A fiber material conveying device

A conveying device and fiber technology, which is applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of uneven concentration of fiber added, reduce the effect of fiber use, increase construction risks, etc., and achieve shortened construction time and simple structure. , The effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

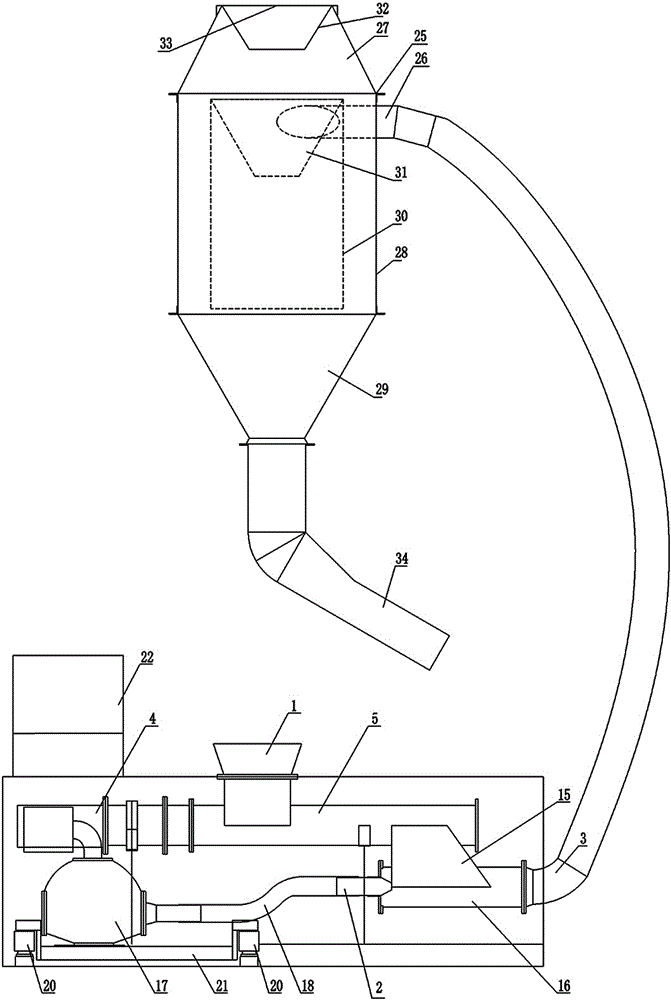

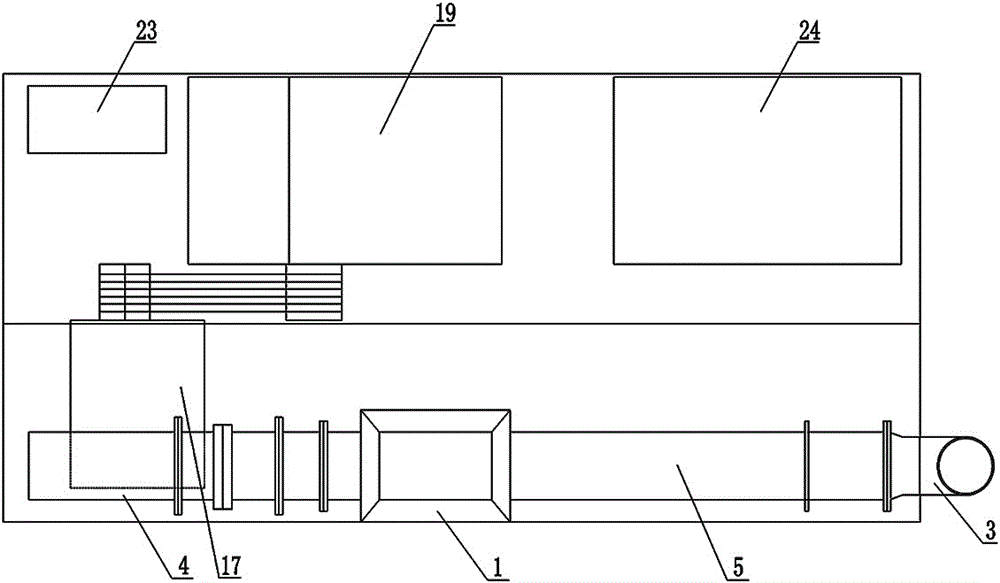

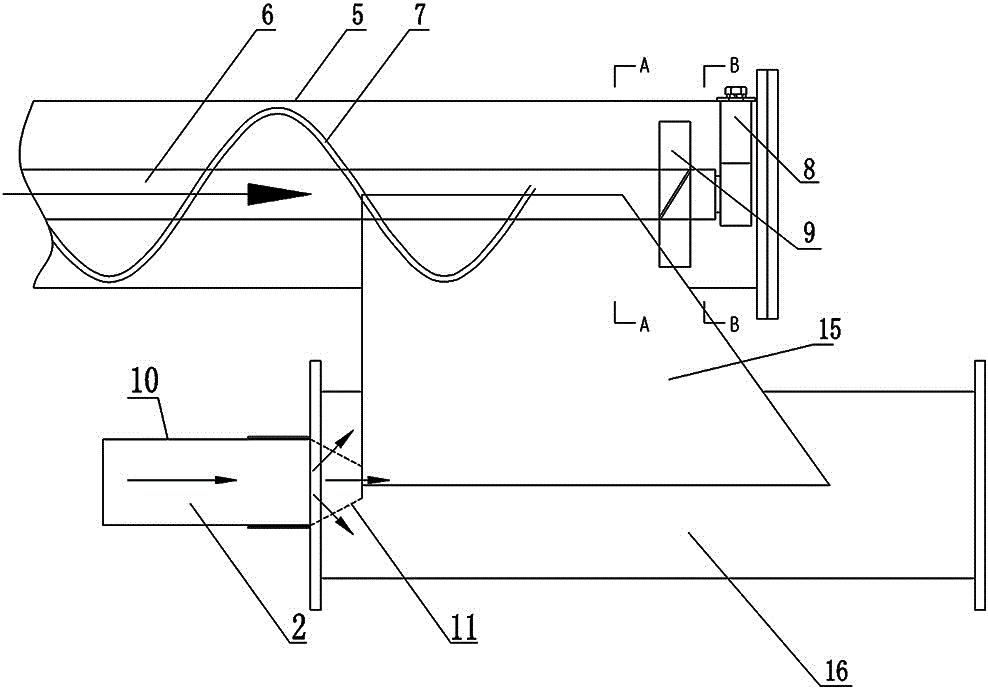

[0037] Such as figure 1 As shown, a fiber material conveying device includes a fiber pump and a fiber material unloader, such as figure 1 , figure 2 As shown, the fiber pump includes a feeding bin 1, a screw feeding device, a mixing bin, a diesel engine 19, a blower 17, a shock absorber bracket, an air inlet pipe 2 and a discharge pipe A3, and the described screw feeding device includes a drive Motor 4, feeding pipe 5 and feeding screw 6, feeding bin 1 is installed above the feeding end of feeding pipe 5, feeding pipe 5 is provided with a feeding port connected to feeding bin 1, and feeding screw 6 is installed in the inner cavity of feeding barrel Internally connected to the drive motor 4, the lower part of the feeding cylinder of the mixing chamber, the feeding cylinder is provided with a discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com