Novel two-component waterproof and decorative integrated paint and construction method thereof

A construction method and two-component technology, applied in antifouling/underwater coatings, coatings, buildings, etc., can solve the problem that the coating quality is difficult to control and stabilize, the quality of exterior wall putty coating has many hidden dangers, and the quality is difficult to obtain. Guarantee and other issues to achieve the effect of reducing the risk of efflorescence and color difference, better color retention, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

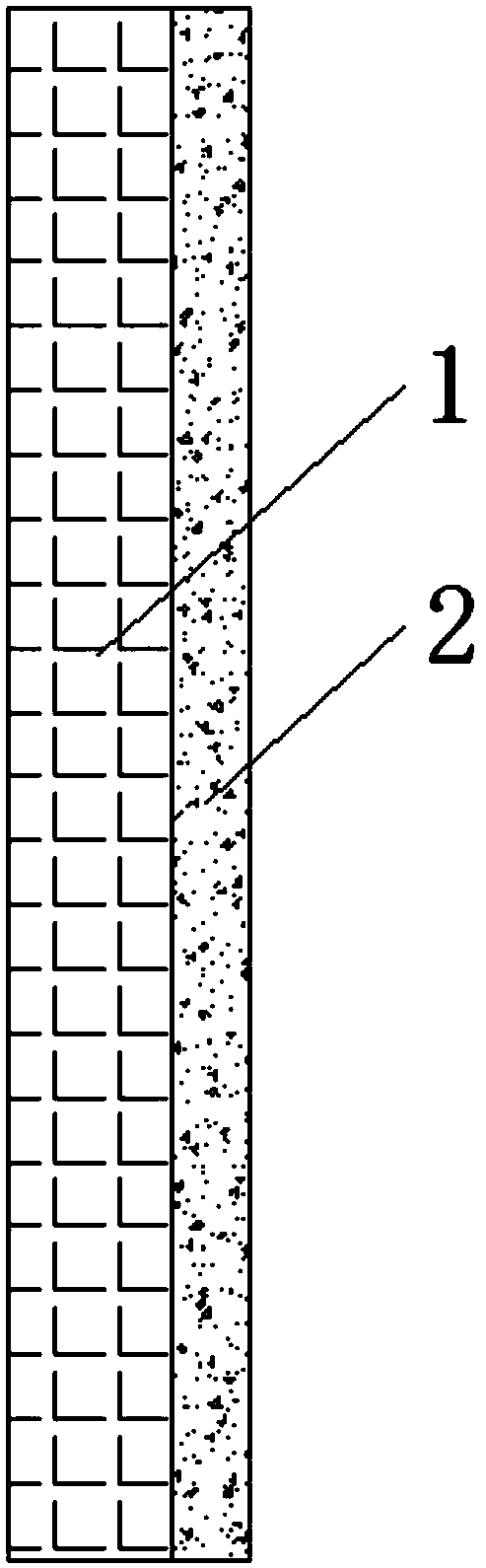

[0020] see figure 1 , the present invention provides a technical solution: a novel two-component waterproof decorative integrated paint, including a base layer 1, the outer layer of the base layer 1 is sprayed with a mortar layer 2, and the mortar layer 2 is composed of acrylic emulsion, special inorganic gelling material, filler and a variety of functional additives, the mortar layer 2 includes the following raw materials by weight: 70-80 parts of acrylic emulsion, 15-25 parts of special inorganic gelling materials, 5-10 parts of fillers, and 6-12 parts of additives.

[0021] Further improved, the mortar layer 2 is a two-component integrated mortar structure.

[0022] Further improved, the mortar layer 2 includes the following raw materials by weight: 70 parts of acrylic emulsion, 15 parts of special inorganic gelling material, 5 parts of filler, and 6 parts of additives.

[0023] Further improved, the filler is one or more of high-strength hydrophobic polyurethane, ultrafin...

Embodiment 2

[0025] see figure 1 , the present invention provides a technical solution: a novel two-component waterproof decorative integrated paint, including a base layer 1, the outer layer of the base layer 1 is sprayed with a mortar layer 2, and the mortar layer 2 is composed of acrylic emulsion, special inorganic gelling material, filler and a variety of functional additives, the mortar layer 2 includes the following raw materials by weight: 70-80 parts of acrylic emulsion, 15-25 parts of special inorganic gelling materials, 5-10 parts of fillers, and 6-12 parts of additives.

[0026] Further improved, the mortar layer 2 is a two-component integrated mortar structure.

[0027] Further improved, the mortar layer 2 includes the following raw materials by weight: 80 parts of acrylic emulsion, 25 parts of special inorganic gelling material, 10 parts of filler, and 12 parts of additives.

[0028] Further improved, the filler is one or more of high-strength hydrophobic polyurethane, ultraf...

Embodiment 3

[0030] see figure 1 , the present invention provides a technical solution: a novel two-component waterproof decorative integrated paint, including a base layer 1, the outer layer of the base layer 1 is sprayed with a mortar layer 2, and the mortar layer 2 is composed of acrylic emulsion, special inorganic gelling material, filler and a variety of functional additives, the mortar layer 2 includes the following raw materials by weight: 70-80 parts of acrylic emulsion, 15-25 parts of special inorganic gelling materials, 5-10 parts of fillers, and 6-12 parts of additives.

[0031] Further improved, the mortar layer 2 is a two-component integrated mortar structure.

[0032] Further improved, the mortar layer 2 includes the following raw materials by weight: 75 parts of acrylic emulsion, 20 parts of special inorganic gelling material, 7 parts of filler, and 9 parts of additives.

[0033] Further improved, the filler is one or more of high-strength hydrophobic polyurethane, ultrafin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com