Hanger platform for T-shaped beam maintenance and reinforcement

A hanger and platform technology, which is applied in the field of hanger platforms for T-beam maintenance and reinforcement, can solve problems such as inconvenient operation, complicated construction technology, and reduced bending load-bearing capacity, and achieve horizontal stability, simple construction technology, and easy construction. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

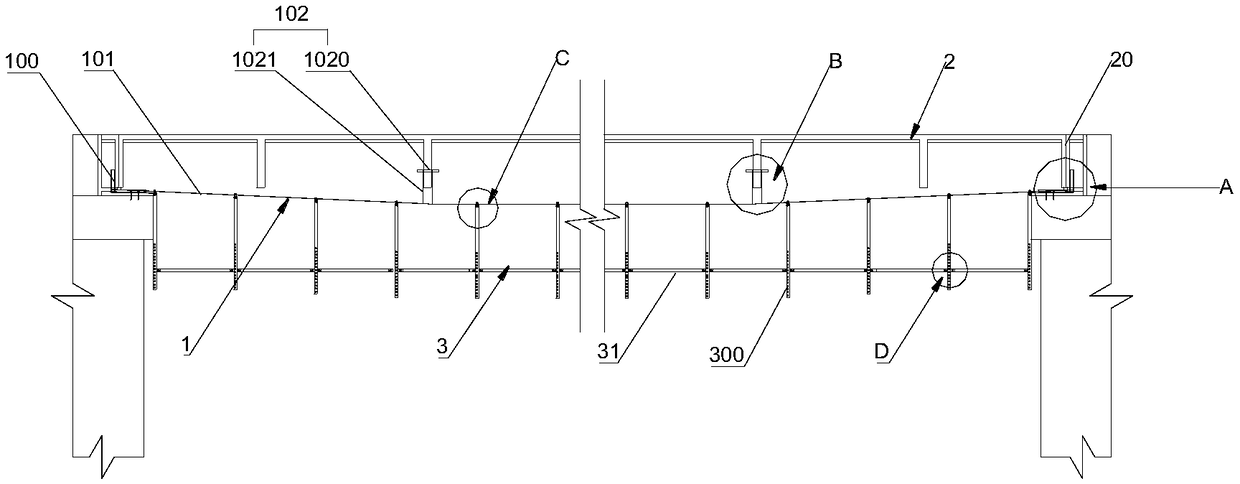

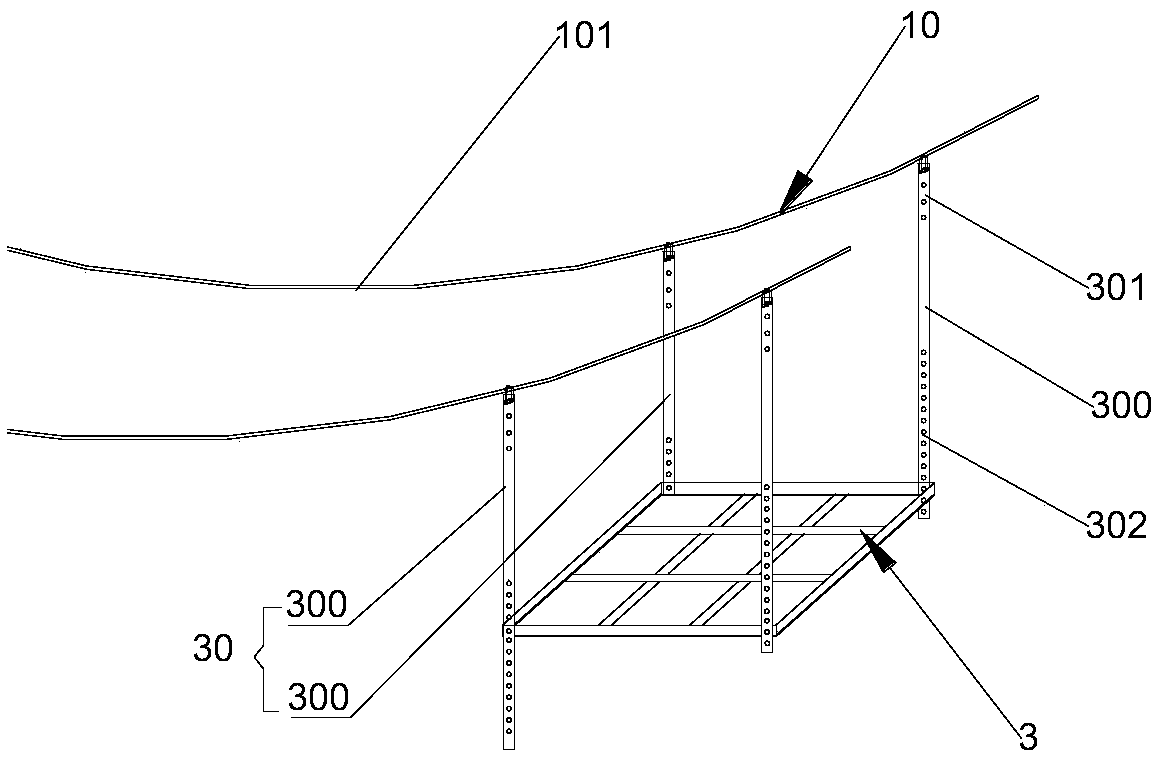

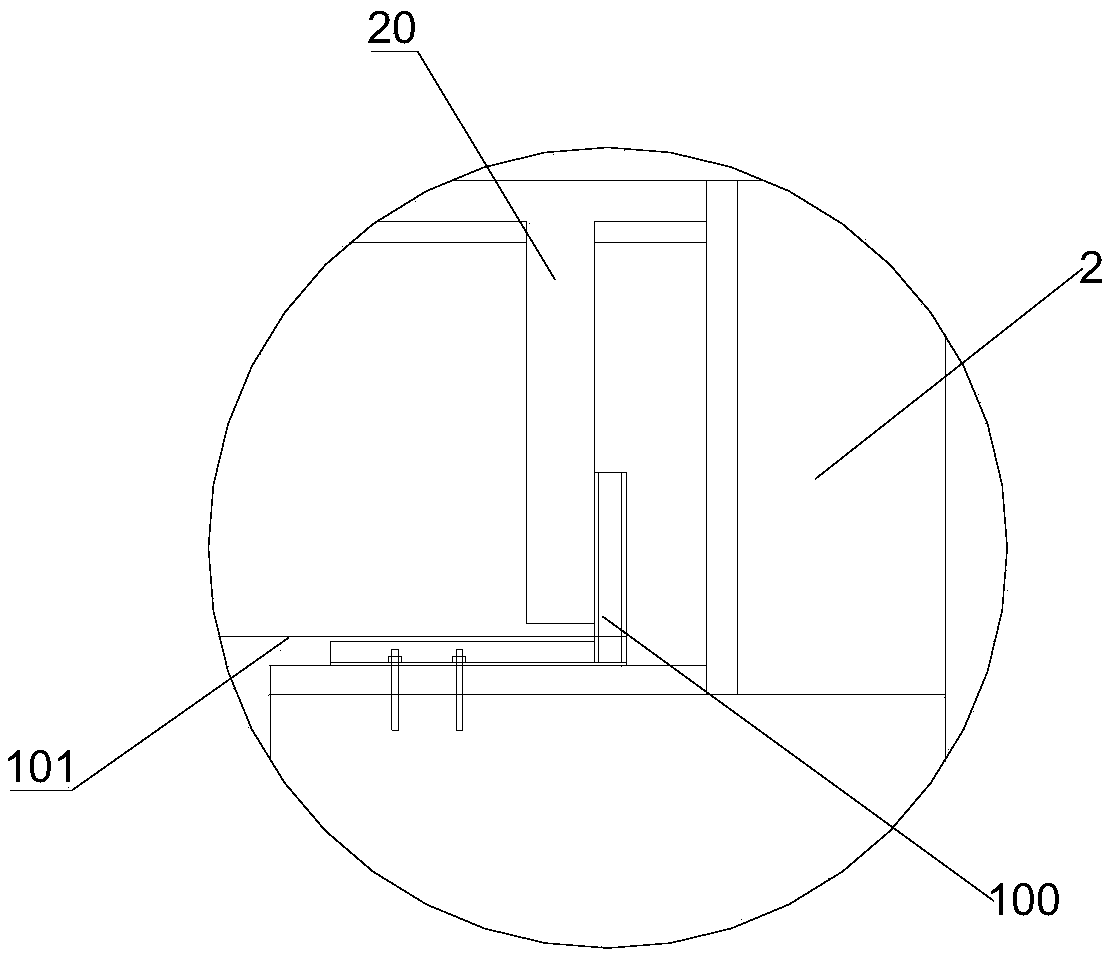

[0033] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a hanger platform for T-beam repair and reinforcement, including: a platform fixing device 1, which is assembled on the T-beam 2; a working platform 3, which includes multiple sets of hanger groups 30, Each group of hanger groups 30 is arranged at intervals along the longitudinal bridge direction, and each group of hanger groups 30 includes two vertically arranged hangers 300 arranged at intervals along the transverse bridge direction. The top of the hanger brackets 300 is detachably connected to the platform for fixed On the device 1, a rectangular frame 31 is detachably arranged between two adjacent hanger groups 30, and a channel for maintenance personnel to pass is formed between the rectangular frame 31 and the platform fixing device 1, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com