

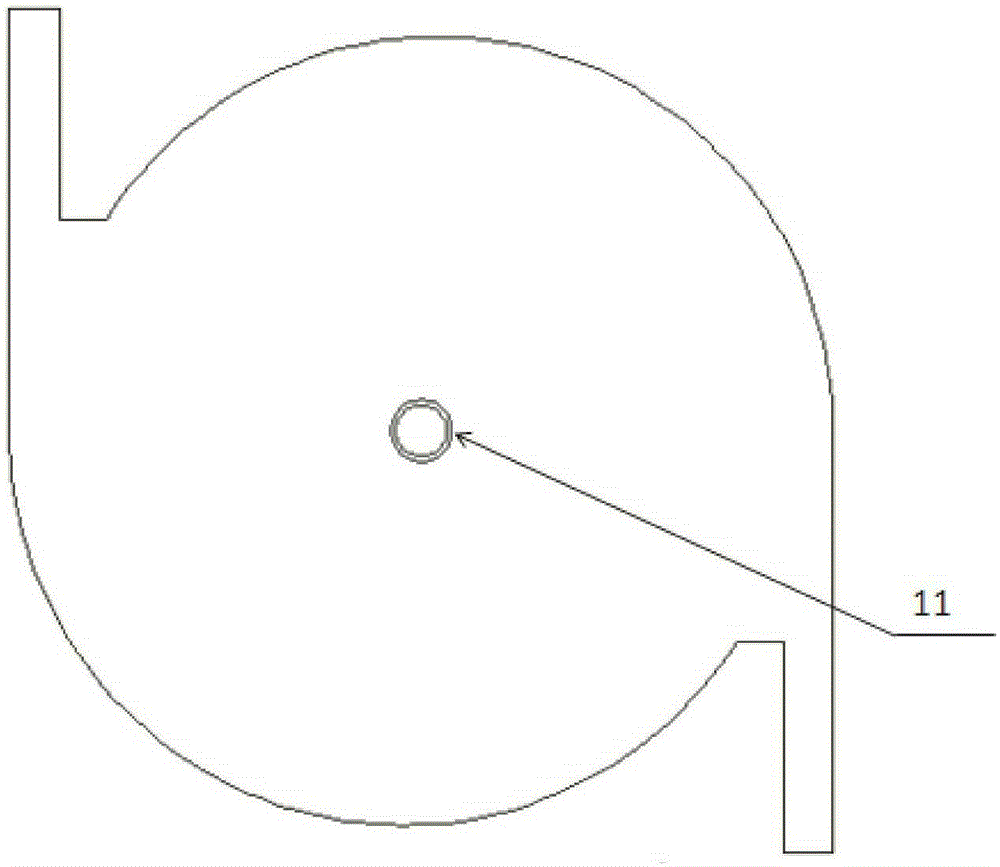

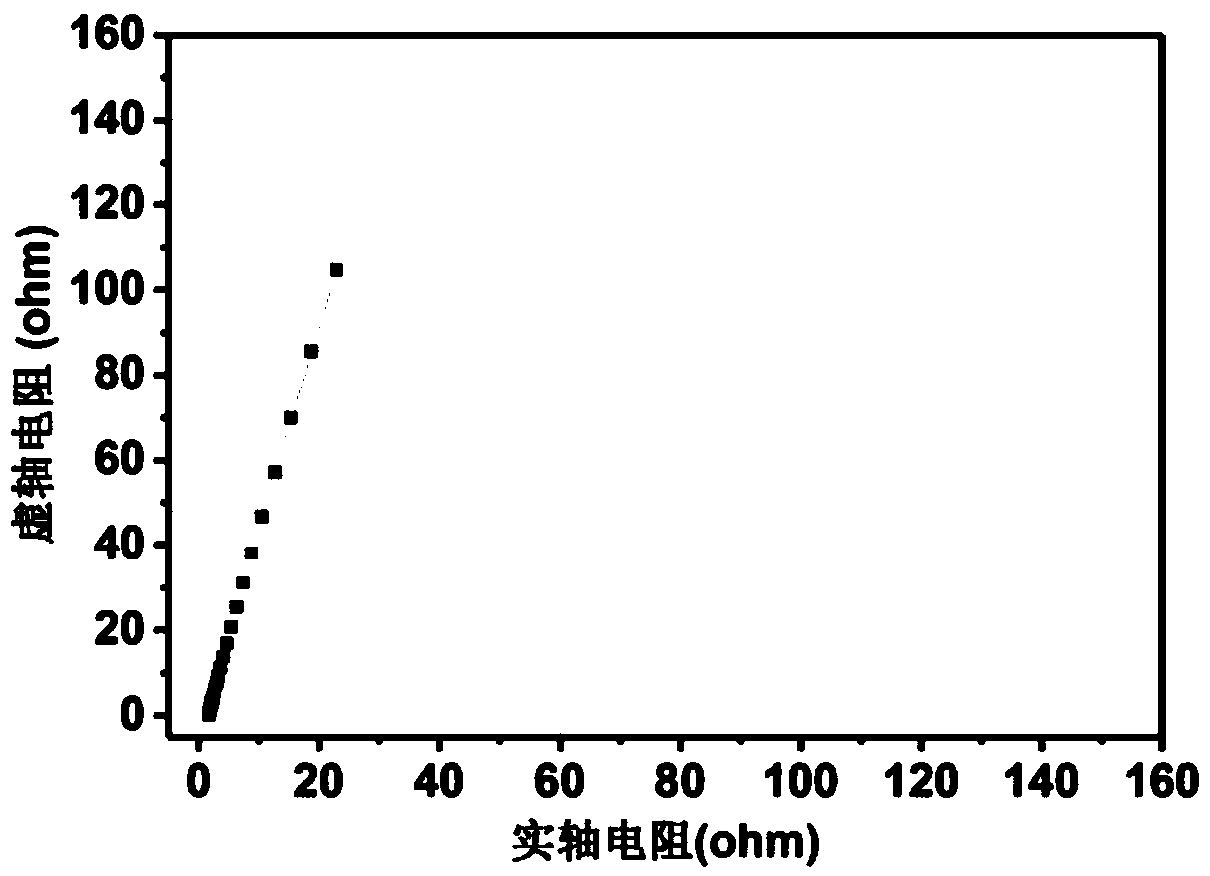

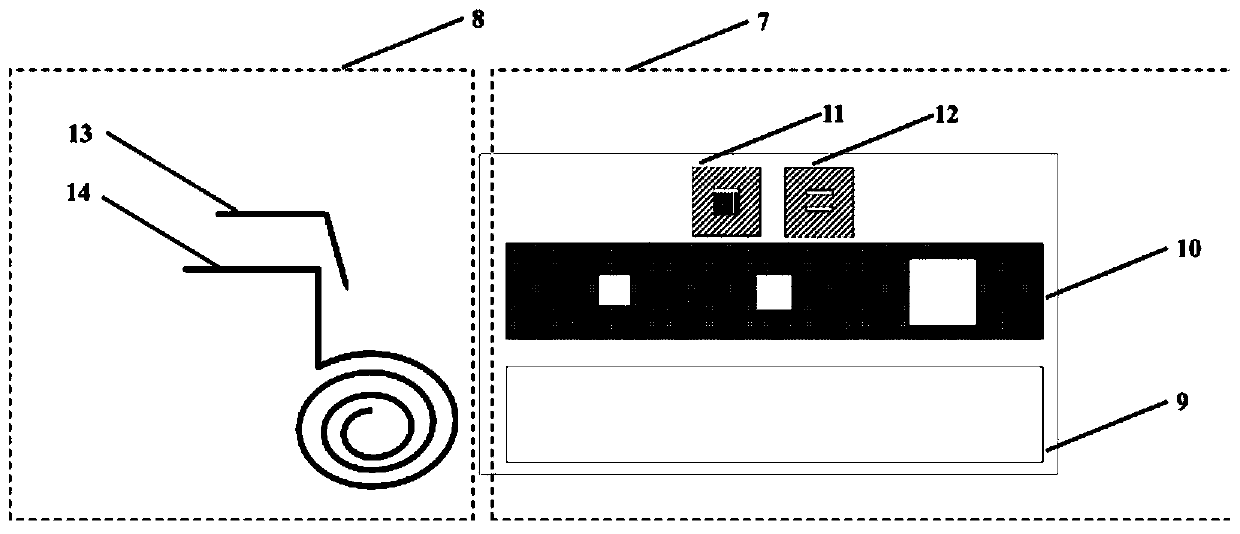

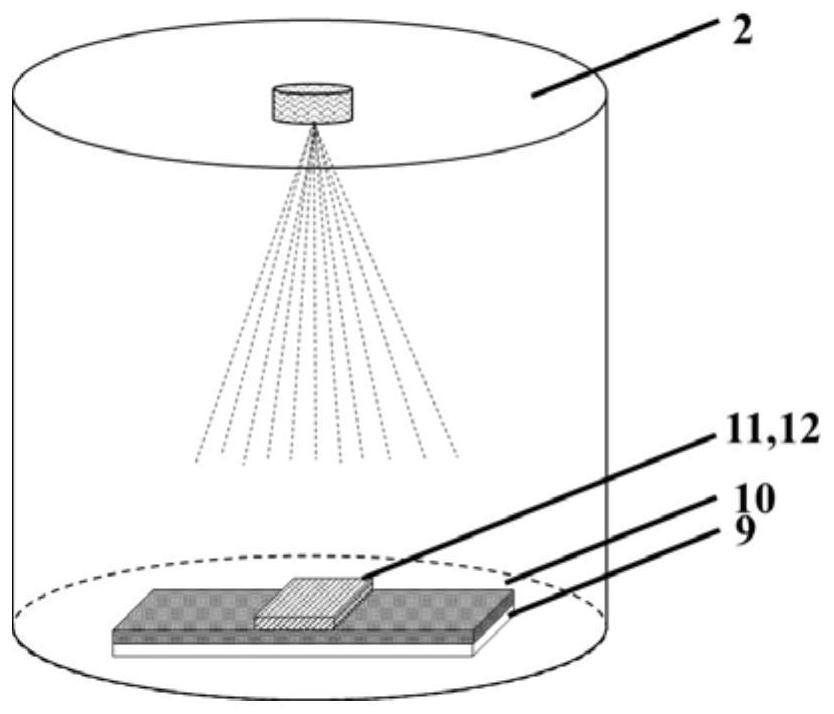

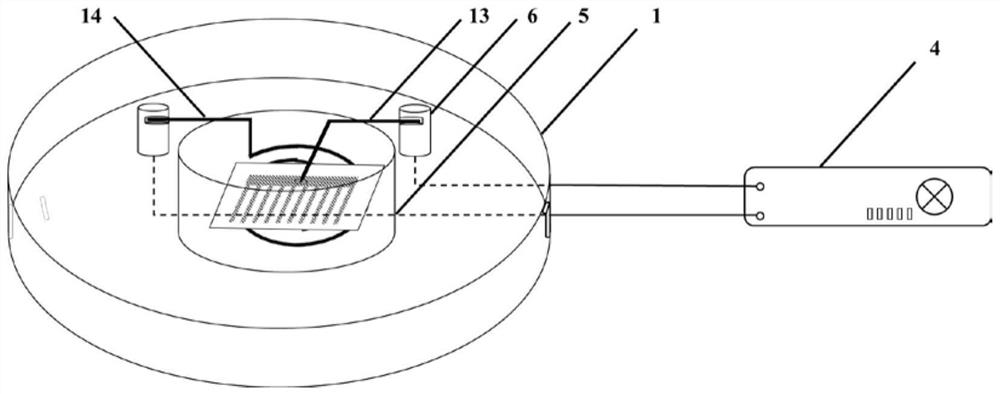

Test equipment and method of film electrode of solid oxide fuel cell

ActiveCN109725025APrecise control of shapeAvoid destructionResistance/reactance/impedenceMaterial resistanceSpecific testElectricity

The invention discloses test equipment and method of a film electrode of a solid oxide fuel cell, and belongs to the field of the electrochemistry test. The equipment comprises a high-temperature heating stage, an ohm meter, an electrochemical workstation, a current collection layer spraying mold and a probe test component; the current collection layer spraying mold comprises a glass baseplate, ablocking sheet, and a hollow masking sheet; the probe test component comprises a bevel probe and a plane spiral probe; the method comprises electrical test and electrochemical test, the film electrodecan be tested by using a test probe combination according to a specific test demand. Through the test equipment disclosed by the invention, the quick precise test of the electrical performance and the electrochemical performance of the film electrode in the temperature range of 600-1000 DEG C, and the test equipment has the features of being accurate in test, high in efficiency and space-saving.

