Industrialized EPS module wall plate system matched with fabricated steel frame

A steel frame and assembly technology, applied to walls, protective buildings/shelters, building components, etc., can solve the problems of unfavorable EPS module wall promotion and application, low construction efficiency, difficult splicing, etc., and it is easy to achieve dimensional accuracy The effect of grasping, enhancing safety, and shortening the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the technical solutions of the present invention will be further described through specific implementation modes below in conjunction with the accompanying drawings.

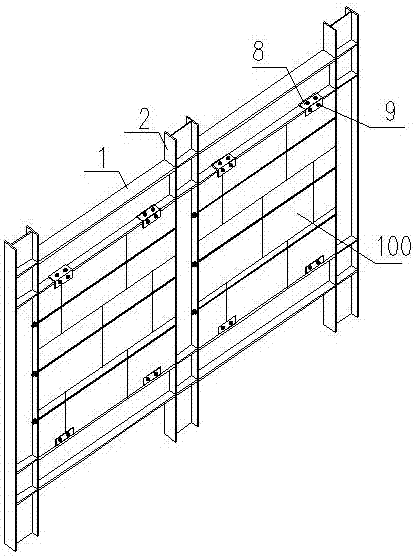

[0044] An industrialized EPS modular wall panel system matched with a prefabricated steel frame, including wall panels and connection nodes between the wall panels and the steel frame, and the beams and columns of the steel frame are all I-beams;

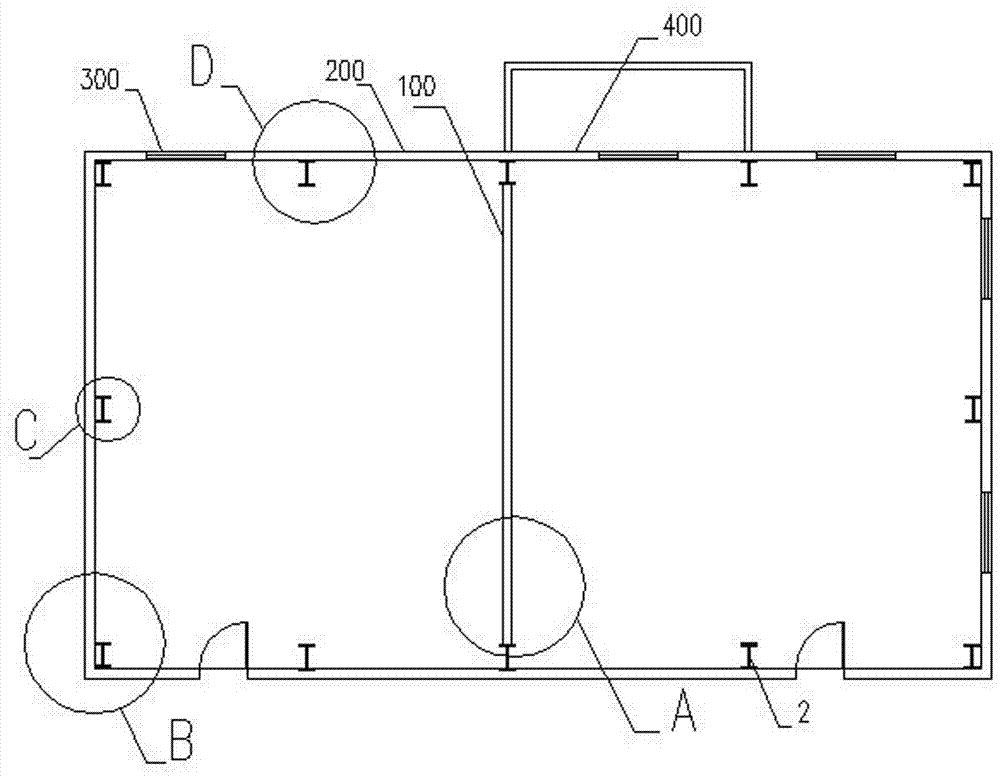

[0045] figure 1 It is a schematic diagram of the wall panel system. According to the different positions of the wall panels, the wall panels are divided into four types: prefabricated interior partition wall panels 100, prefabricated exterior wall panels 200, prefabricated window opening wall panels 300, and prefabricated external bay window wall panels 400.

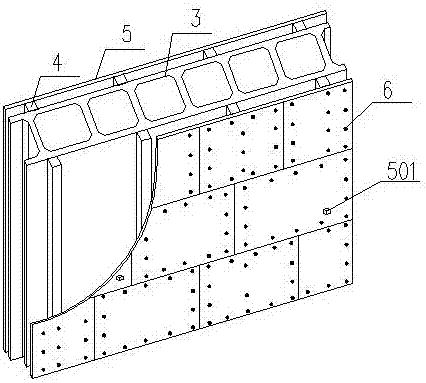

[0046] The structure of the above four types of wall panels are: EPS module 3, wooden ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com