Patents

Literature

46results about How to "Construction time is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

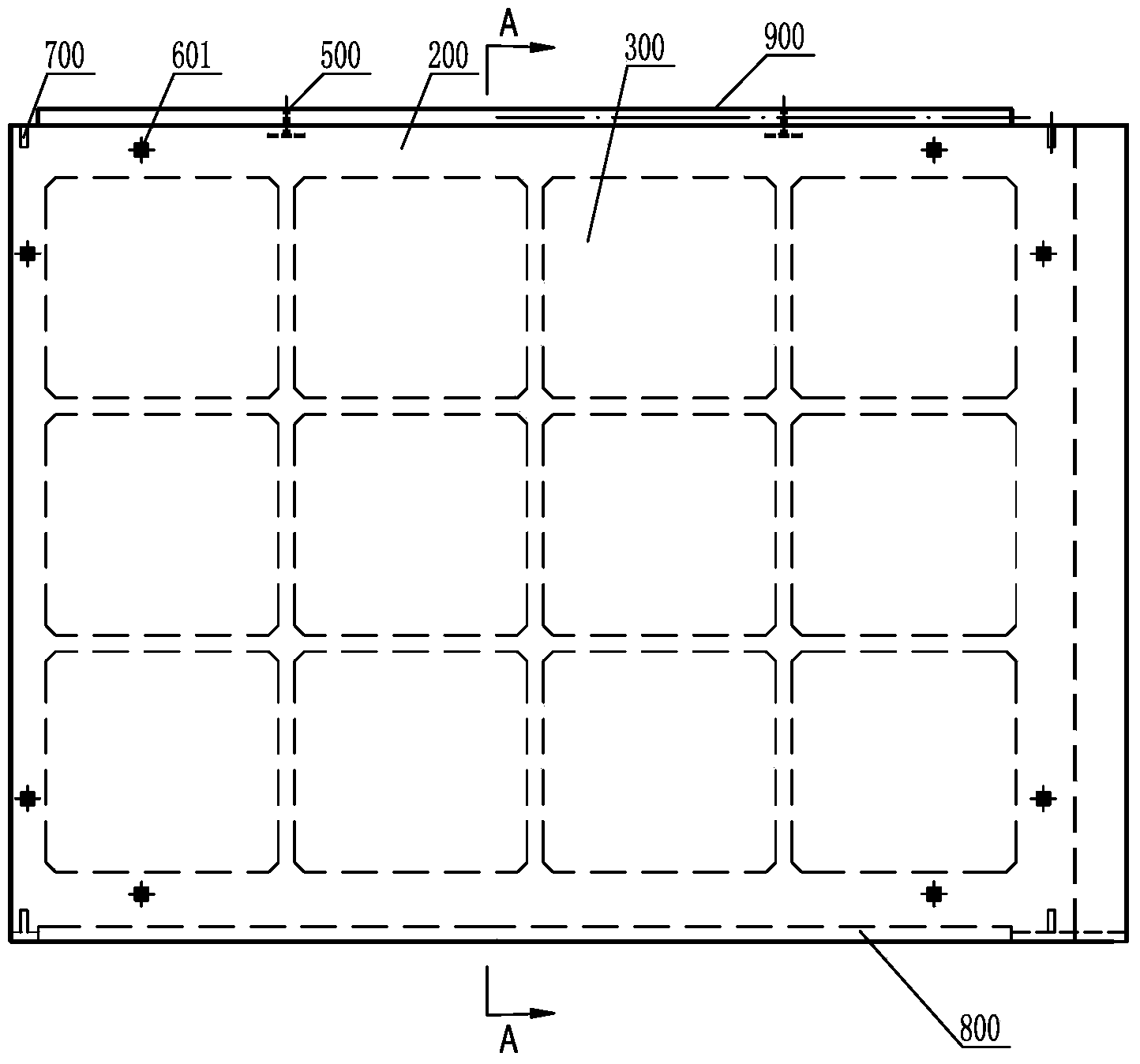

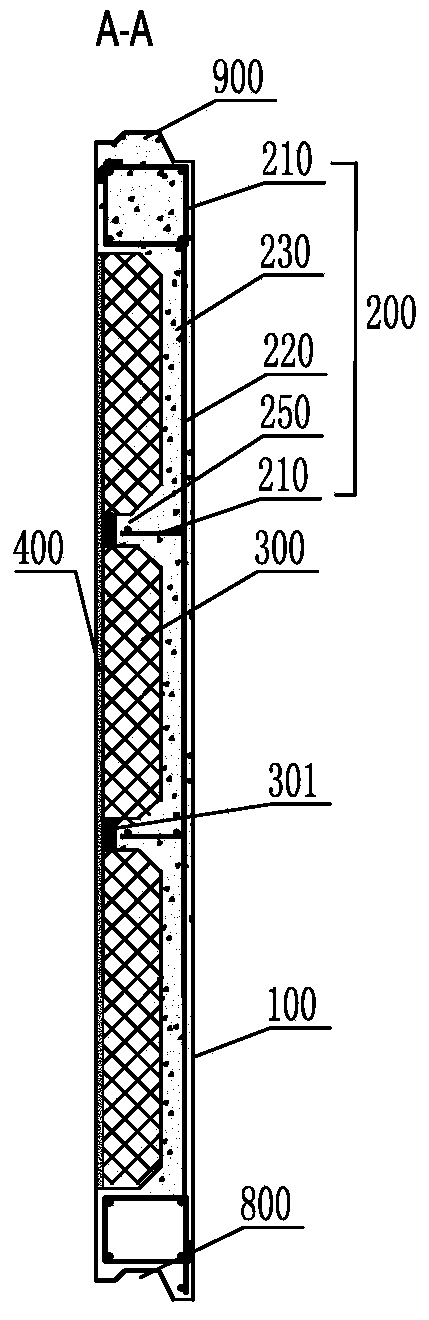

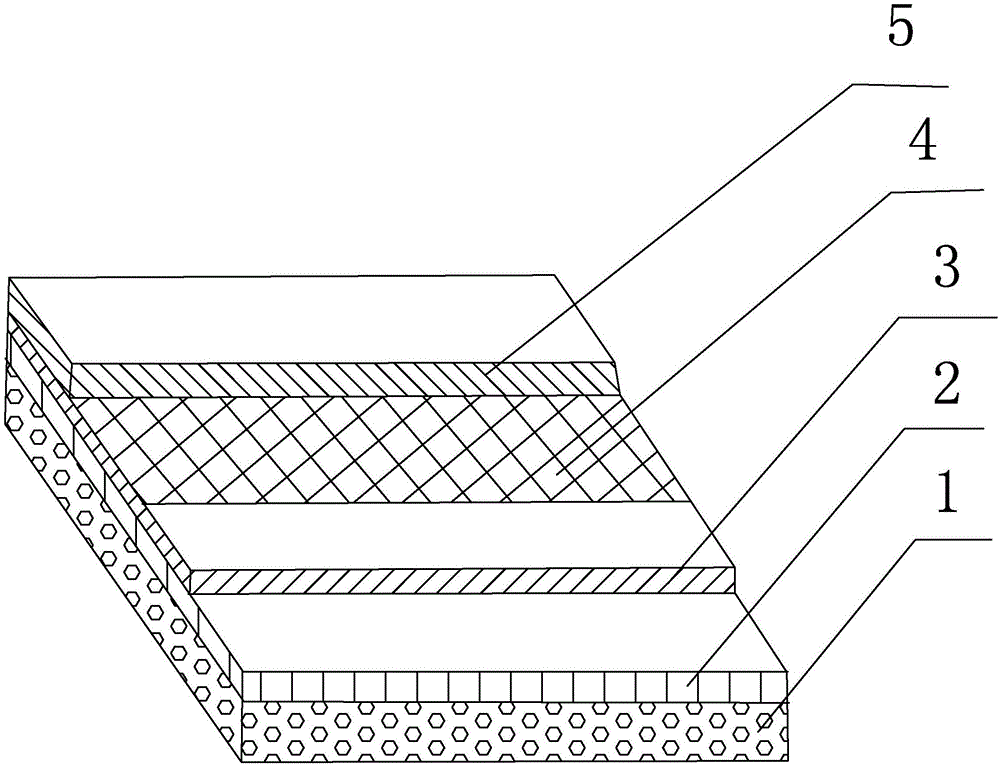

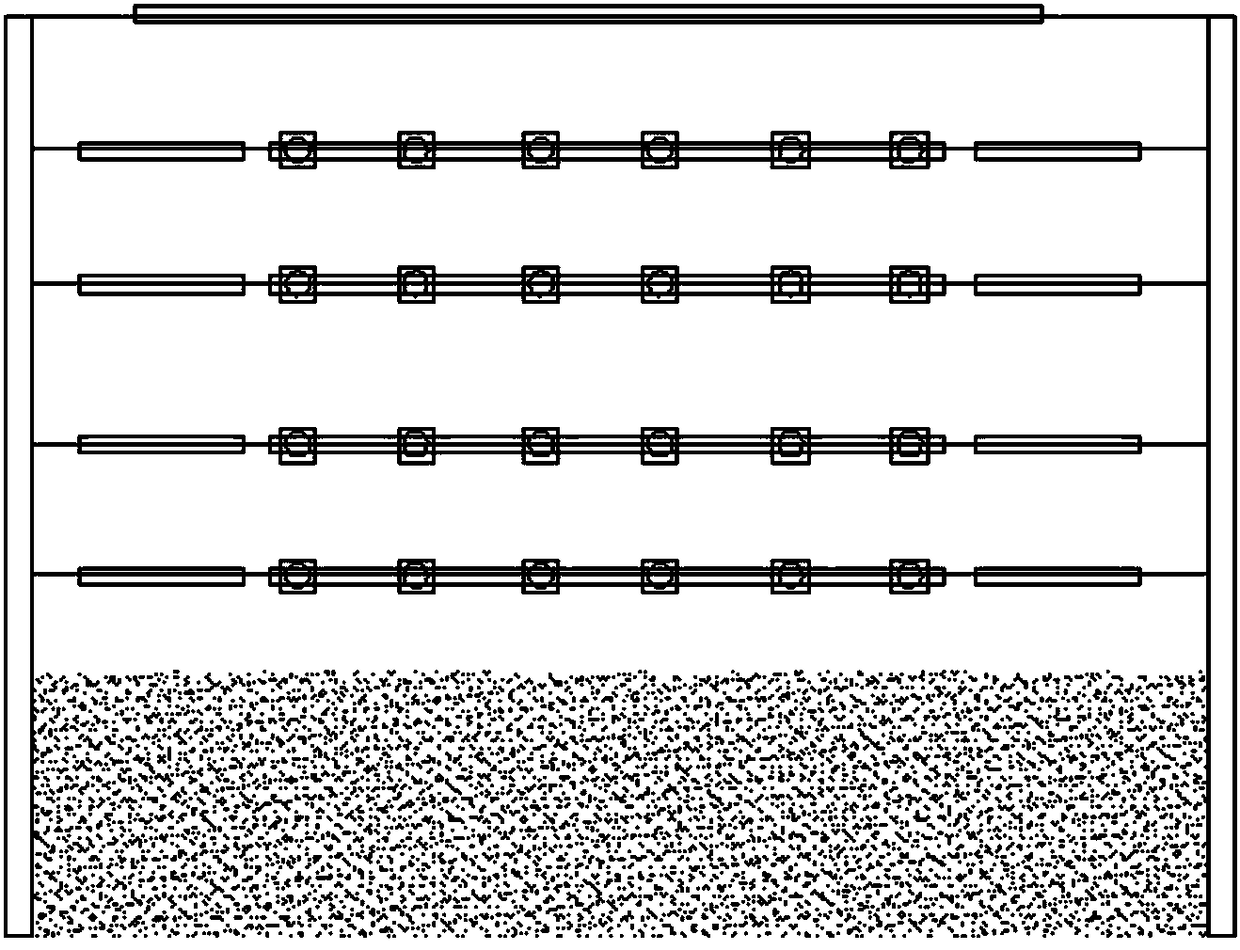

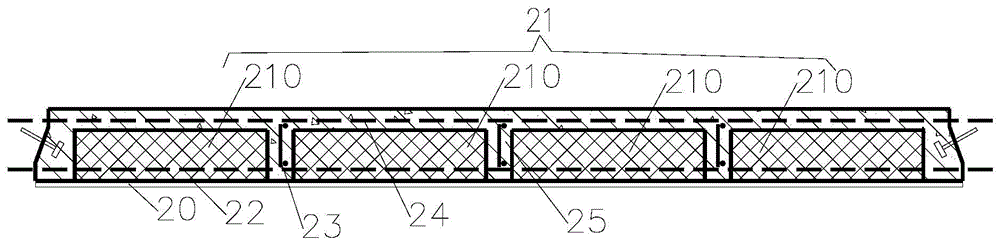

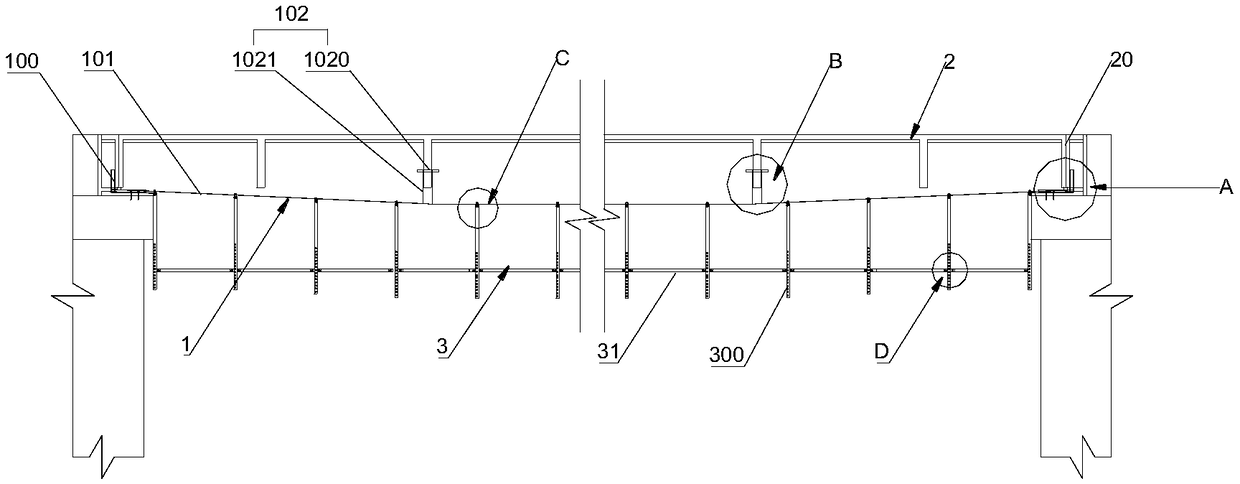

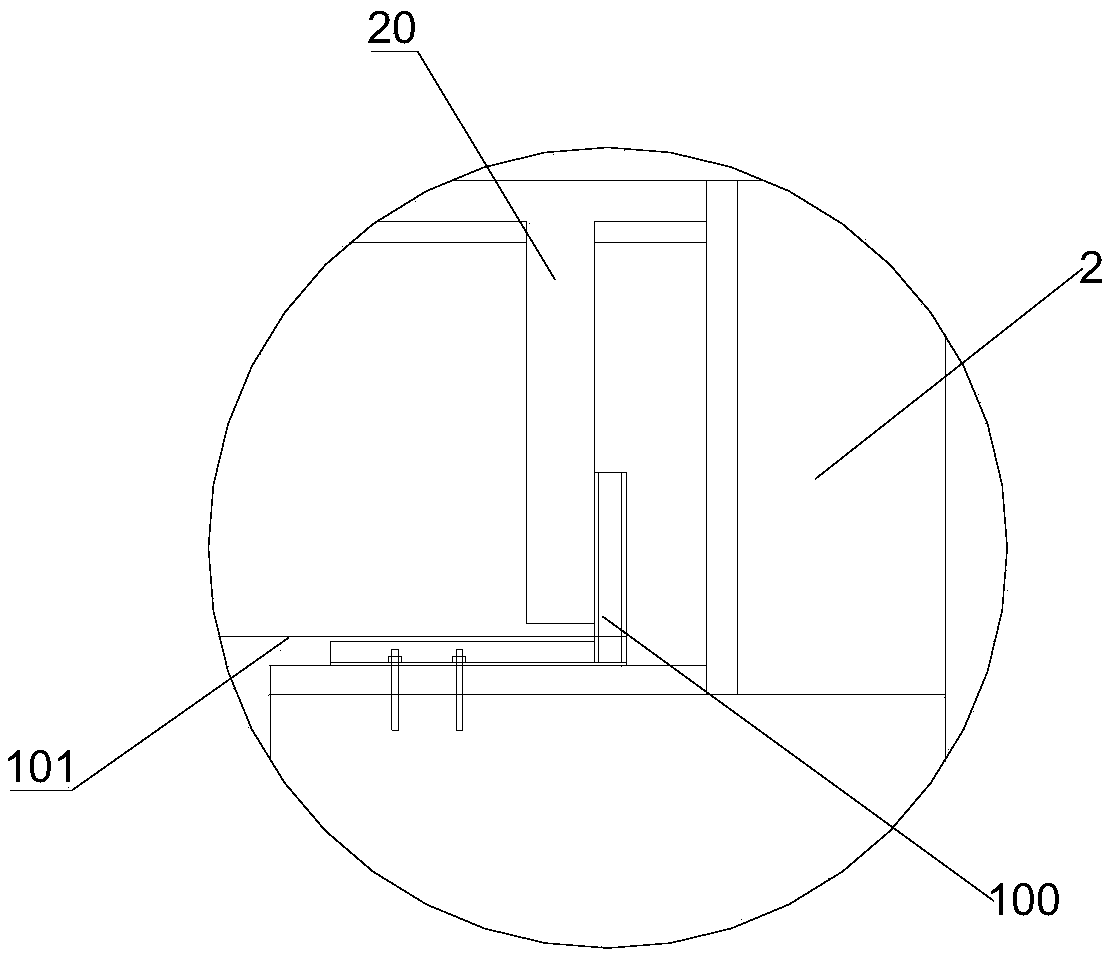

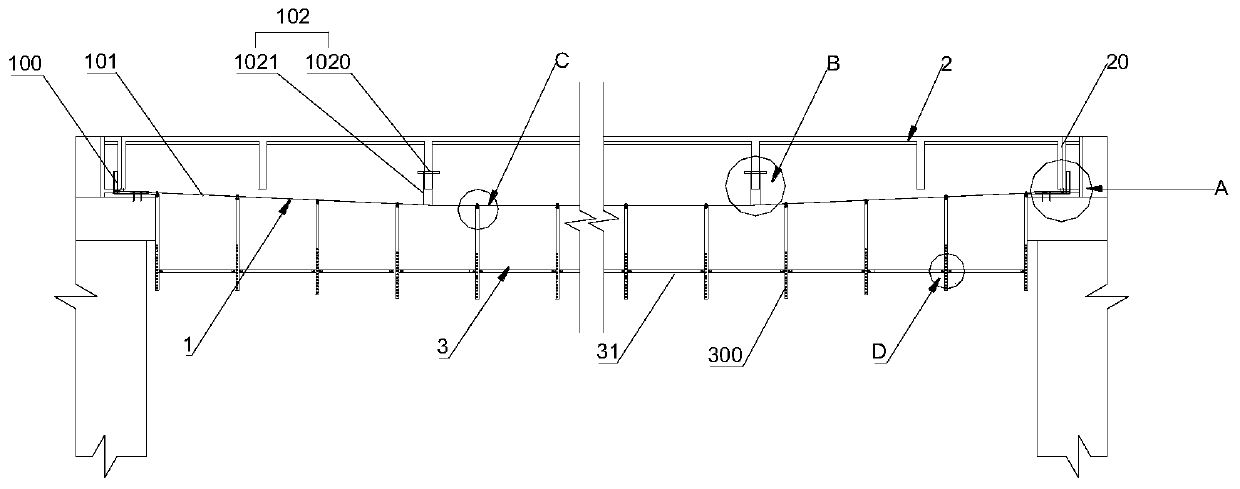

Prefabricated and light floor cover plate and industrialized building house floor plate structure

