Volumetric efficiency based lift pump control

An efficiency and control system technology that can be used in charging systems, machines/engines, liquid fuel feeders, etc., to solve problems such as low efficiency and low efficiency, and efficiency damage to fuel economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

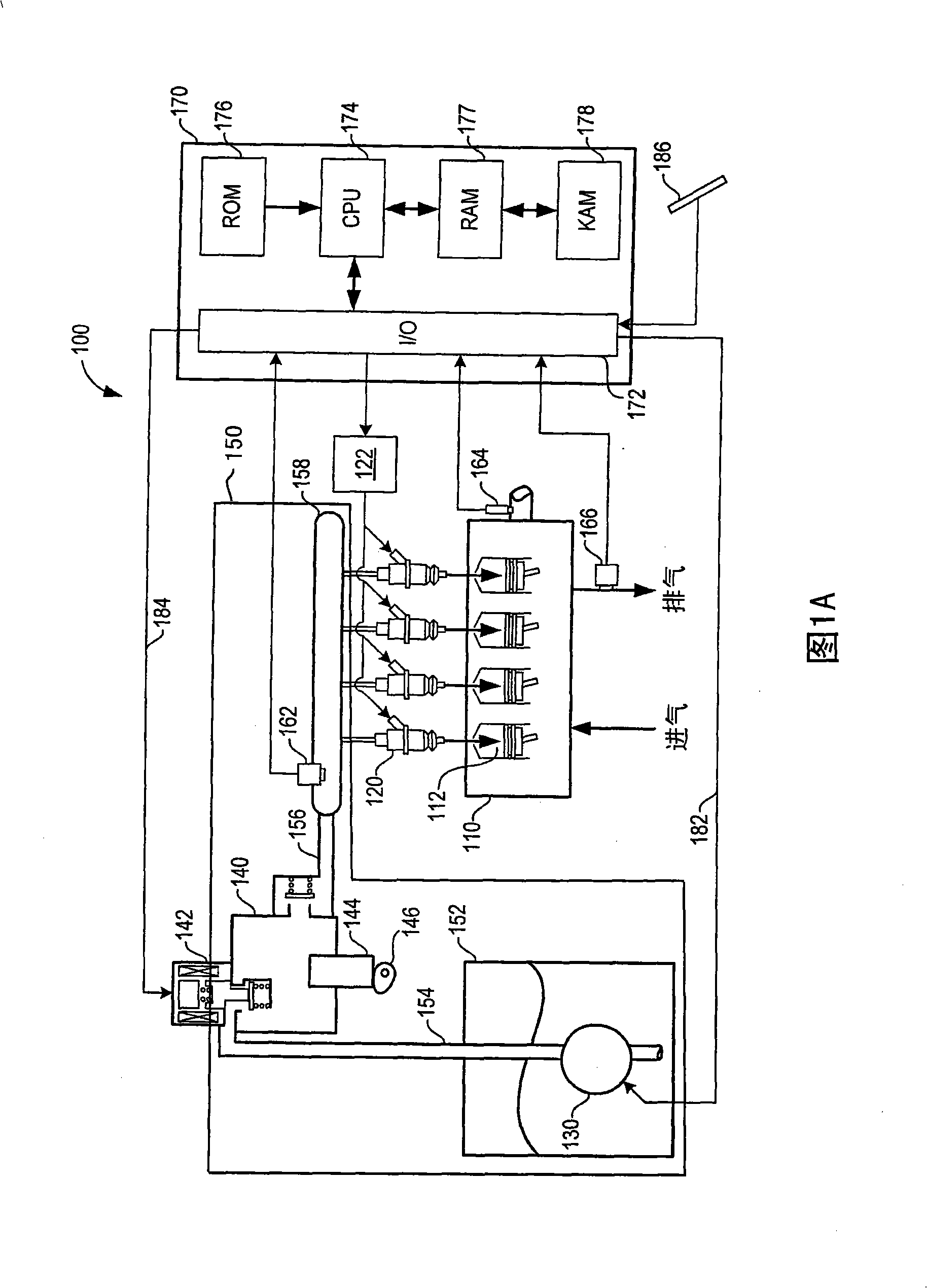

[0014] FIG. 1A shows an engine system 100 that may be configured as a propulsion system for a vehicle. Engine system 100 includes an internal combustion engine (engine) 110 having a plurality of combustion chambers or cylinders 112 . Fuel may be provided directly to cylinder 112 via in-cylinder direct fuel injector (injector) 120 . As indicated schematically in FIG. 1A , engine 110 is capable of receiving intake air and exhausting products of fuel combustion. Engine 110 may comprise a suitable type of engine, including a gasoline or diesel engine.

[0015] Fuel may be provided to engine 110 via injector 120 via a fuel system indicated generally at 150 . In this particular example, fuel system 150 includes fuel storage tank 152 for storing on-board fuel, low-pressure fuel pump (low-pressure pump) 130, high-pressure fuel pump (high-pressure pump) 140, fuel rail 158, and various fuel lines 154 and 156.

[0016] Controller 170 may operate low pressure fuel pump 130 to provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com