Owner:TSINGHUA UNIV

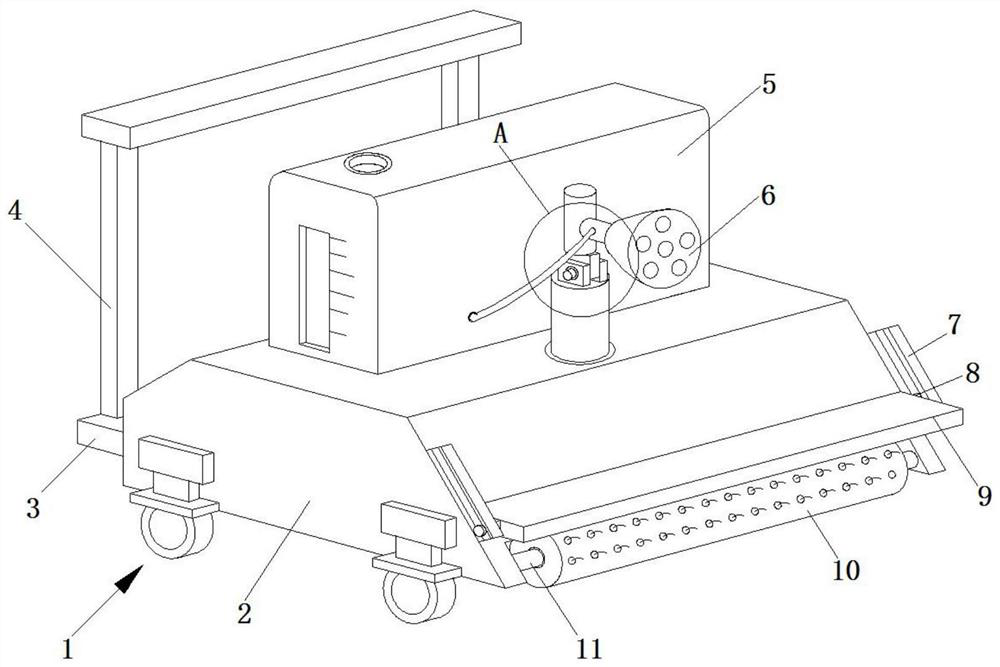

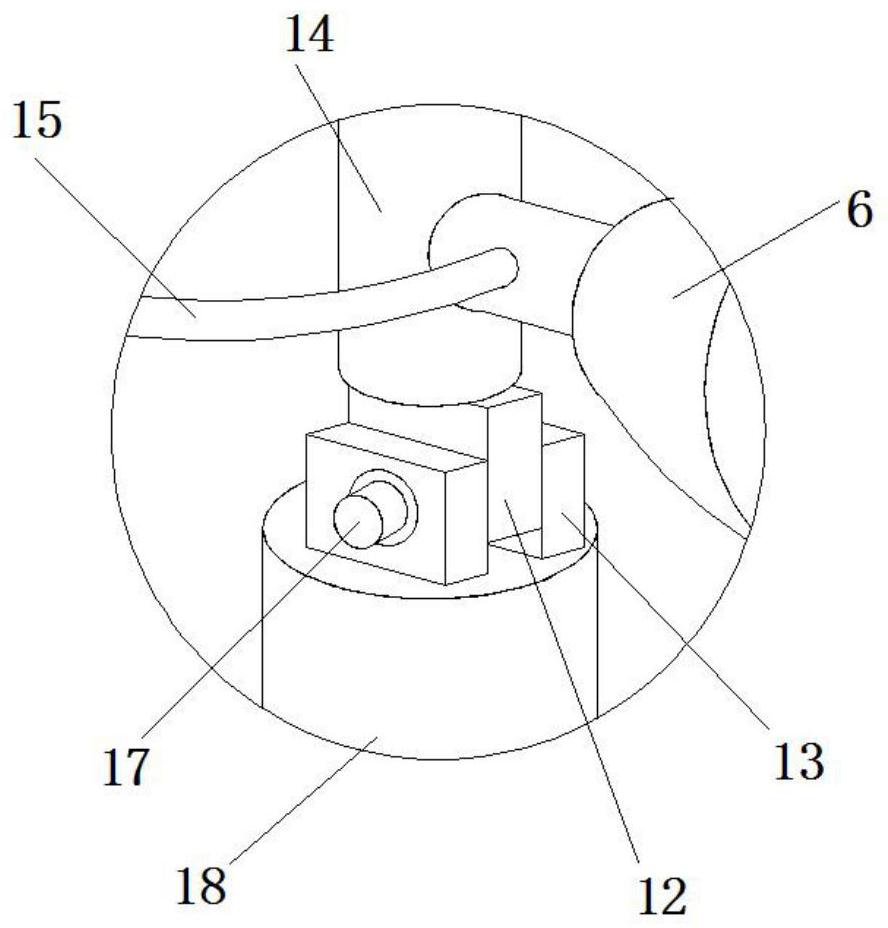

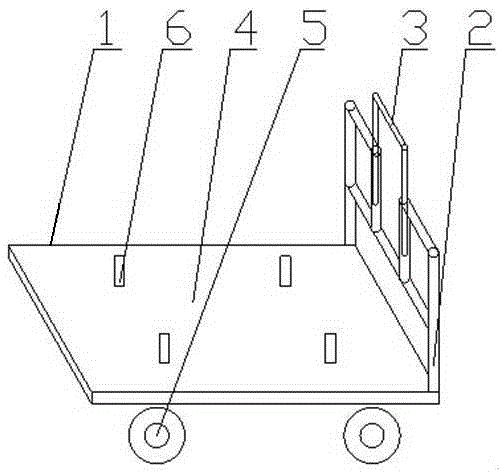

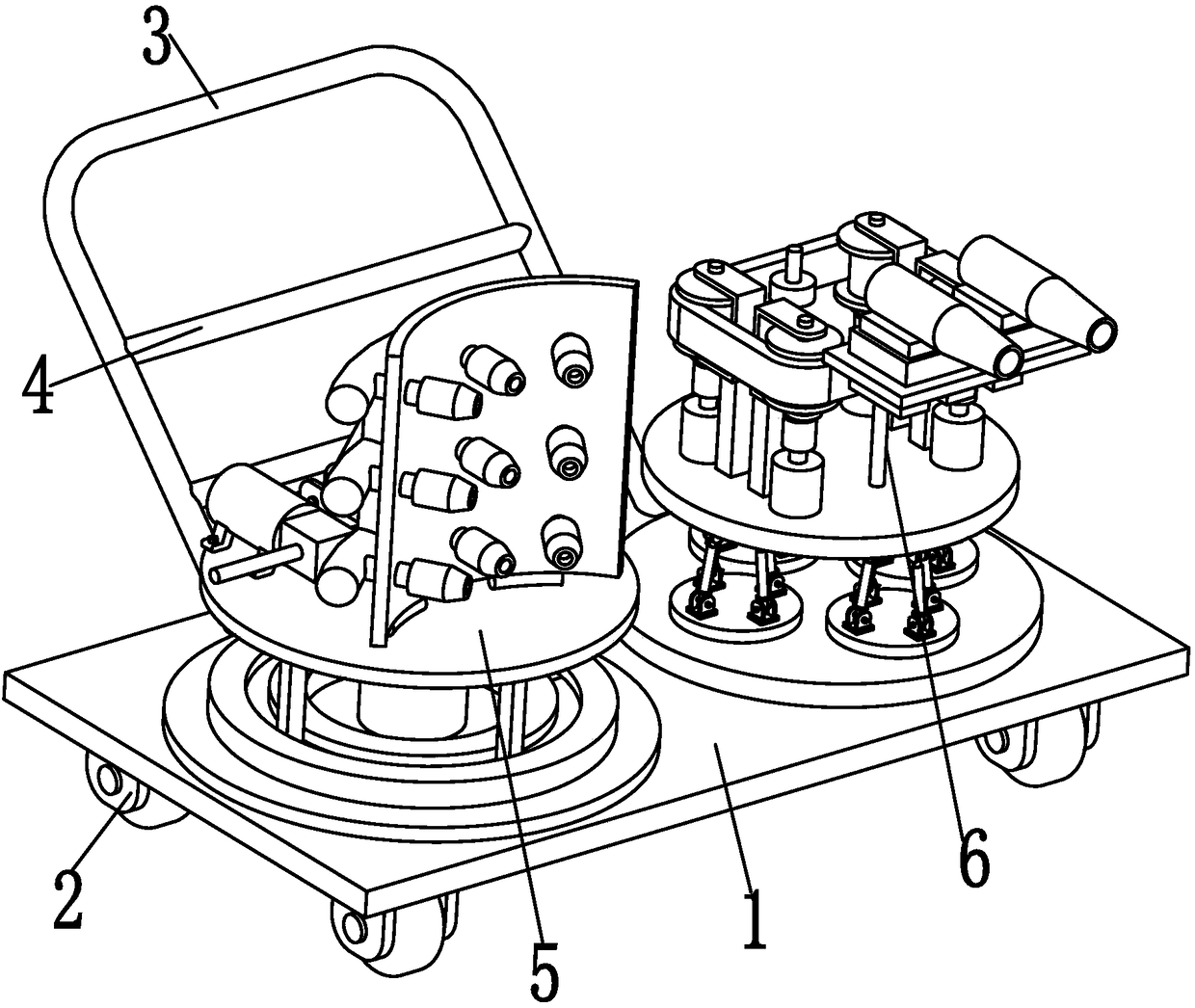

Spraying dust-collecting robot for down-the-hole drill drilling

ActiveCN106285494ARealize the function of spray dust suppressionImprove the effect of dust suppressionEarth drilling toolsConstructionsEngineeringAutomation

The invention relates to a spraying dust-collecting robot for down-the-hole drill drilling. The spraying dust-collecting robot comprises a base plate. Four universal wheels are symmetrically installed at the lower end face of the base plate; a handrail is arranged at the back side of the upper end face of the base plate; two transverse rods are arranged on the handrail; and a worker assisted by the four universal wheels drives the spraying dust-collecting robot to move to a down-the-hole drill rock drilling position through the handrail. A spraying device is installed at the left side of the upper end face of the base plate and can achieve a spraying dust-reducing function when a down-the-hole drill conducts rock drilling; and a dust-collecting device is installed at the right side of the upper end face of the base plate and can achieve an automatic dust-collecting function when the down-the-hole drill conducts rock drilling. The spraying dust-collecting robot for down-the-hole drill drilling can simultaneously achieve the spraying dust-reducing and automatic dust-collecting functions when the down-the-hole drill conducts rock drilling, and has the advantages that no manual spraying adjusting operation is needed, spraying angles can be automatically adjusted, operation is easy, the automation degree is high, the spraying effect is good, a movable dust-collecting mode is adopted, the dust-collecting direction is adjustable, dust collecting is fast, and the dust-collecting effect is good.

Owner:临沂恩科开发建设有限公司

A kind of flexible, solid supercapacitor and its preparation method and application

ActiveCN109473294BEasy to prepareRaw materials are non-toxic and renewableHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceSupercapacitor

The invention belongs to the field of supercapacitors and discloses a flexible and solid supercapacitor, a preparation method and application thereof. The supercapacitor comprises a positive electrode, a negative electrode and an electrolyte interposed therebetween, wherein the electrolyte is double-network lignin hydrogel, and both the positive and negative electrodes are conductive electrodes. The double-network lignin hydrogel as the electrolyte in the present invention not only has high mechanical strength property, but also has a simple preparation method, low raw material cost, renewability, green environmental protection, and high ionic conductivity; when the hydrogel is used as the electrolyte to assemble the supercapacitor, additional soaking of an ionic solution is not required and additional use of a diaphragm is not needed, thereby effectively reducing the thickness and weight of the supercapacitor. The obtained capacitor specific capacitance value is higher than the current hydrogel electrolyte type flexible supercapacitor specific capacitance value. In addition, the supercapacitor has very good charging and discharging cycle stability, compression resistance and bending resistance.