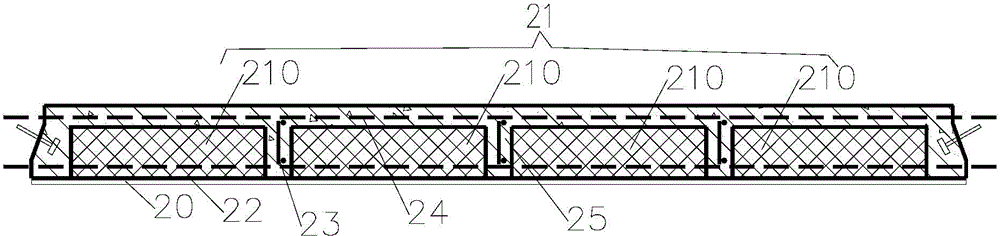

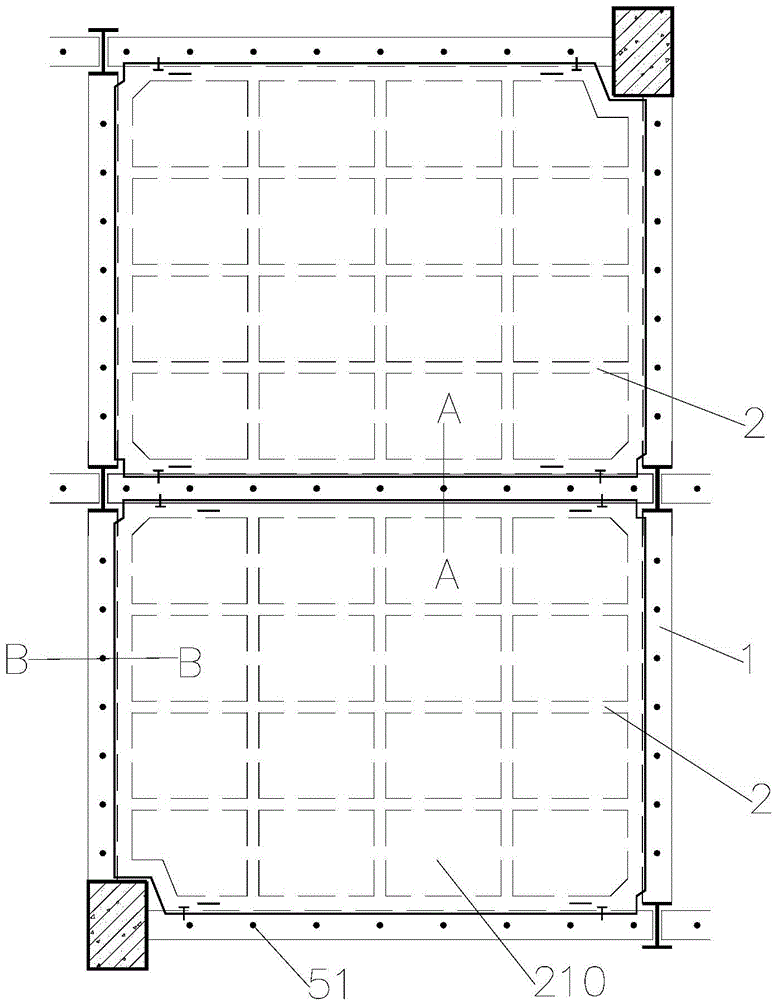

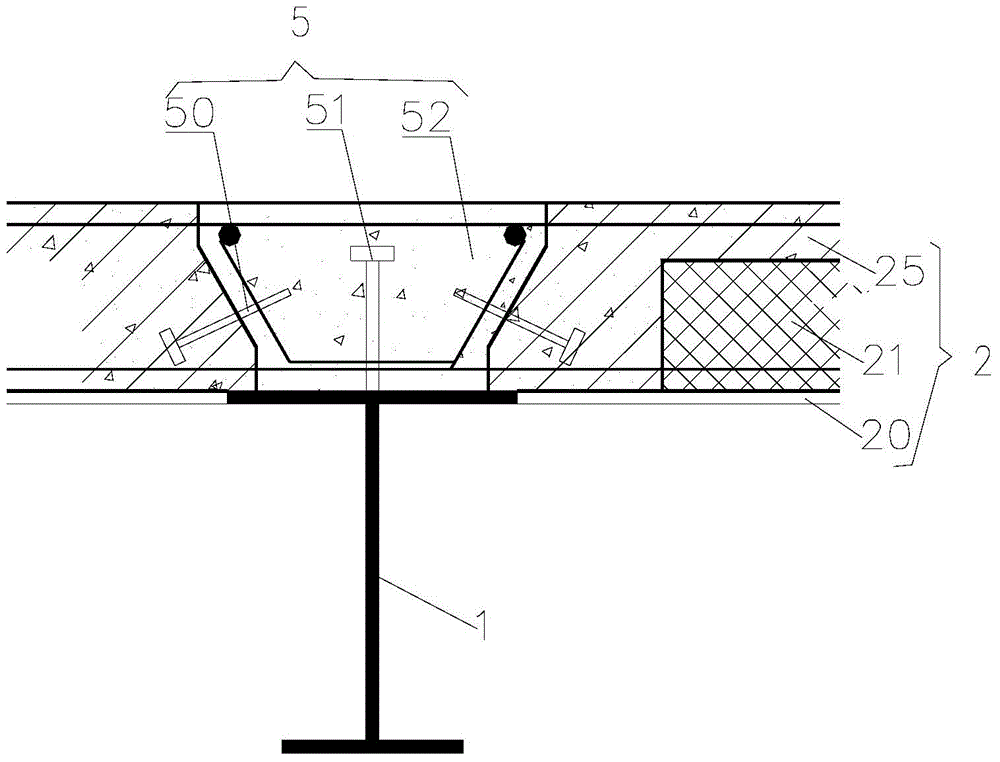

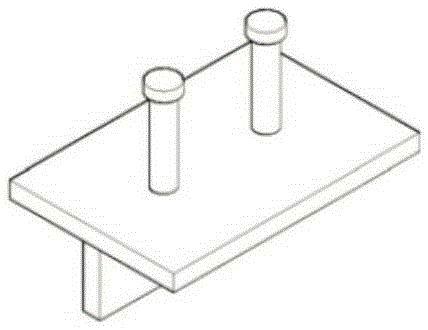

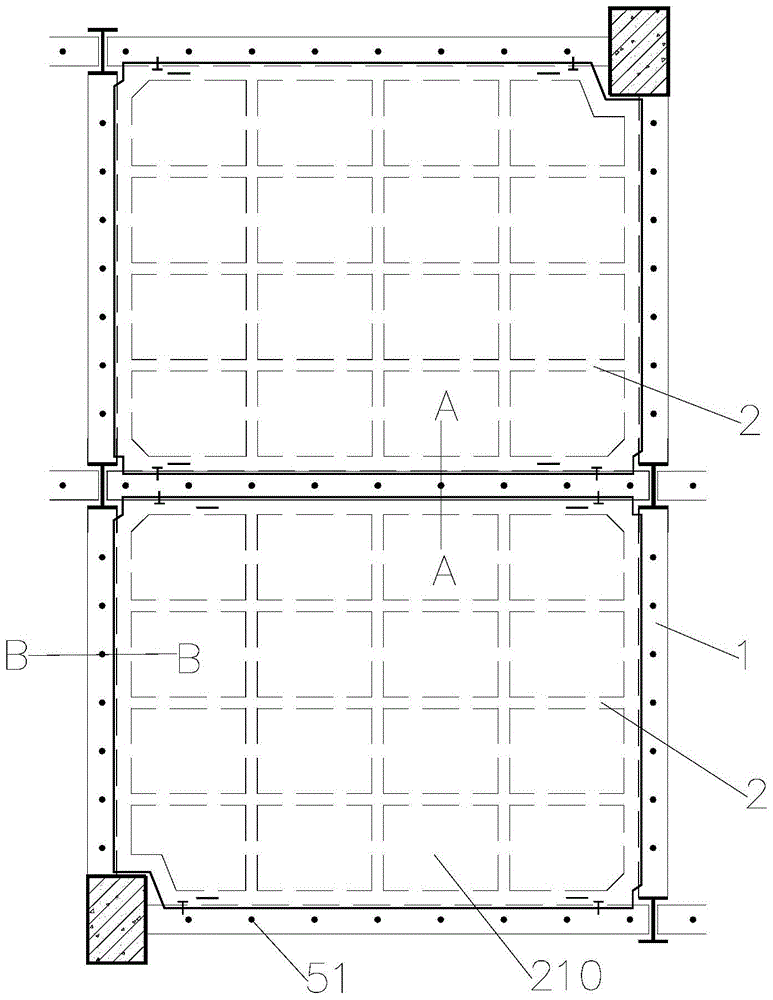

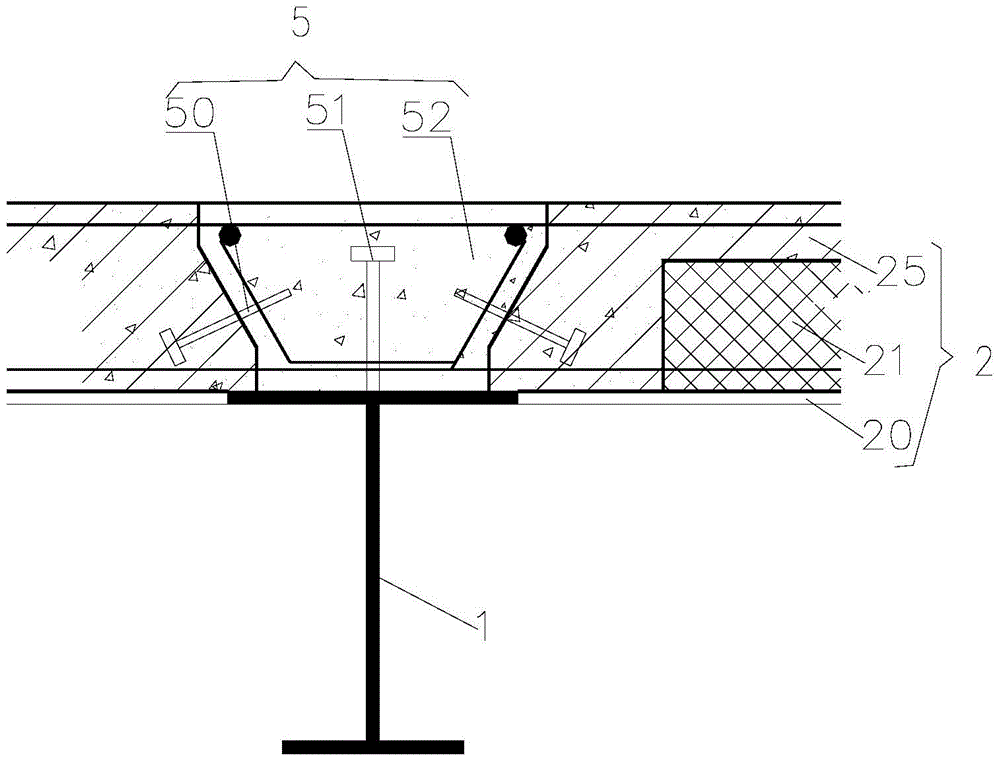

The invention discloses a prefabricated and light floor cover plate and an industrialized building house floor plate structure. The prefabricated and light floor cover plate comprises a facing layer, light packing layers where light packing blocks on the back face of the facing layer are arranged and bonding piece for fixing the facing layer and the light packing layers in a locating mode, steel reinforcement framework sheets are arranged between the light packing blocks, steel reinforcement meshes are laid at the backs of the light packing layers, and concrete structure layers are poured at the backs of the light packing layers and extend to gaps between the light packing layers to enable the facing layer, the steel reinforcement meshes, the steel reinforcement framework sheets and the light packing layers to be bonded to form a whole. The industrialized building house floor plate structure comprises a plurality of prefabricated and light floor cover plates transversely and fixedly arranged on a supporting beam, prefabricated lower sunk grooves, prefabricated balcony assemblies and cast-in-place concrete connecting pieces. The industrialized building house floor plate structure is simple in construction process and has the advantages of being light in weight, high in anti-shocking capacity, safe and the like.

Owner:黄涛 +1

Novel efficient assembly-type reinforced concrete composite beam

InactiveCN105350445ASolve corrosiveSolve Concrete CrackingBridge structural detailsBridge materialsReinforced concreteEconomic benefits

The invention discloses a novel efficient assembly-type reinforced concrete composite beam, and belongs to the technical field of bridge construction. The novel efficient assembly-type reinforced concrete composite beam comprises a concrete bridge deck and a steel girder; the concrete bridge deck is arranged on the steel girder; a top flange plate of the steel girder is fixedly connected with a ribbed plate extending in the vertical direction of the steel girder; the bottom of the concrete bridge deck is provided with a channel extending in the vertical direction of the steel girder; the ribbed plate is arranged in the channel; two side edges of the top flange plate are fixedly connected with rubber sealing strips extending in the vertical direction of the steel girder; the bottom surface of the concrete bridge deck is in lap joint with the rubber sealing strips; the top flange plate, the rubber sealing strips, the bottom surface of the concrete bridge deck, and the channel of the concrete bridge deck defines a grouting channel; and the grouting channel is filled with a high-strength pouring sealant material. According to the invention, a series of problems brought by processing of reinforced concrete connecting pieces and cast-in-place of jointed concrete are effectively avoided, the construction quality is guaranteed, at the same time, the on-site work efficiency is improved, and the novel efficient assembly-type reinforced concrete composite beam is more environmentally friendly, and has good economic benefits.

Owner:CCCC SECOND HARBOR ENG +1

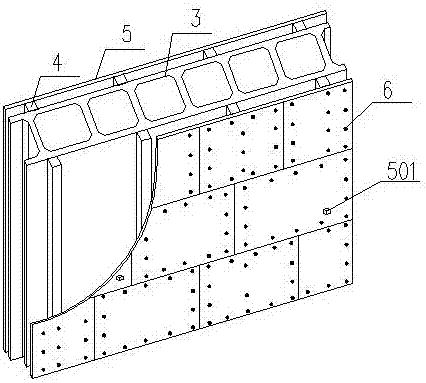

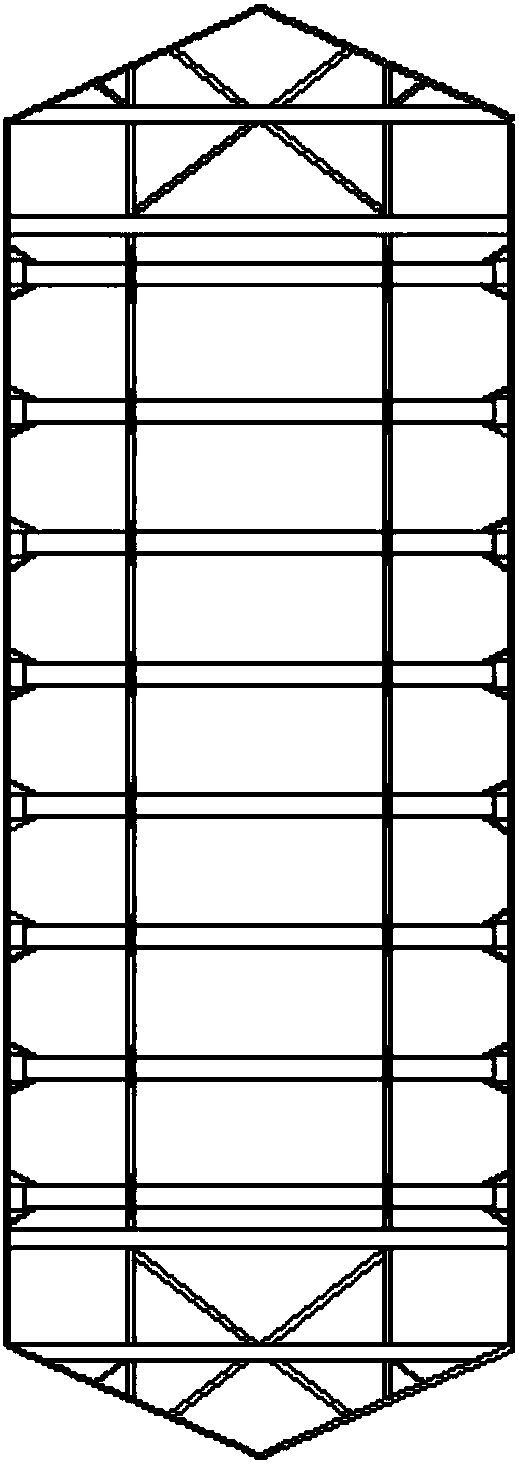

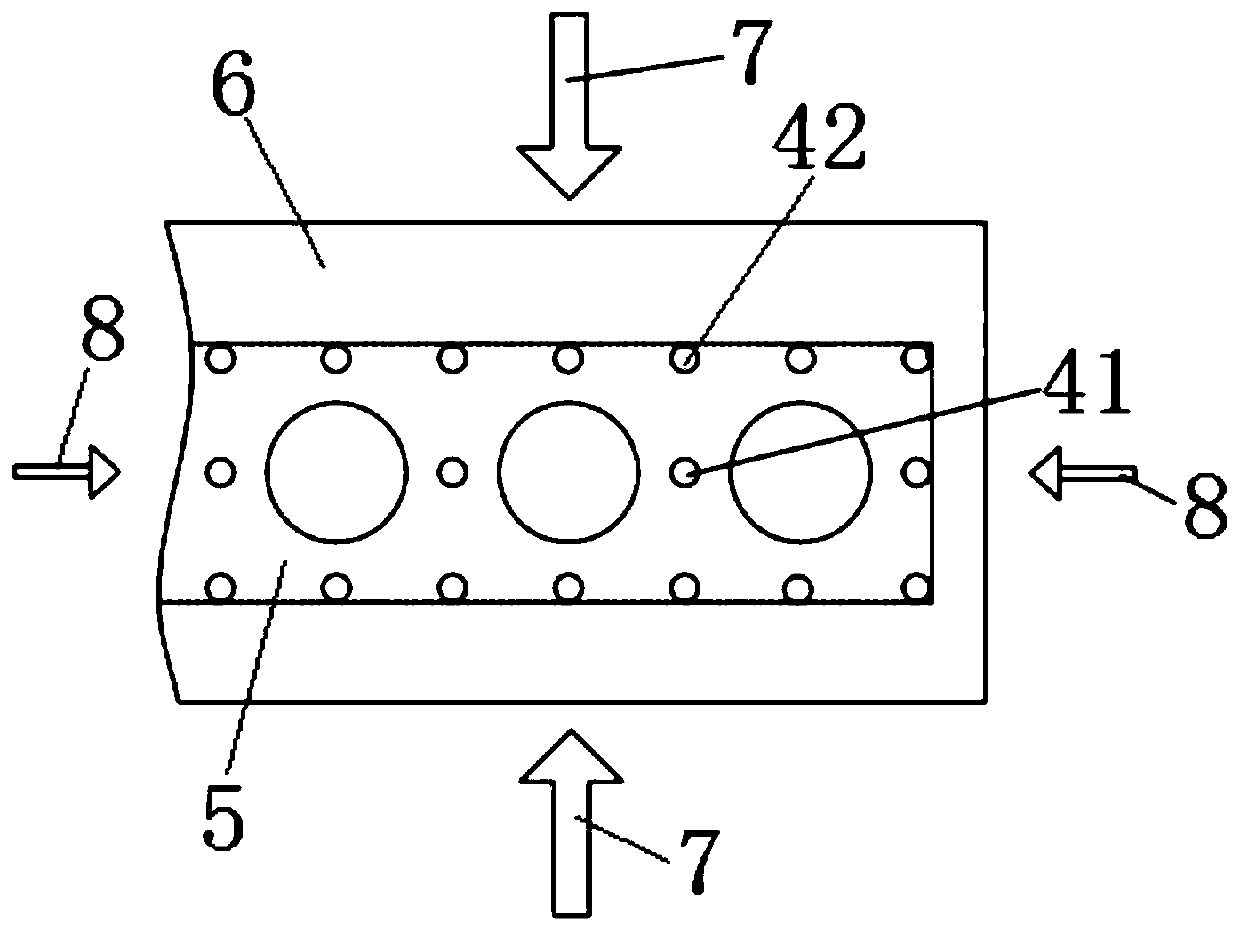

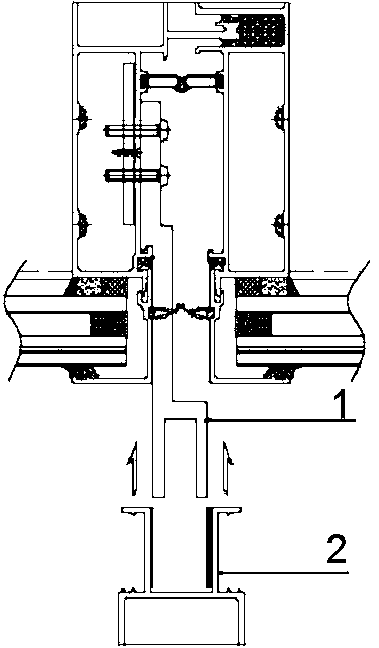

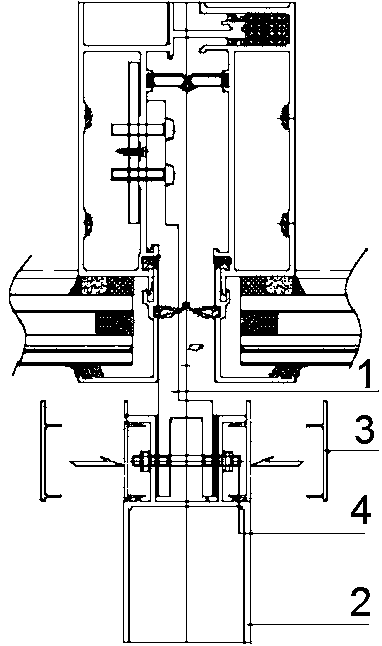

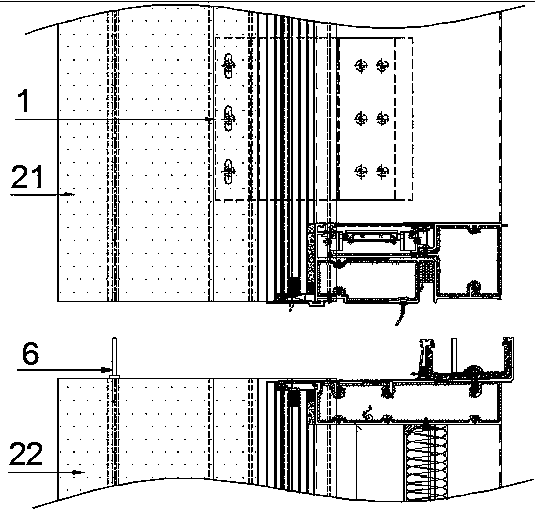

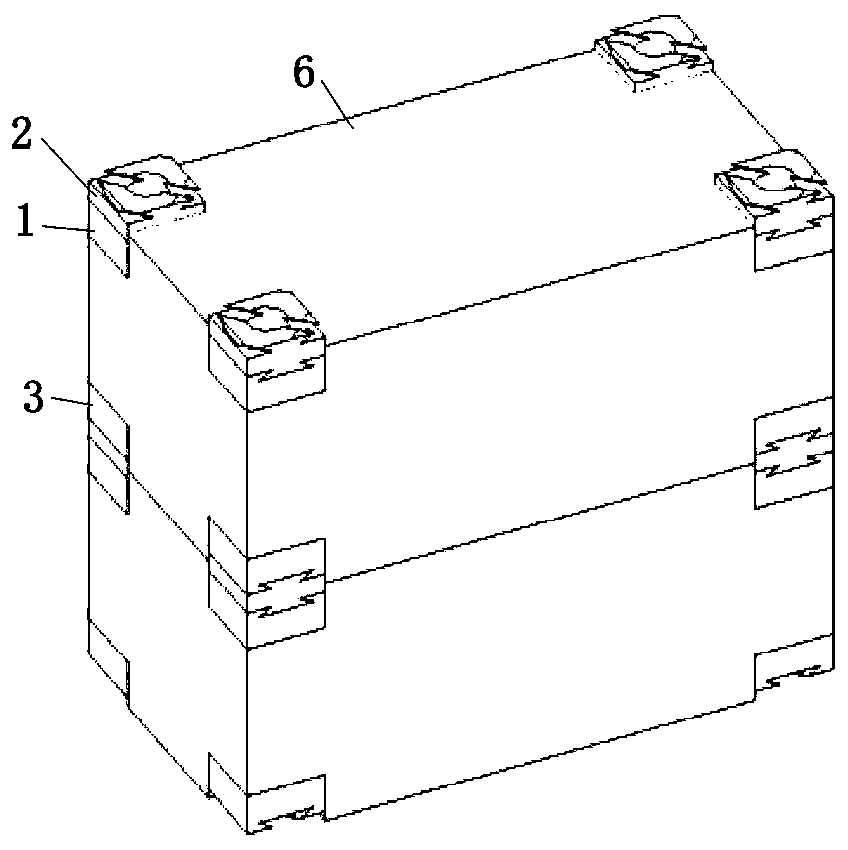

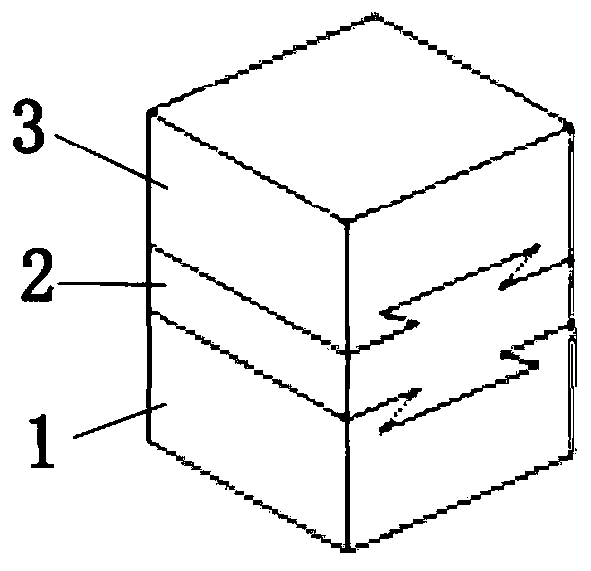

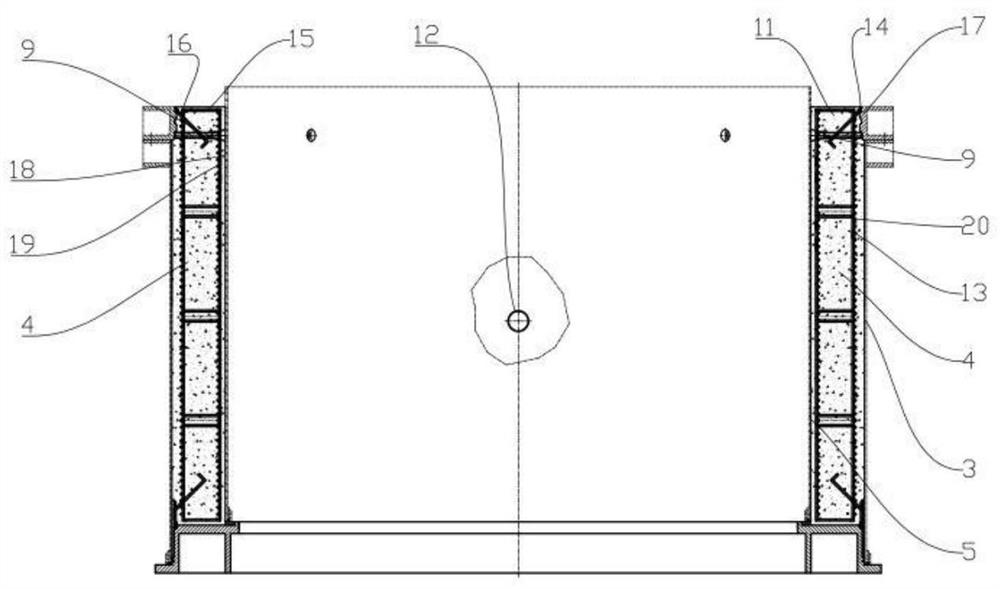

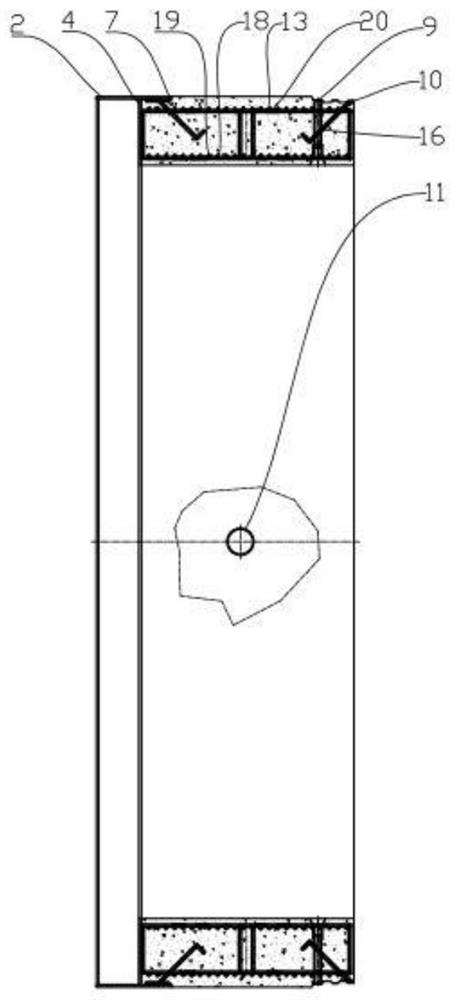

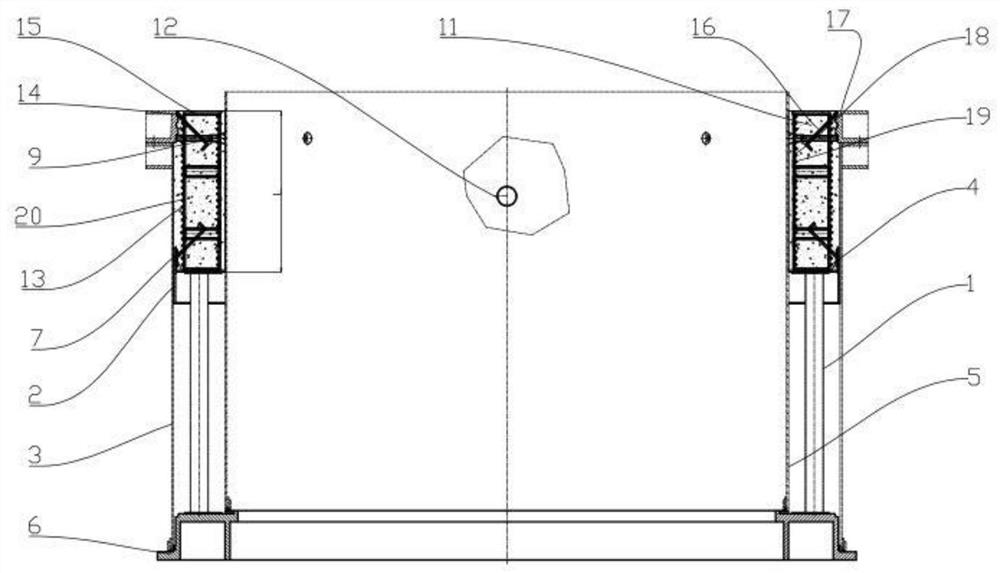

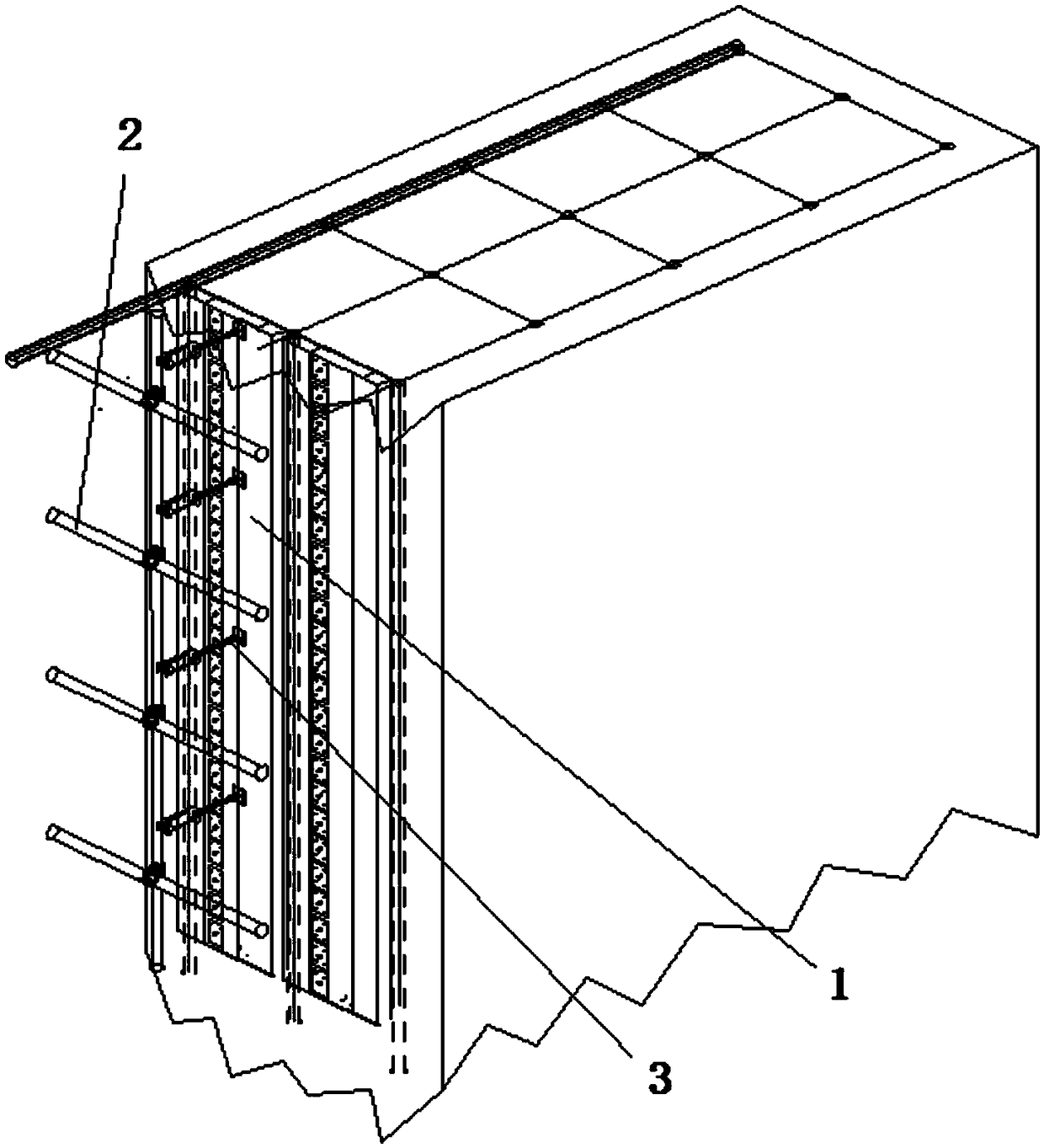

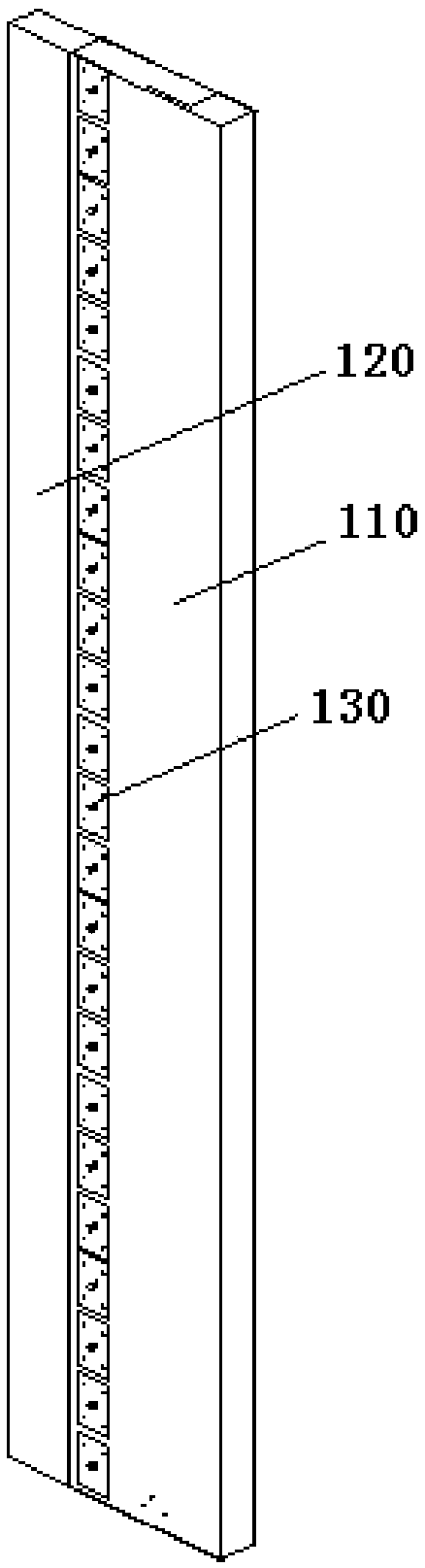

Integrally prefabricated multifunctional composite external wall panel and industrial building external wall

The invention discloses an integrally prefabricated multifunctional composite external wall panel and an industrial building external wall. The external wall panel comprises an outer decoration layer, a reinforcing bar fine aggregate concrete structural layer, a light-weight heat insulation layer and an indoor decoration layer which are fixedly connected from the outside to the inside, wherein the reinforcing bar fine aggregate concrete structural layer is filled into the light-weight heat insulation layer for forming plate ribs; heat insulation pads are arranged on the end surfaces of the plate ribs; first connecting elements are arranged on the periphery of the external wall panel; the top and the bottom of the external wall panel are respectively provided with positioning mechanisms; the top of the external wall panel is provided with hanging rings; and pre-buried accessories are arranged in the external wall panel. The external wall is formed by the external wall panels through vertical and horizontal distribution, surrounding and shielding, the periphery of each external wall panel is provided with a connecting mechanism connected with a main body stress component; the back part of the connecting mechanism is pre-buried in the reinforcing bar fine aggregate concrete structural layer of the external wall panel; and the adjacent external wall panels are sealed and connected through telescopic sealing elements. The integrally prefabricated multifunctional composite external wall panel and the industrial building external wall have the advantages that the industrial production can be realized; the weight is light; the transportation and the construction are convenient; the heat insulation performance and the sound isolation performance are good; the intensity and the weatherability are good; the internal and external decoration construction is not needed; and the installation is convenient.

Owner:黄涛 +1

Non-demolition type reforming and refitting construction method

InactiveCN106638209AThe detection and collection items are reasonable and applicableMature technologyIn situ pavingsRoads maintainenceService qualityEngineering

The invention discloses a non-demolition type reforming and refitting construction method. The method particularly comprises the following four steps: (1) acquiring information data of old road traffic conditions; (2) evaluating the diseases and defects of an old road; (3) formulating an operation scheme for reforming and refitting the old road, and performing construction; (4) evaluating and tracking the refitting effect. When the construction method is used for reforming and refitting an urban old and damaged road with a rigid surface layer, the resources of the old road are fully and reasonably utilized, so that excellent service quality performance is obtained; the service life period of the refitted road is long; furthermore, compared with a mode of dismantling the old road and then building a new road, the construction method greatly reduces old structure demolition work load and resource consumption and greatly shortens the construction period; therefore, the construction method corresponds with the development direction of high quality and low consumption, fastness and high efficiency as well as energy conservation and environmental protection, thus being remarkable in promotion and application values.

Owner:石家庄市道桥管理处 +1

Anti-flaming bag-packing small coal fast building material capable of flexibly bearing pressure

The invention discloses quick a laying material capable of realizing the flexible load bearing and the fire retardation of bagged crushed coal, belonging to the building material. The quick laying material is made of various crushed coals, 20kg debris (less than 3cm, the finer the better), 10kg to 15kg water and 2kg to 4kg composite additive which are evenly stirred and then are packed in a woven bag. The invention has the advantages that: the material adopts composite viscose to fill in the gap between the coal and the debris inside the bag, thereby having good airtightness and preventing the slide between bags during building various wall bodies; when the quick laying material is under the pressure of a top plate and a bottom plate, the material can increase compressive resistance by means of contraction deformation, thereby obtaining the engineering effects that the material realizes deformation without air leakage and is tighter under increasing pressure; and the material which is time-saving, trouble-saving, labor-saving and material-saving, is convenient for construction. The quick laying material can quickly seal a goaf, an old underground chamber and a laneway; moreover, the material which has excellent sealing effect and can resist the pressure of the top plate, is of great significance to the disaster prevention in a gassy mine.

Owner:徐州意创化工科技有限公司

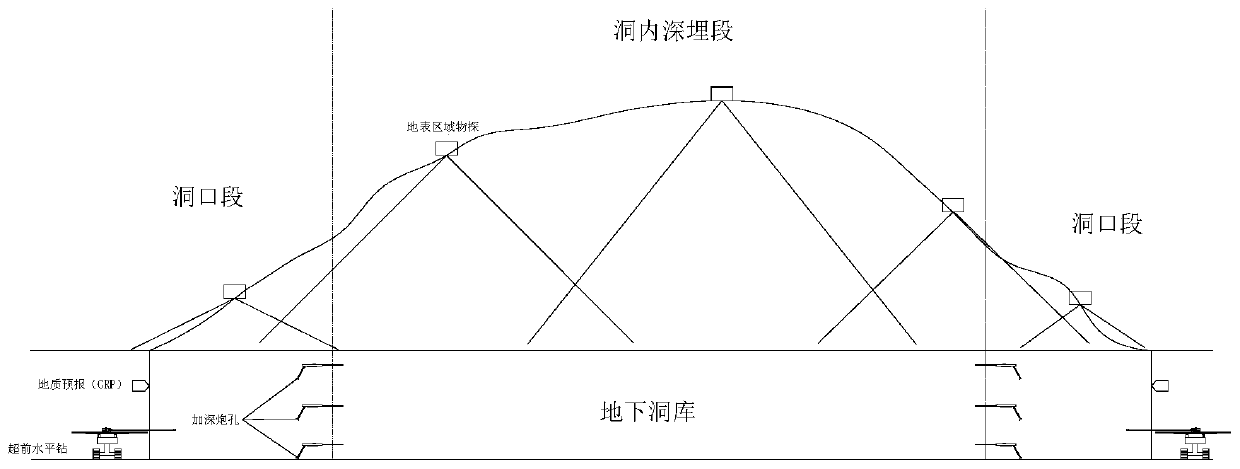

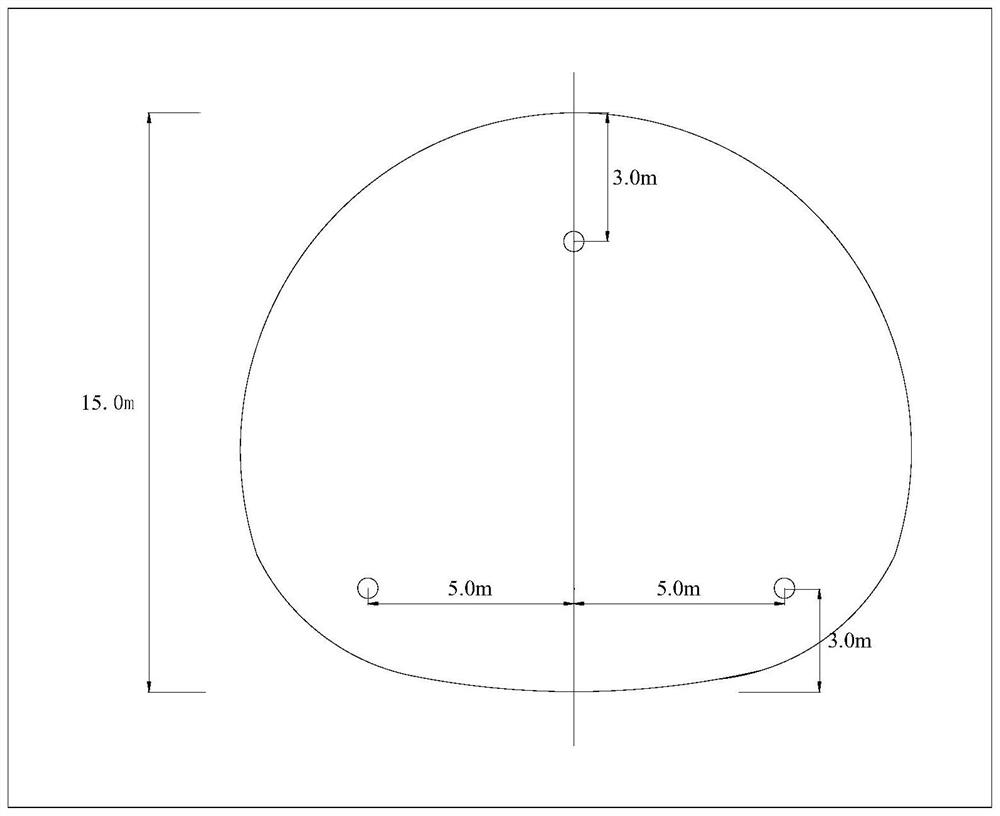

Horizontal geological survey arrangement method for deep buried underground cave depot

ActiveCN111335928AConstruction time is shortReduce labor intensitySurveyUnderground chambersMining engineeringGeotechnical engineering

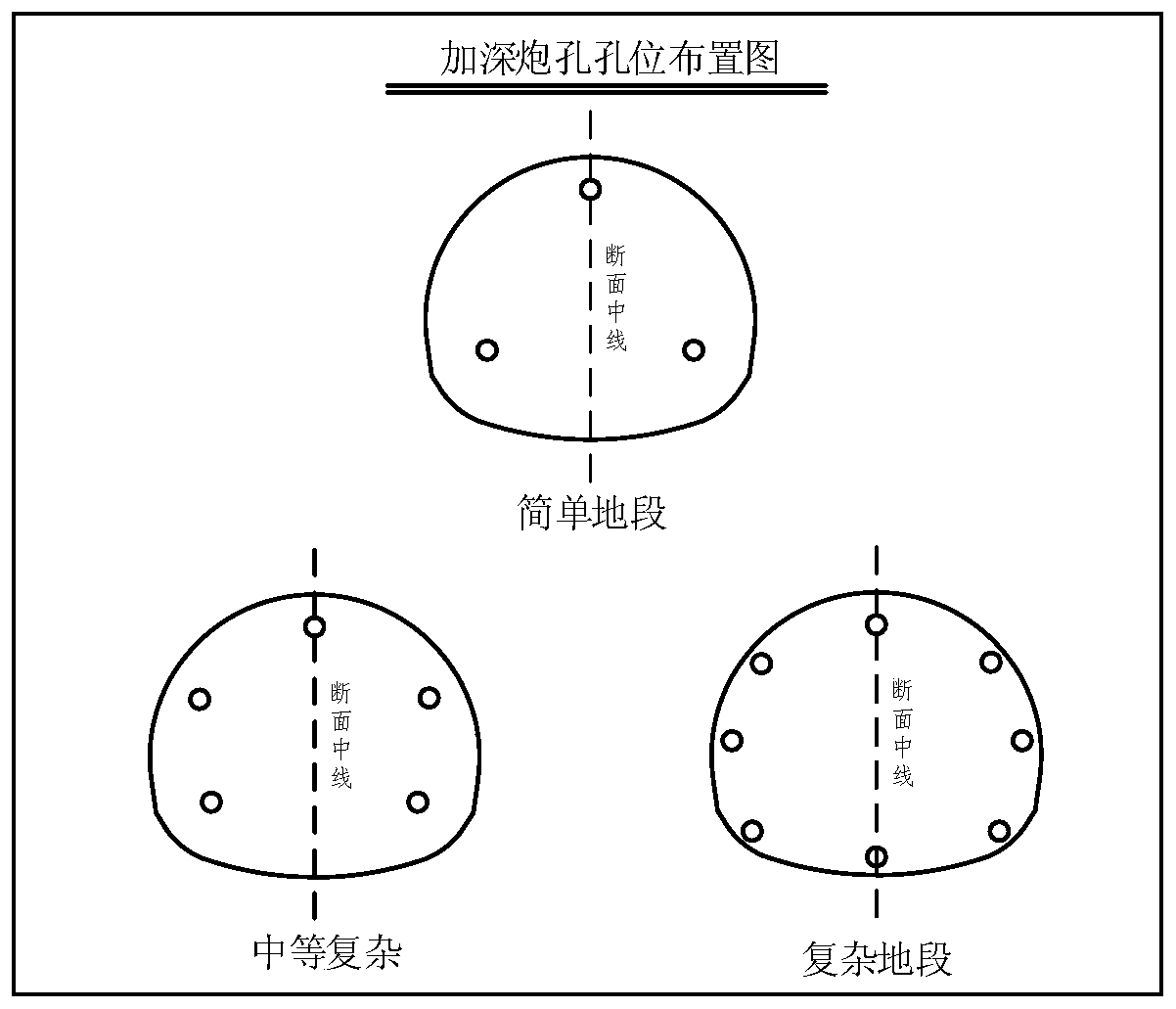

The invention discloses a horizontal geological survey arrangement method for a deep buried underground cave depot. The method comprises the following steps: 1, performing ground survey, forming a measurement area geological background report and a geological survey implementation scheme; 2, carrying out surface area geophysical prospecting, carrying out engineering geological area division, generating a measuring area project geology partition map, and delineating a geophysical prospecting abnormal band; 3, carrying out long-distance horizontal drilling, taking a core and reserving a sample for indoor geotechnical test, and analyzing the front situation of excavation of the cave depot; 4, predesigning a cave depot excavation support; 5, carrying out the tunnel excavation of the cave depot, and carrying out intra-hole advanced geophysical prospecting before excavation; 6, carrying out deep blast hole detection, and judging front geological conditions; 7, comparing advance geophysical prospecting information, and dynamically adjusting support design parameters in time; and 8, summarizing detection results, constructing an underground cavern three-dimensional geological model, carrying out cave depot support design and timely support modification according to the detected geological conditions so as to guarantee the tunnel excavation safety. According to the method, the geological condition of the underground cave depot can be accurately surveyed, and the construction time is short.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

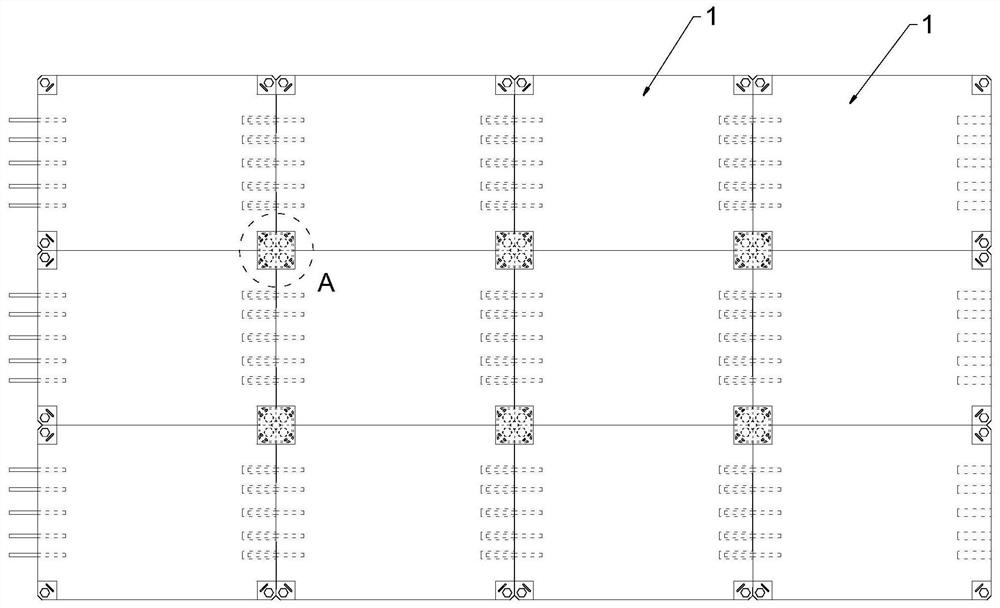

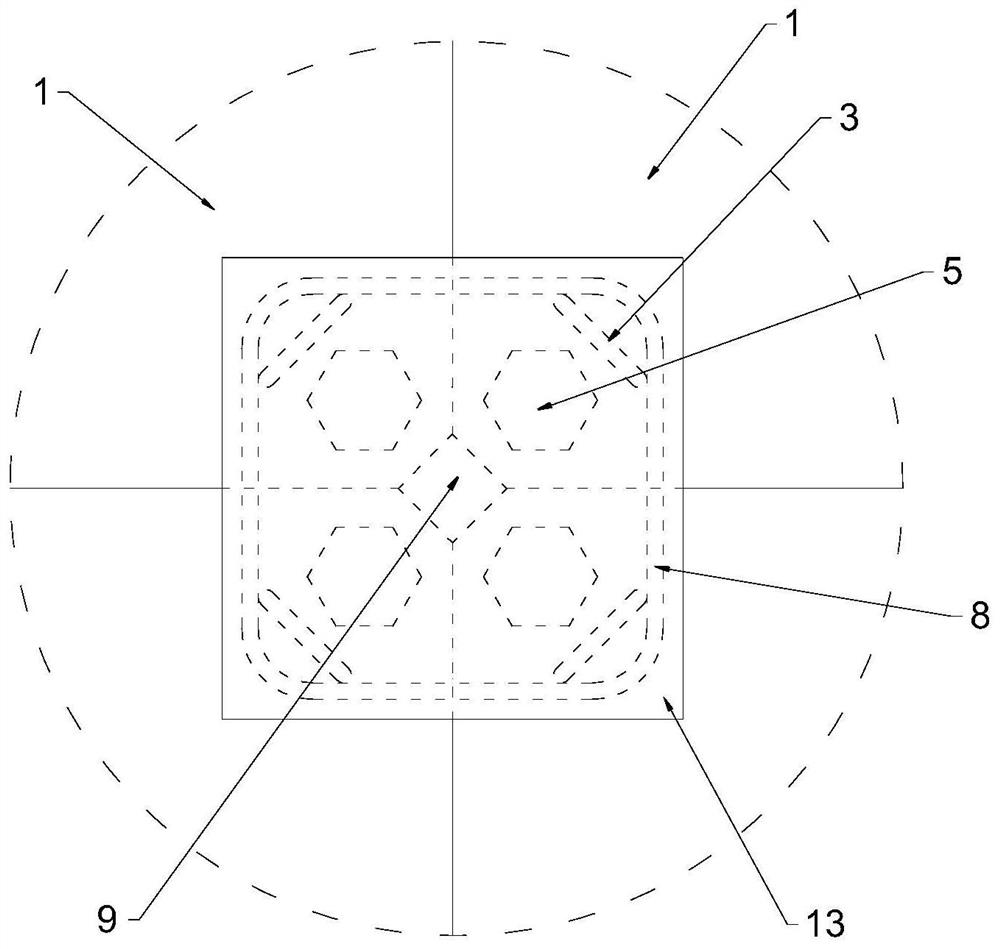

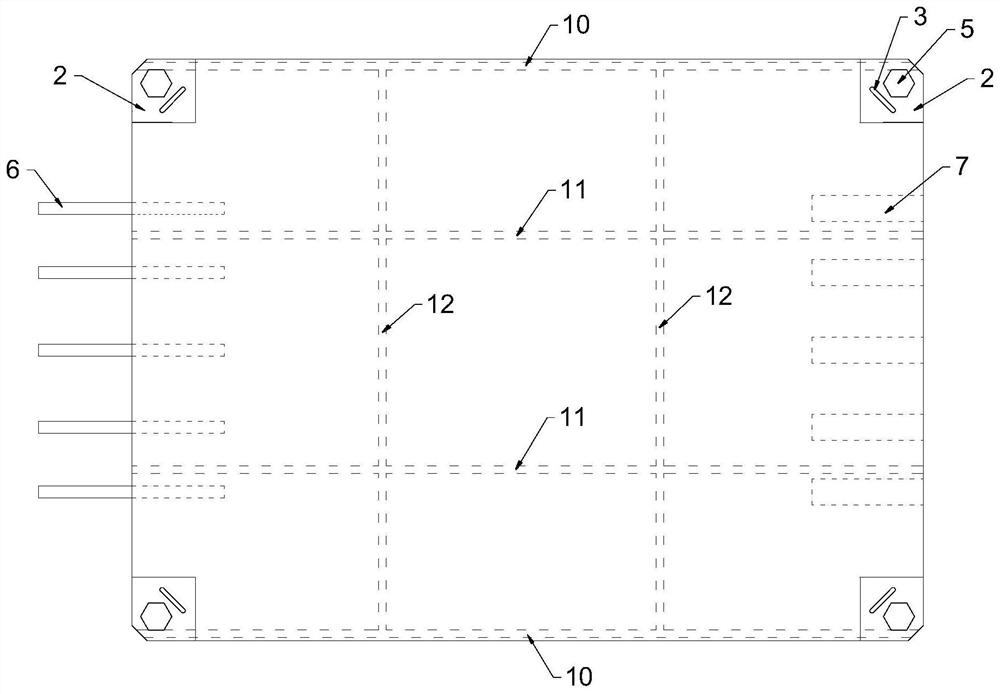

Prefabricated concrete pavement and construction method thereof

PendingCN112227133AShort on-site construction timeConstruction time is shortSingle unit pavingsCeramic shaping apparatusArchitectural engineeringRoad surface

The invention relates to a prefabricated concrete pavement and a construction method thereof. The prefabricated concrete pavement comprises a plurality of concrete prefabricated panels laid on a leveling layer, the four corners of the top faces of the concrete prefabricated panels are concaved downwards to form connecting platforms, and the connecting platforms are provided with hoisting devices and leveling devices. A dowel bar is pre-buried in one side of the concrete prefabricated panel, and a dowel bar groove is formed in the other opposite side of the concrete prefabricated panel; the four adjacent corners of the four adjacent concrete prefabricated panels jointly define a grouting hole; the prefabricated concrete pavement further comprises a grouting material filling part which is formed by pouring a slurry flowing channel formed in the bottom surface of the concrete prefabricated panel between the concrete prefabricated panel and the leveling layer through the grouting hole anda dowel bar groove containing the dowel bar and a concrete sealing part formed by pouring on the connecting platforms. The concrete prefabricated panels of the prefabricated concrete pavement are goodin flatness, and the connection between the concrete prefabricated panels is firm.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

