Hazardous waste incineration smoke further denitrification purification system and method

A technology for incinerating flue gas and hazardous waste, applied in the field of environmental protection of garbage treatment and medical hazardous waste treatment, can solve the problems of high NOx emission concentration, low thermal efficiency of rotary kiln, white smoke plume, etc., to ensure compliance with emission standards and reasonable system structure , technically reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following will further illustrate the present invention through specific examples, but it is not intended to limit the protection scope of the present invention. Those skilled in the art can make improvements to the preparation method and the equipment used within the scope of the claims, and these improvements should also be considered as the protection scope of the present invention. Therefore, the protection scope of the patent for the present invention should be based on the appended claims.

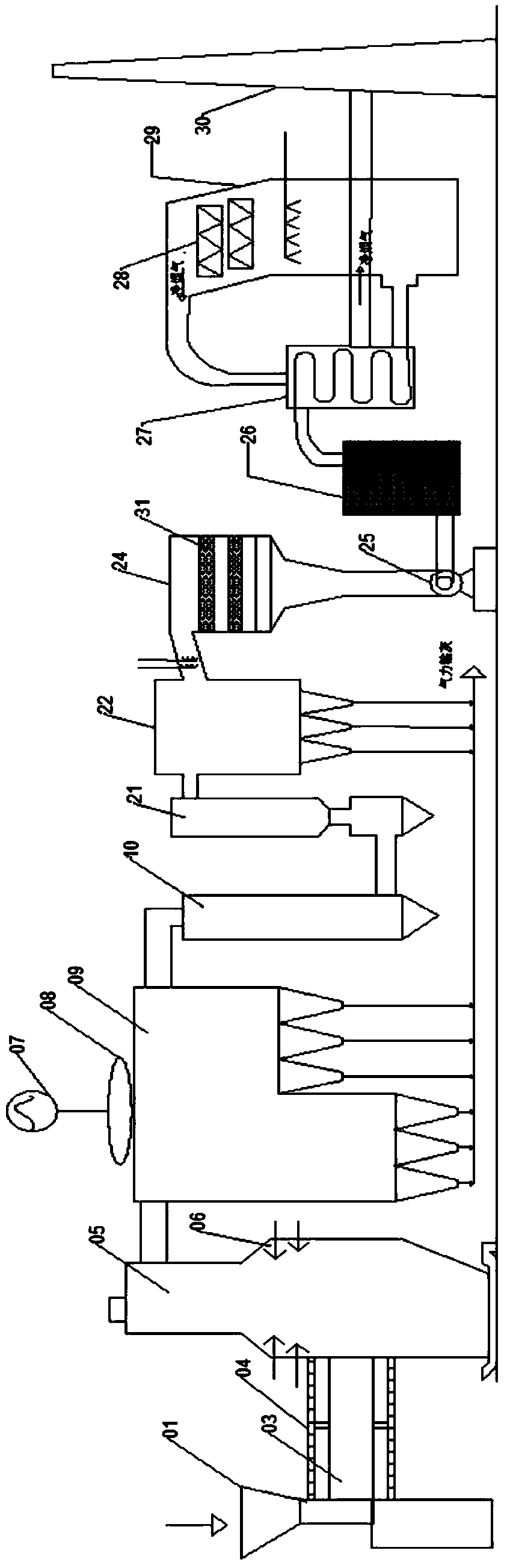

[0044] like figure 1 As shown, a hazardous waste incineration flue gas deep denitrification purification system, including waste transportation storage and pretreatment crushing system, rotary kiln 03, primary air device connected to rotary kiln 03, high calorific value waste material feeding device and low calorific value waste material The feeding device 01, the heat preservation chamber 04 arranged outside the rotary kiln 03 and connected with the rotary kiln 03, the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap