Excavation construction method of silty foundation pit

A construction method and silt-based technology, which is applied in excavation, infrastructure engineering, soil protection, etc., can solve problems such as inability to meet construction period requirements, low efficiency of construction machinery and equipment, and long waiting time for shutdown, so as to shorten construction time. , Improving construction efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

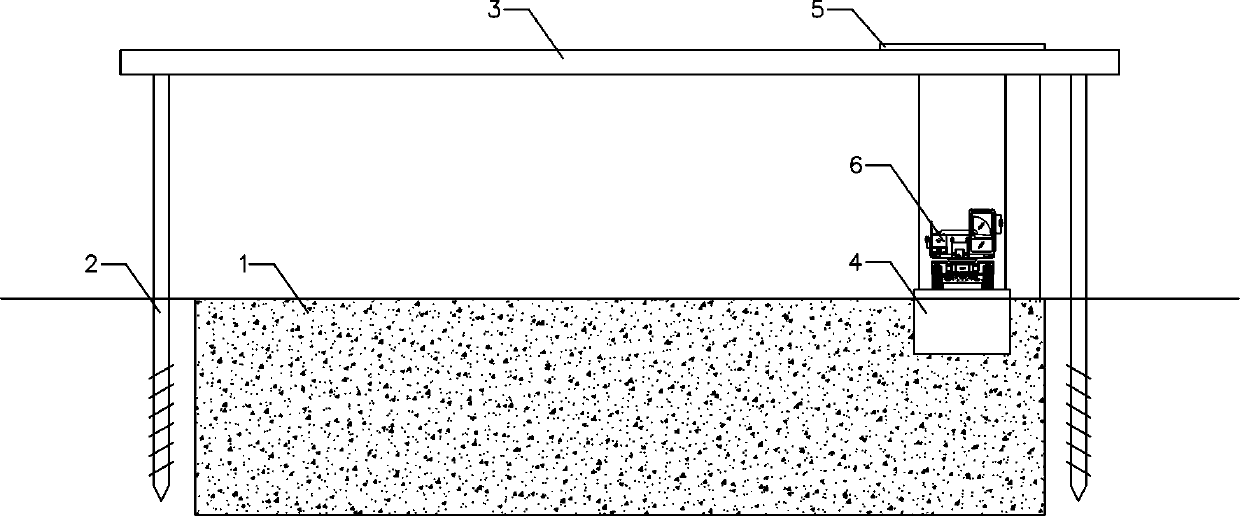

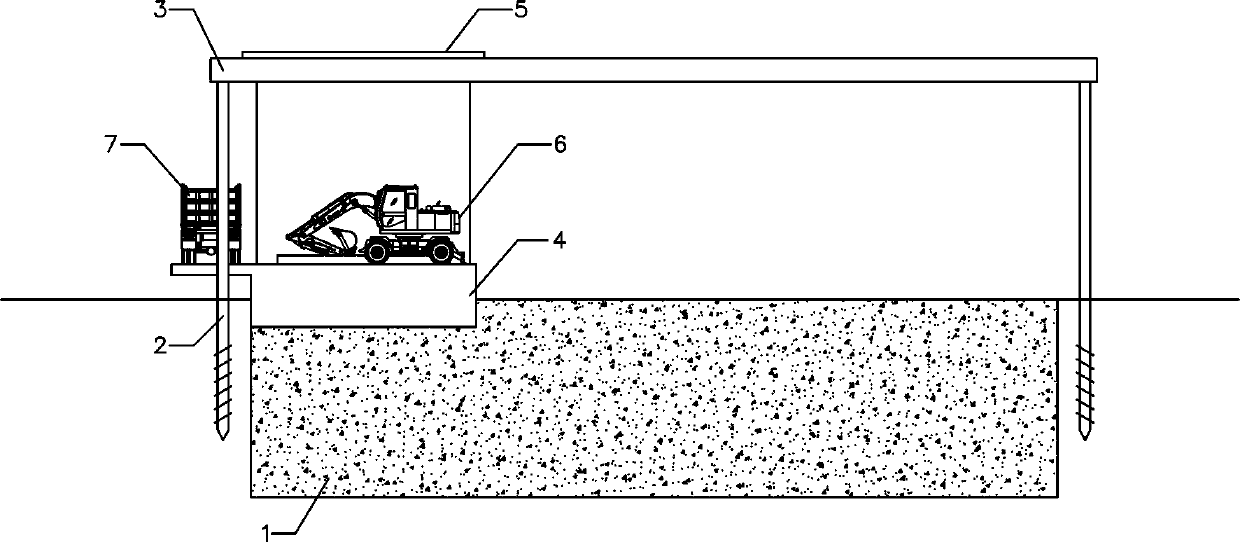

[0040] Such as Figure 1-2 Among them, a muddy foundation pit excavation construction method, the excavator 6 and the dump truck 7 are hoisted by a bridge crane, and the excavation of the foundation pit is carried out in blocks and layers by riprap and silt filling;

[0041] Specifically include the following steps:

[0042] 1) Define the area to be excavated 1, and drive piles 2 around the area to be excavated 1 with a pile driver;

[0043] 2) Hoist and install the bridge frame 3 and the bridge machine 5 above the pile 2;

[0044] 3) Fix the work platform plate 4 on the hoisting rope 19 of the bridge crane 5;

[0045] 4) Drive the excavator 6 onto the work platform plate 4;

[0046] 5) Throw and fill gravel into the area 1 to be excavated by dump truck 7;

[0047] 6) After the gravel dumping operation is completed, use the excavator 6 to grind the gravel into the area 1 to be excavated;

[0048] 7) Carry out the foundation pit excavation operation of the area 1 to be exc...