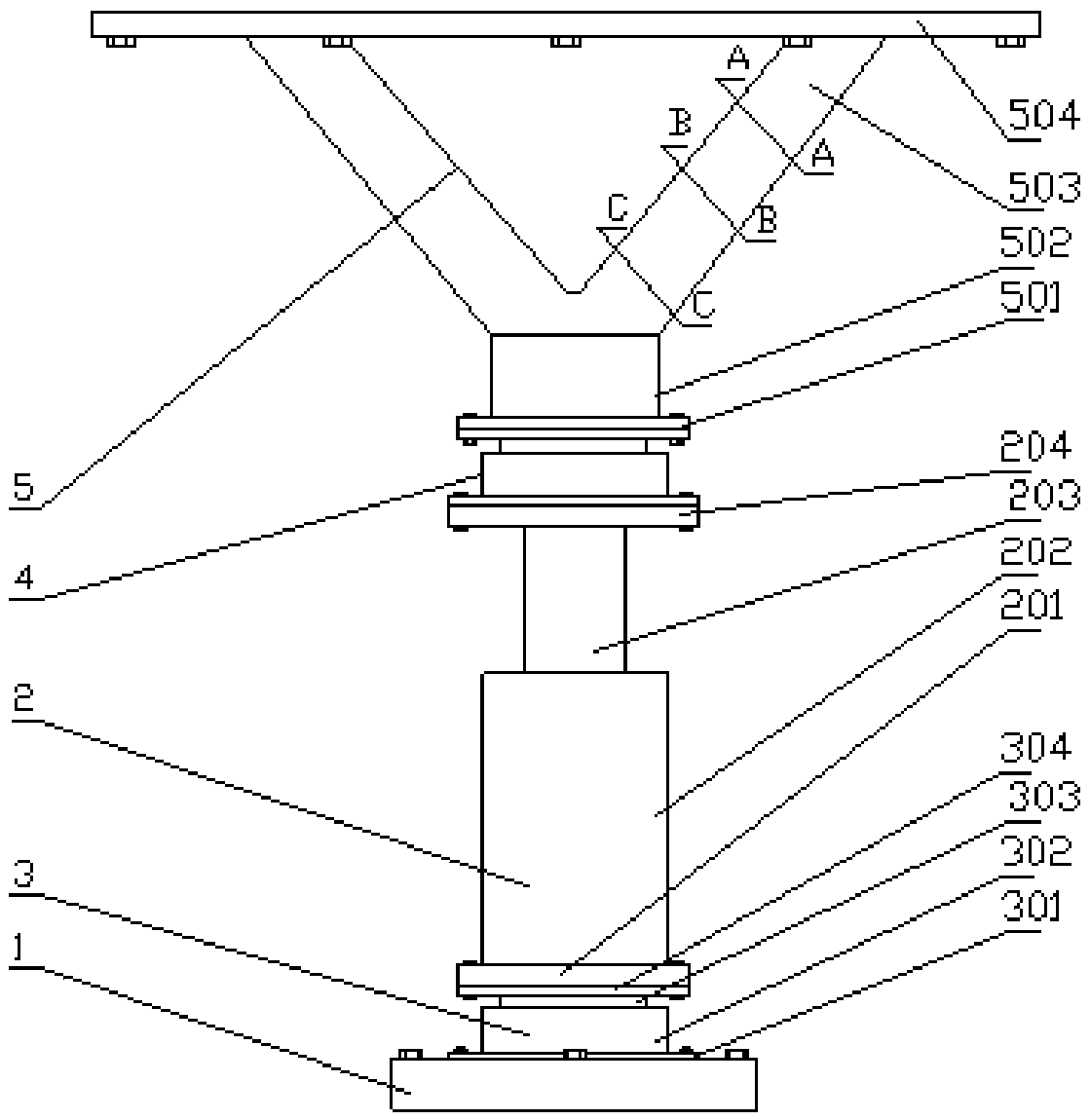

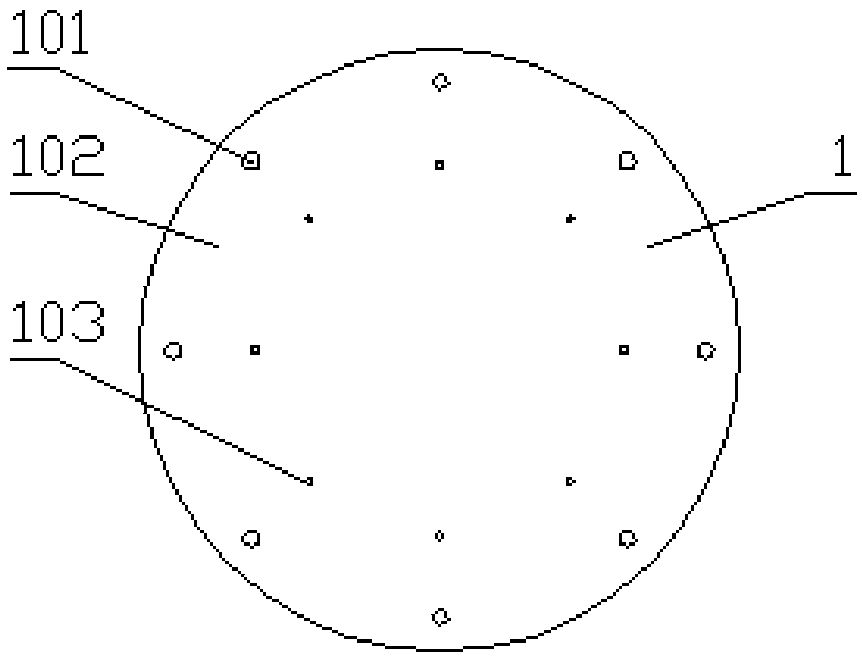

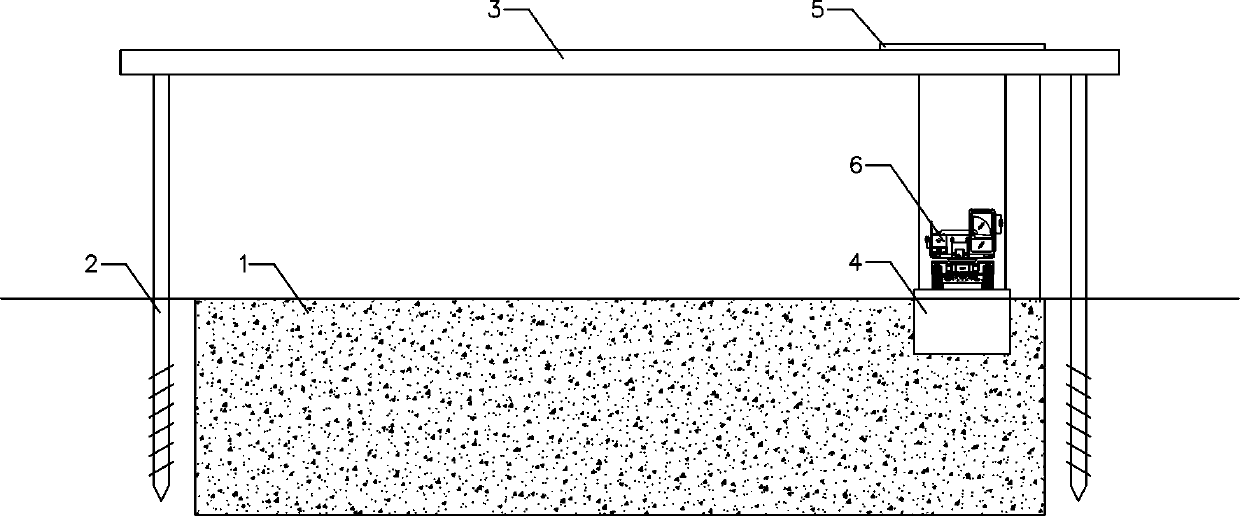

Reinforcing device for repairing buildings

The invention relates to a reinforcing device for repairing buildings. The reinforcing device comprises a first connecting plate fixed with a base substrate, a first vibration isolation device for buffering and damping is arranged on the upper portion of the first connecting plate, a lifting device for adjusting the height of a whole device is arranged on the upper portion of the first vibration isolation device, a second vibration isolation device is arranged on the upper portion of the lifting device, a supporting device is arranged on the upper portion of the second vibration isolation device, the top end of the supporting device is fixed with the top surface, and carbon fiber layers are arranged between the supporting device and the top surface, horizontally and vertically intersectedto form a screen and fixedly connected with the top surface. The reinforcing device is reasonable in overall structure, convenient to use and applicable to different building storey heights and top surface inclined angles, the supporting area is increased, the reinforcing device and carbon fiber reinforcing screens are matched to form a compound reinforcing structure, the rigidity of the overall structure is increased, ground occupied area is small, usage rate is increased, construction time is shortened by the aid of a prefabricated structure, investment cost is low, and the anti-vibrating stability of the overall structure is improved by the vibration isolation devices.

Owner:郭思麟

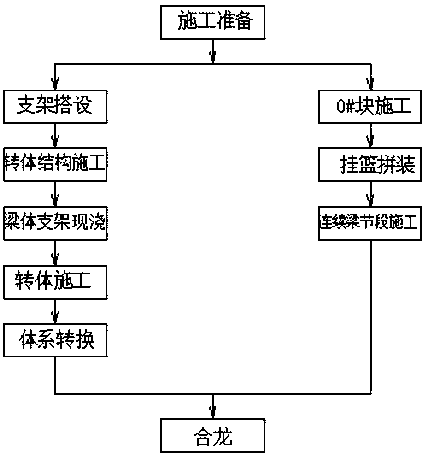

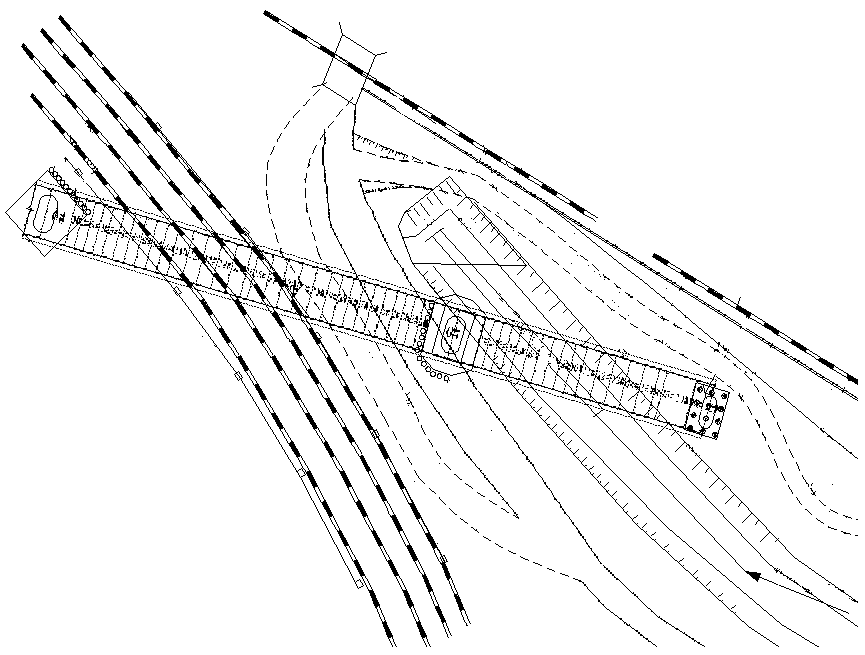

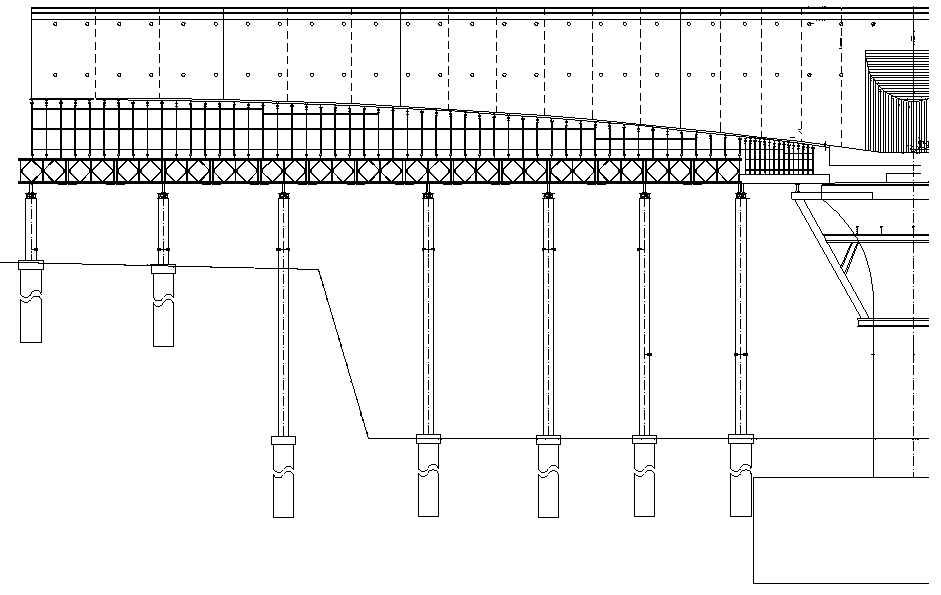

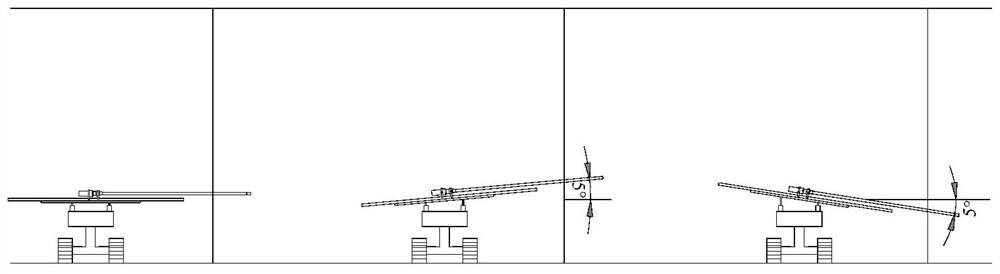

Support cast-in-place, pier top rotation and cast in cantilever combined construction method for continuous beams

InactiveCN110629675AConstruction time is shortGuaranteed laying periodBridge erection/assemblyContinuous beamHanging basket

The invention belongs to the technical field of bridge construction, and particularly relates to a support cast-in-place, pier top rotation and cast in cantilever combined construction method for continuous beams. The support cast-in-place, pier top rotation and cast in cantilever combined construction method for the continuous beams comprises the following steps of 1# pier construction and 2# pier construction. The 1# pier construction comprises the following steps that: S100: support building construction: after the support finishes being built and the support confirms to be qualified in acceptance, carrying out piling preloading, eliminating the non-elastic deformation of the support, and determining an elastic deformation value so as to determine formwork erection elevation; S200: theinstallation construction of a pier top rotation construction; S300: beam body support cast-in-place construction; S400: the rotation construction of the pier top rotation construction; and S500: system transformation. The 2# pier construction comprises the following steps that: U100: 0#block construction; U200: hanging basket splitting; and U300: continuous beam segment construction: when both the 1# pier and the 2# pier finish being constructed, carrying out closure construction of the continuous beam. The method is short in construction time, a construction site is provided with a regulation space, and meanwhile, an existing railway can prevent from being blocked.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

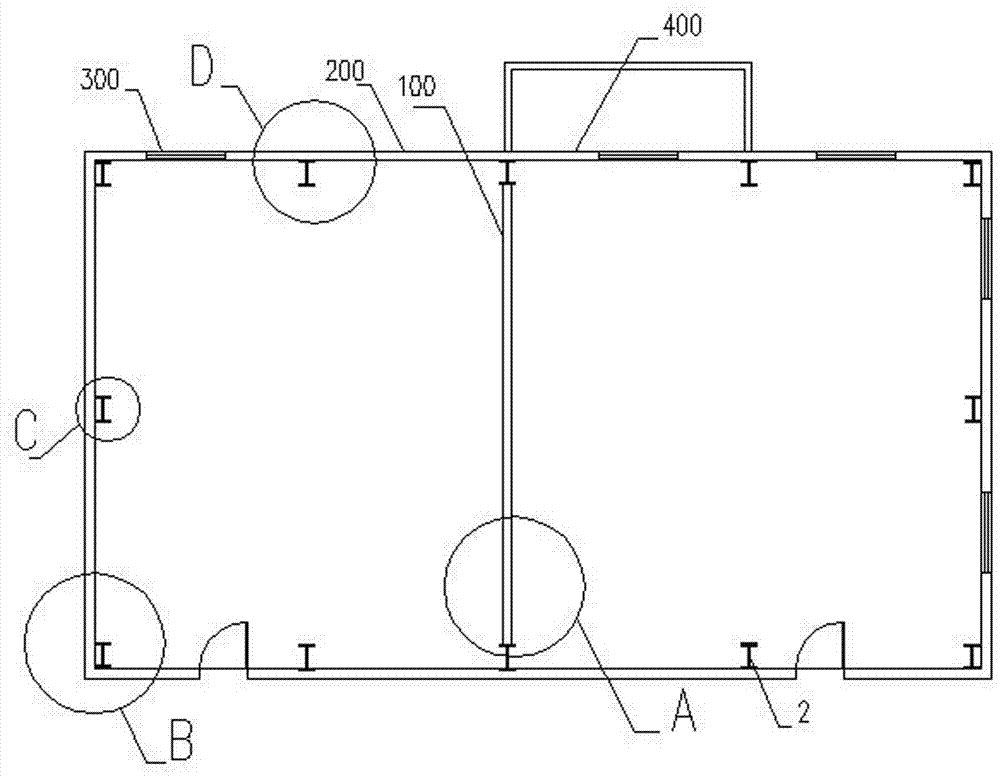

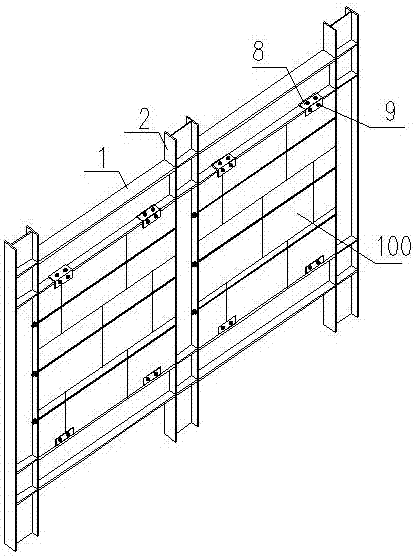

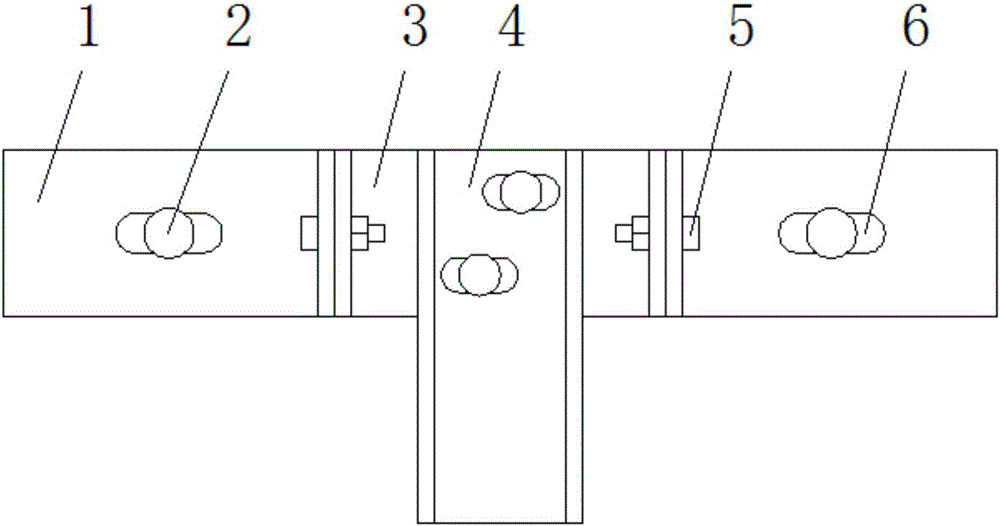

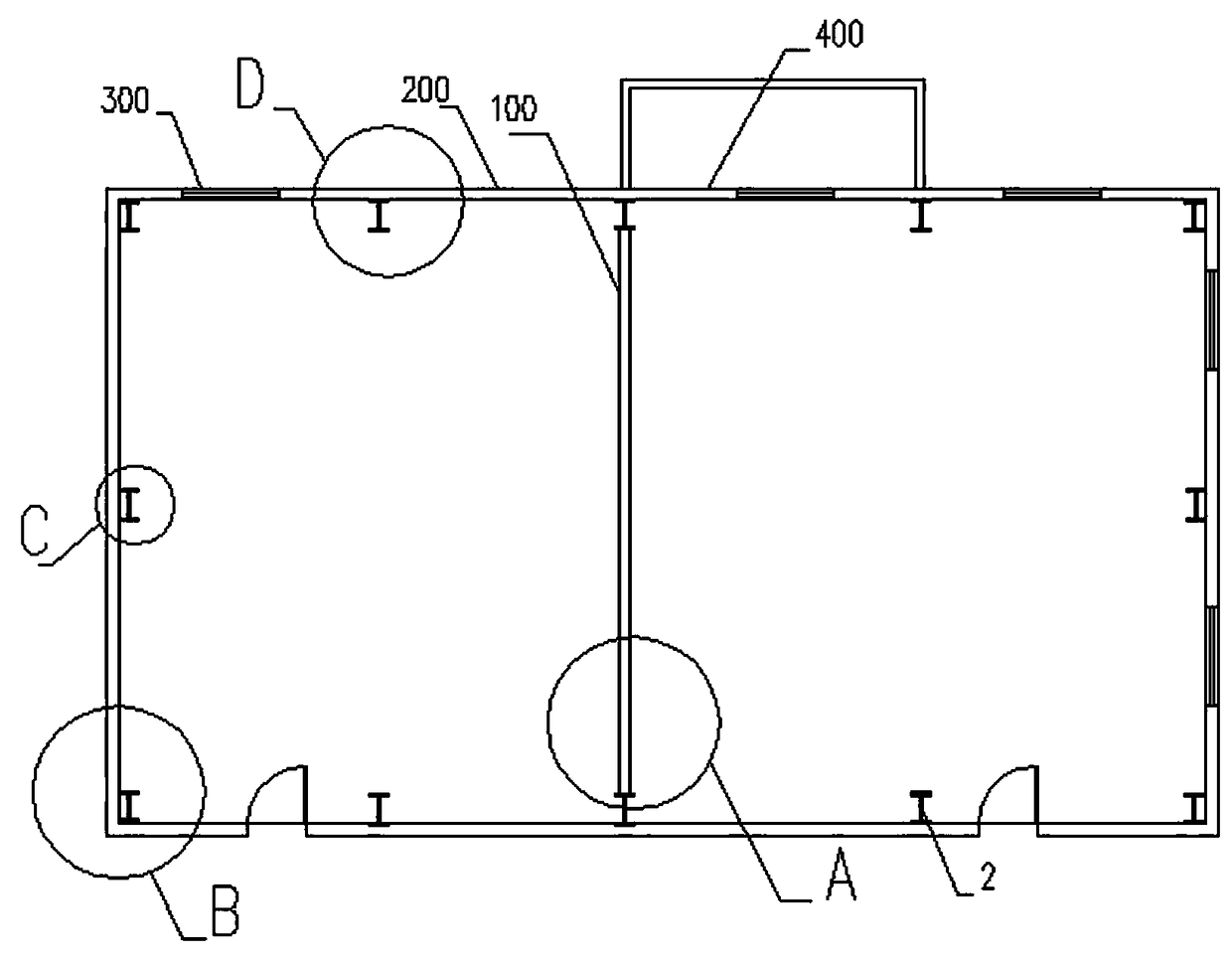

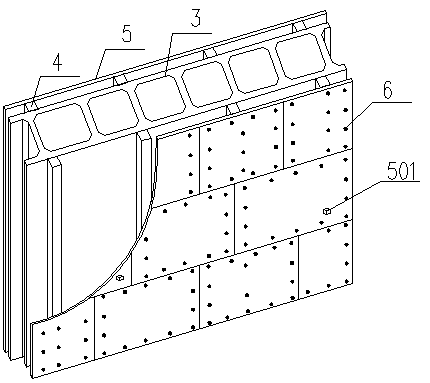

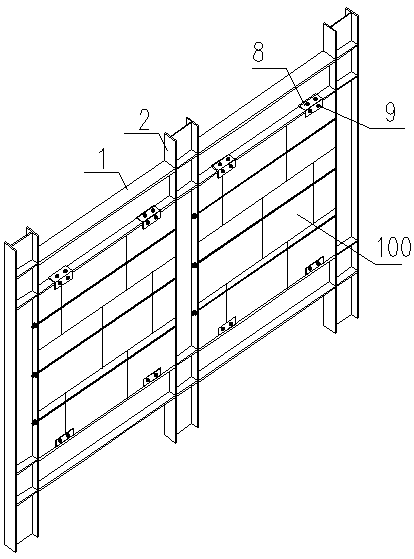

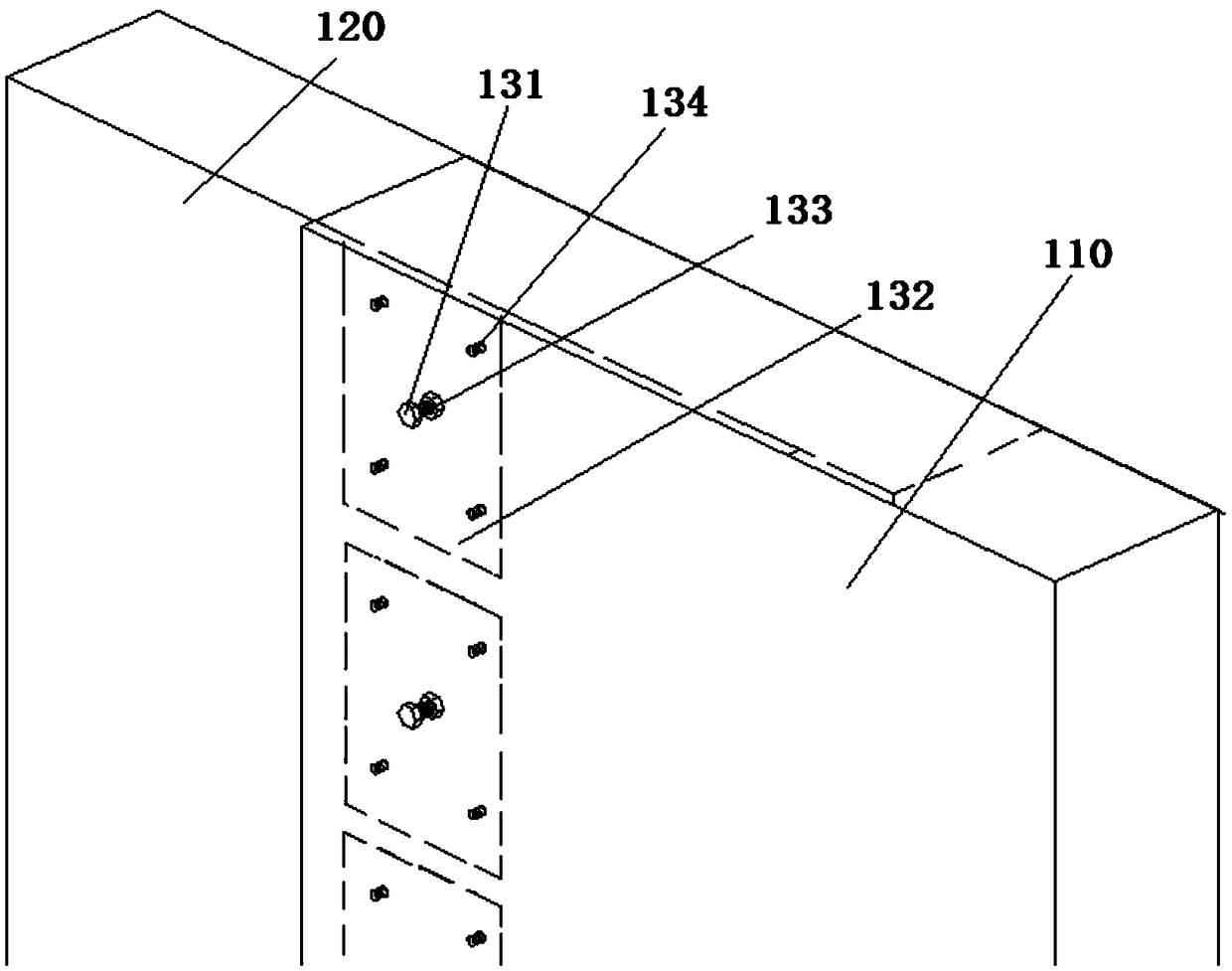

Industrialized EPS module wall plate system matched with fabricated steel frame

InactiveCN106988452AQuality assuranceDimensional accuracy is easyWallsProtective buildings/sheltersWeather resistanceKeel

An industrialized EPS module wall plate system matched with a fabricated steel frame comprises a wall plate and connecting nodes between the wall plate and the steel frame, and beam columns of the steel frame are all I-shaped steel. The wall plate comprises EPS modules, wooden keels and a light surface covering plate, the EPS modules are spliced into a wall plate main body through tongue-and-groove boards, the wooden keels are fixed to the two side faces of the wall plate main body, and the wooden keels are covered with the light surface covering plate; the wall plate is divided into a prefabricated inner partition wall plate body, a prefabricated outer wall plate body, a prefabricated windowing hole wall plate body and a prefabricated wall plate body with a bay window; and the connecting nodes comprise the connecting nodes of the wall plate and steel frame columns and the connecting nodes of the wall plate and steel frame beams, the connecting nodes of the wall plate and the steel frame columns comprise four kinds of nodes including the nodes A, the nodes B, the nodes C and the nodes D, and the connecting modes of the wall plate and the steel frame beams are composed of pieces of angle steel I with bolt holes and bolts I for fixing the pieces of angle steel I. The wall plate system can be subjected to industrialized production, conveying and mounting are convenient, the heat insulation effect is good, and rigidity, strength and weather resistance are good.

