Hydraulic servo variable load loading test bench

A loading test and hydraulic servo technology, which is applied in the field of fatigue test benches, can solve the problems of slow response and small output load range, and achieve the effects of low cost, compact structure, and adjustable loading frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

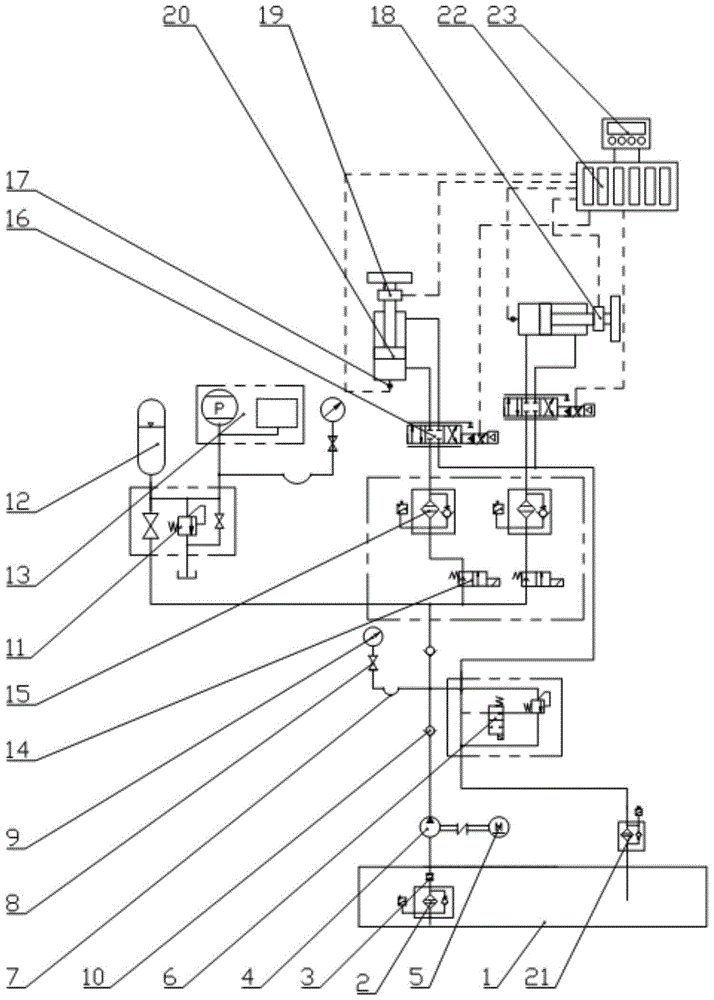

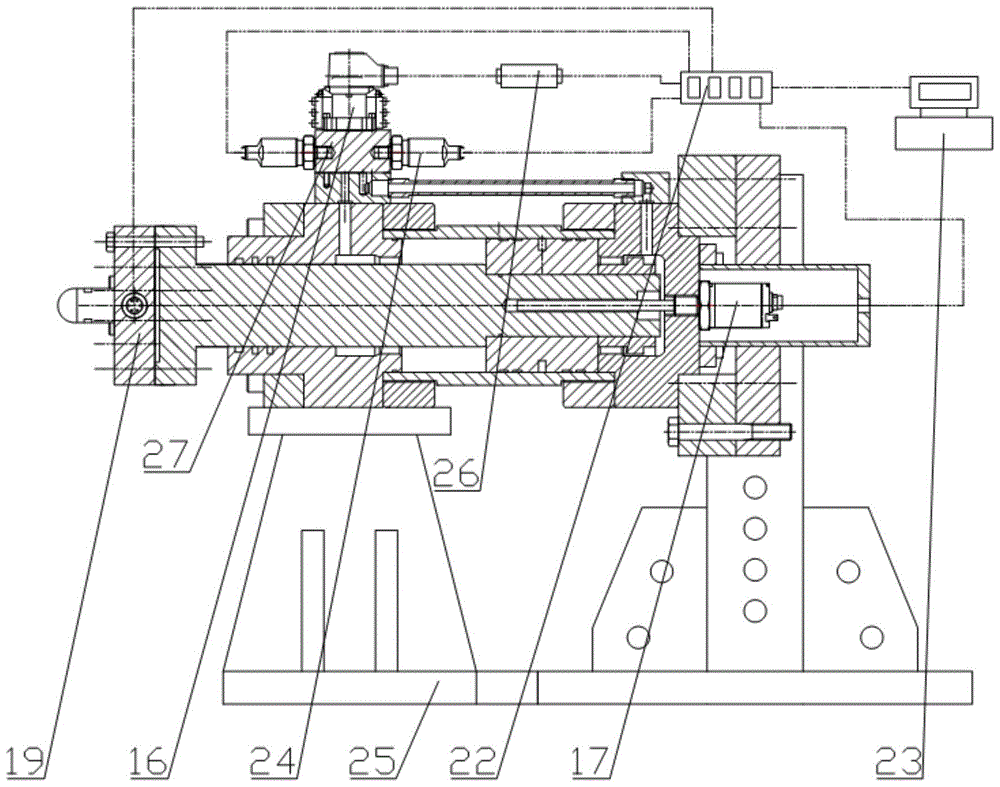

[0012] The implementation of the present invention will be further described in detail below in conjunction with the drawings and technical solutions.

[0013] The hydraulic servo variable load loading test bench is composed of two parts: the control system and the loading mechanism;

[0014] The hydraulic servo variable load loading test bench has four parallel loading mechanisms, two of which are used for axial loading and the other two are used for radial loading. Each loading mechanism is fixed on the horizontal ground through bolts and baffle plates, and the servo hydraulic cylinder 20 and the base 25 are connected with 12 bolts. The front end of the servo hydraulic cylinder 20 for axial loading is equipped with a force sensor 18 , and the front end of the servo hydraulic cylinder 20 for radial loading is connected with a small force sensor 19 . The displacement sensor 17 is installed at the rear of the servo hydraulic cylinder 20 , and the servo valve 16 and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com