Embodiment 2

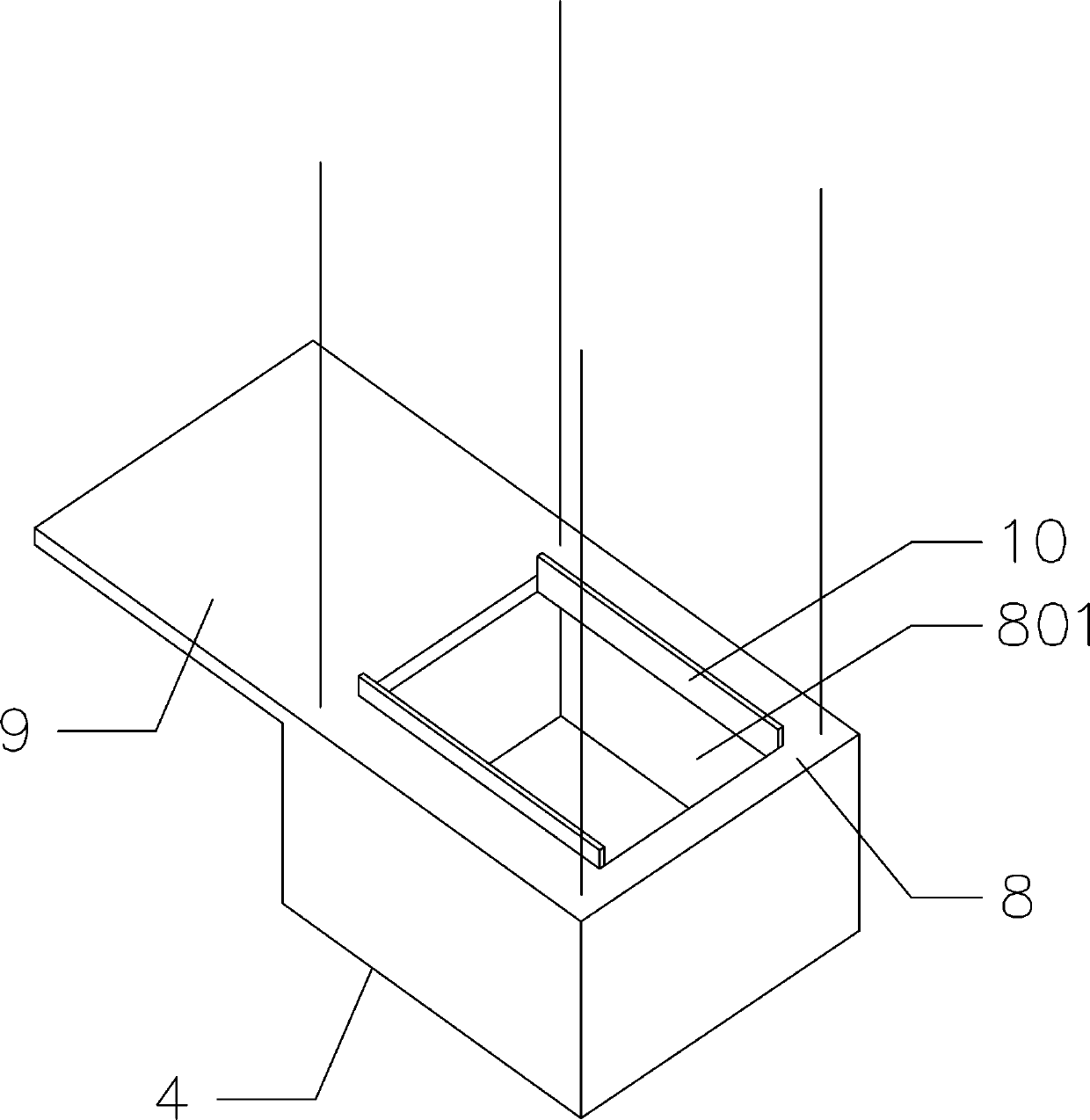

[0051] Such as Figure 3-4 On the basis of Embodiment 1, the working platform plate 4 includes an excavator working platform 8 and a dump truck parking platform 9, and the dump truck parking platform 9 is fixed on one side of the excavator working platform 8;

[0052] The excavator work platform 8 is provided with a downward lower side plate 11 around, and the top surface of the excavator work platform 8 is provided with a work hole 801, and the lower side plate 11 of the excavator work platform 8 includes a constant width plate section 111 in the upper half. And the widened plate section 112 in the lower half, the plate width of the widened plate section 112 gradually decreases from top to bottom.

[0053] In a preferred solution, the height of the lower side plate 11 is 3-5m.

[0054] In a preferred solution, side baffles 10 for positioning the excavator 6 are provided on the top surface of the excavator working platform 8 on both sides of the working hole 801 .

Embodiment 3

[0056] Such as Figure 5 Among them, the bridge frame 3 is composed of a plurality of section steels 12, the section steels 12 on both sides are provided with a first rail 13, the cart 14 of the bridge machine 5 is arranged on the first rail 13 and passes through the cart motor 15 Drive to realize movement along the direction of the first track 13;

[0057] Be provided with crossbeam 16 on cart 14, be provided with second track 17 on the top surface of crossbeam 16, the hoist trolley 18 of bridge crane 5 is arranged on the second track 17 and can move along the second track 17 direction.

[0058] In a preferred solution, the section steel 12 at both ends of the bridge frame 3 is made of I-beam, the section steel 12 and the beam 16 on both sides of the bridge frame 3 are made of channel steel, and the grooves of the channel steel are directly used as tracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com