Owner:HENAN UNIV OF SCI & TECH

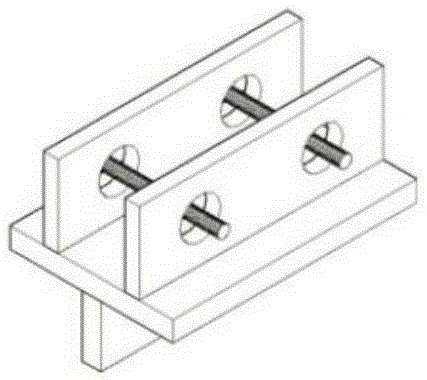

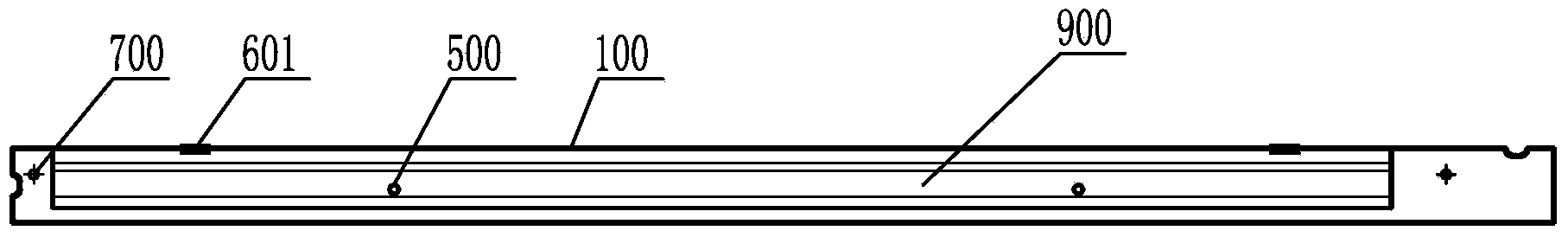

Mounting frame of elevator landing door

The invention discloses a mounting frame of an elevator landing door. The mounting frame comprises a trough type landing door connecting part, wall face connecting parts and a landing door connecting part. The wall face connecting parts are mounted on the two sides of the trough type landing door connecting part. Bolt holes are formed in the wall face connecting parts. The landing door connecting part is mounted on the front portion of the trough type landing door connecting part. Bolt holes are formed in the landing door connecting part. The landing door connecting part is provided with the two bolt holes. The landing door connecting part is connected with the trough type landing door connecting part through a fixing bolt. According to the mounting frame, the trough type landing door connecting part, the wall face connecting parts and the landing door connecting part are provided with the bolt holes, the positions of the mounting frame can be allowed to be flexibly adjusted in all direction such as up, down, left, right, front and back according to actual mounting conditions, mounting and debugging are facilitated, the mounting efficiency is effectively improved, and the construction time is shortened.

Owner:钟立朋

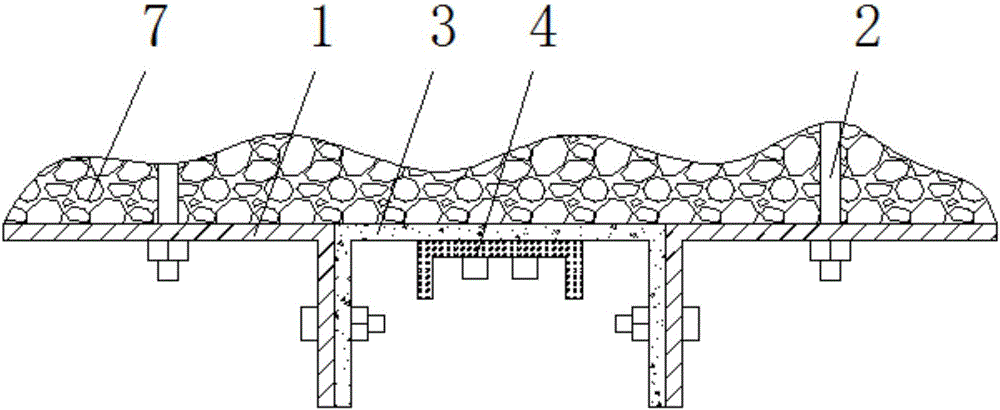

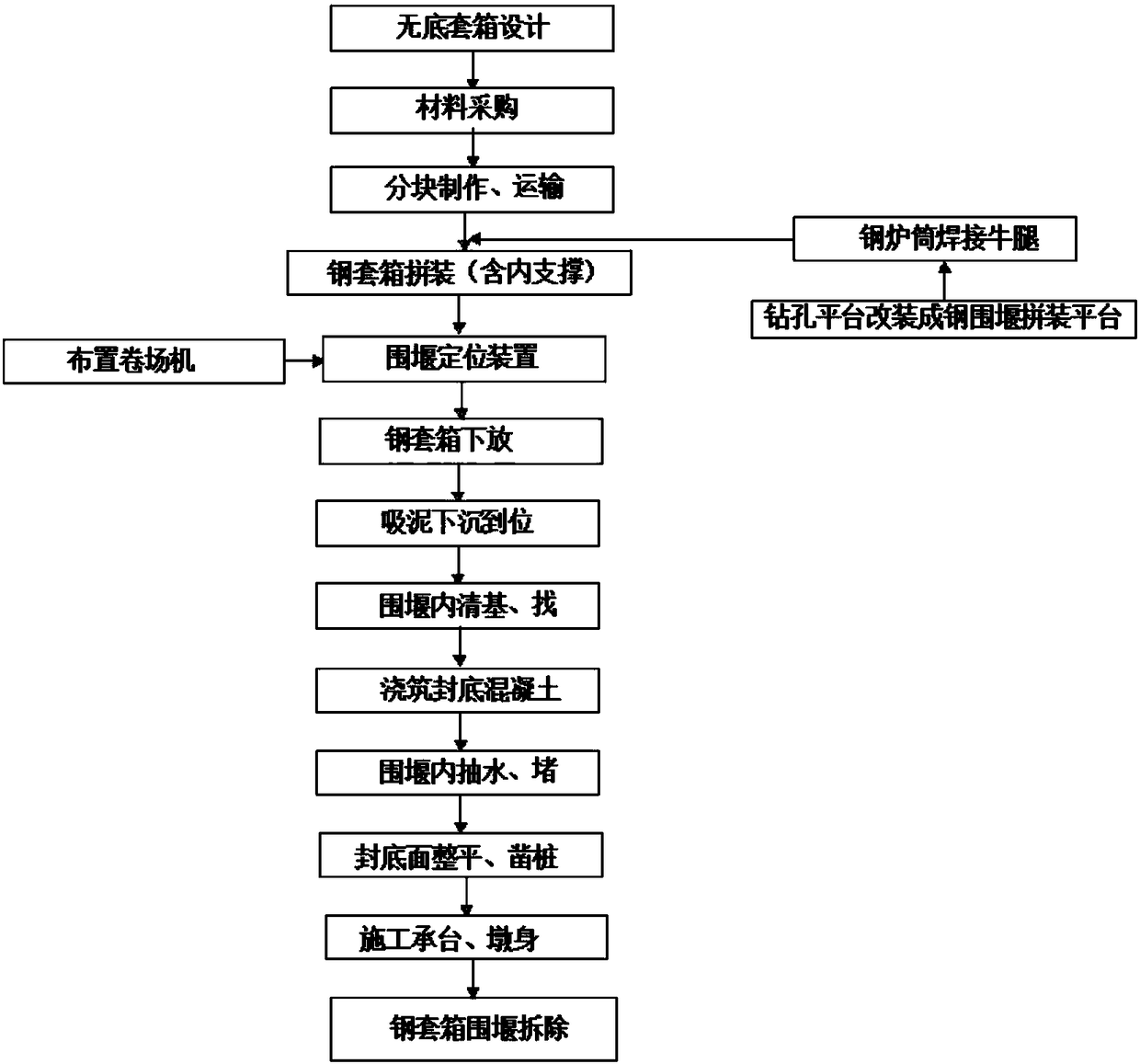

Large deepwater foundation single-wall steel cover box cofferdam construction method

PendingCN108222041AHigh degree of mechanizationReduce the waste of manpower and material resourcesFoundation engineeringDry seasonCofferdam

The invention discloses a large deepwater foundation single-wall steel cover box cofferdam construction method. A single-wall structure is selected in a selected main pier steel cover box cofferdam, amain pier bearing platform is arranged to be constructed in the Xinjiang river dry season, analysis is made in combination with hydrologic data, the water level of the Yellow Sea elevation in the dryseason is positive 24.0 m, the protection water level of the cofferdam is positive 24.20 m, 0.30 m is considered to serve as the wave resistance height, in other words, the cofferdam top elevation ispositive 24.50 m, the bearing platform bottom face elevation is positive 13.0 m, the bottom sealing concrete thickness is 3.0 m, the cofferdam bottom elevation is positive 10.0 m, and the total height of a steel cover box is designed as 14.50 m. A closed structure is formed by a side plate and bottom sealing concrete for temporary water isolation, water in the cofferdam is pumped thoroughly, a cover box side plate is utilized as a bearing plate construction template, bearing platform and pier body construction in the cover box cofferdam is achieved, and manpower and material resource waste isreduced; and the operation difficulty is lowered, the mechanical degree is high, time consumed for construction is short, and the large deepwater foundation single-wall steel cover box cofferdam construction method can be used for large deepwater foundation equipment construction.

Owner:中铁二十四局集团新余工程有限公司 +1

An industrialized eps modular wall panel system matched with a prefabricated steel frame

InactiveCN106988452BQuality assuranceDimensional accuracy is easyWallsProtective buildings/sheltersWeather resistanceKeel

Owner:HENAN UNIV OF SCI & TECH

A kind of road bridge crack repairing device and repairing method

ActiveCN108755333BEffective reinforcementEfficient repairPaving detailsBridge erection/assemblyFiberCarbon fibers

Owner:ZHENGZHOU UNIV OF IND TECH

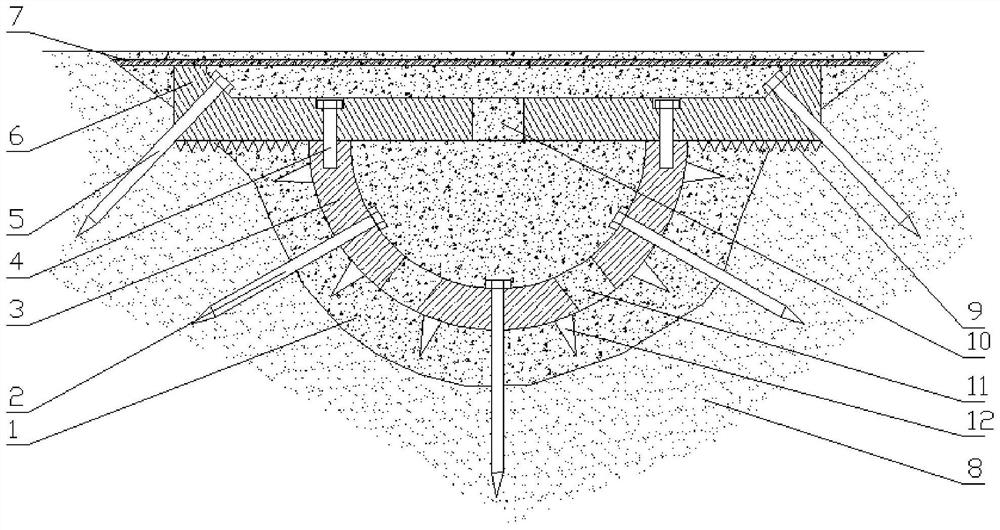

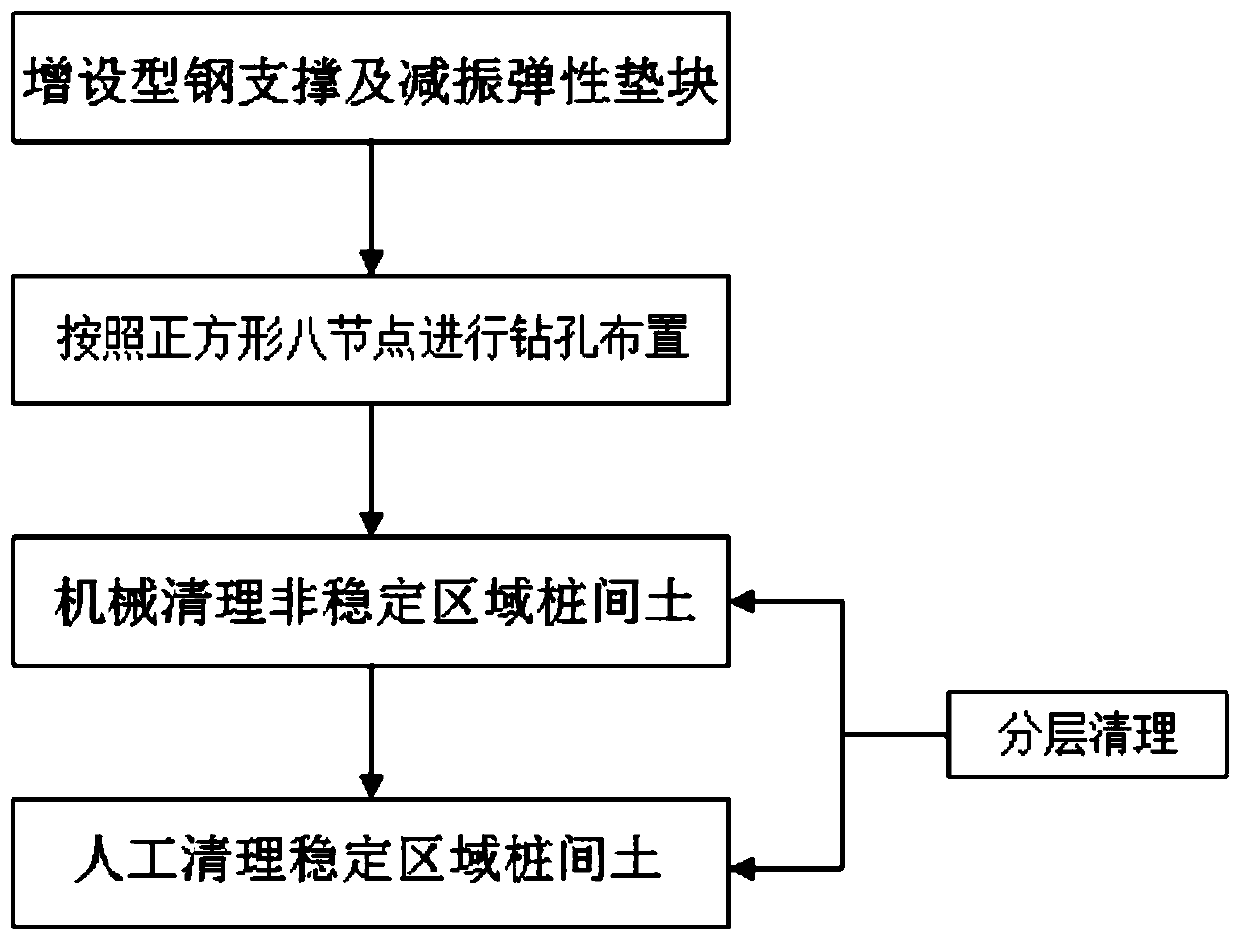

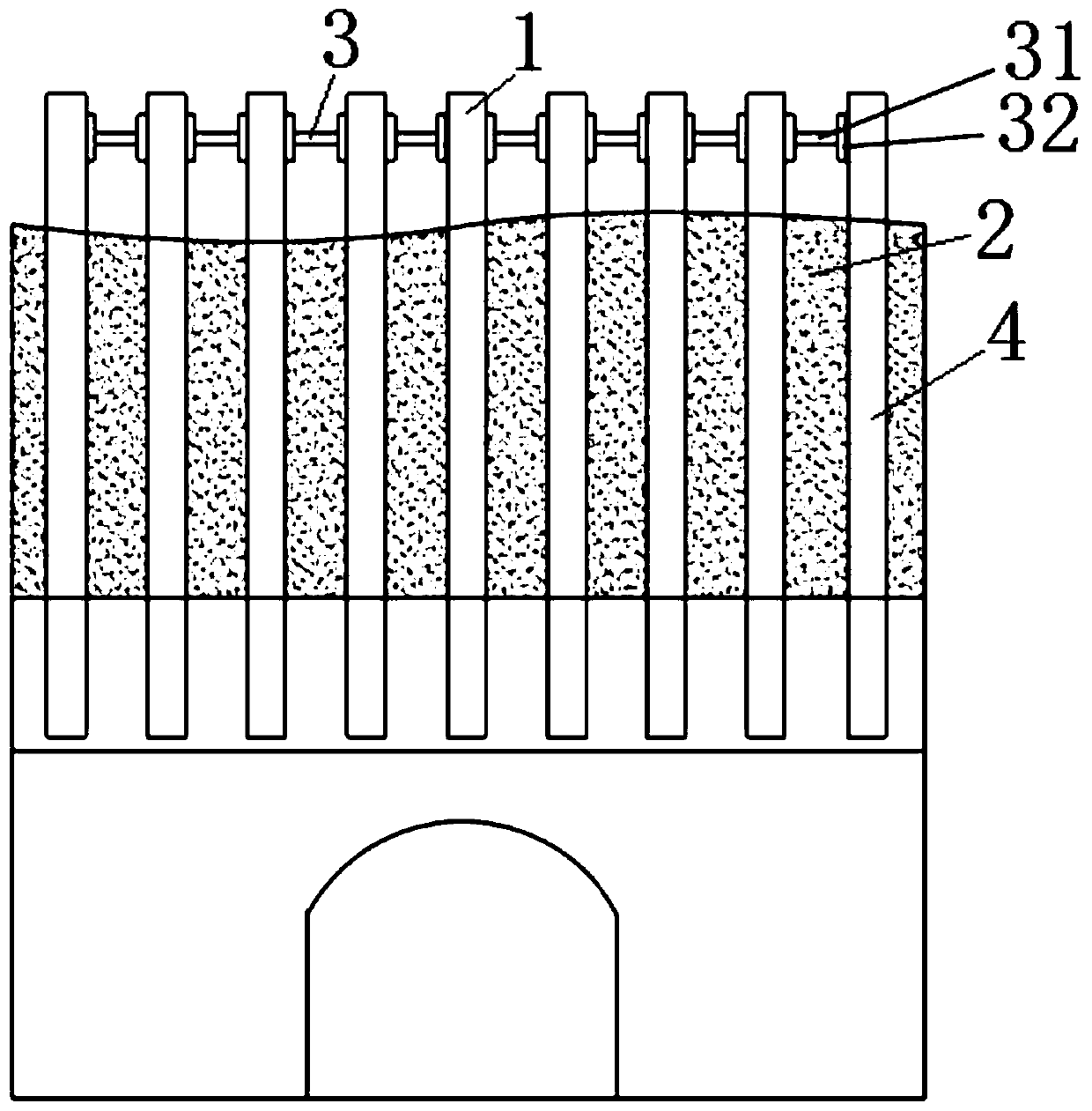

Over-crossing existing subway tunnel between-pile soil clearing method

InactiveCN111155526ADestroy integrityEasy to dig outHand-operated machines/dredgersBulkheads/pilesSoil scienceStructural engineering

The invention discloses an over-crossing existing subway tunnel between-pile soil clearing method. The over-crossing existing subway tunnel between-pile soil clearing method comprises the following steps of: firstly, arranging an shock absorbing elastic support between two adjacent isolating piles; vertically arranging a plurality of pre-cracking drill holes surrounding each isolating pile; dividing the between-pile soil surrounding each isolating pile into a stable region and an unstable region; finally carrying out layered excavation on the between-pile soil in the unstable region by adopting machinery; and carrying out layered excavation on the between-pile soil in the stable region by adopting manpower. By utilizing vibration wave transmission theory and arranging the shock absorbing elastic support, the over-crossing existing subway tunnel between-pile soil clearing method disclosed by the invention realizes effective absorption of disturbance and vibration generated in excavation, reduces the disturbance to the isolating piles, damages the integrity of the between-pile soil by forming the pre-cracking drill holes surrounding the isolating piles so that the between-pile soil in the stable region can be conveniently removed in an excavation way and partial vibration wave generated in excavation in the unstable region is effectively absorbed, greatly reduces the disturbanceto the isolating piles and over-crossing existing tunnel surrounding rock in an excavation process by adopting machinery and manpower in combination with excavation, realizes high safety and simple operation, and spends a short time.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Aluminum alloy vertical trim strip inserting construction process

InactiveCN110259049AConstruction time is shortImprove efficiencyWallsAluminium alloyBuilding construction

The invention discloses an aluminum alloy vertical trim strip inserting construction process. The aluminum alloy vertical trim strip inserting construction process comprises the following steps: 1, unit plates are flatly stacked to be assembled; 2, aluminum alloy trim strips are inserted into a plate reserved clamp; 3, the unit plates are hoisted in place; 4, stainless steel plug pins are inserted into reserved pin holes; and 5, the upper-layer unit plates and the trim strips are put in place. According to the aluminum alloy vertical trim strip inserting construction process, the aluminum alloy large-section vertical trim strips are designed in a split mode, the rear parts of the trim strips are provided with attached grooves matched with the clamp in specification, the front faces of the trim strips are pressed into the opening-type aluminum alloy clamp where the unit plates stretch out, then the front faces of the trim strips and the opening-type aluminum alloy clamp are firmly connected through stainless steel studs, then the grooves are covered through a trim strip cover plate to form a smooth whole, after the unit plates reach the mounting position together with the vertical trim strips, trim strip reserved pin shaft holes are finely adjusted to be aligned with stainless steel dowels reserved on the lower trim strips, then the whole can be put in place, the time for site construction is short, and the efficiency is high.

