Transverse mortise and tenon type connecting joint for modular building and construction method

A technology of transverse tenon and mortise joints, which is applied in the direction of building and building structure, can solve the problems of restricting the freedom of steel structures, increasing the difficulty of on-site operation, and unable to adjust the direction of the nodes, so as to increase the stability, shorten the construction period, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

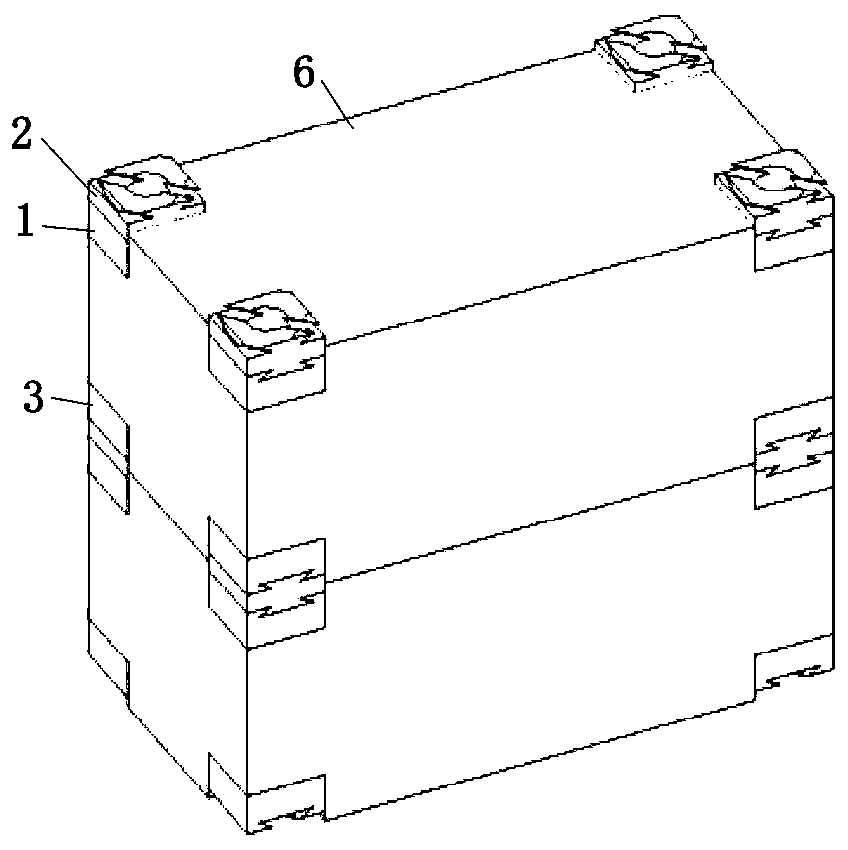

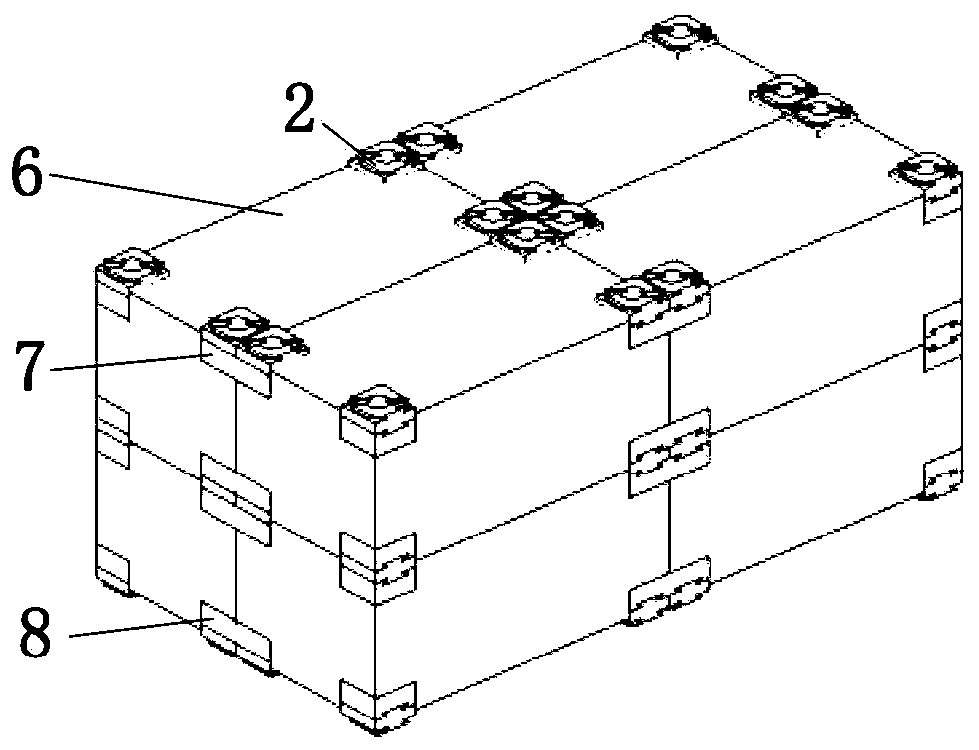

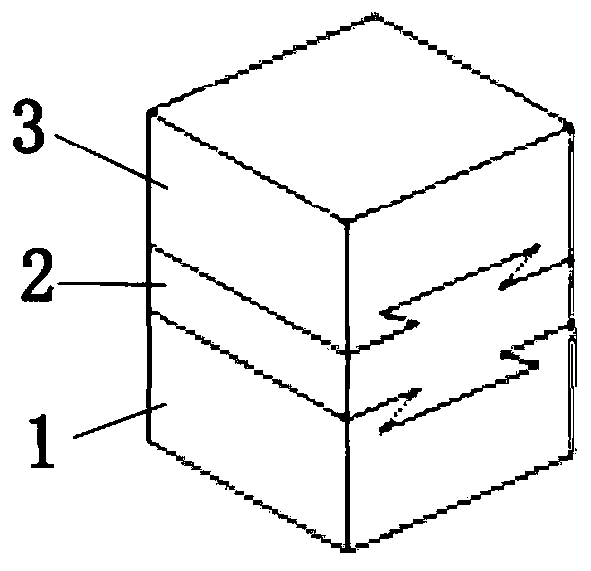

[0039] In one embodiment of the present invention, as figure 1 , image 3 As shown, a modular building horizontal mortise and tenon connection node, including: a lower clip 1, an intermediate connector 2, an upper clip 3, and the lower clip 1 is set on the adjacent four corners of the previous steel structure module 6 , the upper clips 3 are arranged on the adjacent four corners of the next steel structure module 6; The bottom surface of the lower clip 1 is snap-connected with the bottom surface of the upper clip 3 through the intermediate connector 2.

[0040] Preferably, the two sides and the bottom surface of the lower clip 1 are flush with the surface of the last steel structure module 6 and fixedly connected; the two sides and the top surface of the upper clip 3 are flush with the surface of the next steel structure module 6, and secure the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com