A kind of technological method of drcp type pipe jacking regulating pipe

A process method and a technology for regulating pipes, which are applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., and can solve the problems of large size, time-consuming and labor-intensive construction safety factor, difficulty in cutting and breaking, etc. problems, to improve the construction process and reduce the time-consuming effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further elaborate the technical means and effects that the present invention takes to achieve the above-mentioned purpose, the specific implementation, structure, characteristics and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments. It should be understood that the present invention The specific embodiments described are only used to explain the present invention, not to limit the present invention.

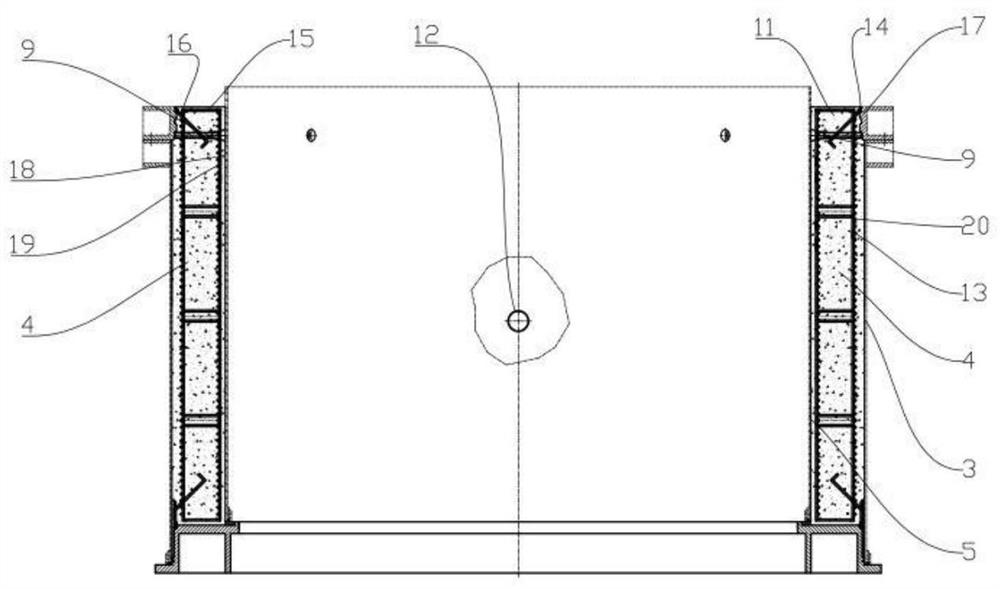

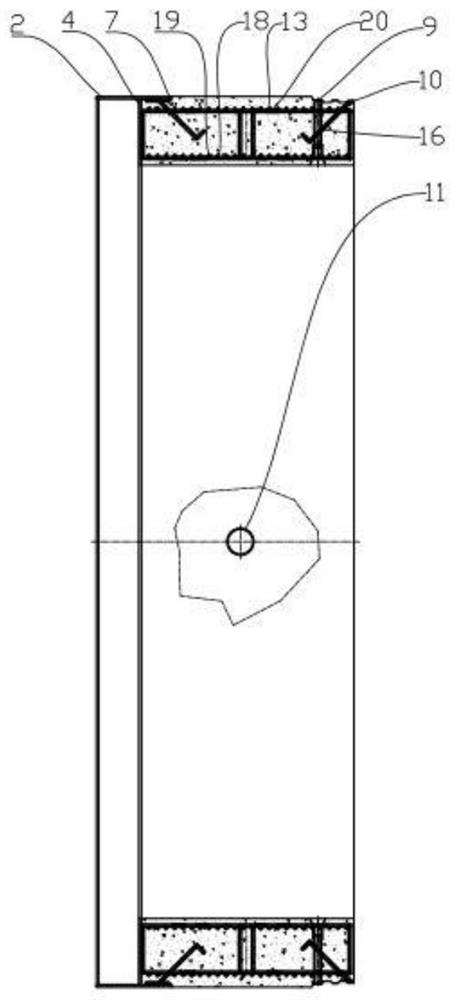

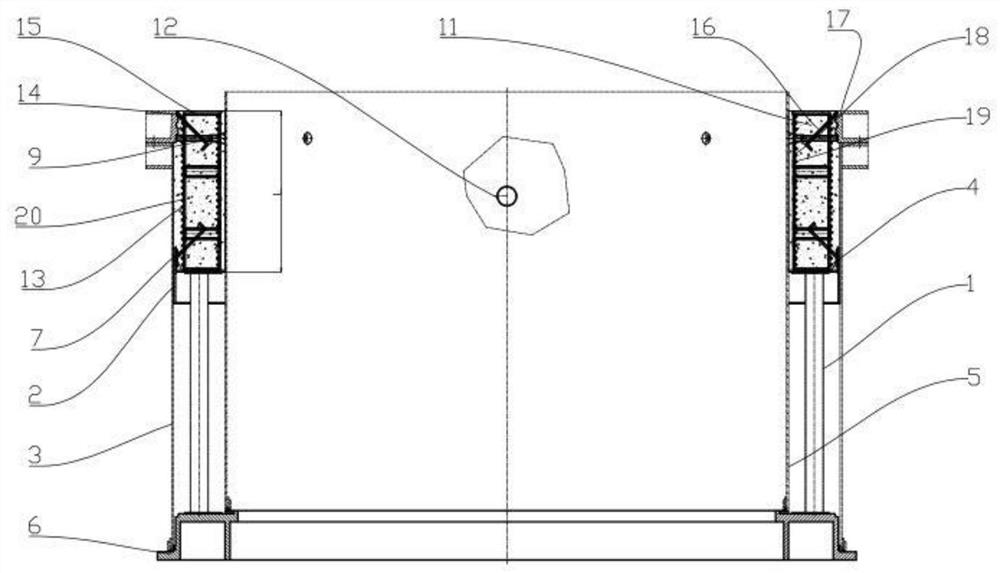

[0024] refer to Figure 1-3 As shown, the present invention provides a kind of technological method of DRCP type pipe jacking adjusting pipe, in the molding cavity of the forming mold of existing standard length, add the adjusting pipe height bracket 1 of its corresponding height; b. by adjusting the pipe socket The steel ring 2 is used to support and fix it in the forming cavity of the molding die; c. By installing the locking force in the outer mold body 3, the steel ring 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com