Owner:中建装饰海南有限公司

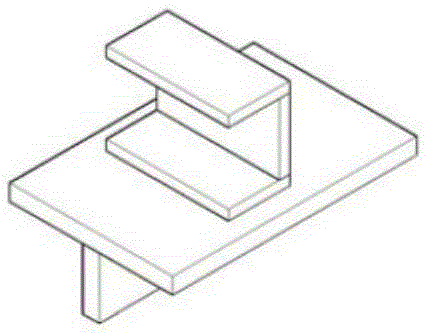

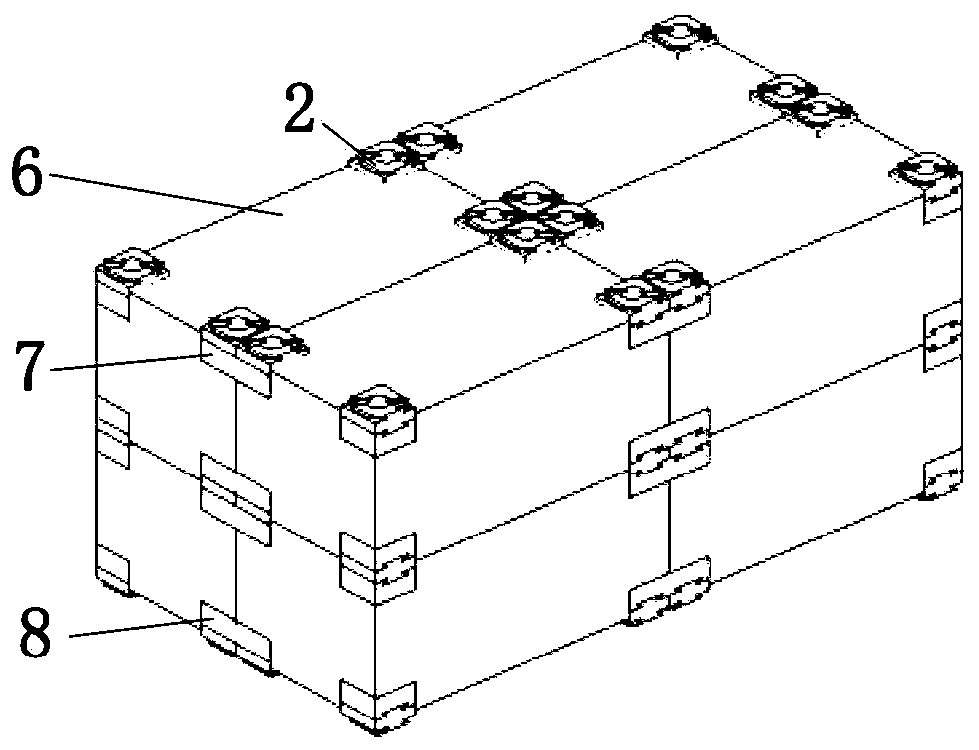

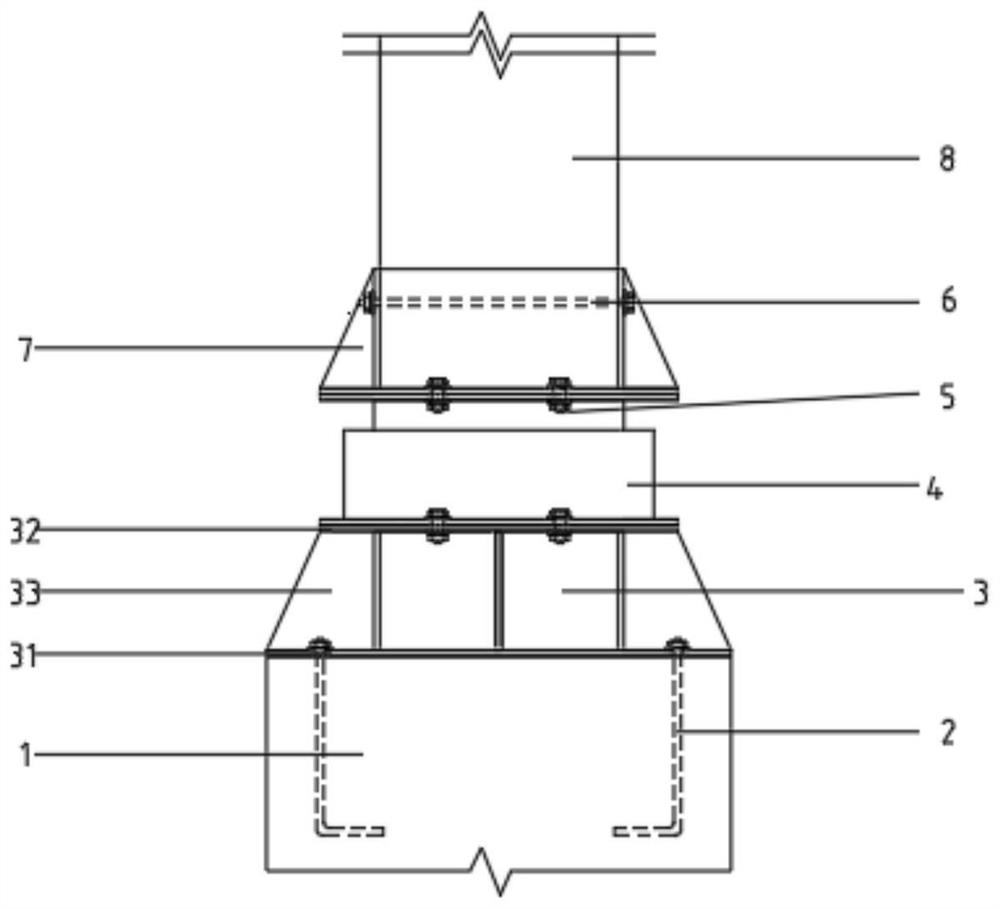

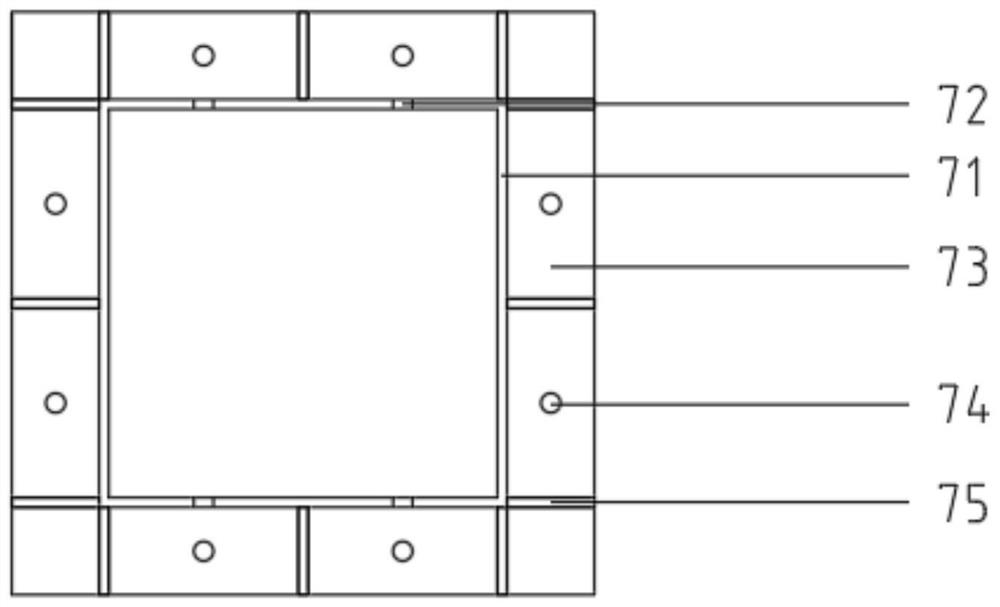

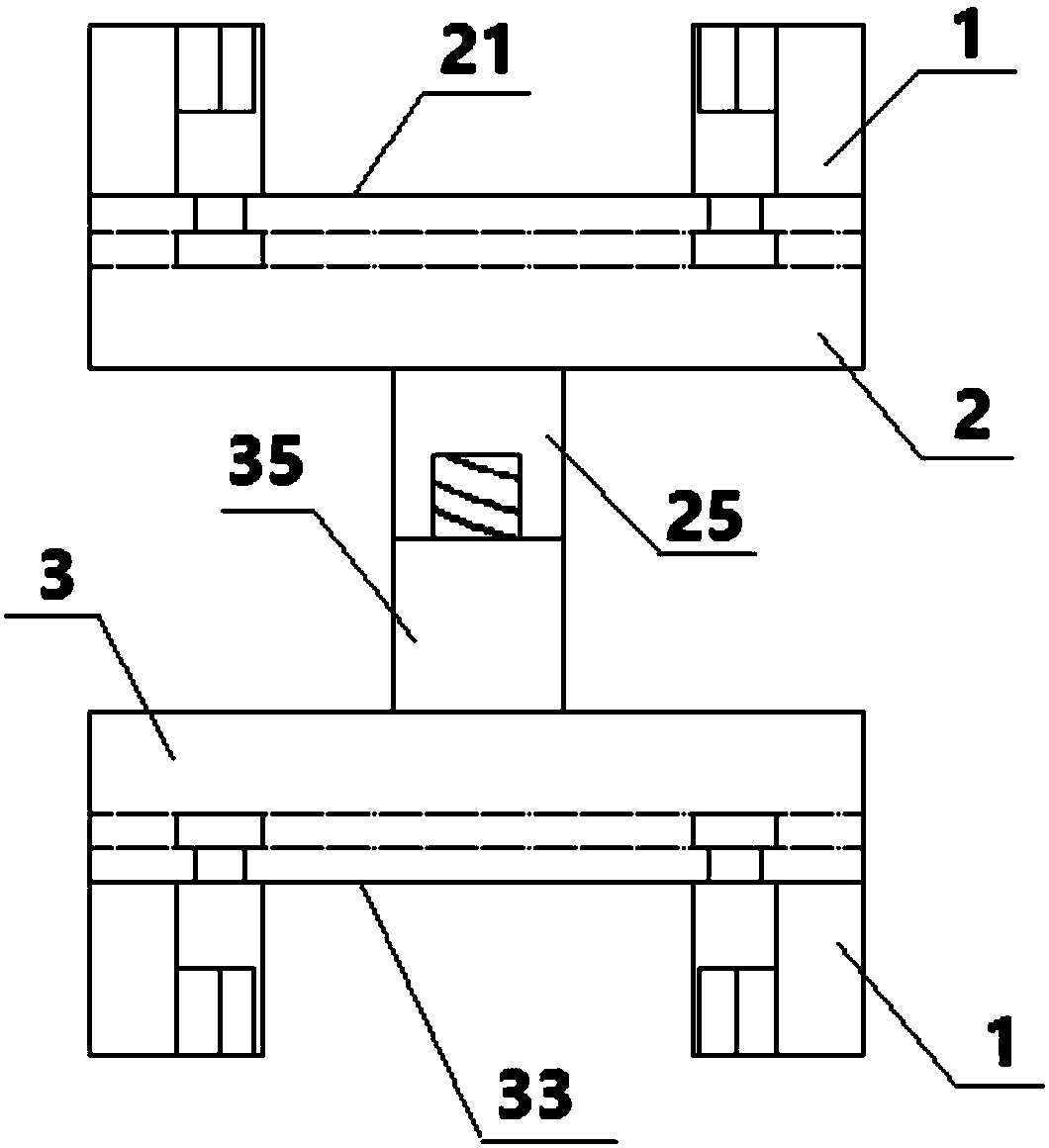

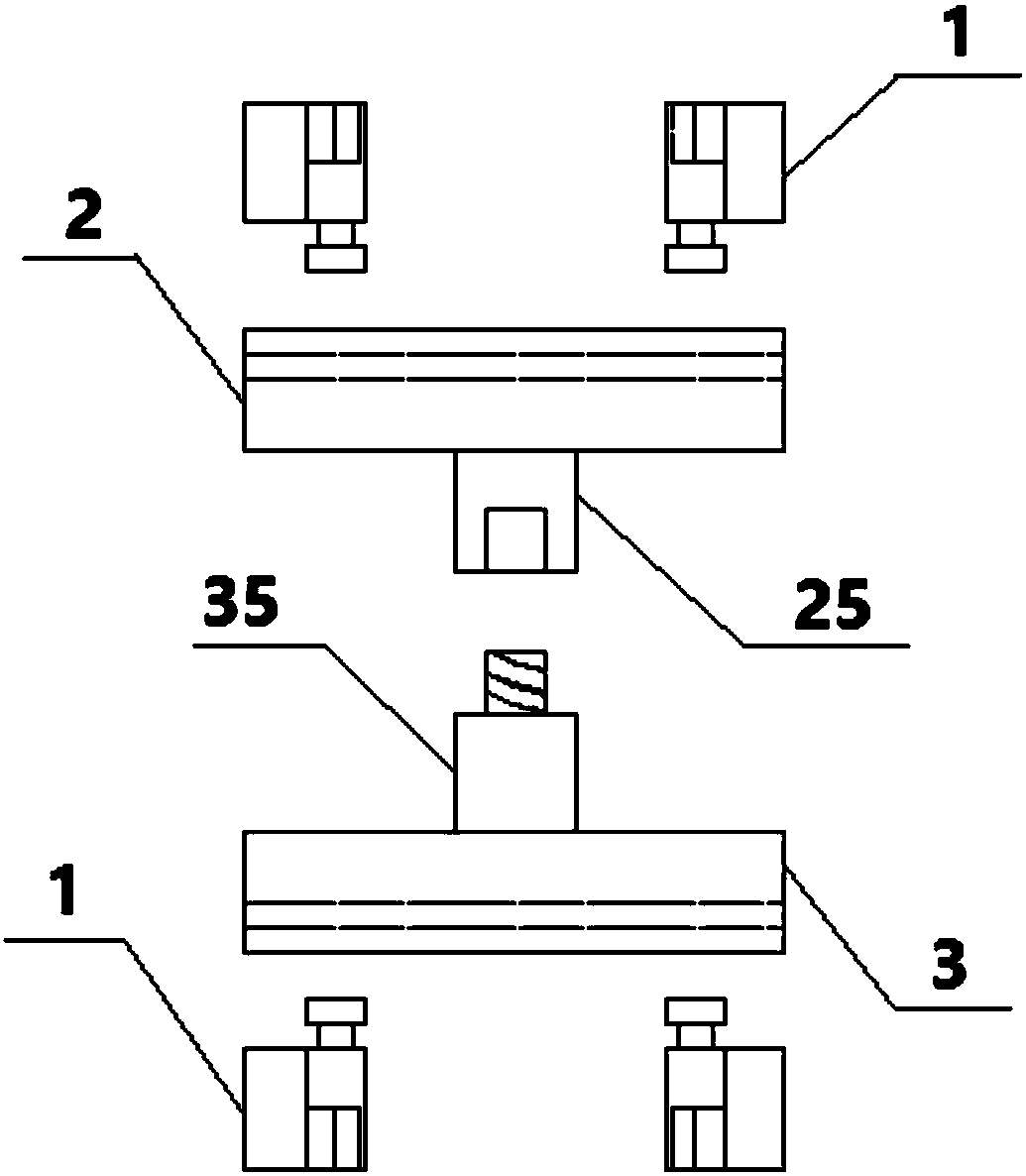

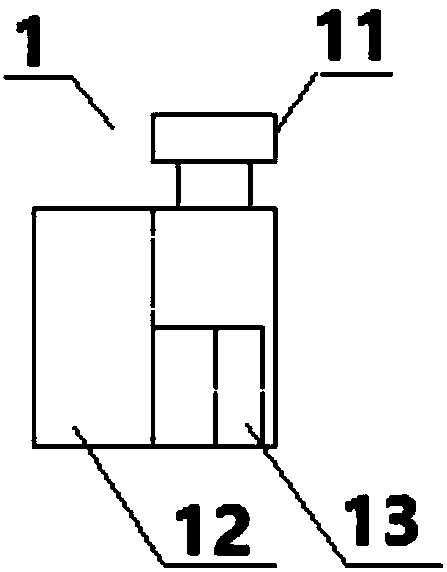

Transverse mortise and tenon type connecting joint for modular building and construction method

PendingCN110792174AIncrease flexibilityImprove stabilityBuilding constructionsMortise and tenonArchitectural engineering

The invention provides a transverse mortise and tenon type connecting joint for a modular building. The transverse mortise and tenon type connecting joint for the modular building comprises lower clamping parts, middle connecting parts and upper clamping parts. The lower clamping parts are arranged at the adjacent four corners of an upper steel structure module, the upper clamping parts are arranged at the adjacent four corners of a lower steel structure module, one ends of the middle connecting parts are connected with the top faces of the lower clamping parts in a buckling manner, the otherends of the middle connecting parts are connected with the bottom faces of the upper clamping parts in a buckling manner, and the top faces of the lower clamping parts are connected with the bottoms of the upper clamping parts through the middle connecting parts in a buckling manner. The invention further provides a construction method of the transverse mortise and tenon type connecting joint forthe modular building, by means of the detachable design, the structure is simple, the production efficiency is high, and operation is easy and convenient; the installation position is flexible, and the direction is adjustable; a module unit composed of the connecting joint and the steel structure modules can move and be installed overall, and the space model plasticity is high; manufacturing can be conducted in advance, and the construction period is shortened; diversity of the connecting joint is achieved, the application range of the module unit is enlarged, and stability of the module unitis improved.

Owner:MCC TIANGONG GROUP

A kind of prefabricated light-weight floor slab and floor slab structure of industrialized building

Owner:黄涛 +1

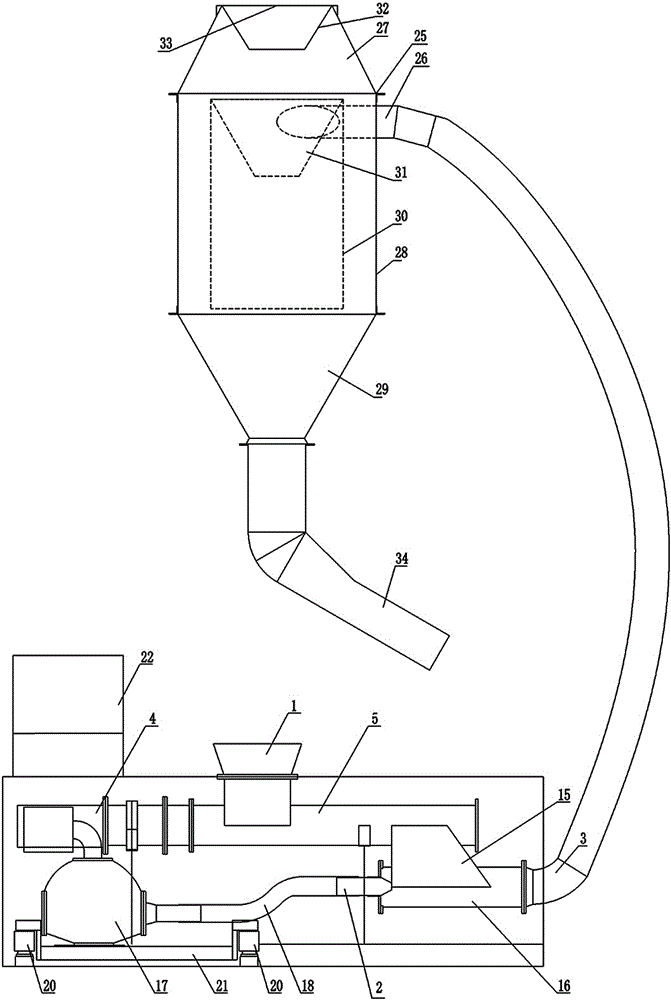

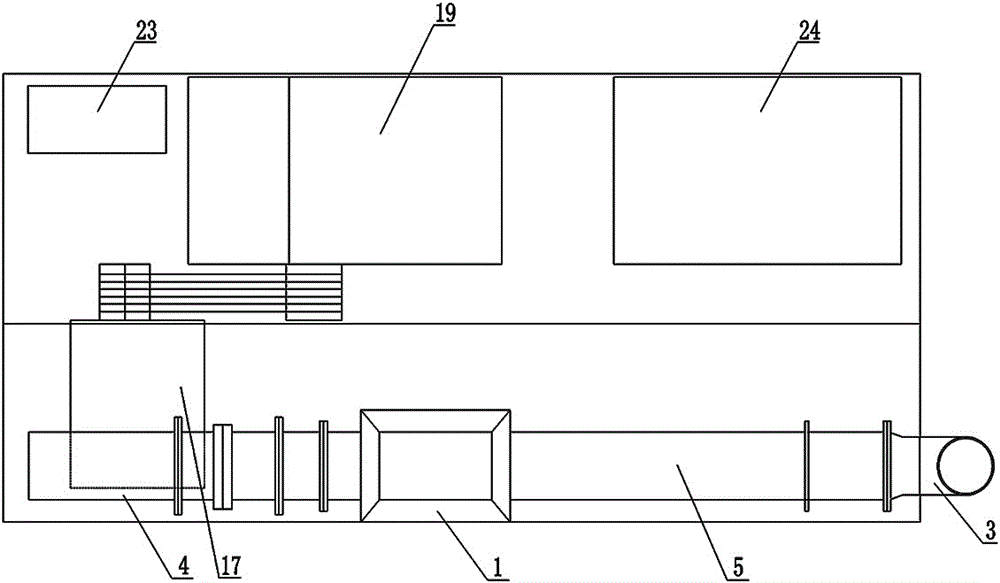

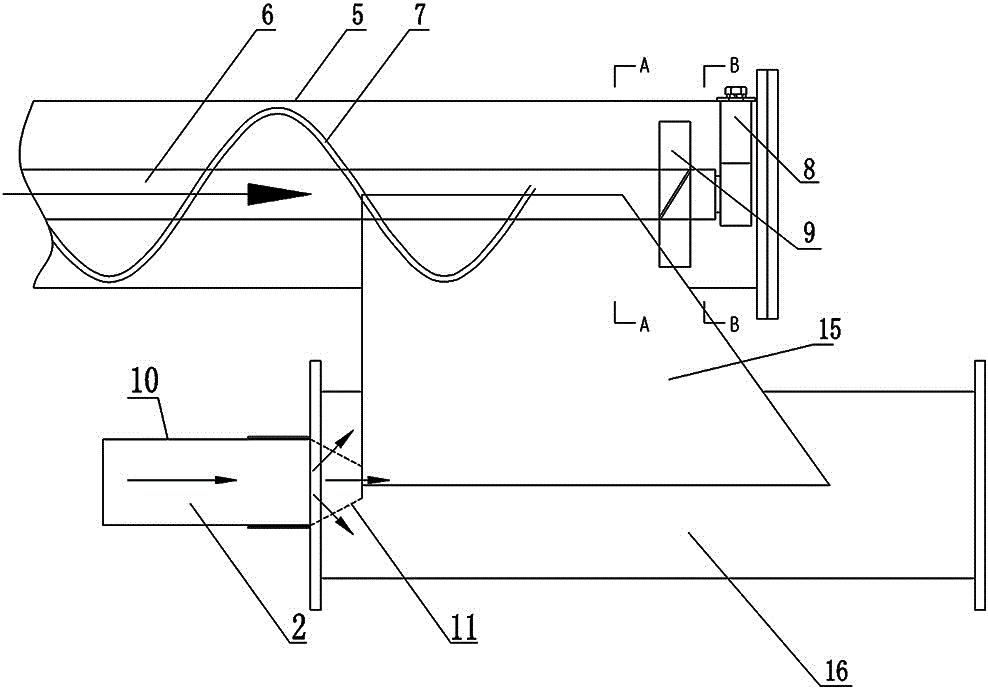

A fiber material conveying device

The invention discloses a fiber material conveying device, which includes a fiber pump and a fiber material unloader. The fiber pump includes a feeding bin (1), a screw feeding device, a mixing bin, a diesel engine (19), a blower (17), Shock absorbing bracket, air inlet pipe (2) and discharge pipe A (3), screw feeding device includes drive motor (4), feeding pipe (5) and feeding screw (6), fiber material unloader includes shell ( 25), the feed pipe (26) and the separation device, the upper and lower ends of the housing (25) are respectively provided with an air outlet and a fiber outlet, and the outlet of the fiber pump is connected to the feed of the fiber material unloader through a pipeline. Tube. The beneficial effect of the present invention is that: the fiber is blown away by the blast air flow, the automatic control of feeding is realized, the labor is saved, the cost is reduced, and the dispersion efficiency is high; and the separation of the transported fiber and the air flow is realized, and the separation effect is good, which can Effectively prevent loss of fiber material.

Owner:四川省博仁达石油科技有限公司

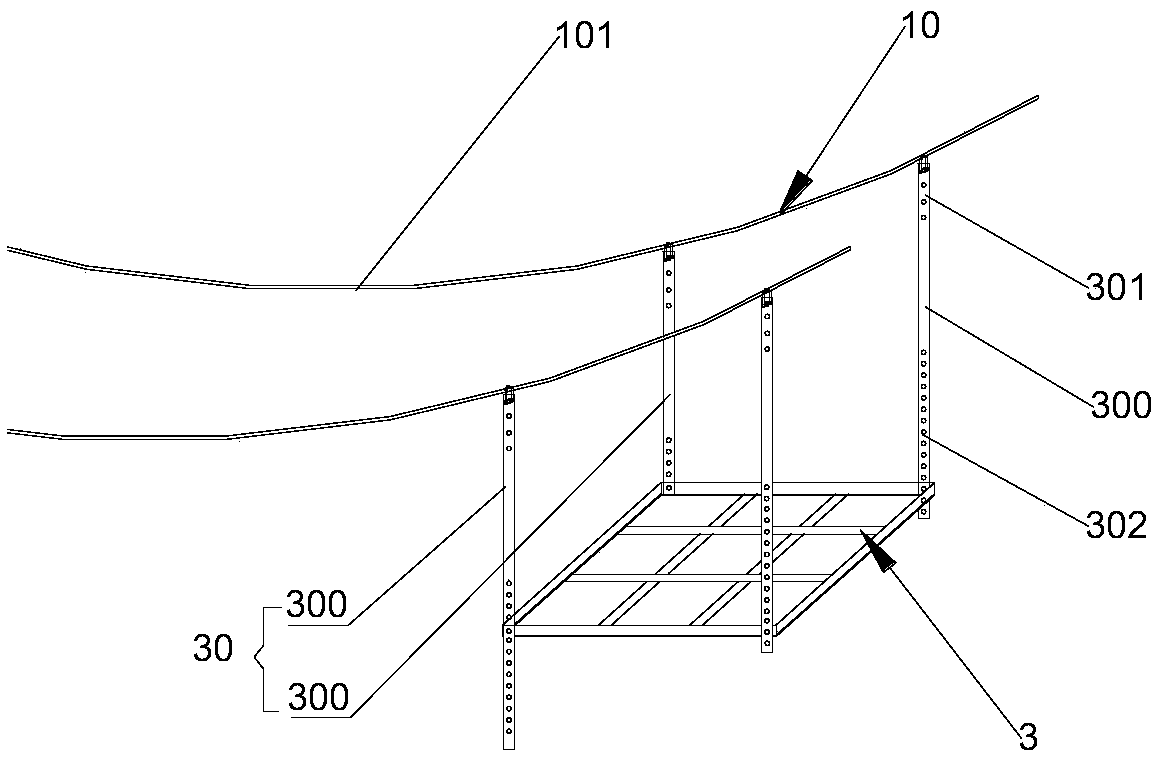

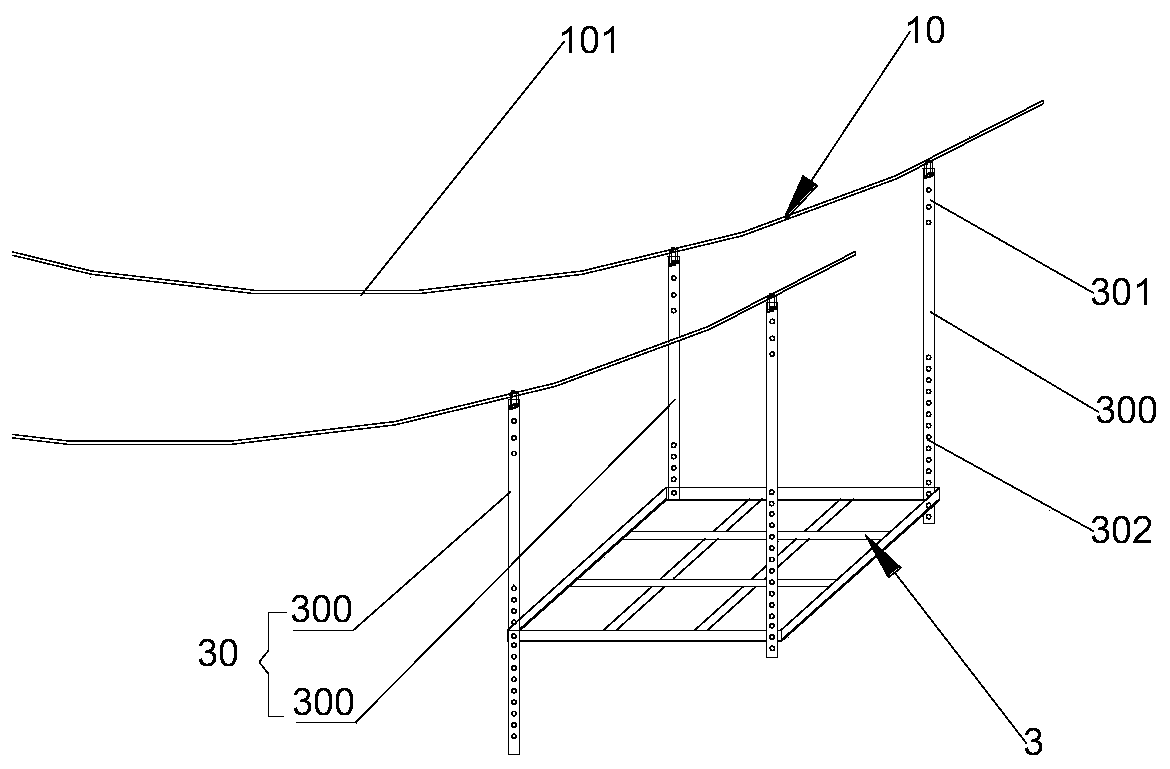

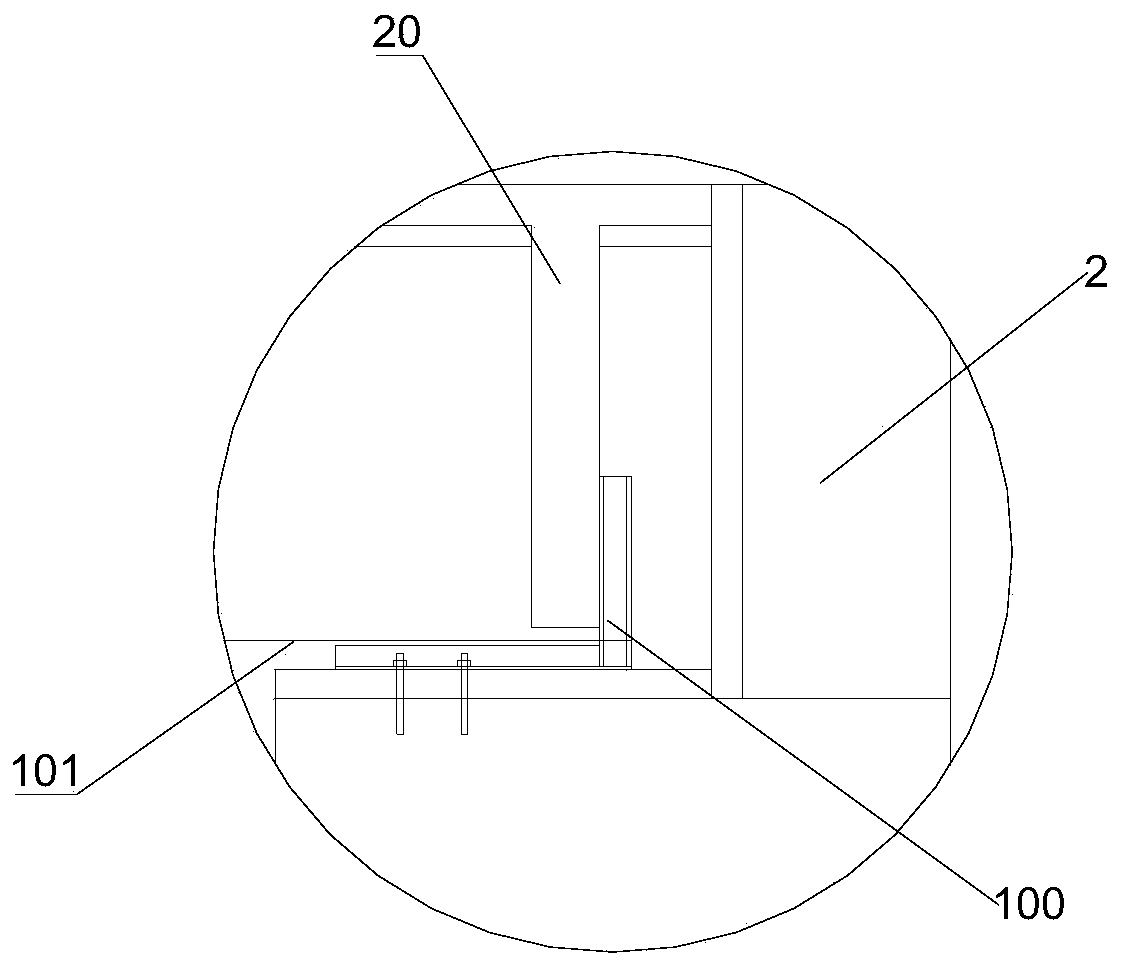

Hanger platform for T-shaped beam maintenance and reinforcement

ActiveCN108715431AEasy to set upEasy to fixLifting devicesBridge erection/assemblyShaped beamModularity

