Quick cutter aligning machine

A tool setter and fast technology, which is used in the accessories of tool holders, turning equipment, metal processing equipment, etc., can solve the problems of inability to align the center of the workpiece, poor accuracy, and low efficiency, and achieve accurate tool setting and improve tool setting. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

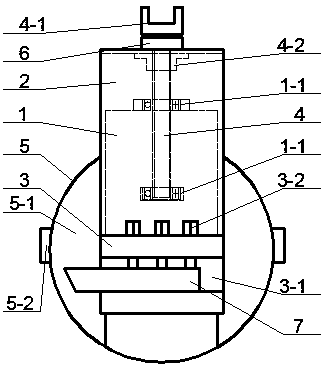

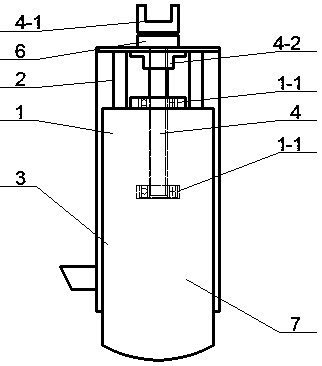

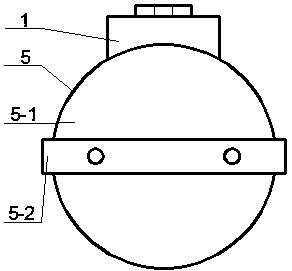

[0020] as attached figure 1 , 2 . As shown in 3, a quick tool setting device includes a fixed guide rail 1, a sliding guide rail 2, a tool holder 3, a screw 4 and a mounting seat 5, one side of the fixed guide rail 1 is provided with a mounting seat 5, and the other side The sliding guide rail 2 is connected by sliding fit, and the bottom end of the sliding guide rail 2 is fixedly equipped with a knife holder 3; The rod nut 4-2, the lead screw nut 4-2 is fixedly connected with the sliding guide rail 2; 2 drives the sliding guide rail 2 to move along the fixed guide rail 1 to realize the up and down translation of the tool.

[0021] Two bearing seats 1-1 are provided, one is arranged on the top of the fixed guide rail 1, and the other is arranged on the middle part of the fixed guide rail 1, which are respectively connected with the upper part and the bottom end of the lead screw 4, which can effectively ensure the stability of the lead screw , and limit the movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com