Owner:SOUTH CHINA AGRI UNIV

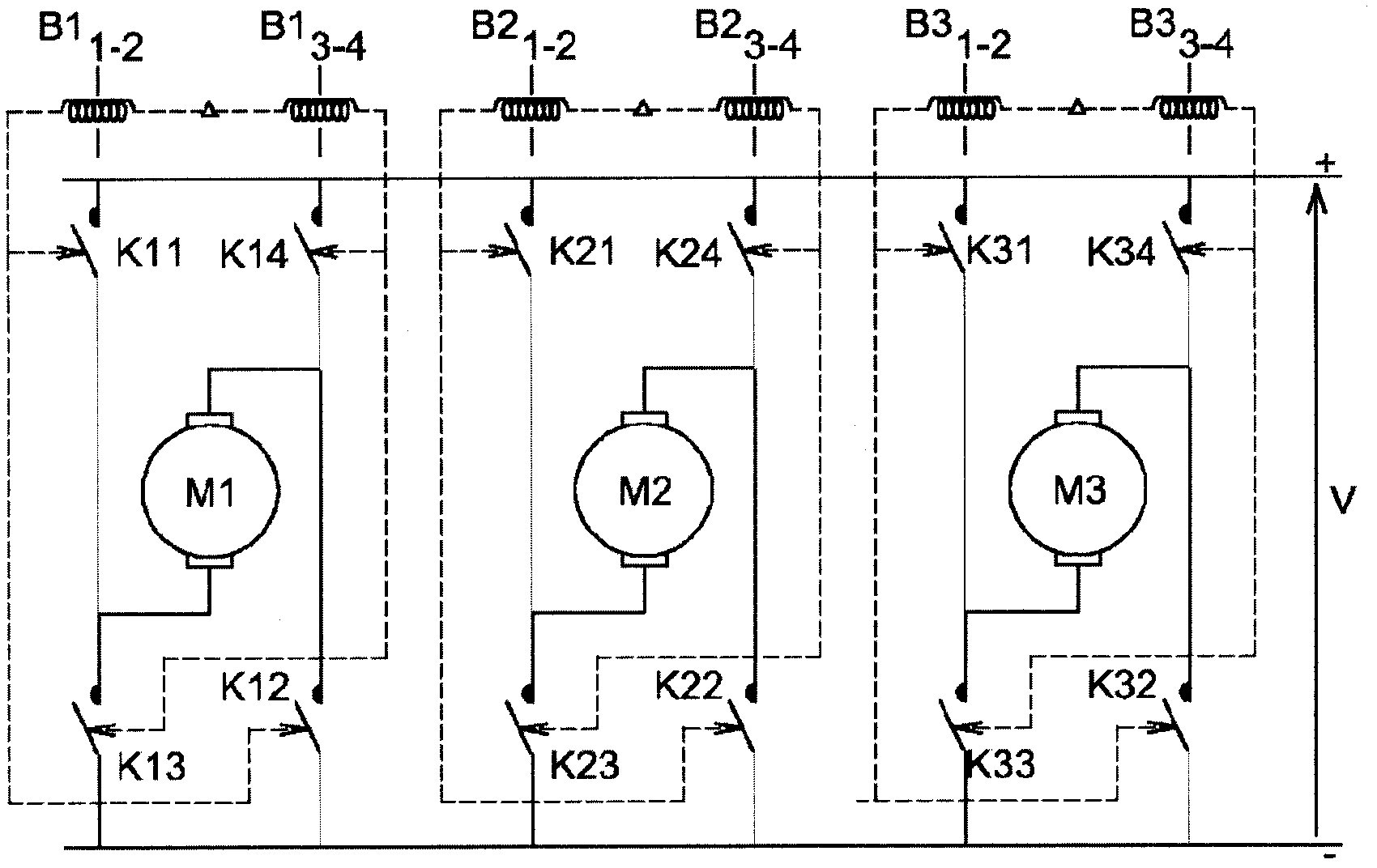

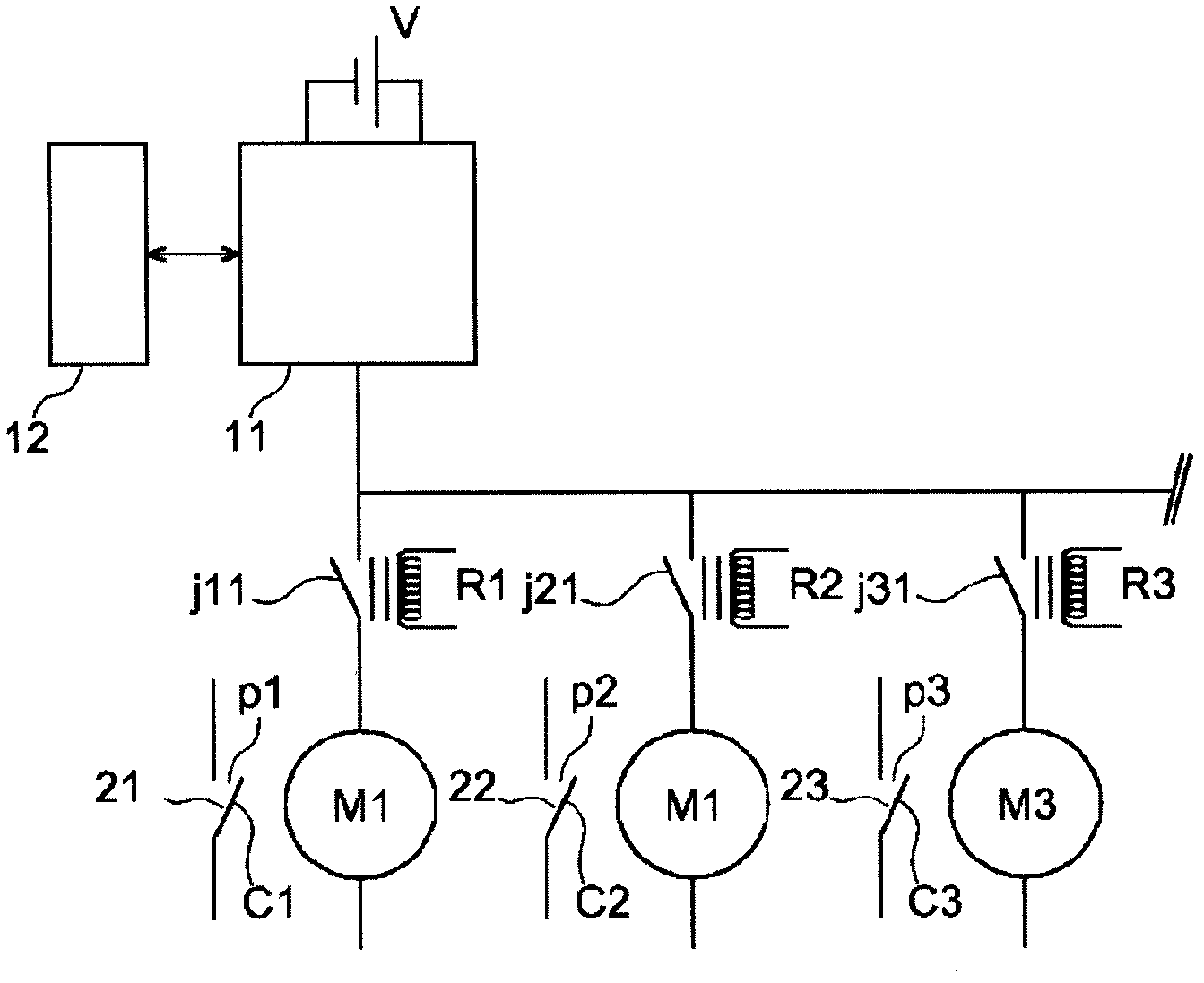

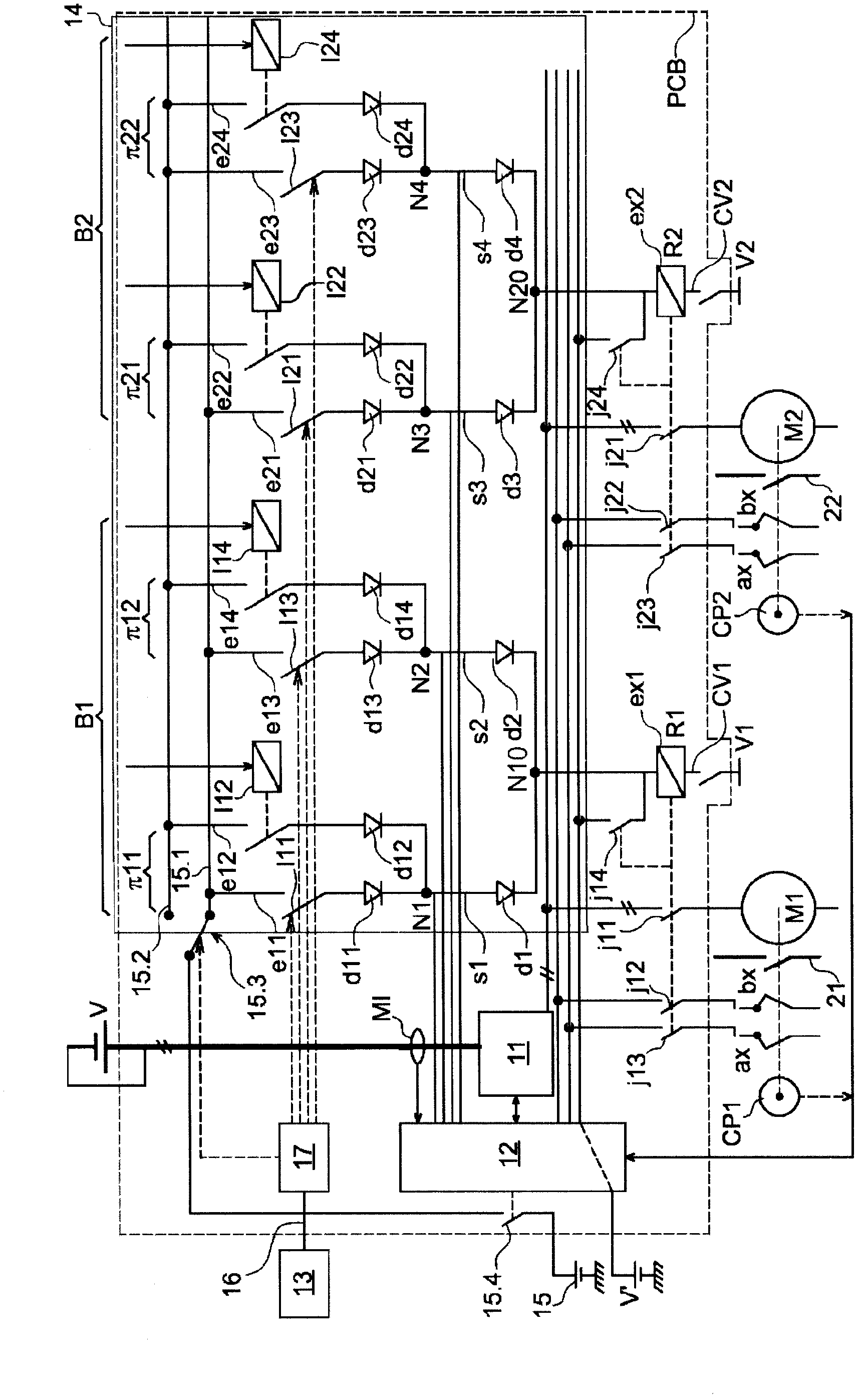

Device for controlling a plurality of current breaking apparatuses via electric motors

InactiveCN102934186AReduce the numberAdjustable operationInversing contactorsHigh-tension/heavy-dress switchesElectricityEngineering

The invention relates to a device for controlling a group of current breaking apparatuses (21, 22) via, for each current breaking apparatus, an actuation motor (M1, M2) which actuates at least one electrical contact of the current breaking apparatus. Said device comprises a single changeover contactor (11) controlled by control means (12) for connection to a power source (V) for the motors, and connected to the motors via switching means (R1, R2) for a current originating from the power source (V) and flowing through the changeover contactor (11). The invention is used for the control of current breaking apparatuses of a switch bay of a high-voltage electrical station.

Owner:ALSTOM TECH LTD

Automatic device for prevention and treatment of dust in quarry drilling perforation operation

InactiveCN108104864ARealize the function of spray dust suppressionImprove the effect of dust suppressionEarth drilling toolsConstructionsEngineeringMaterial Perforation

The invention relates to an automatic device for prevention and treatment of dust in a quarry drilling perforation operation. The automatic device comprises a bottom plate, four universal wheels are symmetrically installed on the lower end surface of the bottom plate, an armrest is arranged on the back side of the upper end face of the bottom plate, two crossbars are arranged on the armrest, and astaff moves the automatic device through the armrest with the assistance of four universal wheels to the perforation position of the drilling perforation of a down-the-hole drill; the left side of the upper end surface of the bottom plate is provided with a spraying device, and the spraying device can realize the spraying and dust-removing function during the drilling perforation of the down-the-hole drill; and the right side of the upper end surface of the bottom plate is provided with a dust suction device which can realize the automatic dust-suction function during the drilling perforationof the down-the-hole drill. The automatic device can simultaneously realize the function of spraying and dust removing and the function of automatic dust suction during the drilling perforation of the down-the-hole drill, and has the advantages of no manual adjustment of spray operation, automatic adjustment of spray angle, simple and convenient operation, high degree of automation, good sprayingeffect, vacuuming by means of activities, adjustable dust-suction direction, high dust-suction speed, and good vacuum effect.