The invention discloses a hanger platform for T-shaped beam maintenance and reinforcement. The hanger platform comprises a platform fixing device and a working platform. The platform fixing device isarranged on a T-shaped beam in an assembled mode. The working platform comprises a plurality of hanger sets, and all the hanger sets are arranged at intervals in the longitudinal direction of a bridge. Each hanger set comprises two vertically-arranged hangers which are arranged in a spaced mode in the transverse direction of the bridge. The tops of the hangers are detachably connected to the platform fixing device. A rectangular frame is detachably arranged between every two adjacent hanger sets, and a passage for allowing a maintainer to pass through is formed between each rectangular frame and the platform fixing device. All the rectangular frames are located in the same horizontal face. By adopting modular construction, the construction time for platform erecting is short, the construction technology is simple, operation is easy, and safety of a constructor can be ensured.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU +1

A kind of technological method of drcp type pipe jacking regulating pipe

ActiveCN110307397BPrevent annular water leakage and slurry leakageEliminate deformationPipe laying and repairWater leakageStructural engineering

The invention provides a process method for a DRCP type pipe jacking adjustment pipe, the method comprising the following steps: a. adding an adjustment pipe height bracket corresponding to the height in the molding cavity of the existing standard length molding die; b. Adjust the steel ring of the pipe socket to support and fix it in the forming cavity of the forming mold; c. By installing the locking force in the outer mold body, the steel ring hoop of the adjusting pipe socket is rounded to ensure the tightness of the steel ring of the regulating pipe socket The shape and position deviation of the working end face meets the working requirements; d. The inner wall of the outer mold body and the ring surface of the outer wall of the adjusting pipe socket steel ring are in contact to form a good seal, which can prevent annular water leakage and slurry leakage; e. At least one layer of double-sided adhesive is bonded to the inner circle of the end plate of the adjusting pipe socket along the peripheral surface. The invention rounds the outer wall of the steel ring of the adjusting pipe socket through the locking force when the outer mold body is closed, eliminating the need for adjusting the pipe socket. The steel ring is deformed, and the installation of a seal on the inner wall of the outer mold body can effectively prevent the occurrence of annular water leakage and slurry leakage in the regulating pipe.

Owner:HUBEI ZHONGNAN PIPELINE CO LTD

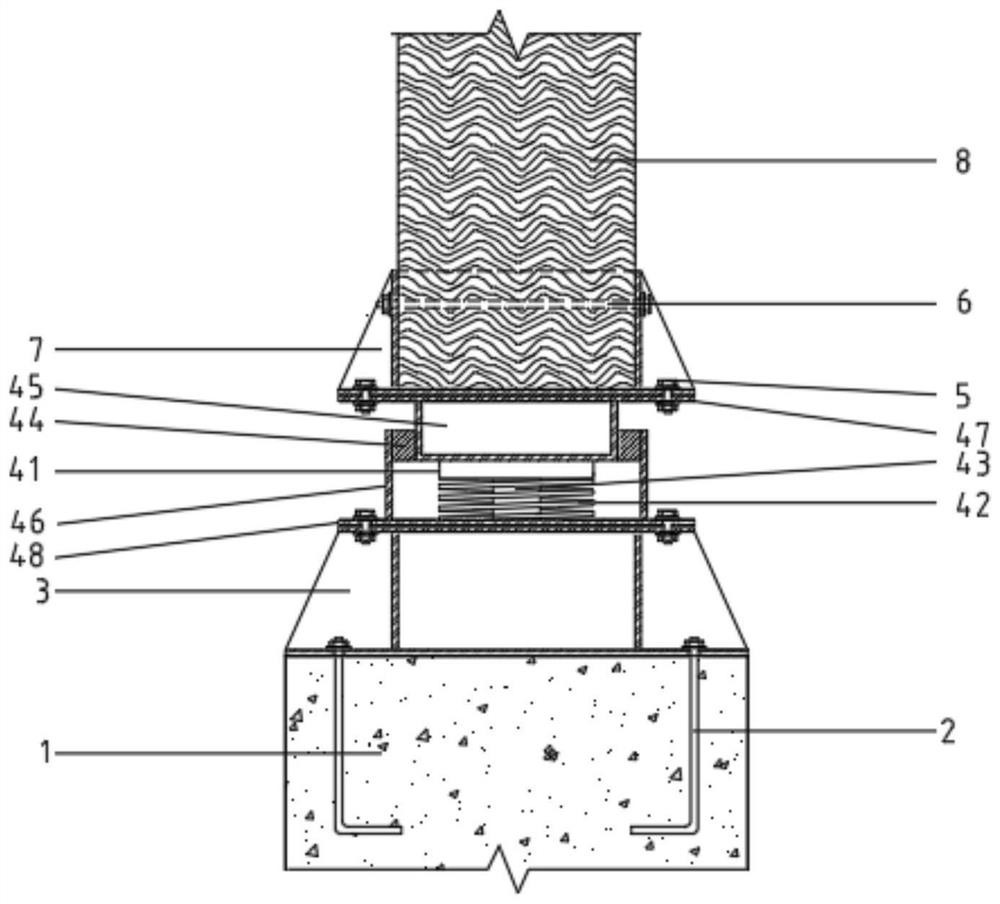

A load-bearing member for timber construction

ActiveCN112049244BReasonable structureFlexible replacementShock proofingViscous dampingEarthquake resistance

The invention relates to a load-bearing component for wooden buildings, which includes a base, a connecting seat is arranged above the base, and a shock-absorbing structure is arranged between the connecting seat and the base, which includes: a first flange, on which a plurality of Installation hole one; cylinder one, the lower end of which is fixed on the first flange; viscous damping liquid, which is filled in cylinder one; cylinder two, which is set in cylinder one and the lower end of cylinder two is immersed in viscous damping liquid Inside; the sealing element is arranged between the cylinder body 2 and the cylinder body 1; the connection plate is fixed on the lower end surface of the cylinder body 2; the column body is vertically arranged and coaxially fixed with the connection plate; body, and one end of it is fixed to the connection plate, and the other end is fixed to the inner bottom surface of the cylinder body one; the second flange has a plurality of mounting holes two evenly distributed on it, and the second flange is fixed on the upper end of the cylinder body two . The invention has reasonable structure, good overall anti-seismic stability, improves the anti-risk ability of the overall structure, and improves the overall anti-seismic performance, durability and stability of the structure.

Owner:DALI UNIV

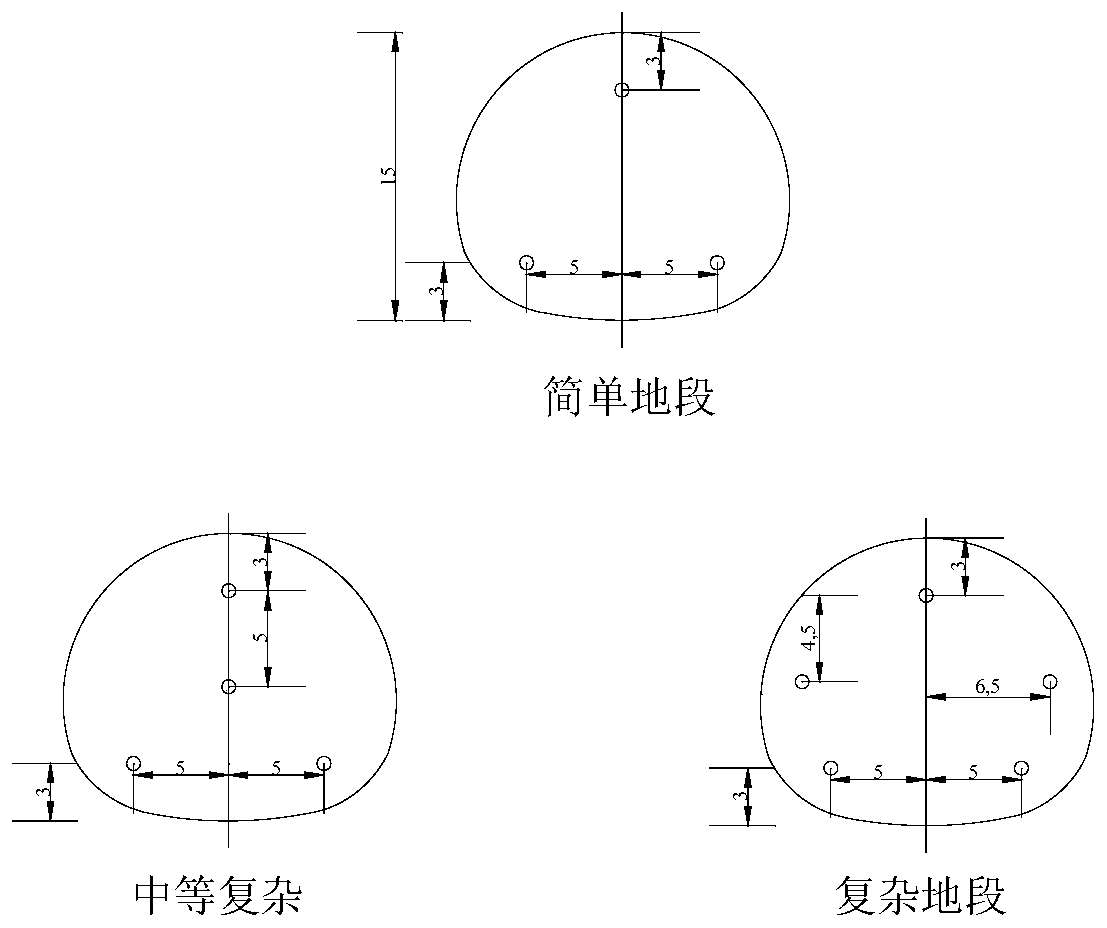

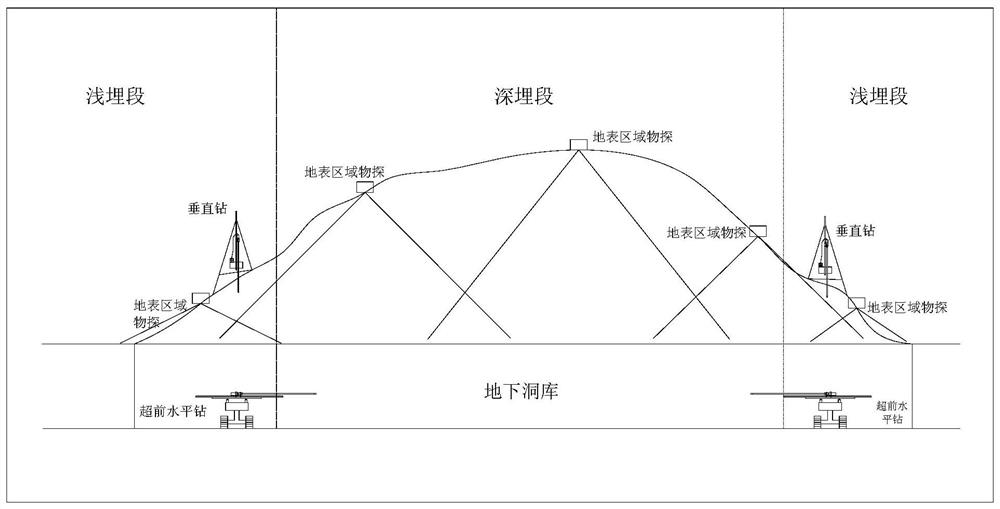

A deep-shallow combined geological survey layout method for underground engineering

ActiveCN111502677BConstruction time is shortReduce labor intensityUnderground chambersTunnel liningMining engineeringGeological survey

The invention discloses a geological survey layout method for deep and shallow combination of underground engineering, comprising: conducting ground survey, forming a survey area geological background report and a geological survey implementation plan; carrying out surface area geophysical exploration, performing engineering geological division, and generating a survey area engineering geological division map , to delineate the geophysical abnormal zone; carry out conventional vertical drilling on the shallow buried section of the underground project, conduct in-situ testing, and take core samples for testing, analyze and judge the engineering geological conditions of the shallow buried section; pre-design the excavation and support of the underground project; Excavate the shallow buried section of underground engineering, conduct advanced geophysical exploration in the cave before excavation; conduct long-distance horizontal drilling, carry out in-situ pressure water tests and take core samples for testing, and analyze the situation ahead of underground engineering excavation; and advanced geophysical exploration Geological data are compared and support design parameters are dynamically adjusted. The invention conducts precise investigation on the geological conditions of the underground engineering, is suitable for underground caverns with different formation lithologies, and has high construction efficiency.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

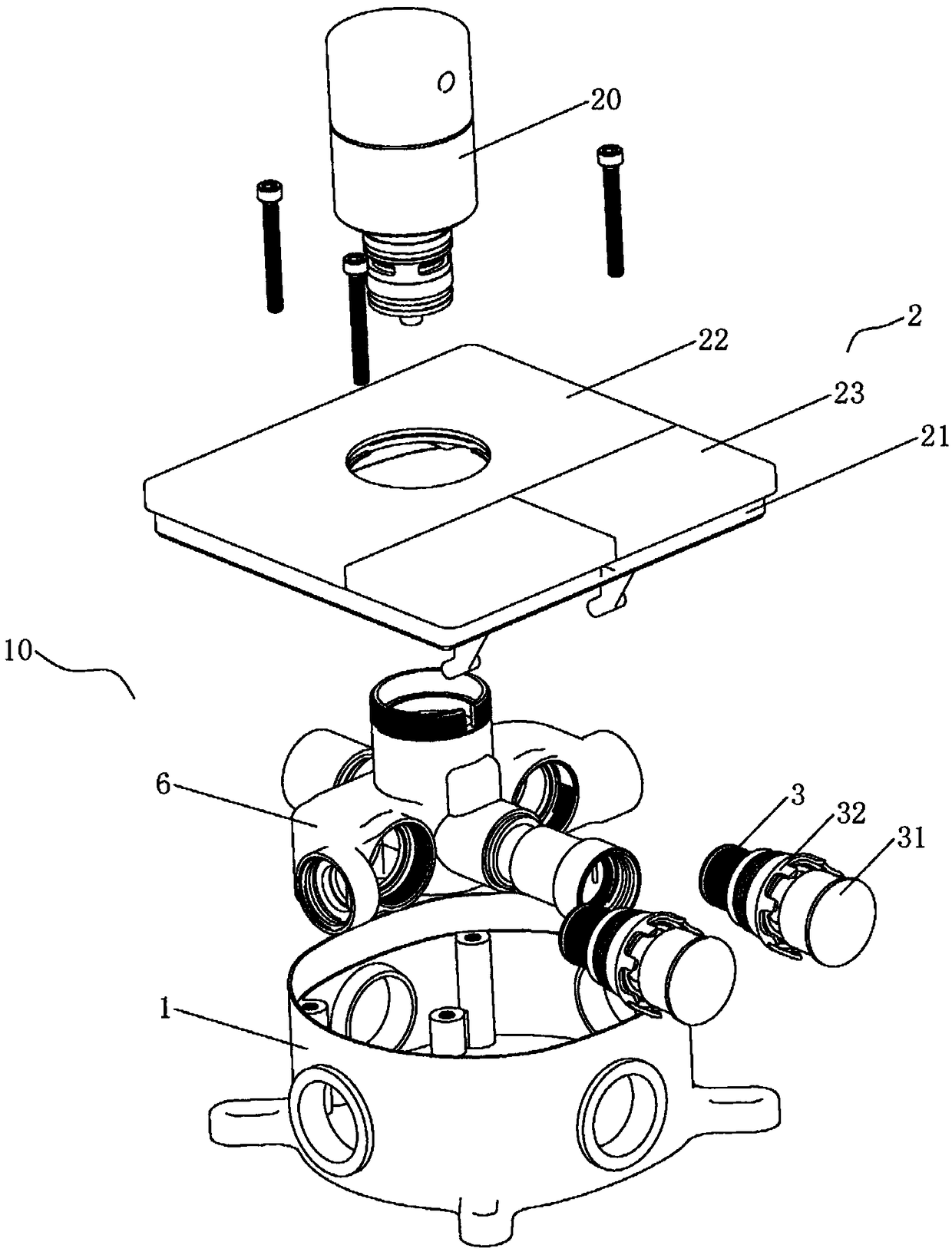

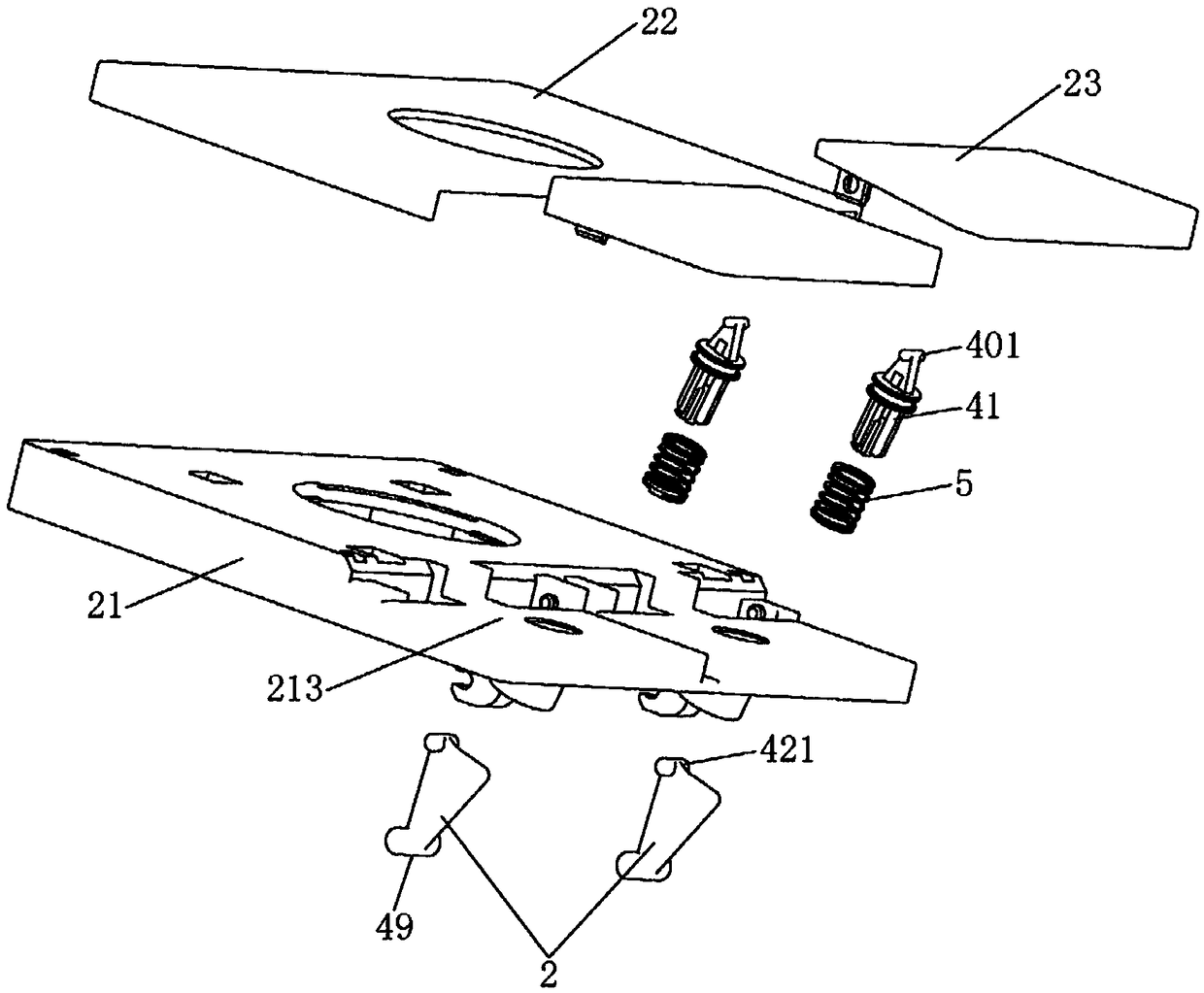

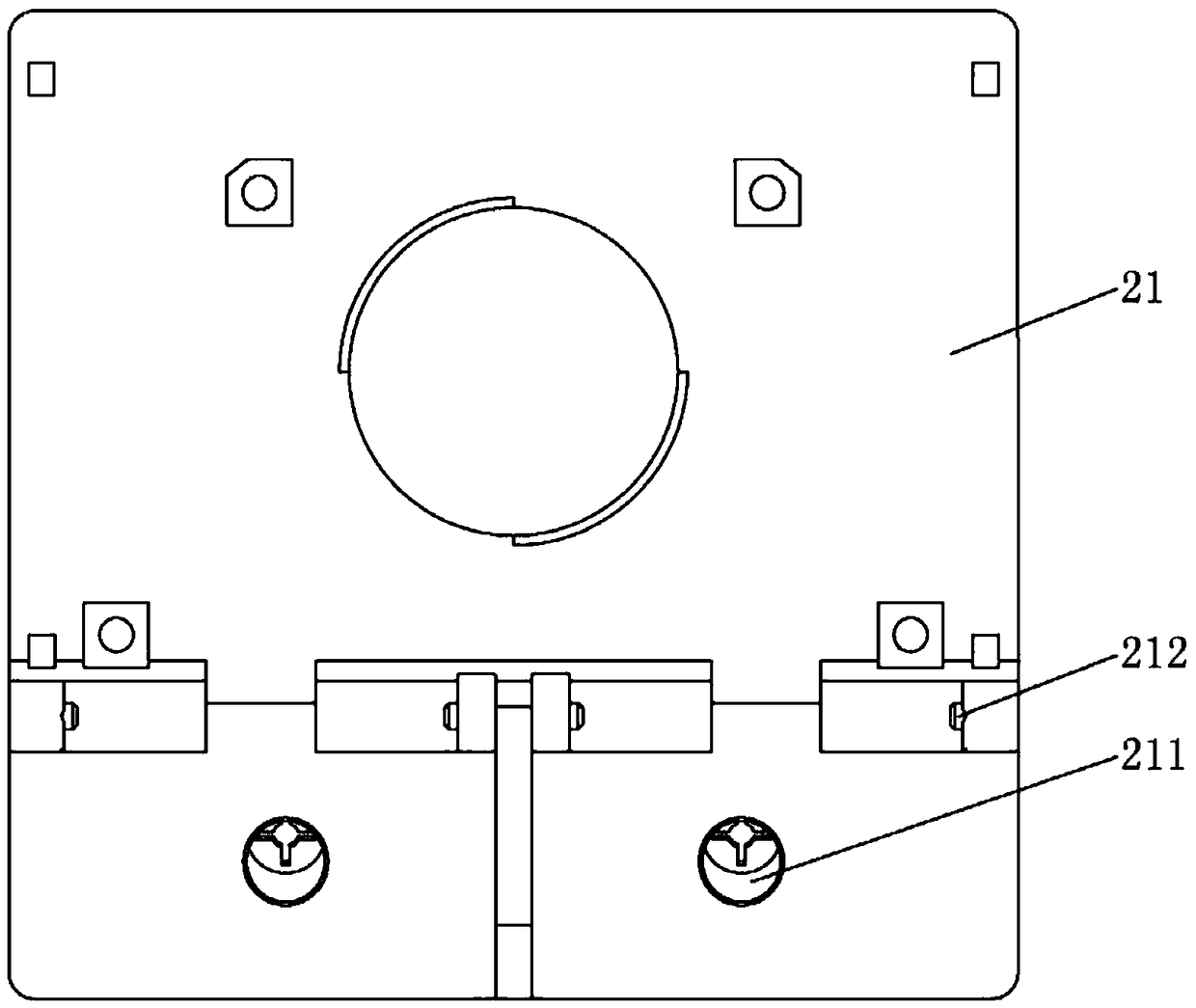

Concealed waterway control box and shower

ActiveCN109296819AThe overall thickness is thinEasy installation needsOperating means/releasing devices for valvesKey pressingVirtual position

The invention discloses a concealed waterway control box. The concealed waterway control box comprises a shell buried in a wall body and a face cover unit used for covering. According to the concealedwaterway control box, a key valve element is arranged in the shell so as to open and close a waterway, and the pressing direction of the pressing end is parallel to the wall face; a drive unit is arranged in the shell, one end of the drive unit stretches out of the face cover unit to form a drive end so as to provide external force for pushing, and the other end of the drive unit is connected with the pressing end of the key valve element in an abutting manner so as to form an abutting end; and the thrust stroke which acts on the driven end and is perpendicular to the wall face is converted into the pressing stroke of the abutting end to the pressing end of the key valve element through a conversion structure between the drive end and the abutting end. According to the concealed waterwaycontrol box, pressing operation can be achieved on the key valve element arranged in the shell, it can be guaranteed that a corresponding shower has low pre-buried depth, meanwhile, no virtual position exists during pressing to the key valve element in the technical scheme, pressing action is more reliable, mounting is more convenient, and the pressing operation position is reasonable.

