Aluminum alloy vertical trim strip inserting construction process

A construction technology and decorative strip technology, which is applied to building components, walls, buildings, etc., can solve the problems that it is difficult to ensure the verticality and flatness of aluminum alloy vertical decorative strips, and achieve the effect of short time consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

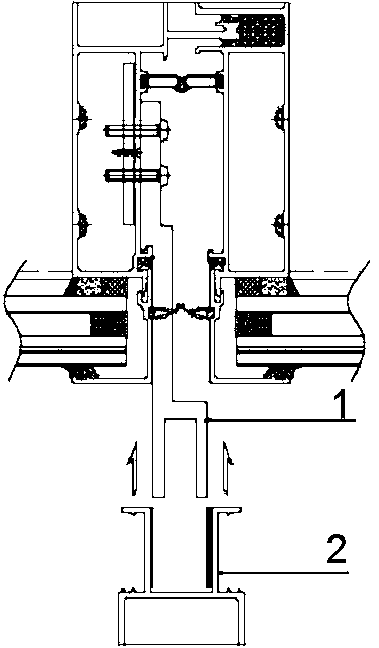

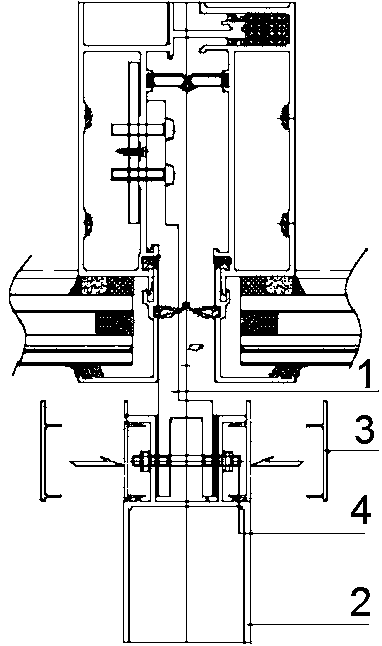

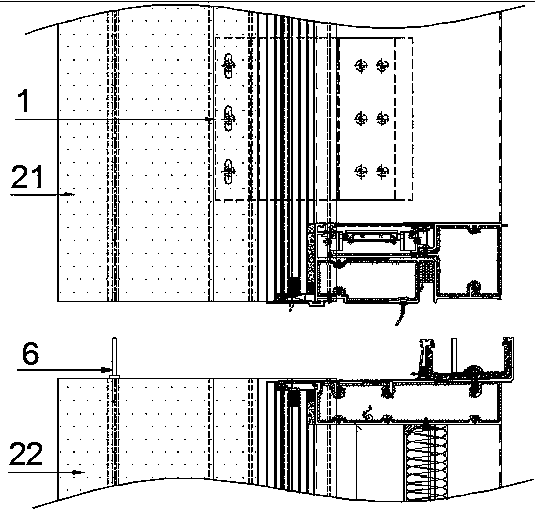

Image

Examples

Embodiment

[0029] The main structural system is: the tower "frame-core tube" structure, the podium adopts a frame structure, the project covers an area of S=8831.55㎡, the total construction area of S=107447.01㎡, the above-ground construction area of S=82,000㎡, and the underground construction area of 2.5 10,000 square meters, four basement floors (height 4.5 / 4.8 / 5.4) with a depth of 17 meters, 37 floors above ground (height 4.2 meters), and a building height of 159.9 meters (7\18\29 are refuge floors). The podium is a frame curtain wall with an exterior area of 5386.02㎡; the tower building is a unitized glass curtain wall with an exterior area of about 26652.47m2. The construction site of the project adopts the technology of the present invention, and the whole construction process is in a safe, high-quality, fast and controllable state, and the vertical flatness of the aluminum alloy vertical decorative strip meets the design requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com