Owner:潘春燕

Nailing machine of corrugated case

InactiveCN101456265BQuality improvementAdjustable pressure partBox making operationsPaper-makingAxial displacementEngineering

The invention carton stapler for corrugated cases and belongs to the field of corrugated case manufacturing equipment. The carton stapler adopts a paper conveying mechanism which uses a hexagonal steel type transmission shaft to drive two small belts (1). A driving roller (2) and a driven roller (3) one each side of each small belt (1) are connected together through a small wall plate (17) on thesame side, and each small belt (1) is also provided with a complete manual adjustment mechanism which adjusts axial displacement by using a threaded rod threaded rod shaft as well as an array roll type transverse positioning mechanism and a paper pressing belt (36) type paper pressing mechanism with a small roll (38), wherein the manual adjustment mechanism, the array roll type transverse positioning mechanism and the paper pressing belt (36) type paper pressing mechanism are all connected with the small wall plate (17) the transverse position of which can be adjusted. The carton stapler alsoadopts an automatic head nailing device which has a light controlled automatic system and is matched with the continuous paper conveying device. The transverse position of the automatic head nailing device is adjustable, the vertical position of a nail head holder (57) and the size of the paper pressure are adjustable, and a nail tongue (64) of a belt base plate (55) is changeable. The rollers can be changed easily and the transverse positions of the rollers can be adjusted conveniently, the friction is small, and the paper pressure is adjustable in terms of size. The carton stapler can not damage the surface of corrugaled board and the patterns on the surface of the corrugaled board, achieves excellent nailing quality, high efficiency and low energy consumption, and is convenient in adjustment and maintenance and is suitable to nail corrugaled boards with different thicknesses.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