Owner:JOMOO KITCHEN & BATHROOM

Portable multi-directional steel mesh spacing locator

ActiveCN106382012BSimple and fast operationEasy to operateBuilding material handlingTerrainEngineering

The invention discloses a portable multi-directional steel bar net piece space positioning device, which comprises a positioning clamping element, a hole connecting disc and a head connecting disc. A hollow design concept is used; in addition, an entity of the portable multi-directional steel bar net piece space positioning device is formed by assembling all parts; the carrying, the assembly and the operation are convenient; meanwhile, the arrangement of the portable multi-directional steel bar net piece space positioning device is flexible; the precision is controllable; each part can be designed and processed according to unit length; after the assembly, the integral precision is also controlled in the unit length; no artificial operation error and no processing error exist; in addition, the cost of the portable multi-directional steel bar net piece space positioning device is low; the processing is convenient; the positioning is firm; the space is adjustable. The portable multi-directional steel bar net piece space positioning device can also be widely used in different terrains without limitation; meanwhile, the one-way positioning function can be realized; in addition, the space positioning function in any direction can also be realized, for example in the X direction, the Y direction, the Z direction, the XY direction, the XZ direction, the YZ direction and the like; meanwhile, the space positioning device can be used for the steel bar net space positioning of various components such as beams, plates, posts, walls and blinding layers.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

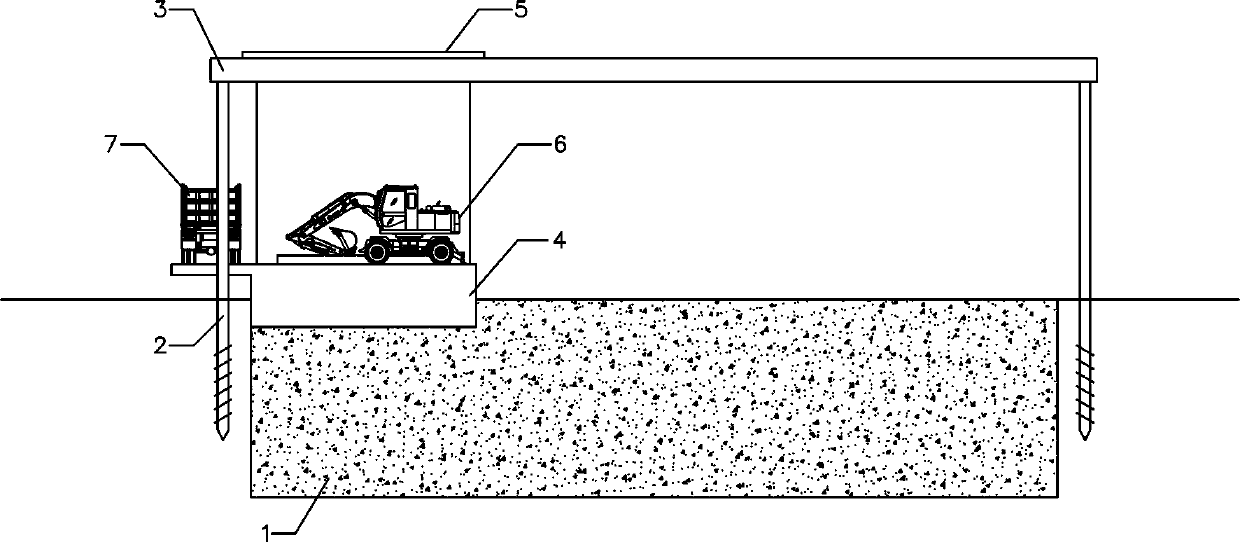

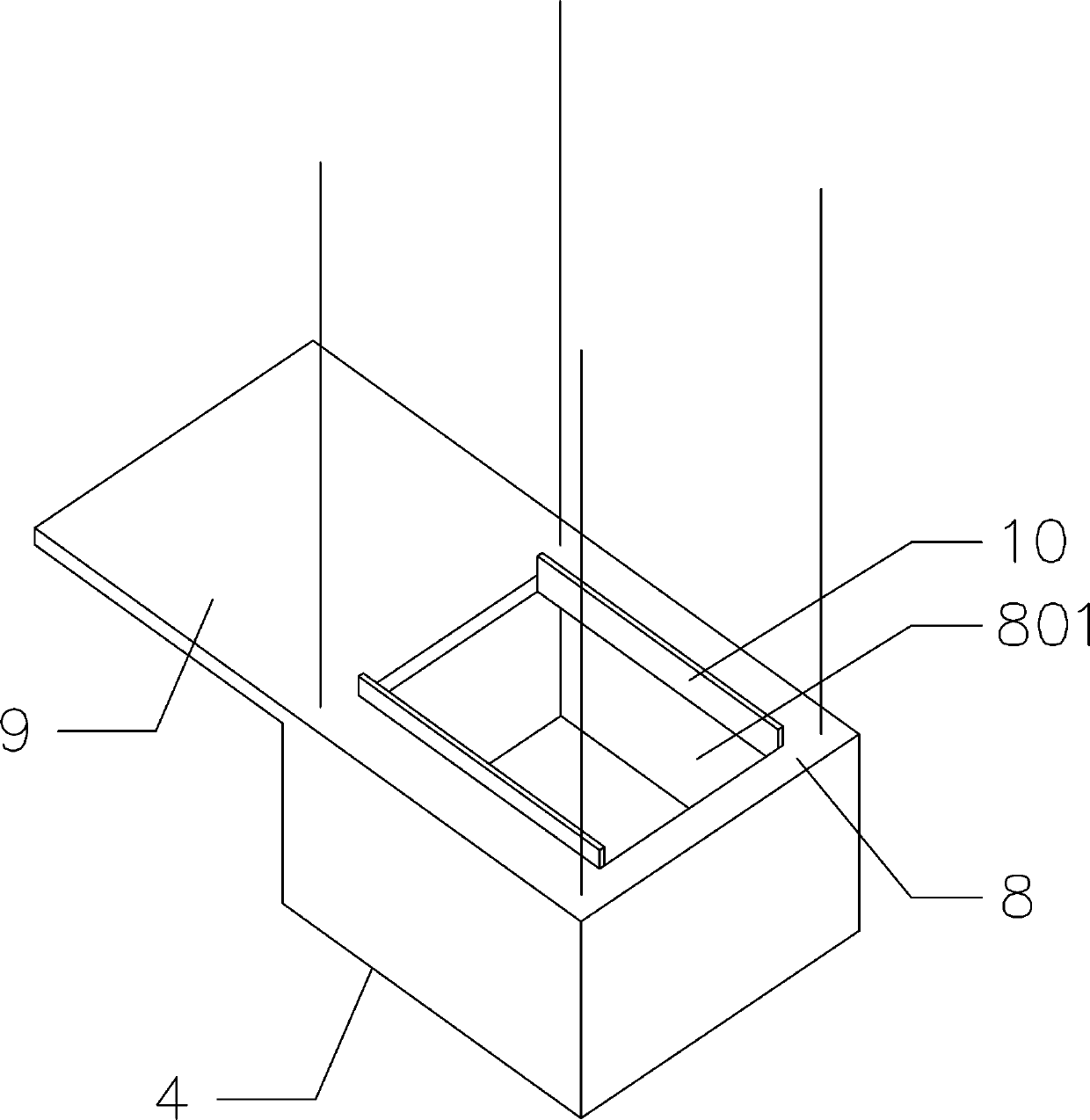

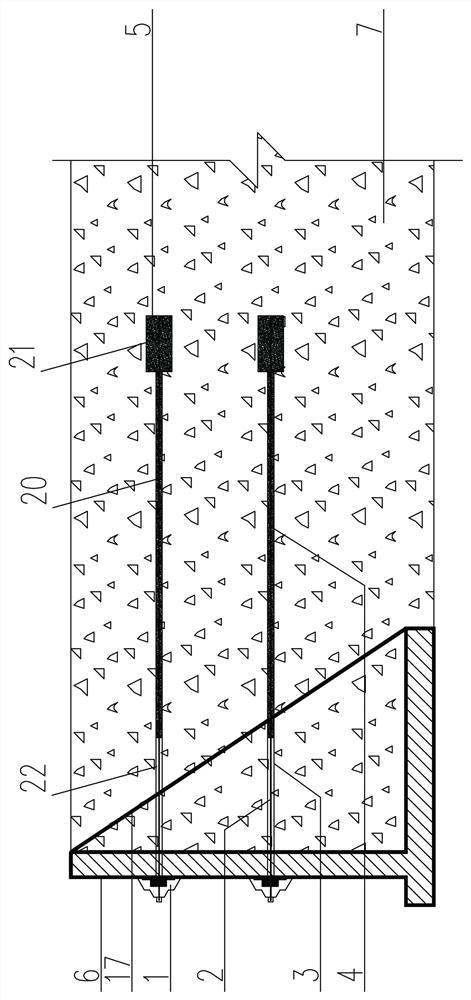

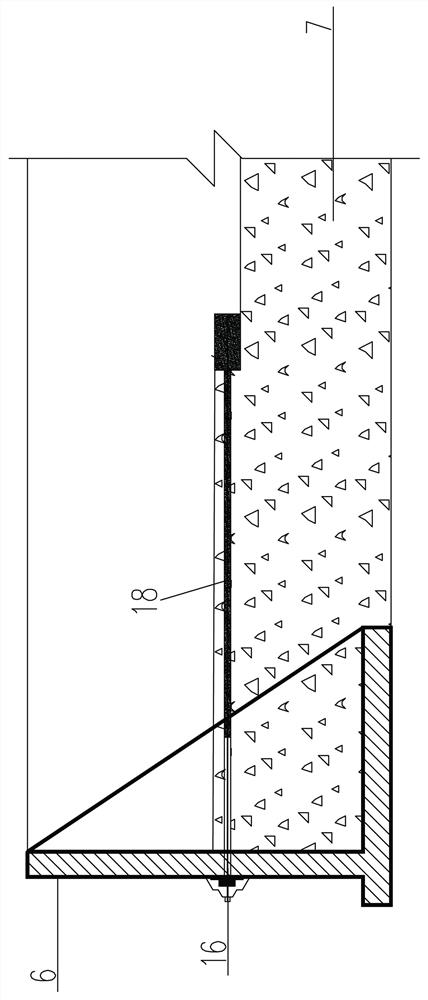

Excavation construction method of silty foundation pit

ActiveCN110004934BConstruction time is shortImprove construction efficiencyExcavationsSoil preservationOverhead craneTruck

The invention provides a muddy foundation pit excavation construction method. An excavator and a dump truck are hoisted through a bridge crane, and foundation pit excavation operation is conducted instone dumping and mud filling modes and in partitioning and layering modes. The muddy foundation pit excavation construction method specifically comprises the following steps that (1) a to-be-excavated area is designated, and piles are driven around the to-be-excavated area through a pile driver; (2) a bridge crane frame and the bridge crane are mounted on the upper parts of the piles in a hoistedmode; (3) an operation platform plate is fixedly arranged on a hoisting rope of the bridge crane; (4) the excavator is driven onto the operation platform plate; (5) rock ballast is dumped into the to-be-excavated area through the dump truck; (6) the rock ballast is ground into the to-be-excavated area through the excavator; (7) foundation excavation operation of the to-be-excavated area is conducted through the excavator; and (8) the foundation excavation operation of the to-be-excavated area is conducted in the partitioning and layering modes. By adopting the construction method of stone dumping and mud filling, the bearing ability and water permeability of mud are improved through the rock ballast, the construction demands of transporting while excavating of a foundation pit are met, the excavation construction period of the muddy foundation pit is shortened, and the construction efficiency is improved.

Owner:国能大渡河猴子岩发电有限公司 +1

Embedded anchoring-buttress type combined retaining wall structure and construction method

PendingCN113802602AFix stability issuesSolve sizeArtificial islandsUnderwater structuresButtressPre stress

The invention discloses an embedded anchoring-buttress type combined retaining wall structure and a construction method, and belongs to the technical field of geotechnical engineering. A plurality of parallel inclined buttresses are arranged on the inner side of a buttress type retaining wall. A vertical face of the buttress type retaining wall is provided with reserved anchor cable holes, and the inner side of the buttress type retaining wall is a backfilled gravel soil layer. The backfill gravel soil layer is provided with a groove body, and the groove body comprises an anchor cable free groove, an anchor cable anchoring groove and an expansion head groove. The inner end of the anchor cable forms an anchor cable anchoring section and an expansion head in the anchor cable anchoring groove and the expansion head groove by pouring cement mortar. A plurality of steel strands at the outer end of the anchor cable penetrate through the anchor cable free groove and are fixed to the anchor head through reserved anchor cable holes. A plurality of steel strands in the anchor cable free section and the anchor cable anchoring section are supported in the groove body through a plurality of centering supports. The invention further provides a construction method. The pre-stressed anchoring technology is combined with a traditional buttress type retaining wall to work, so that the problems that a high buttress type retaining wall is poor in stability, large in size, high in manufacturing cost and the like when working independently are solved. The construction time is short, the engineering cost is low, and the quality is good.

Owner:SHENYANG ZHONGJIAN DONGSHE GEOTECHN ENG +1

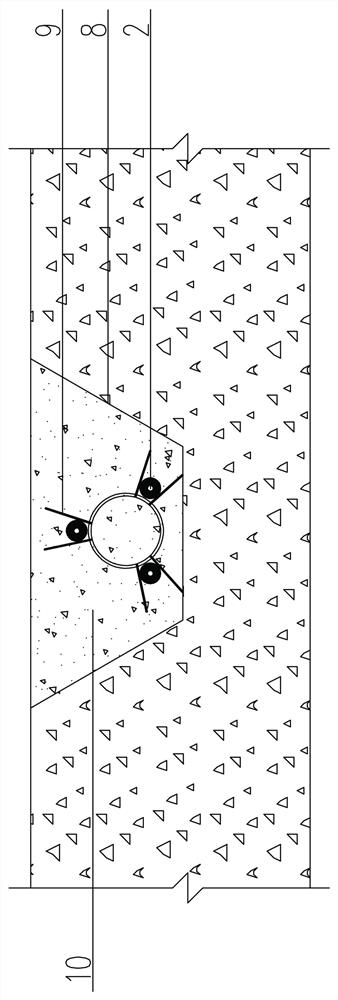

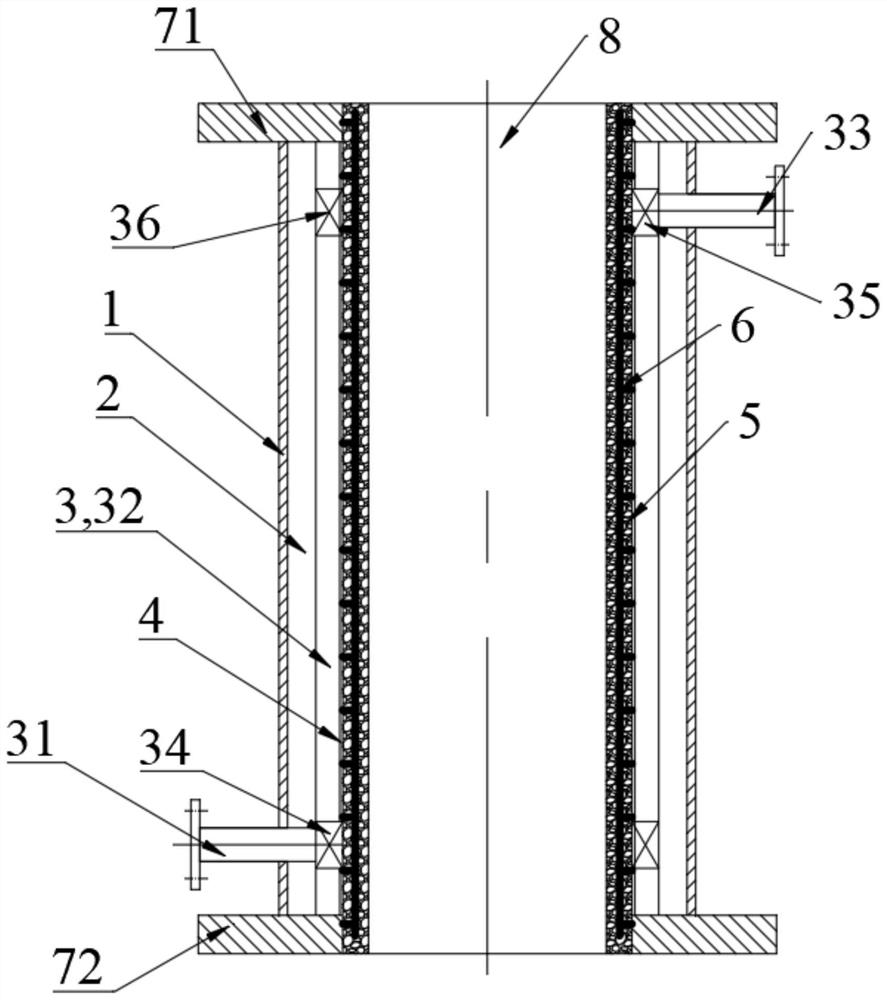

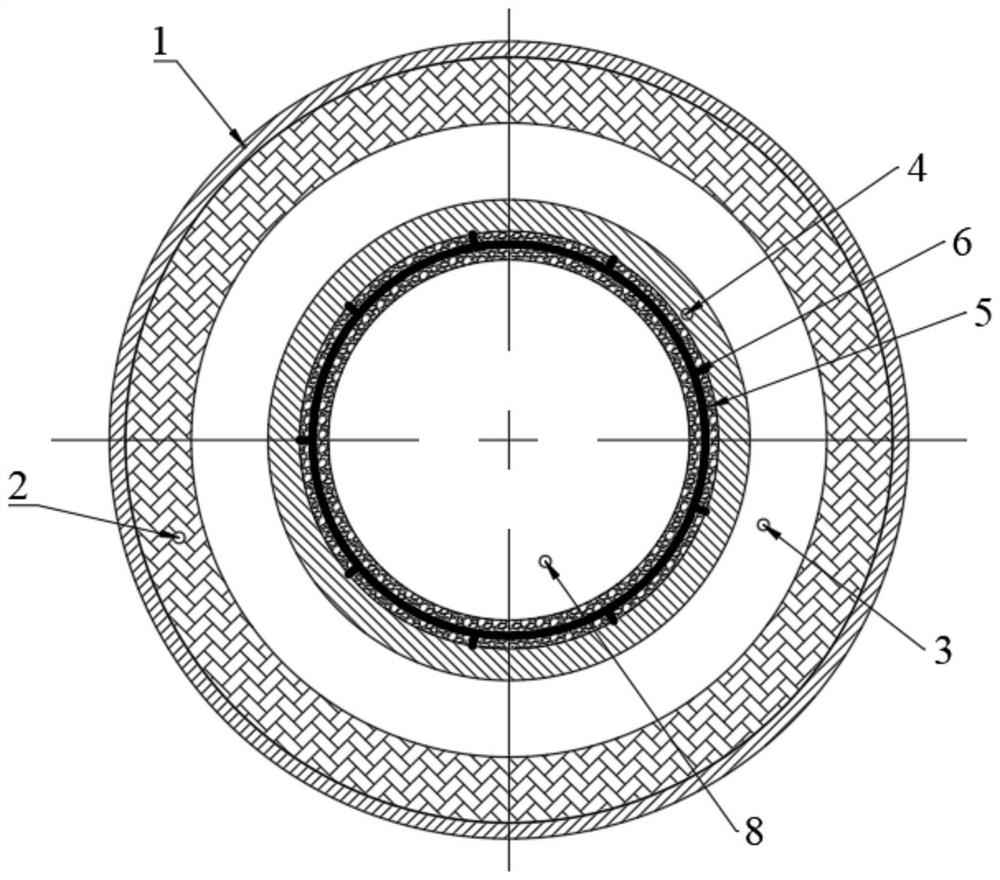

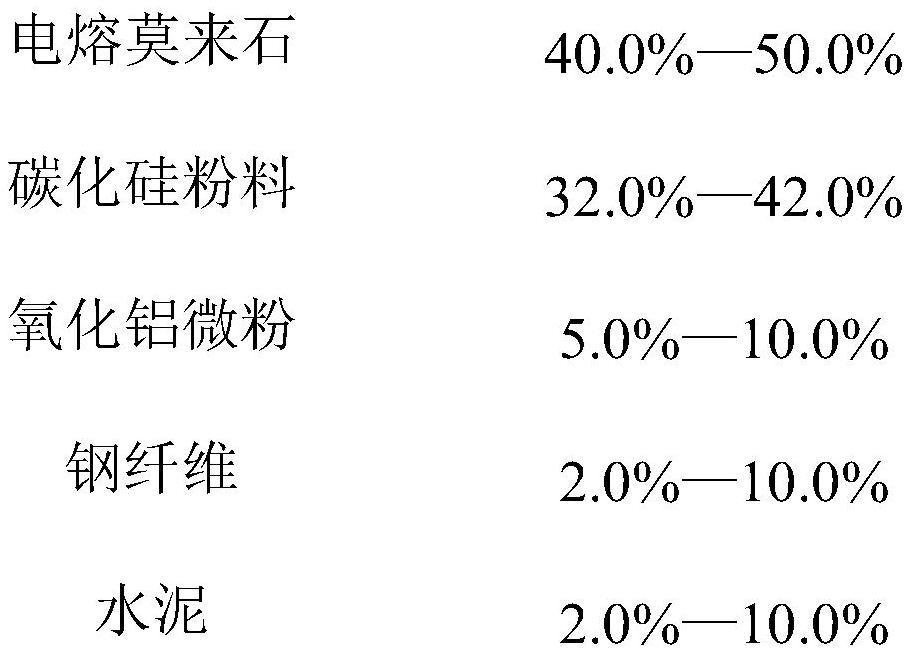

Temperature-resistant anti-corrosion lining coating for riser heat exchanger and construction method thereof

ActiveCN113501681ASolve cokingSolve the smokePretreated surfacesCoatingsCarbide siliconCorrosion prevention

The invention relates to a temperature-resistant anti-corrosion lining coating for a riser heat exchanger and a construction method thereof. The lining coating comprises the following components in percentage by mass: 40.0%-50.0% of fused mullite, 32.0%-42.0% of silicon carbide powder, 5.0%-10.0% of alumina micro powder, 2.0%-10.0% of steel fibers and 2.0%-10.0% of cement, and the total mass percentage of the fused mullite, the silicon carbide powder, the alumina micro powder, the steel fibers and the cement is 100%. The mass of the silica sol accounts for 5-10% of the total mass of the fused mullite, the silicon carbide powder, the alumina micro powder, the steel fiber and the cement; the construction method comprises the steps of solid raw material mixing, coating preparation, framework fixing and coating coating, the prepared coating is evenly coated on the inner wall of the ascending pipe, and after natural curing, the formed solid coating layer is formed through baking. The lining coating is uniformly coated on the inner wall of the riser heat exchanger and is fixed through the hexsteel, so that the coating is effectively prevented from stripping, the problems of corrosion, coking and smoking of the riser heat exchanger are effectively solved, the riser heat exchanger is prevented from being damaged, and the safety and the stability of the heat exchange device are improved.

Owner:常州江南冶金科技有限公司

Disconnected-type plugging structure and method of wall beam on concrete-poured wall

ActiveCN108824804AWill not harmEliminate weldsForms/shuttering/falseworksRebarTransverse reinforcement

The invention relates to a disconnected-type plugging structure of a wall beam on a concrete-poured wall. The disconnected-type plugging structure comprises a retractable inserting plate, adjustable jacking rods and longitudinal transverse bars; the longitudinal transverse bars are arranged outside the retractable inserting plate; the adjustable jacking rods are arranged between the longitudinal transverse bars and the retractable inserting plate; and the retractable inserting plate is tightly attached to a mould at the breakage plugging position through the adjustable jacking rods. A pluggingmethod comprises the steps that the manufactured retractable inserting plate is inserted into the position, needing breakage plugging, of the wall beam, and the size of the retractable inserting plate is adjusted according to the plugging demand; the longitudinal transverse bars are inserted along the two sides; and the multiple adjustable jacking rods are evenly arranged between the longitudinaltransverse bars and the retractable inserting plate, the adjustable jacking rods are adjusted to enable the two ends of the adjustable jacking rods to tightly abut against the retractable inserting plate and the longitudinal transverse bars correspondingly, and the retractable inserting plate is tightly attached to the mould at the breakage plugging position under the effect of the adjustable jacking rods. The disconnected-type plugging structure and method have the beneficial effects that additional welding of a transverse steel bar can be omitted, disassembly is easier, damage to the structure is avoided, and meanwhile the stability of the whole structure is better.

Owner:CHINA FIRST METALLURGICAL GROUP

A hanger platform for maintenance and reinforcement of a t-beam

The invention discloses a hanger platform for T-shaped beam maintenance and reinforcement. The hanger platform comprises a platform fixing device and a working platform. The platform fixing device isarranged on a T-shaped beam in an assembled mode. The working platform comprises a plurality of hanger sets, and all the hanger sets are arranged at intervals in the longitudinal direction of a bridge. Each hanger set comprises two vertically-arranged hangers which are arranged in a spaced mode in the transverse direction of the bridge. The tops of the hangers are detachably connected to the platform fixing device. A rectangular frame is detachably arranged between every two adjacent hanger sets, and a passage for allowing a maintainer to pass through is formed between each rectangular frame and the platform fixing device. All the rectangular frames are located in the same horizontal face. By adopting modular construction, the construction time for platform erecting is short, the construction technology is simple, operation is easy, and safety of a constructor can be ensured.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com