Plasma combustion-supporting Swiss roll combustor

A plasma and burner technology, which is applied in the field of low calorific value gas utilization, can solve problems such as serious heat dissipation problems and large specific surface area of the structure, and achieve the effects of reducing harmful gases, lowering combustion temperature and reducing energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] The invention provides a plasma-assisted combustion swiss roll burner.

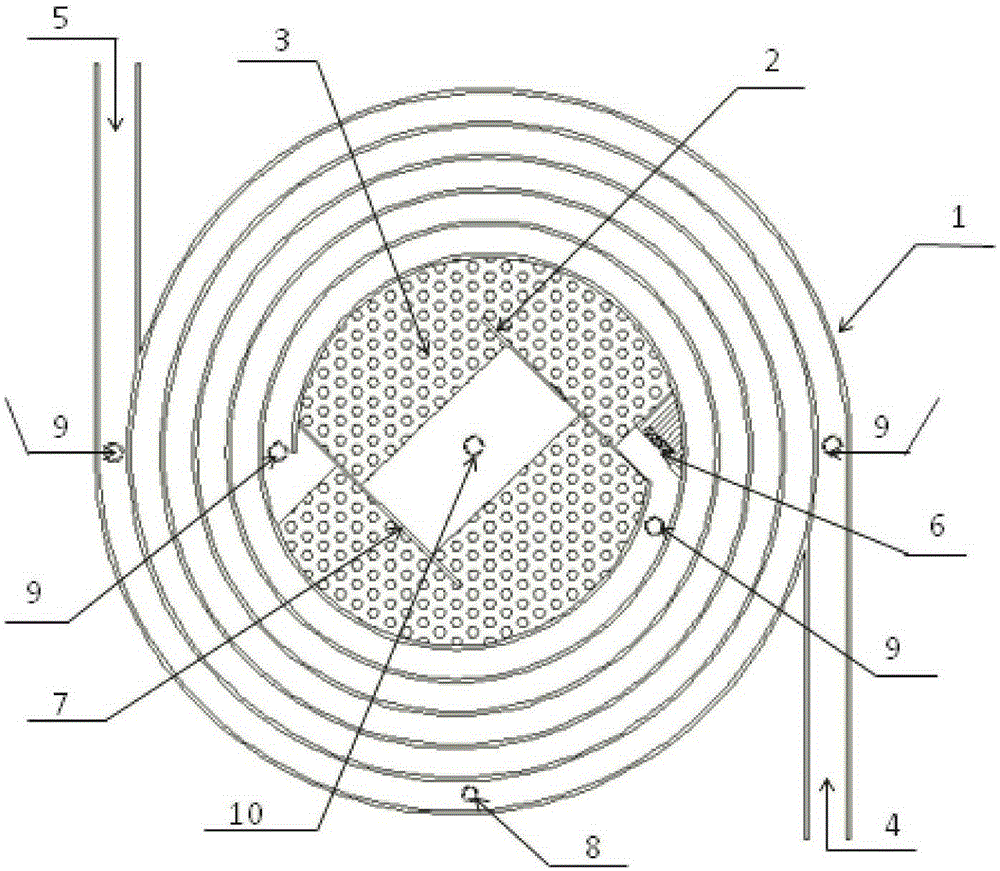

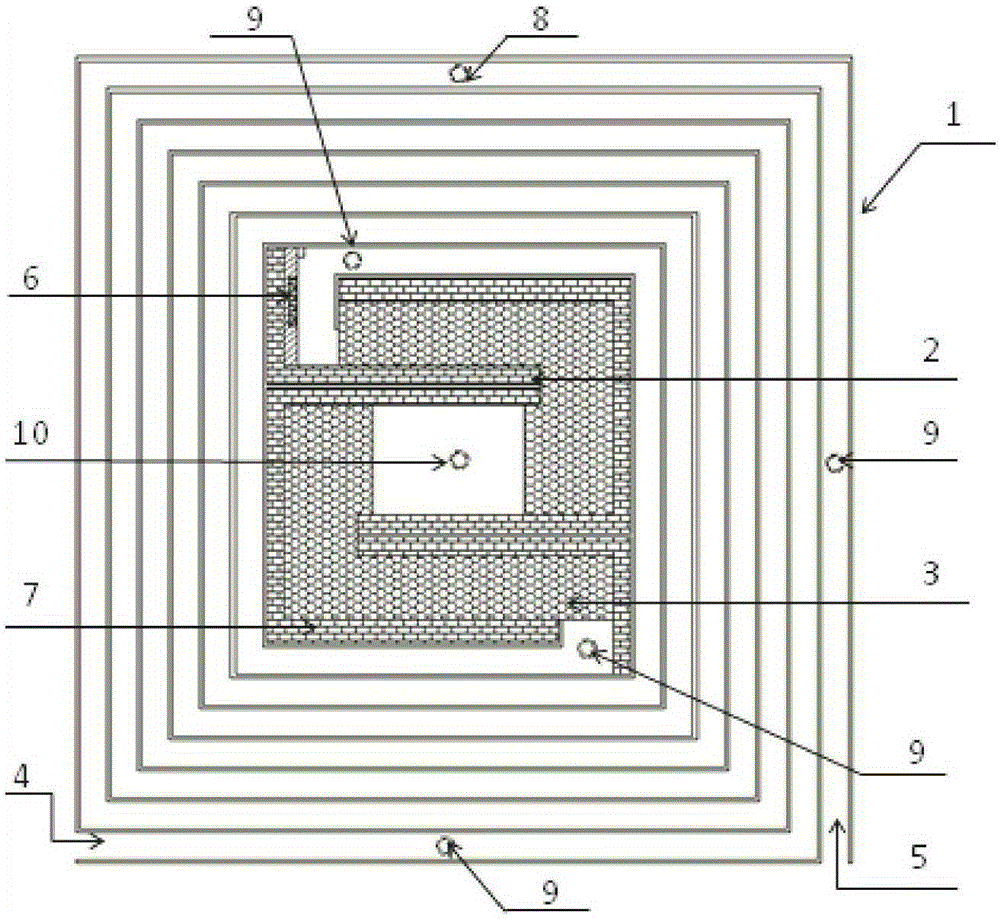

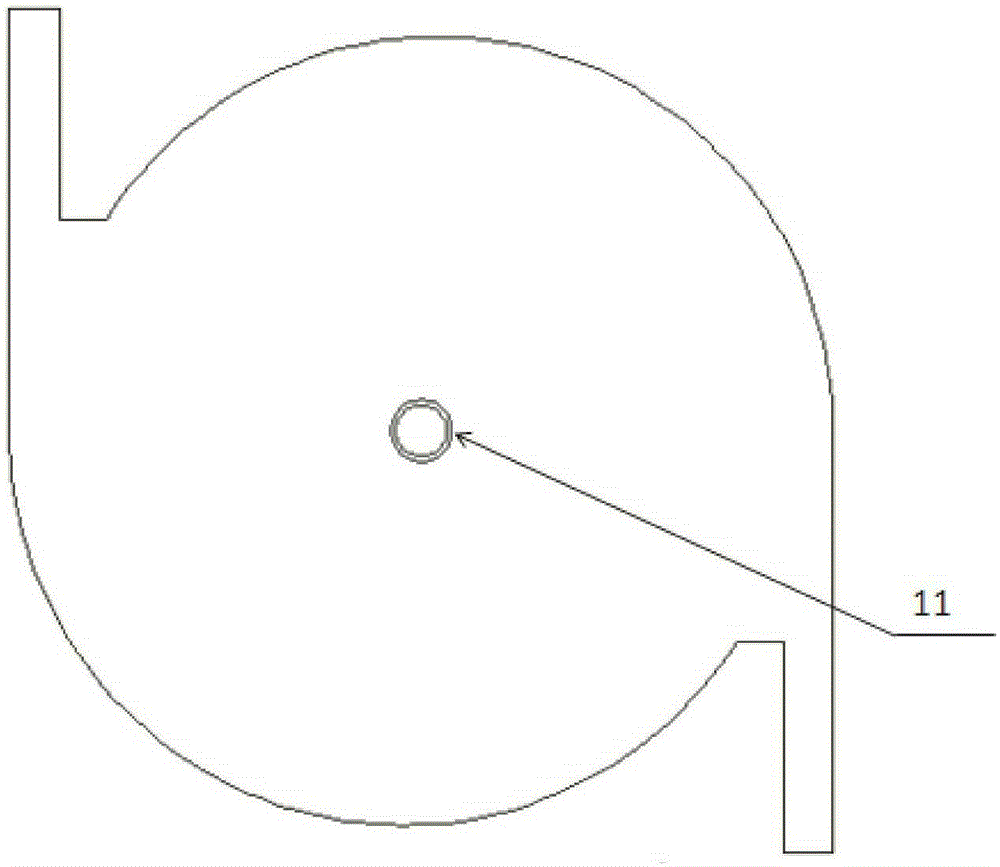

[0031] like figure 1 and figure 2 As shown, the burner is square or round, including the burner casing 1, the combustion chamber, the spiral plate channel, the upper cover and the lower bottom, and the burner is sealed by the upper cover and the lower bottom, as shown in image 3 and Figure 4As shown, the observation hole 11 is set on the upper cover plate, the two ends of the spiral plate channel are the air inlet channel 5 and the air outlet channel 4 respectively, the combustion chamber is located in the center of the spiral plate channel, and the deflector 2 and the discharge device 6 are located at the entrance of the combustion chamber , the porous medium 3 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com