Textile fabric printing device capable of automatically adjusting printing position

A technology for automatic adjustment of textile fabrics, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of inability to adjust, affect the efficiency of fabric processing, inconvenience, etc., and achieve the advantages of avoiding offset, reasonable structural design, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

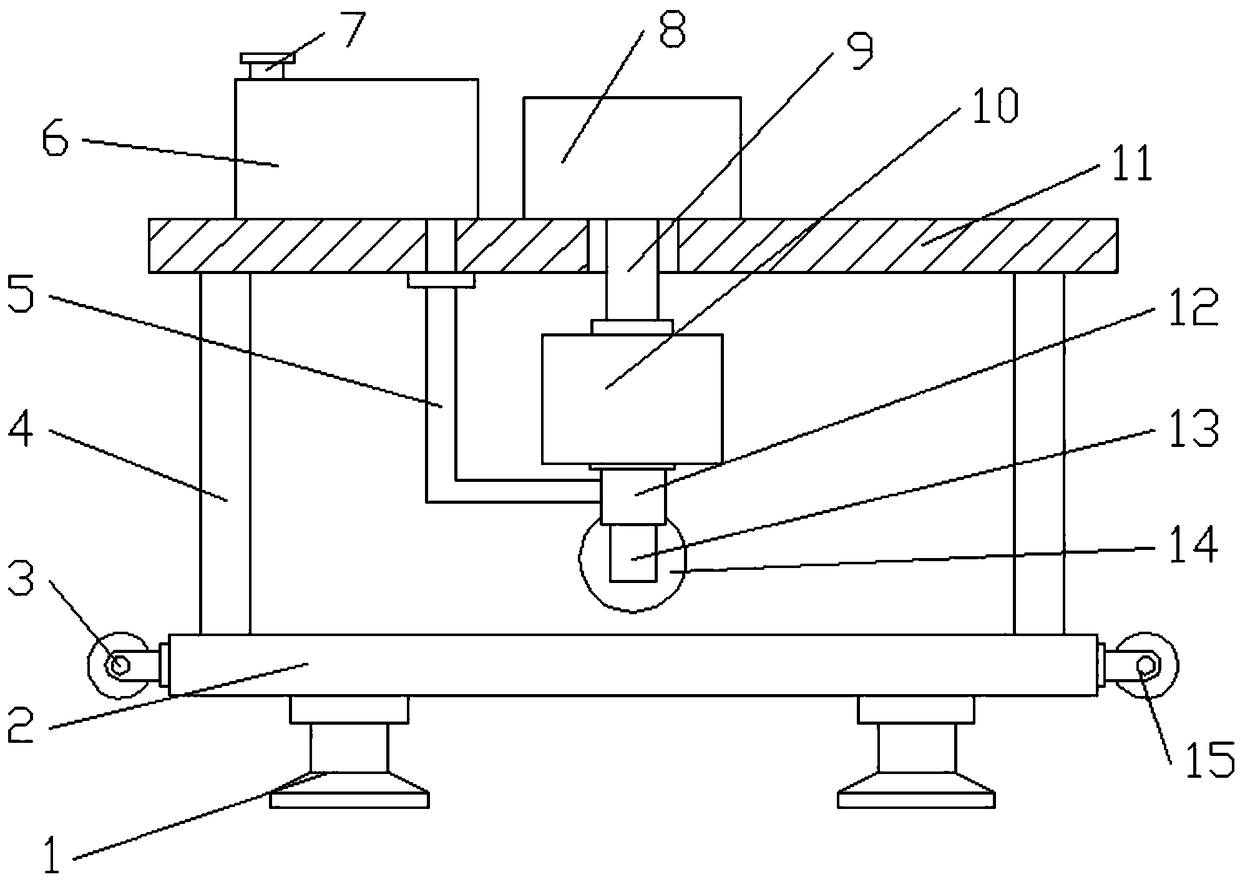

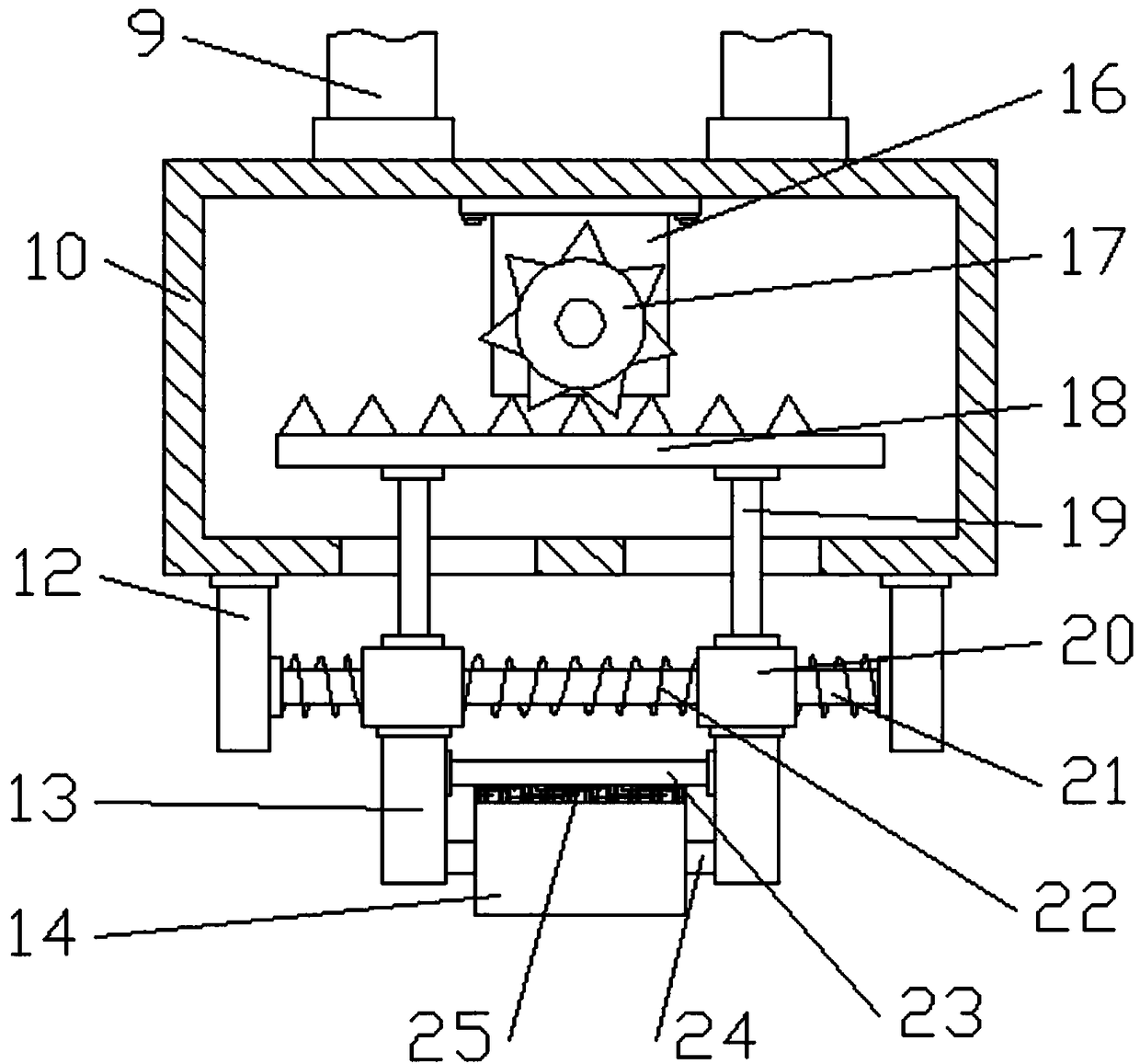

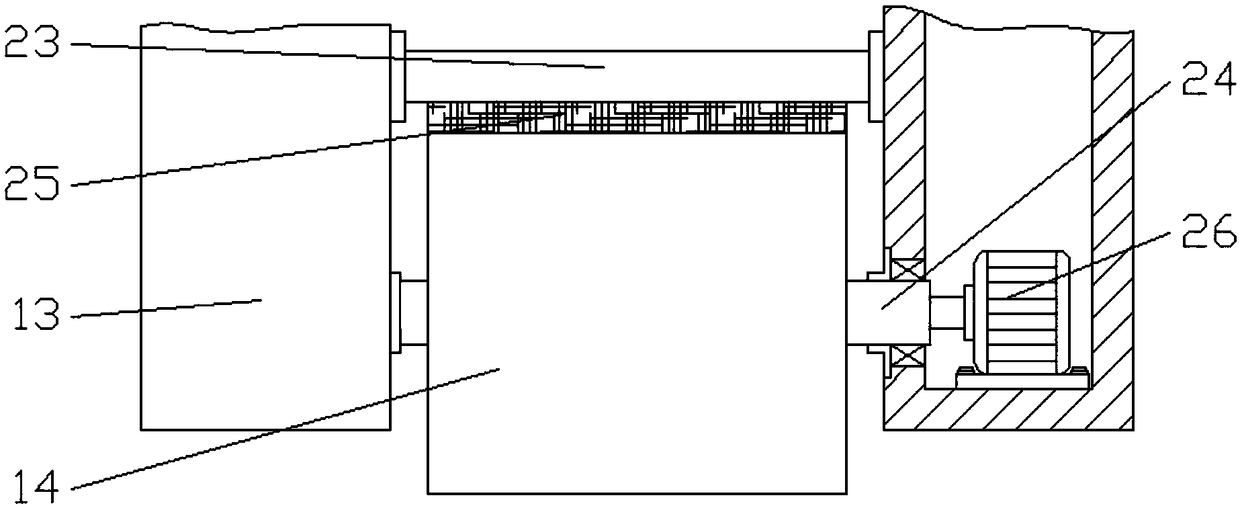

[0022] see Figure 1-4 , a textile cloth printing device that can automatically adjust the printing position, including an operating table 2; the operating table 2 provides support and installation space for other components on the device, and provides operating space for cloth printing. A support leg 1 is connected and fixed; four support legs 1 are arranged evenly on the bottom of the console 2 for supporting the device; a feed guide wheel 3 is connected and fixed on the left outer wall of the console 2; The feeding guide wheel 3 is convenient to guide the cloth on the cloth roller to the top of the operating table 2; the outer wall on the right side of the operating table 2 is connected and fixed with a discharging guide wheel 15; the discharging guiding wheel 15 is convenient to guide the printed cloth , received on the finished product roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com