Universal inertial focus microfluidic chip

A microfluidic chip and inertial technology, applied in the field of microfluidics, can solve problems such as lack of versatility, increase in types and quantities of microfluidics chips, lack of compatibility with different sorting applications, etc., to save the number of chips and control The effect of manufacturing and application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

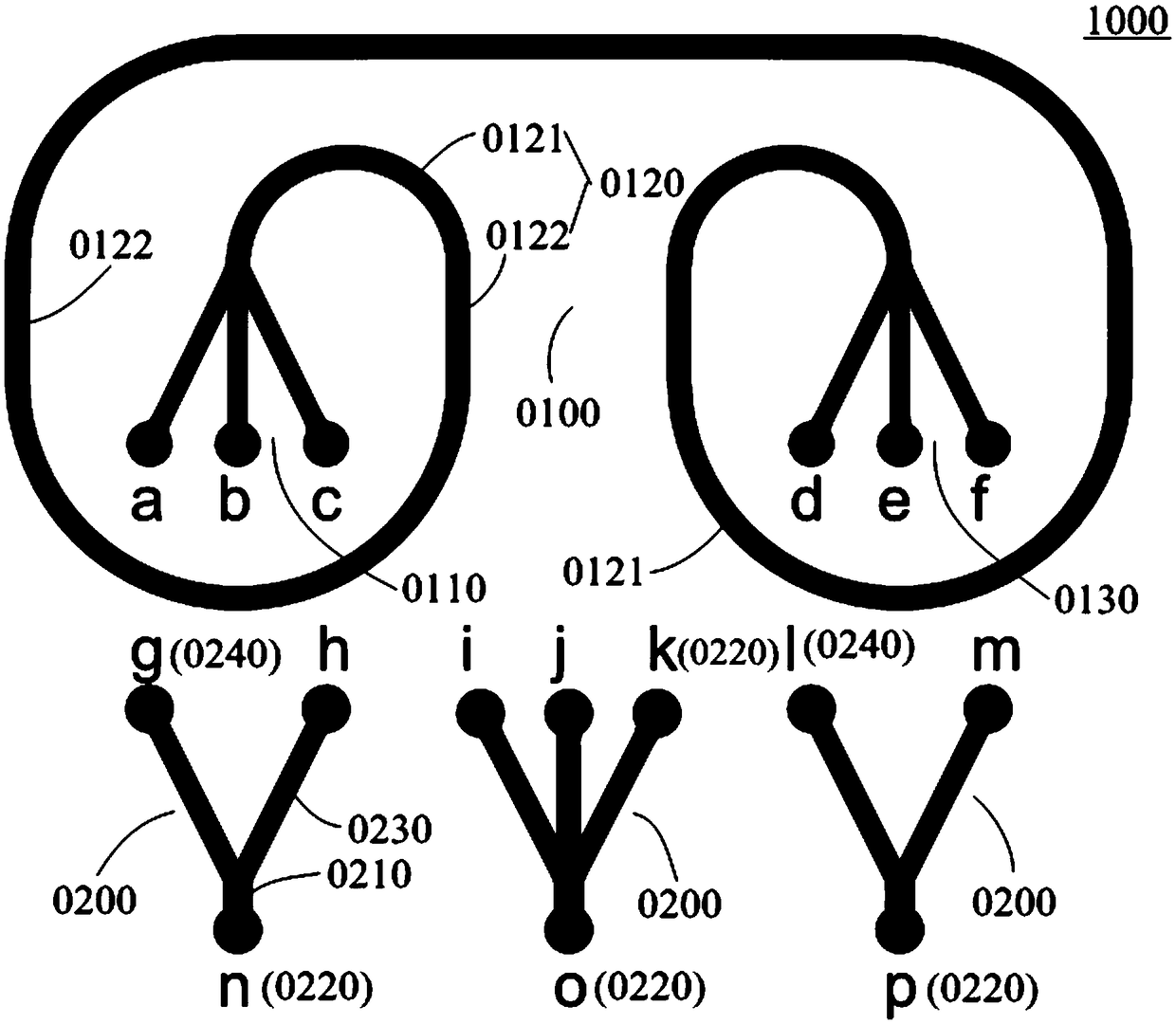

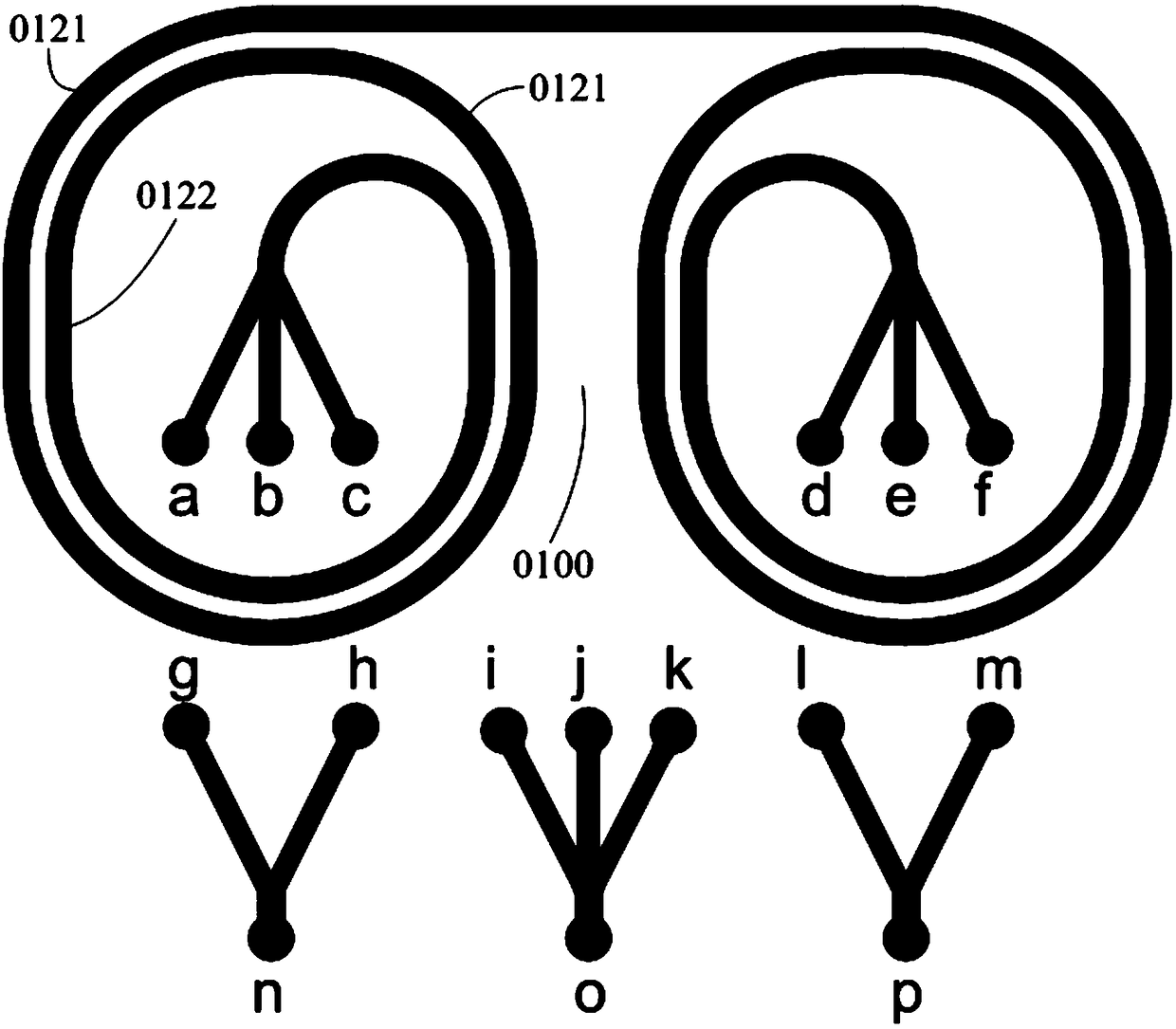

[0035] Please refer to Figure 1~2 , this embodiment discloses a specific structure of a general-purpose inertial focusing microfluidic chip 1000, the chip includes a main functional unit 0100 and at least one kind of flow splitting unit 0200, which are used to realize different forms of inertial focusing Dean vortex structures compatiblely, satisfying different Types of fluids for sorting applications.

[0036] The main functional unit 0100 includes a first exchange port 0110 , a vortex channel 0120 and a second exchange port 0130 connected in sequence, and the first exchange port 0110 and the second exchange port 0130 are located at two ends of the vortex channel 0120 .

[0037] The first exchange end 0110 includes at least three fluid inlets (such as the first inlet a, the second inlet b, and the third inlet c) connected to the outer, middle, and inner sides of the end (which may be the input end) of the vortex channel 0120 respectively. ), for injecting fluid from differe...

