A kind of flexible, solid supercapacitor and its preparation method and application

A supercapacitor and solid-state technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of poor mechanical properties and insufficient flexibility, and achieve good charge-discharge cycle stability and high rate The effect of simple performance and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

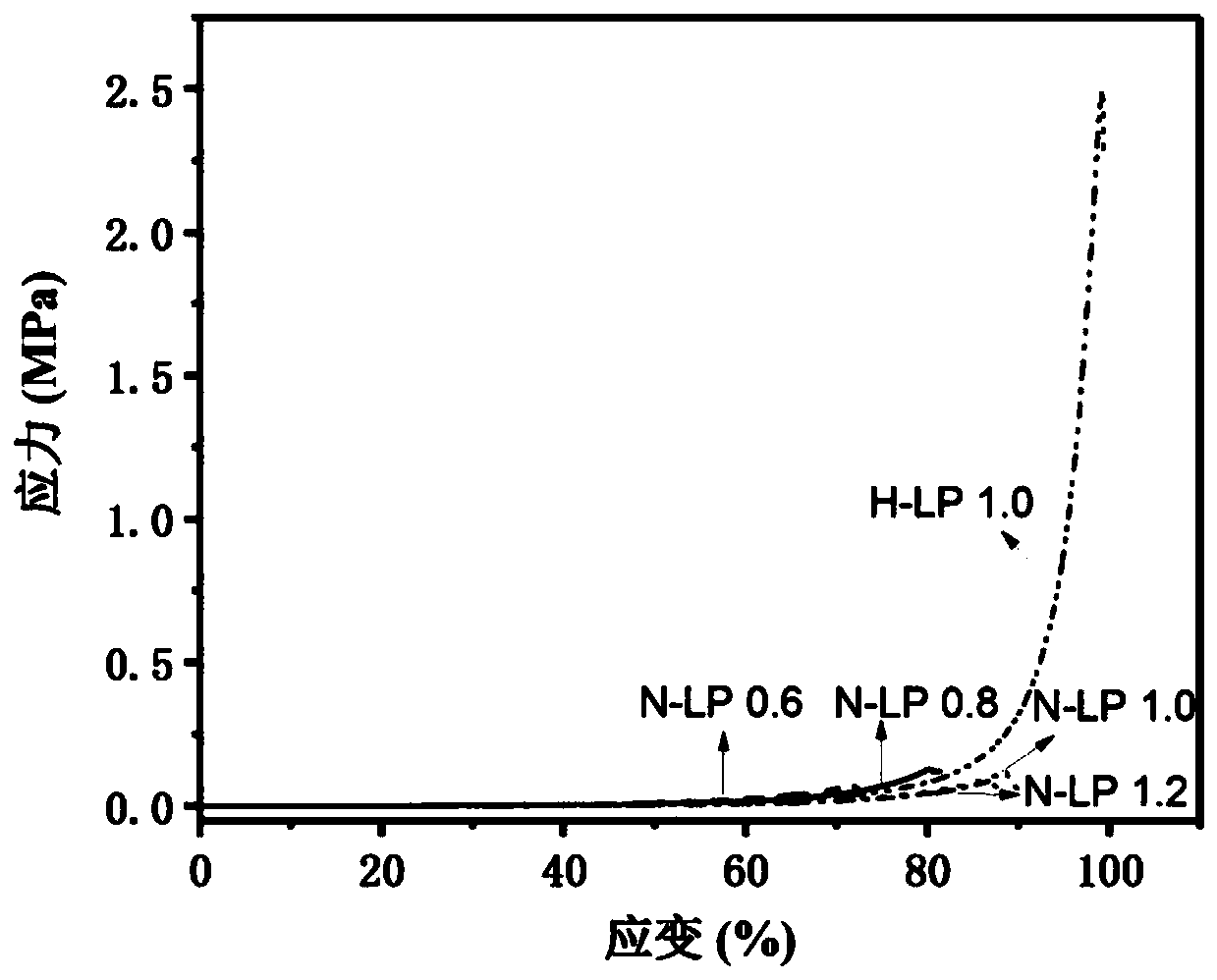

[0061] Example 1: Preparation of the first network lignin hydrogel (N-LP 0.6)

[0062] The lignin was selected as enzymatic lignin derived from corn stalks (Shandong Longli Biotechnology Co., Ltd.), and the cross-linking agent was selected as polyethylene glycol diglycidyl ether (PEGDGE, Mn=500) (purchased from Sigma). Weigh 5g of enzymatic lignin and fully dissolve it in 20mL of 1mol / L NaOH solution, then add 3g of PEGDGE to the above solution according to the mass ratio of lignin to PEGDGE of 1:0.6 and fully dissolve it, then put it in an oven at 50°C The reaction was cured for 2 hours to obtain the first network lignin hydrogel (N-LP 0.6).

Embodiment 2

[0063] Example 2: Preparation of the first network lignin hydrogel (N-LP 0.8)

[0064] The lignin was selected as enzymatic lignin derived from corn stalks (Shandong Longli Biotechnology Co., Ltd.), and the cross-linking agent was selected as polyethylene glycol diglycidyl ether (PEGDGE, Mn=500) (purchased from Sigma). Weigh 5g of enzymatic lignin and fully dissolve it in 20mL of 1mol / L NaOH solution, then add 4g of PEGDGE to the above solution according to the mass ratio of lignin to PEGDGE of 1:0.8 and fully dissolve it, then put it in an oven at 50°C The reaction was cured for 2 hours to obtain the first network lignin hydrogel (N-LP 0.8).

Embodiment 3

[0065] Example 3: Preparation of the first network lignin hydrogel (N-LP 1.0)

[0066] The lignin was selected as enzymatic lignin derived from corn stalks (Shandong Longli Biotechnology Co., Ltd.), and the cross-linking agent was selected as polyethylene glycol diglycidyl ether (PEGDGE, Mn=500) (purchased from Sigma). Weigh 5g of enzymatic lignin and fully dissolve it in 20mL of 1mol / L NaOH solution, then add 5g of PEGDGE to the above solution according to the mass ratio of lignin to PEGDGE of 1:1.0 and fully dissolve it, then put it in an oven at 50°C The reaction was cured for 2 hours to obtain the first network lignin hydrogel (N-LP 1.0).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strain | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com