Support cast-in-place, pier top rotation and cast in cantilever combined construction method for continuous beams

A construction method and technology of cast-in-place piers, which are applied in bridges, buildings, bridge construction, etc., can solve the problems of complex internal force state, heavy weight, and technical difficulty, etc., achieve good environmental protection and energy saving benefits, ensure the laying period, reduce The effect of huge investments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

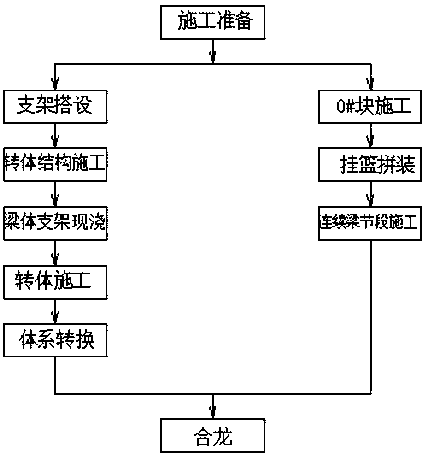

[0048] Such as figure 1 As shown, a continuous beam support cast-in-situ pier top rotation and cantilever pouring combined construction method includes the following methods, 1# pier construction and 2# pier construction respectively, wherein the construction steps of 1# pier are as follows.

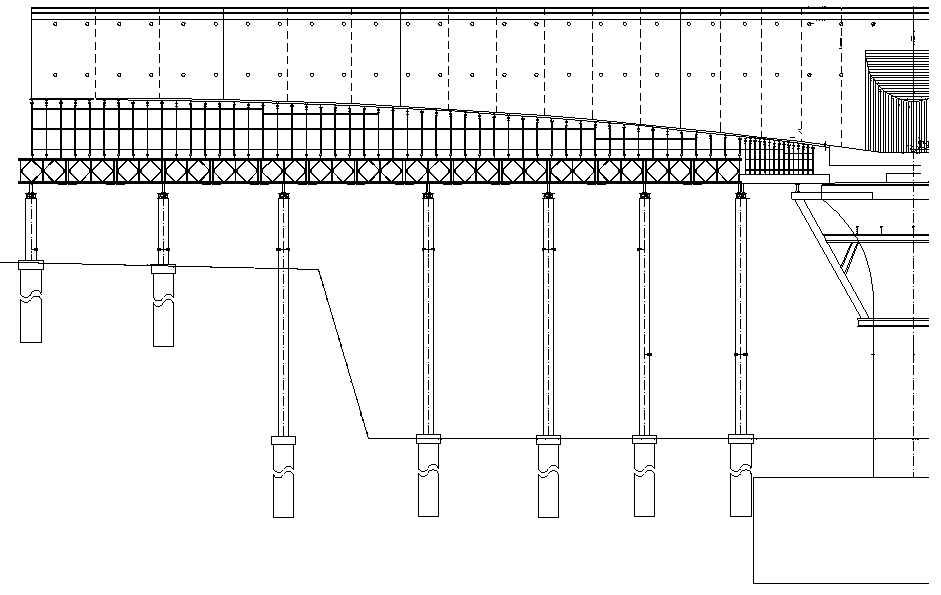

[0049] S100~Strut erection construction: after the erection of the support is completed and the acceptance of the support is confirmed, carry out preloading to eliminate the non-elastic deformation of the support, determine the elastic deformation value, and then determine the elevation of the vertical formwork.

[0050] S200~Pier top swivel structure installation and construction.

[0051] The pier top swivel structure consists of an upper turntable, a lower turntable, a spherical joint, and a swivel traction system.

[0052] (1) Lower turntable:

[0053] The lower turntable plays the role of supporting the whole weight of the structure. The lower turntable is made of C50 concrete. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com