A load-bearing member for timber construction

A technology for load-bearing components and buildings, applied in building components, building structures, buildings, etc., can solve the problems of high economic cost, complicated replacement and maintenance construction, etc., and achieve the effect of low investment cost, reasonable overall structure, and reduced construction and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

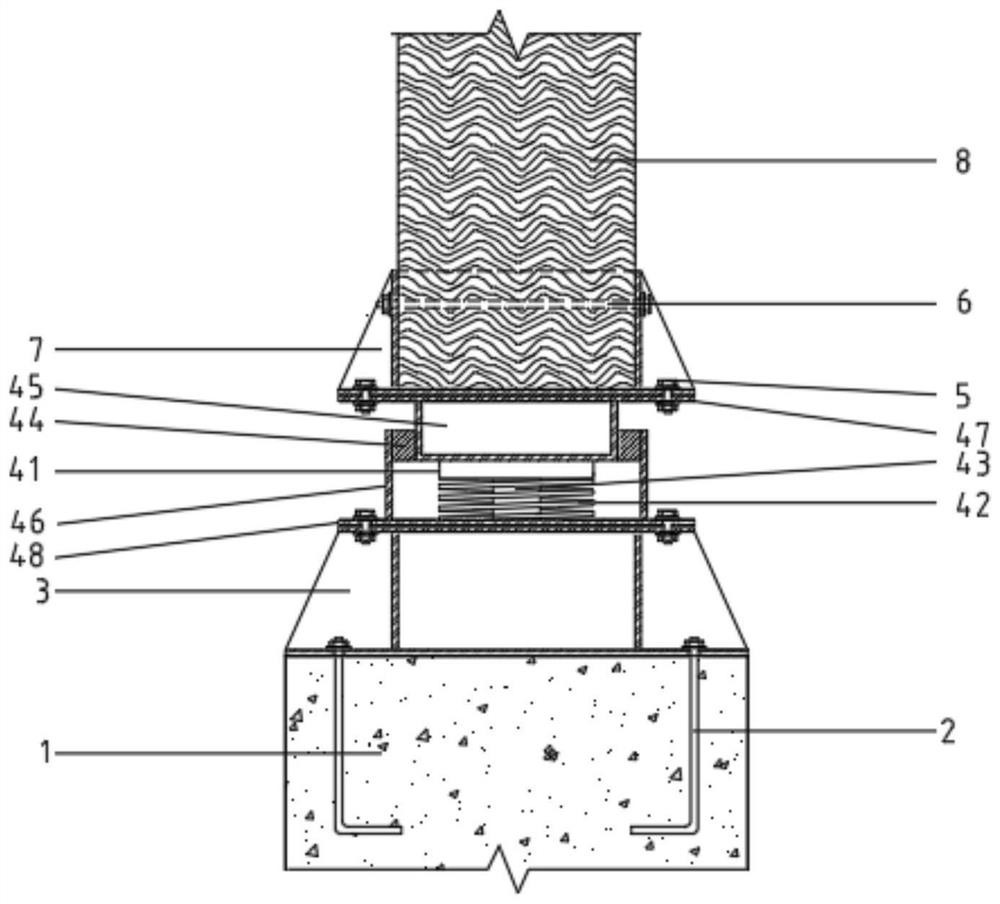

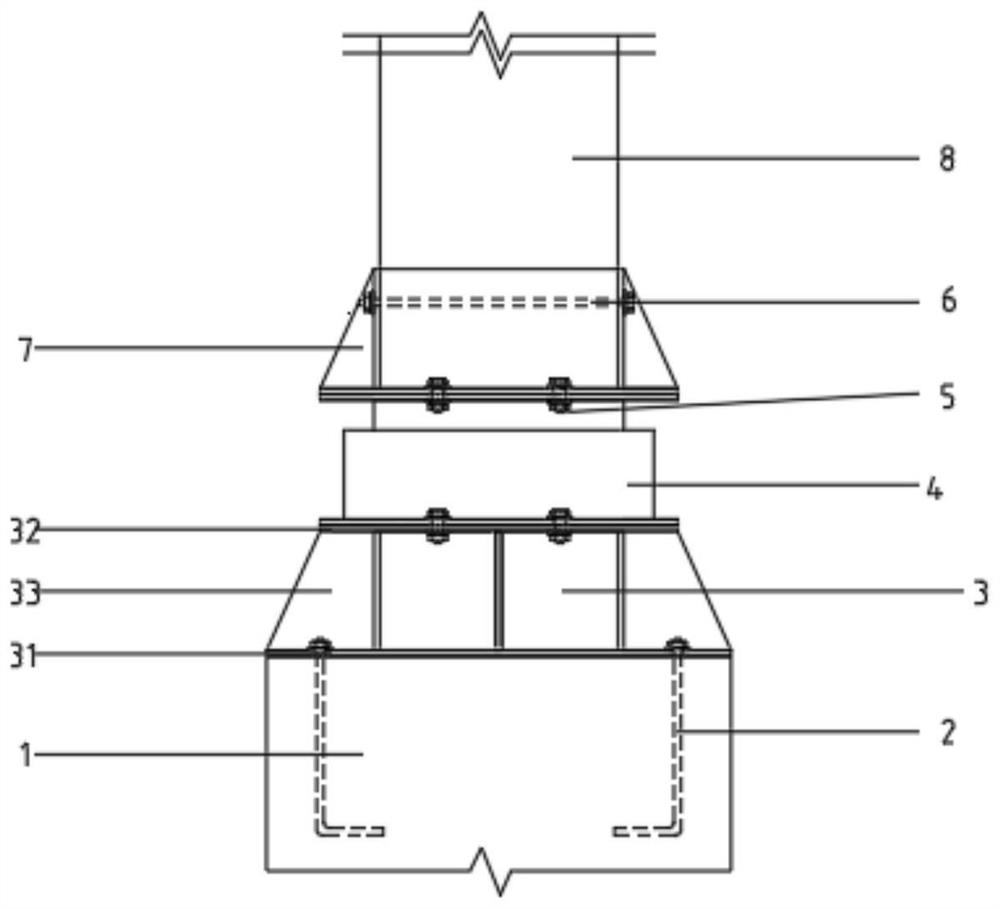

[0039] like figure 1 and figure 2 As shown, a load-bearing component for wooden buildings provided by the present invention includes a base 3, the base 3 is arranged above the concrete foundation 1, and an embedded part 2 is arranged in the concrete foundation 1, and one end of the embedded part 2 It is fixed in the concrete foundation 1, and the other end extends above the base 3 to achieve a fixed connection with the base 3.

[0040] As a further preferred solution, the embedded part 2 is a high-strength stainless steel connecting bolt.

[0041] As a further preferred solution, the concrete foundation 1 may be a prefabricated foundation or a cast-in-place foundation.

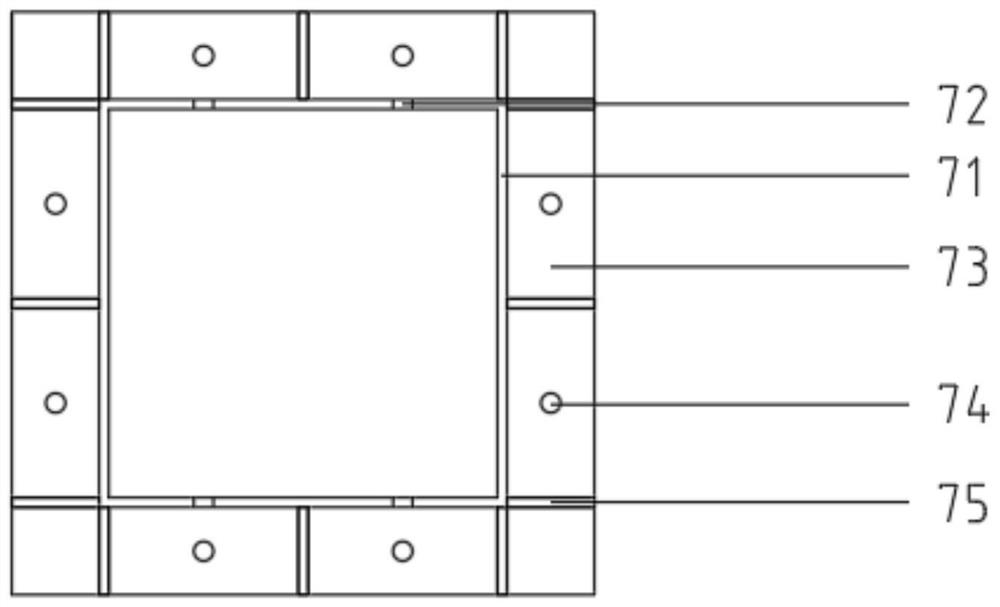

[0042] Wherein, as a further preferred solution, the structural composition of the base 3 includes:

[0043] The fourth flange 31 has a plurality of mounting holes 5 evenly distributed thereon, and the mounting holes 5 are used for piercing the embedded parts 2 to realize the fixed connection with the conc...

Embodiment 2

[0068] In order to achieve multi-stage shock absorption on the vibration propagation path and to reduce the impact of vibration on the entire structure step by step, a bean bag damper for buffering vibration is fixed inside the cylinder 4 33 .

[0069] It is also possible to directly use the cylinder 433 as a shock-absorbing cavity, and then place a variety of mixed-sized particle dampers inside it, which are used to reduce the energy of the vibration by colliding with each other during the vibration, so as to realize the anti-vibration effect. buffer.

[0070] The invention provides a load-bearing member for wooden buildings, the overall structure is reasonable, the load-bearing member is a combined structure, the construction time is less when replacing, and the investment cost is low, and the flexible replacement and rapid assembly of wooden components can also be realized. Significantly reduce construction strength and construction maintenance costs. The structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com