Air-tightness gap-adjustable type spark-gap switch operation method

A spark gap switch and operating method technology, applied in the direction of spark gap adjustment, etc., can solve the problems of not too large breaking voltage and current, small breaking power, and long time, so as to enhance anti-interference energy and improve reliability performance, improving working life and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

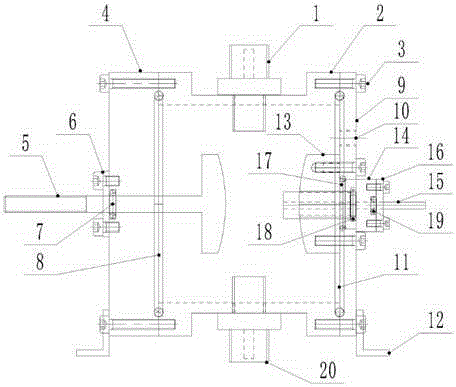

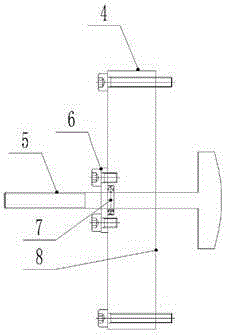

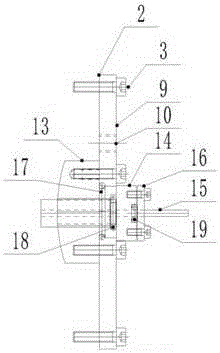

[0025] (1) Set a spark gap switch with adjustable airtight gap, see attached figure 1 , 2, 3, the switch includes an insulating shell 2, anode flange 4, anode 5, cathode flange 9, cathode 13, trigger electrode 15, trigger electrode insulation sleeve 14 composed of the switch body. The anode flange 4 and the cathode flange 9 are respectively fixed on both sides of the insulating casing 2 by bolts 3, the anode 5 is placed in the opening in the center of the anode flange 4, and the cathode 13 is fixed on the cathode flange 9 inside the cavity by bolts. Above, the trigger electrode 15 is placed inside the trigger electrode insulating sleeve 14 and placed together in the central opening of the cathode 13 .

[0026] The anode flange 4 and the insulating casing 2 are sealed by the anode flange sealing gasket 8 , and the cathode flange 9 and the insulating casing 2 are sealed by the cathode flange sealing gasket 11 . The anode 5 and the anode flange 4 are sealed by the anode sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com