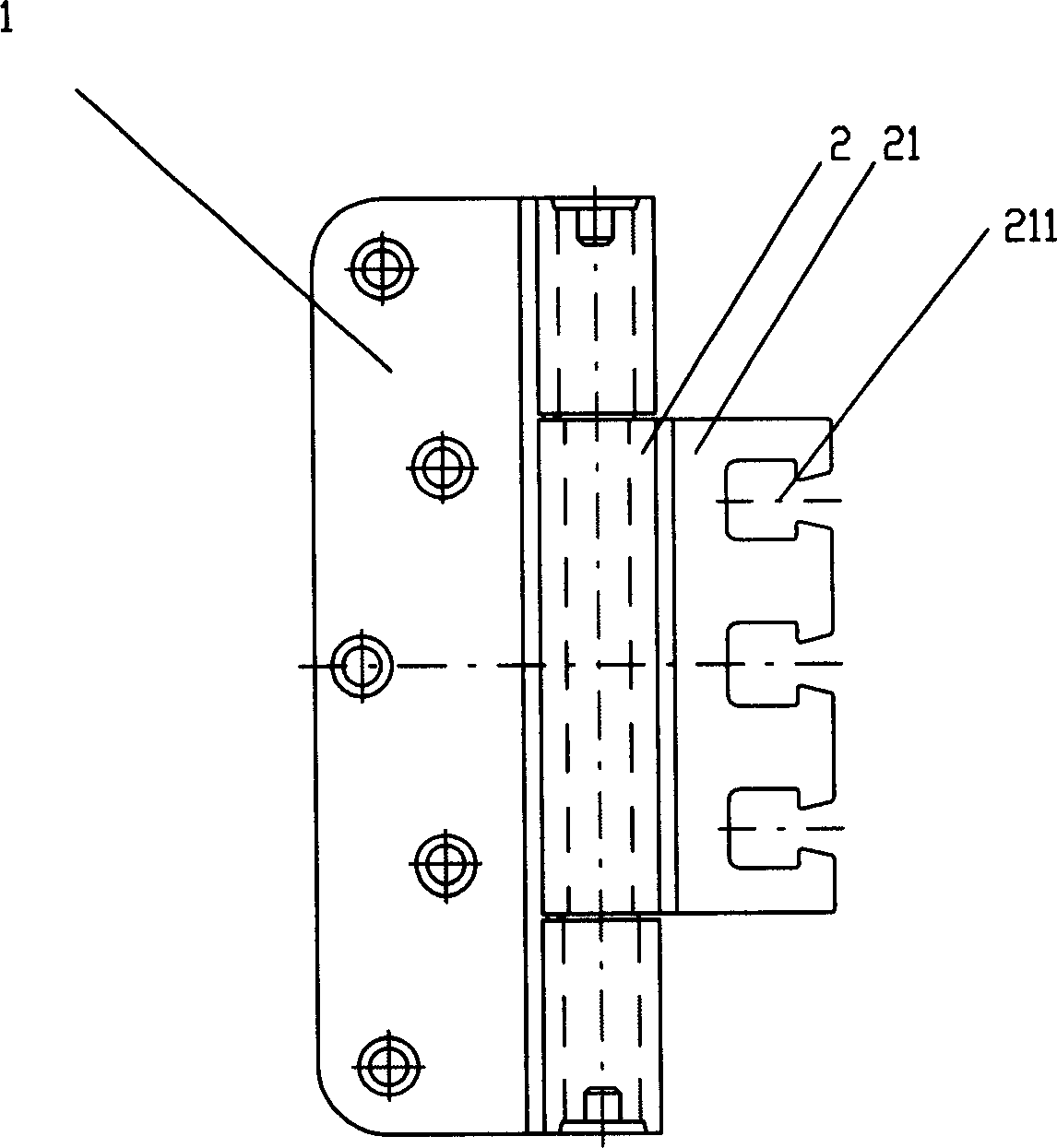

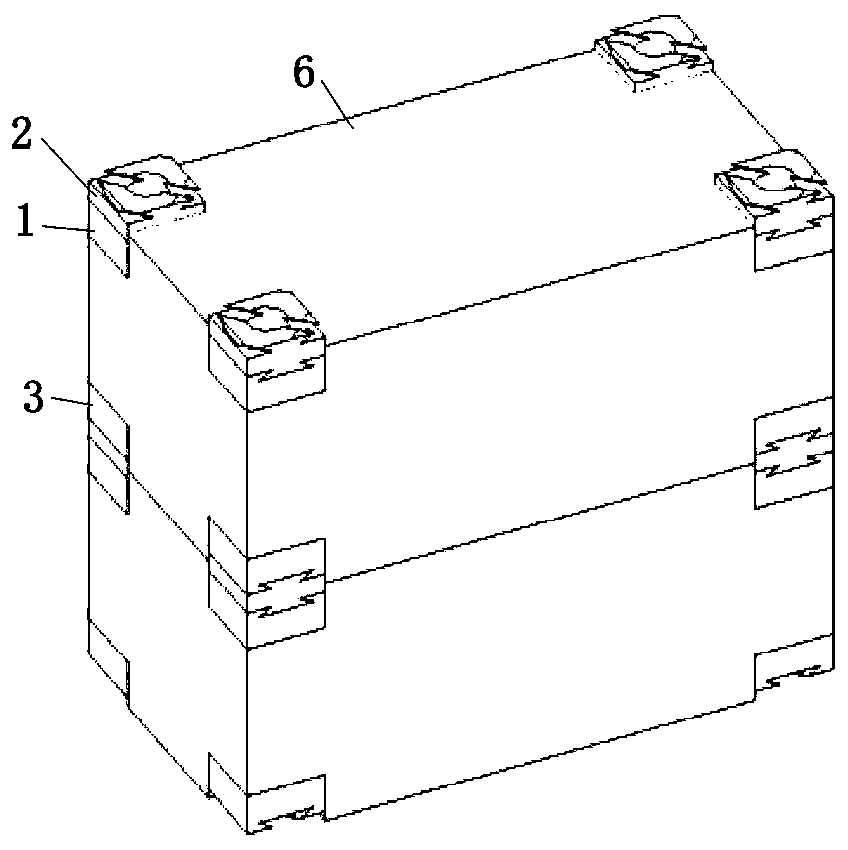

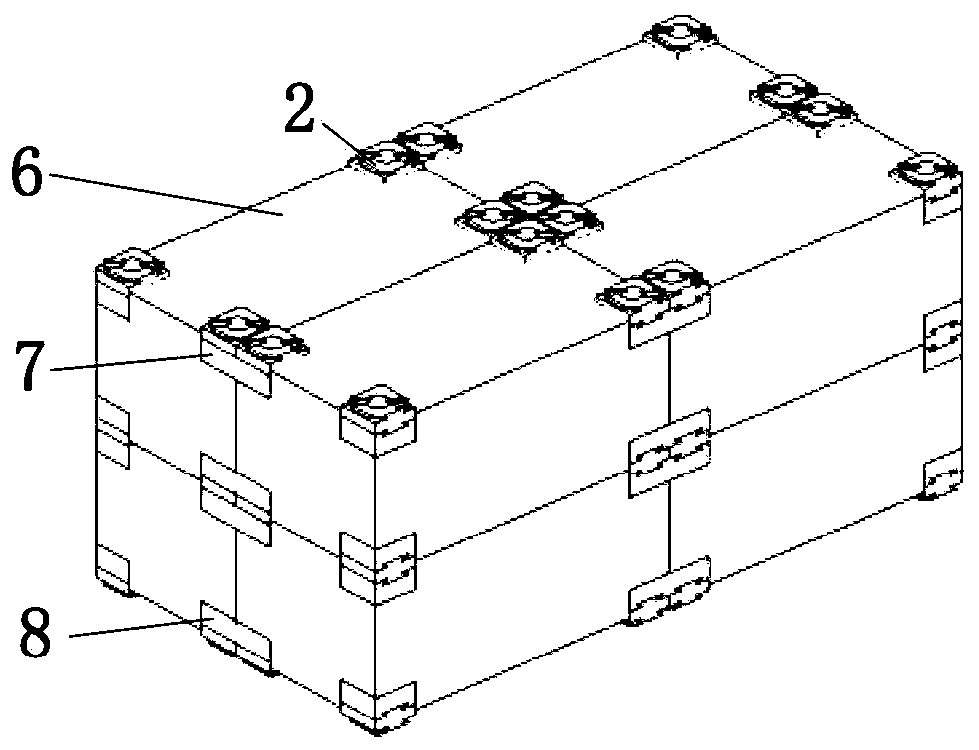

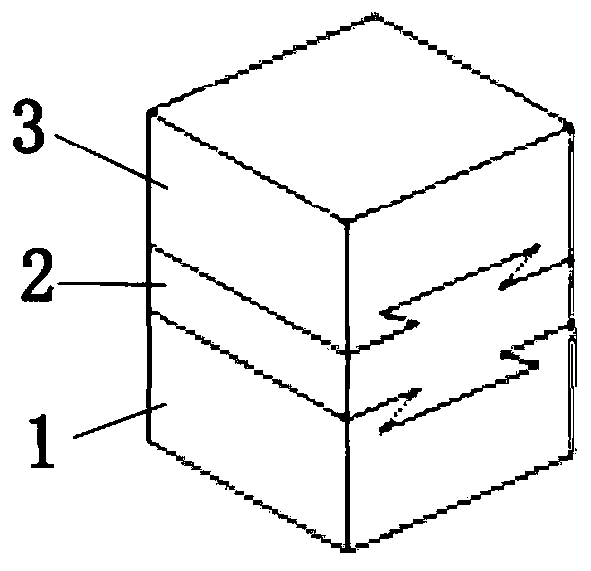

Transverse mortise and tenon type connecting joint for modular building and construction method

PendingCN110792174AIncrease flexibilityImprove stabilityBuilding constructionsMortise and tenonArchitectural engineering

The invention provides a transverse mortise and tenon type connecting joint for a modular building. The transverse mortise and tenon type connecting joint for the modular building comprises lower clamping parts, middle connecting parts and upper clamping parts. The lower clamping parts are arranged at the adjacent four corners of an upper steel structure module, the upper clamping parts are arranged at the adjacent four corners of a lower steel structure module, one ends of the middle connecting parts are connected with the top faces of the lower clamping parts in a buckling manner, the otherends of the middle connecting parts are connected with the bottom faces of the upper clamping parts in a buckling manner, and the top faces of the lower clamping parts are connected with the bottoms of the upper clamping parts through the middle connecting parts in a buckling manner. The invention further provides a construction method of the transverse mortise and tenon type connecting joint forthe modular building, by means of the detachable design, the structure is simple, the production efficiency is high, and operation is easy and convenient; the installation position is flexible, and the direction is adjustable; a module unit composed of the connecting joint and the steel structure modules can move and be installed overall, and the space model plasticity is high; manufacturing can be conducted in advance, and the construction period is shortened; diversity of the connecting joint is achieved, the application range of the module unit is enlarged, and stability of the module unitis improved.

Owner:MCC TIANGONG GROUP

A testing device and method for a thin-film electrode of a solid oxide fuel cell

ActiveCN109725025BPrecise control of shapeAvoid destructionResistance/reactance/impedenceMaterial resistanceThin film electrodeFuel cells

The invention discloses test equipment and method of a film electrode of a solid oxide fuel cell, and belongs to the field of the electrochemistry test. The equipment comprises a high-temperature heating stage, an ohm meter, an electrochemical workstation, a current collection layer spraying mold and a probe test component; the current collection layer spraying mold comprises a glass baseplate, ablocking sheet, and a hollow masking sheet; the probe test component comprises a bevel probe and a plane spiral probe; the method comprises electrical test and electrochemical test, the film electrodecan be tested by using a test probe combination according to a specific test demand. Through the test equipment disclosed by the invention, the quick precise test of the electrical performance and the electrochemical performance of the film electrode in the temperature range of 600-1000 DEG C, and the test equipment has the features of being accurate in test, high in efficiency and space-saving.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com