Flexible and solid supercapacitor, preparation method and application thereof

A supercapacitor, solid-state technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of poor mechanical properties and can not meet the flexibility and other problems, achieve good charge-discharge cycle stability, high rate The effect of performance, preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

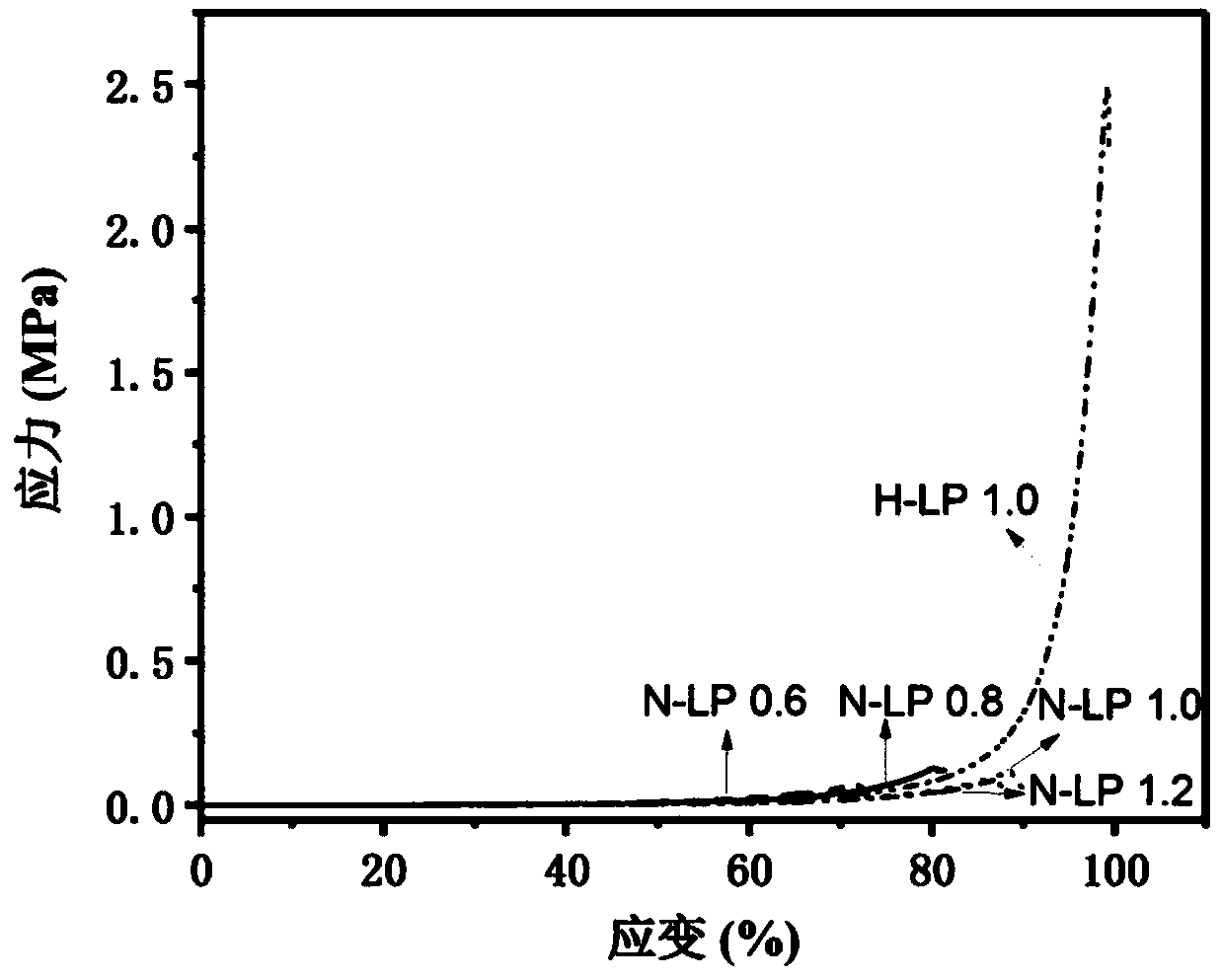

[0061] Example 1: Preparation of the first network lignin hydrogel (N-LP 0.6)

[0062] The lignin was selected as enzymatic lignin derived from corn stalks (Shandong Longli Biotechnology Co., Ltd.), and the cross-linking agent was selected as polyethylene glycol diglycidyl ether (PEGDGE, Mn=500) (purchased from Sigma). Weigh 5g of enzymatic lignin and fully dissolve it in 20mL of 1mol / L NaOH solution, then add 3g of PEGDGE to the above solution according to the mass ratio of lignin to PEGDGE of 1:0.6 and fully dissolve it, then put it in an oven at 50°C The reaction was cured for 2 hours to obtain the first network lignin hydrogel (N-LP 0.6).

Embodiment 2

[0063] Example 2: Preparation of the first network lignin hydrogel (N-LP 0.8)

[0064] The lignin was selected as enzymatic lignin derived from corn stalks (Shandong Longli Biotechnology Co., Ltd.), and the cross-linking agent was selected as polyethylene glycol diglycidyl ether (PEGDGE, Mn=500) (purchased from Sigma). Weigh 5g of enzymatic lignin and fully dissolve it in 20mL of 1mol / L NaOH solution, then add 4g of PEGDGE to the above solution according to the mass ratio of lignin to PEGDGE of 1:0.8 and fully dissolve it, then put it in an oven at 50°C The reaction was cured for 2 hours to obtain the first network lignin hydrogel (N-LP 0.8).

Embodiment 3

[0065] Example 3: Preparation of the first network lignin hydrogel (N-LP 1.0)

[0066] The lignin was selected as enzymatic lignin derived from corn stalks (Shandong Longli Biotechnology Co., Ltd.), and the cross-linking agent was selected as polyethylene glycol diglycidyl ether (PEGDGE, Mn=500) (purchased from Sigma). Weigh 5g of enzymatic lignin and fully dissolve it in 20mL of 1mol / L NaOH solution, then add 5g of PEGDGE to the above solution according to the mass ratio of lignin to PEGDGE of 1:1.0 and fully dissolve it, then put it in an oven at 50°C The reaction was cured for 2 hours to obtain the first network lignin hydrogel (N-LP 1.0).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strain | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com