Austenitic stainless pipe inner wall oxide skin nondestructive testing device

A technology of austenitic stainless steel and wall scale, applied in the direction of material magnetic variables, etc., can solve problems such as inability to accurately reflect spatial morphology, unfavorable operations in narrow spaces, and large volume of detection probes, achieving good application prospects and promotion value , The detection results are accurate and reliable, and the detection sensitivity is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail and completely below in conjunction with the embodiments and the accompanying drawings.

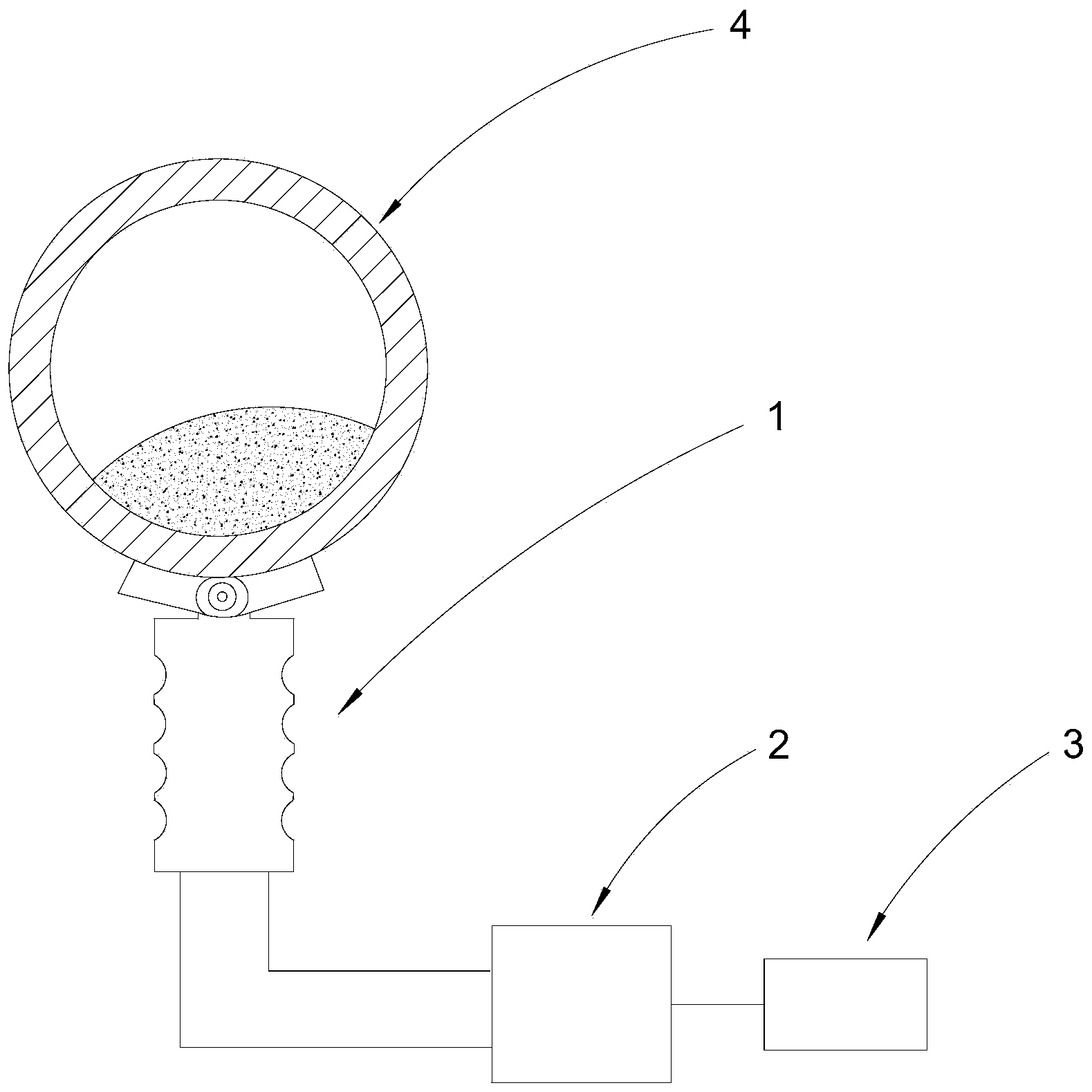

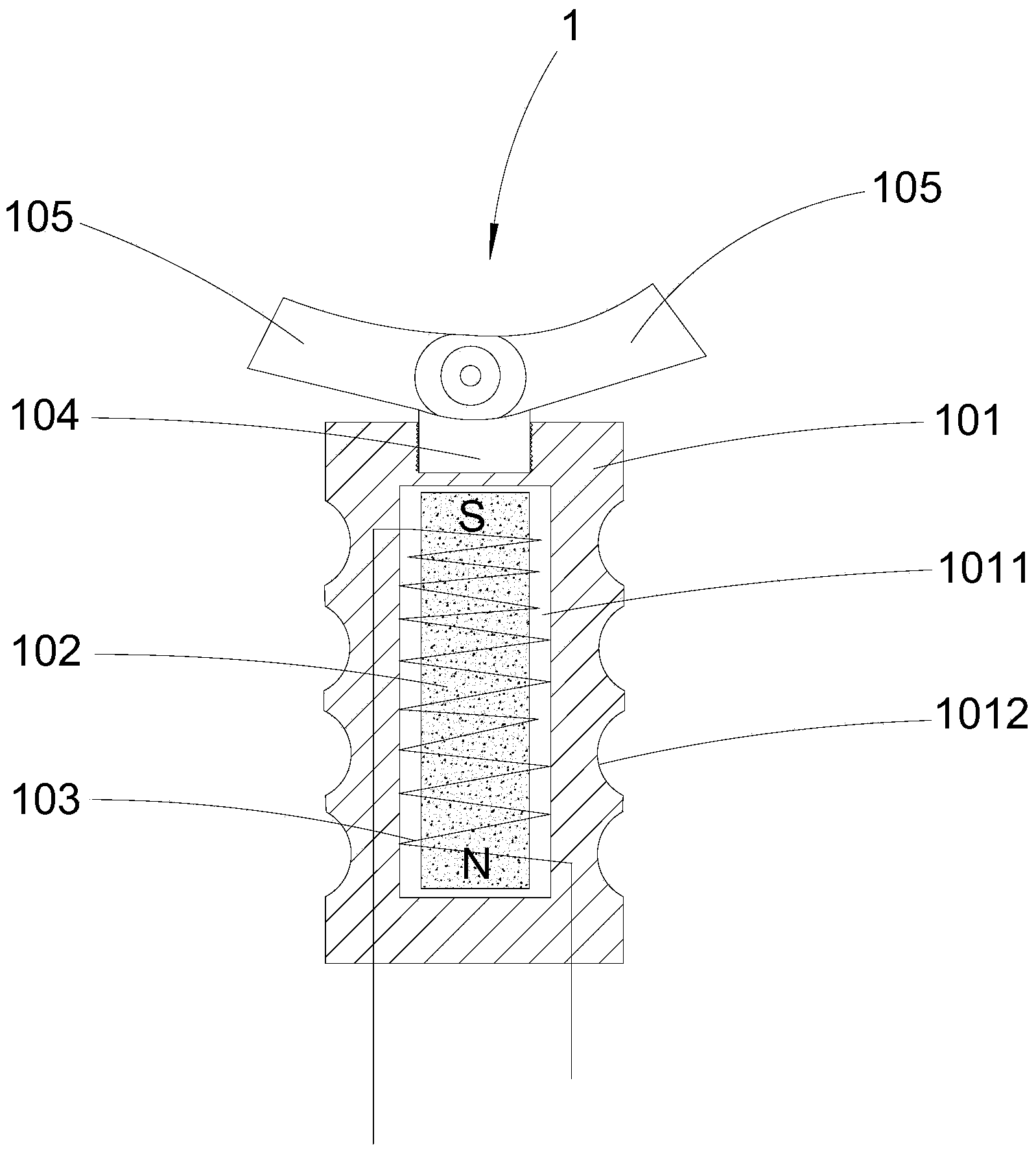

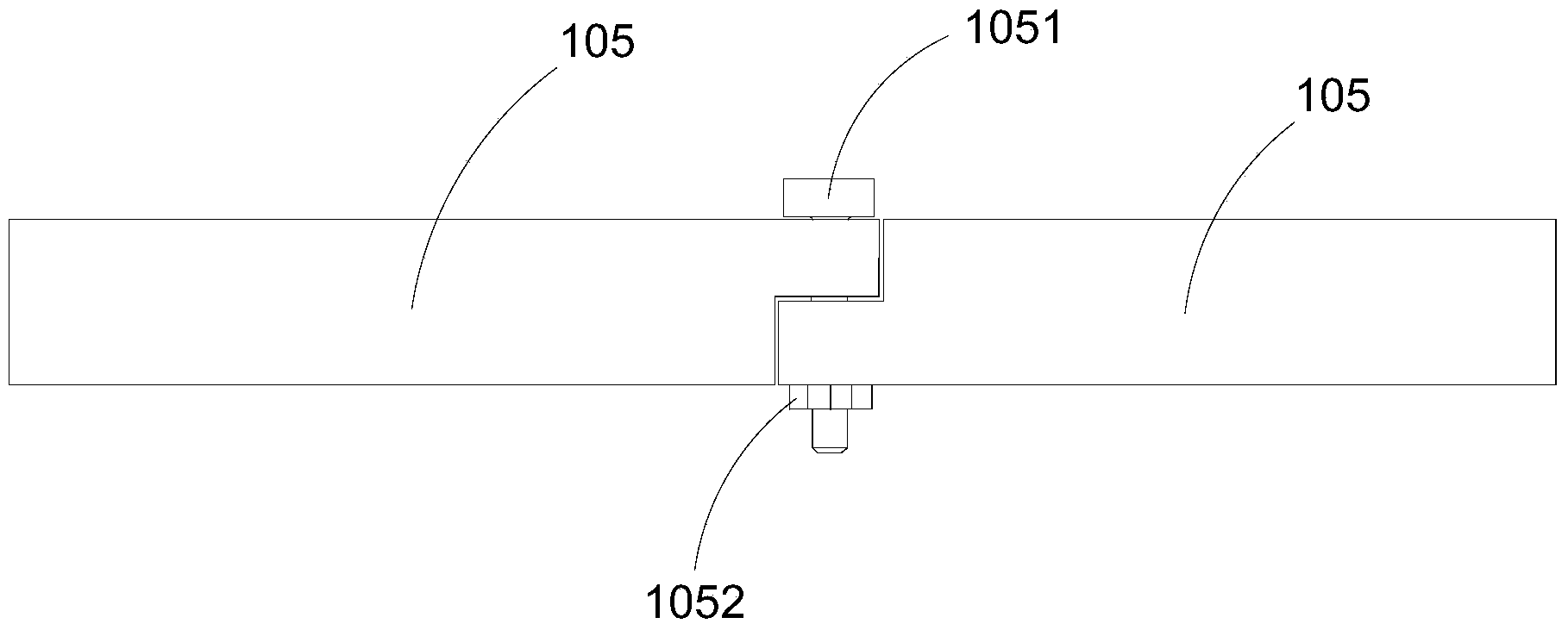

[0032] Figure 1 to Figure 3 , is a schematic diagram of a preferred embodiment of a non-destructive testing device for oxide scale on the inner wall of an austenitic stainless steel pipe provided by the present invention. Such as Figure 1 to Figure 3As shown, the device for non-destructive testing of scale on the inner wall of austenitic stainless steel tubes includes a probe 1, an electromagnetic detector 2 and a data processor 3 that are electrically connected in sequence, wherein the probe 1 includes a cylindrical shell 101, a cylindrical NdFeB A magnet 102 , an induction coil 103 , a mounting part 104 and two scanning parts 105 .

[0033] The housing 101 is provided with a cylindrical hollow cavity 1011, the induction coil 103 is wound on the NdFeB magnet 102 and installed in the cavity 1011 of the housing 101 togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com