Embodiment 2

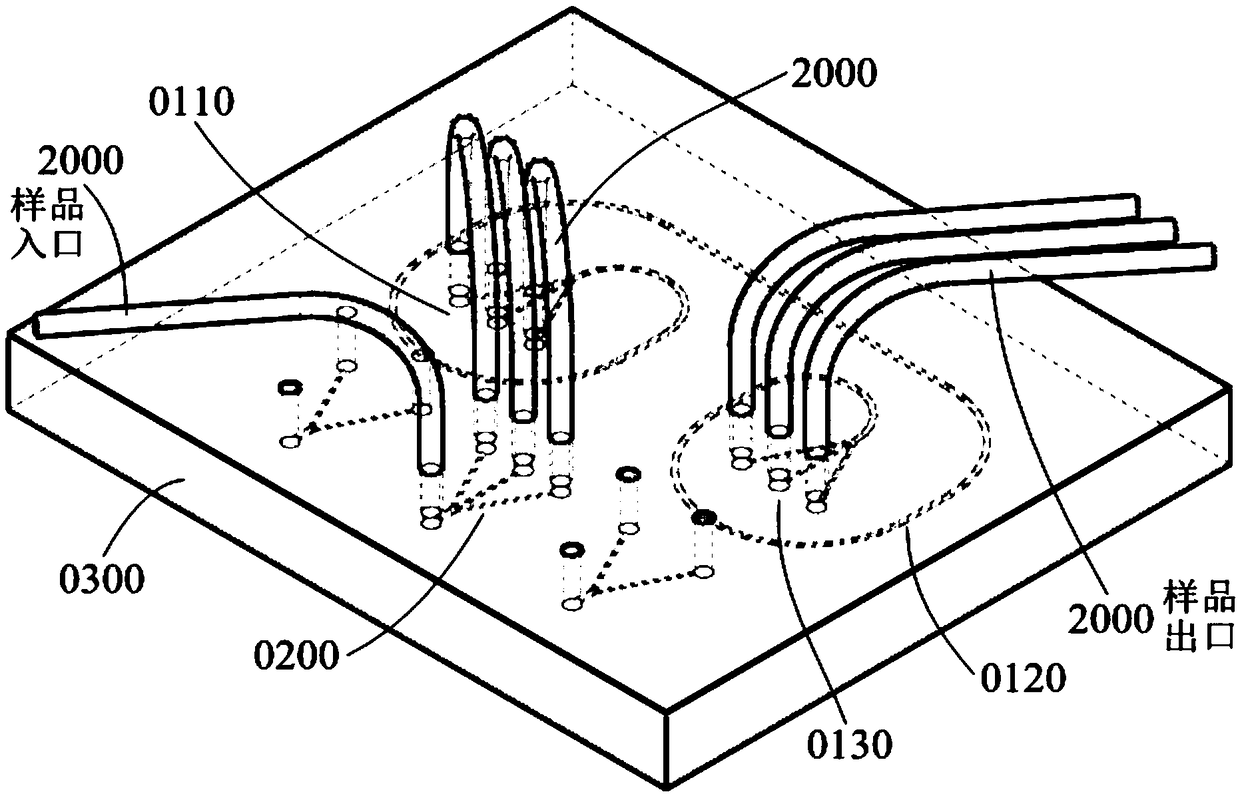

[0058] On the basis of Embodiment 1, this embodiment further introduces a specific application of the general inertial focusing microfluidic chip 1000 .

[0059] Please refer to figure 1 and image 3 , in this embodiment, the number of the branching unit 0200 is one and is a four-way branching structure, including a first dry port o and three first branching ports (i, j, k). Wherein, the first dry interface o is used to connect with the sample source to introduce the sample flow. Wherein, the first sub-ports i, j, k are correspondingly connected to the first inlet a, the second inlet b, and the third inlet c through the pipeline 2000 . At the same time, the first outlet d, the second outlet e and the third outlet f of the main functional unit 0100 respectively output the sorting results through the pipeline 2000 .

[0060] In application, the sample flow flows in from the first dry interface o, and is divided by the flow splitting unit 0200 to form three streams, which are ...

Embodiment 3

[0062] On the basis of Embodiment 1, this embodiment further introduces a specific application of the general inertial focusing microfluidic chip 1000 .

[0063] Please refer to figure 1 and Figure 4 , in this embodiment, the number of flow splitting units 0200 is two, and all of them have a three-way split structure. The first branching unit includes a second dry port n and two second branch ports (g, h) for introducing sheath fluid; the second branching unit includes a third dry port p and two third branch ports (l, m), used to output sorting results.

[0064] Wherein, the third inlet c of the first exchange port 0110 is connected to the sample source through a pipeline 2000 to introduce a sample flow. The second dry port n is connected to the sheath flow pump to input the sheath flow liquid. The second ports g and h are respectively connected to the first inlet a and the second inlet b through the pipeline 2000 , and the sheath fluid is input into the vortex channel 01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com