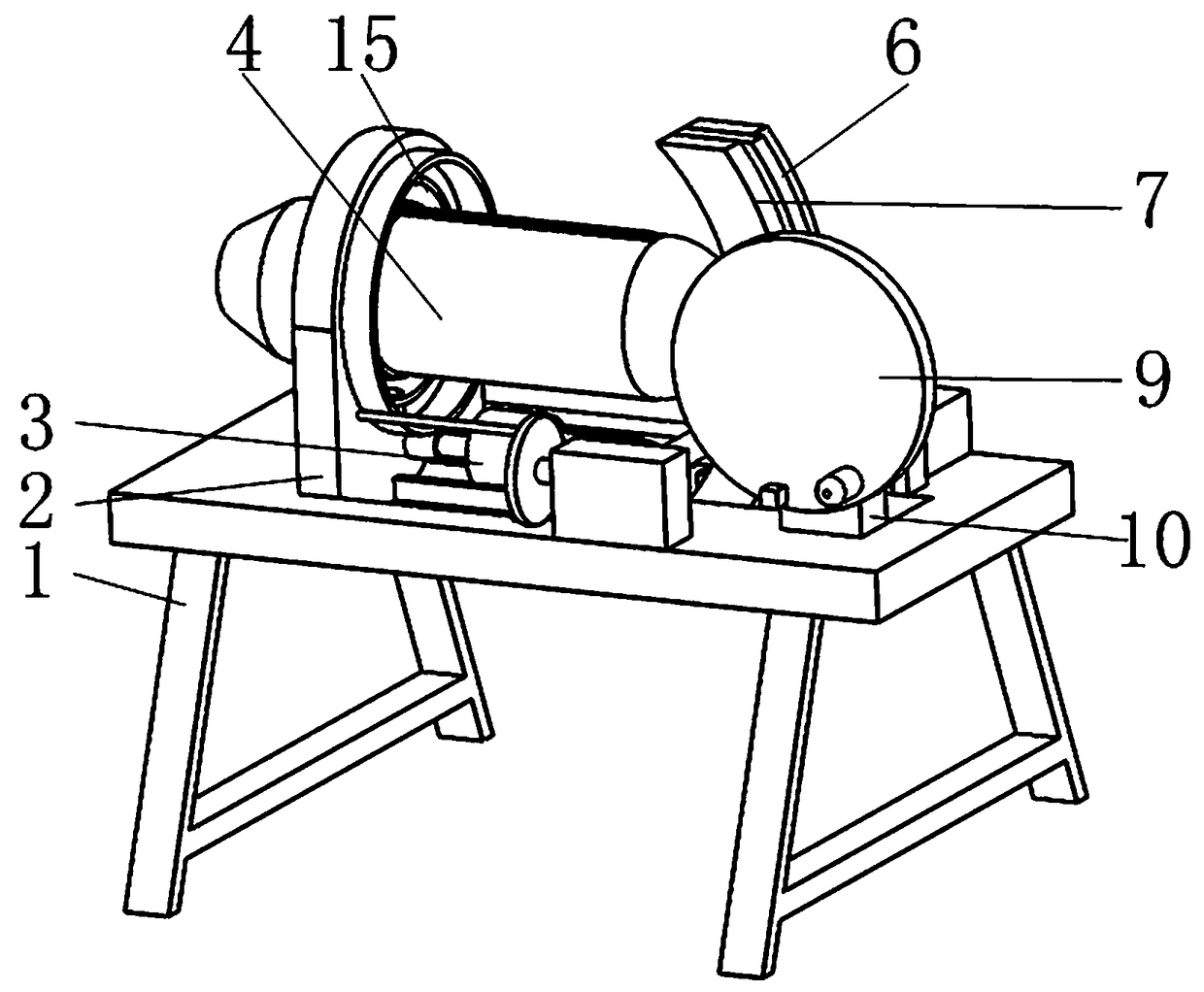

Concrete mixing device for constructional engineering

A technology of mixing device and construction engineering, applied in cement mixing device, clay preparation device, chemical instrument and method, etc., can solve problems such as heavy burden, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

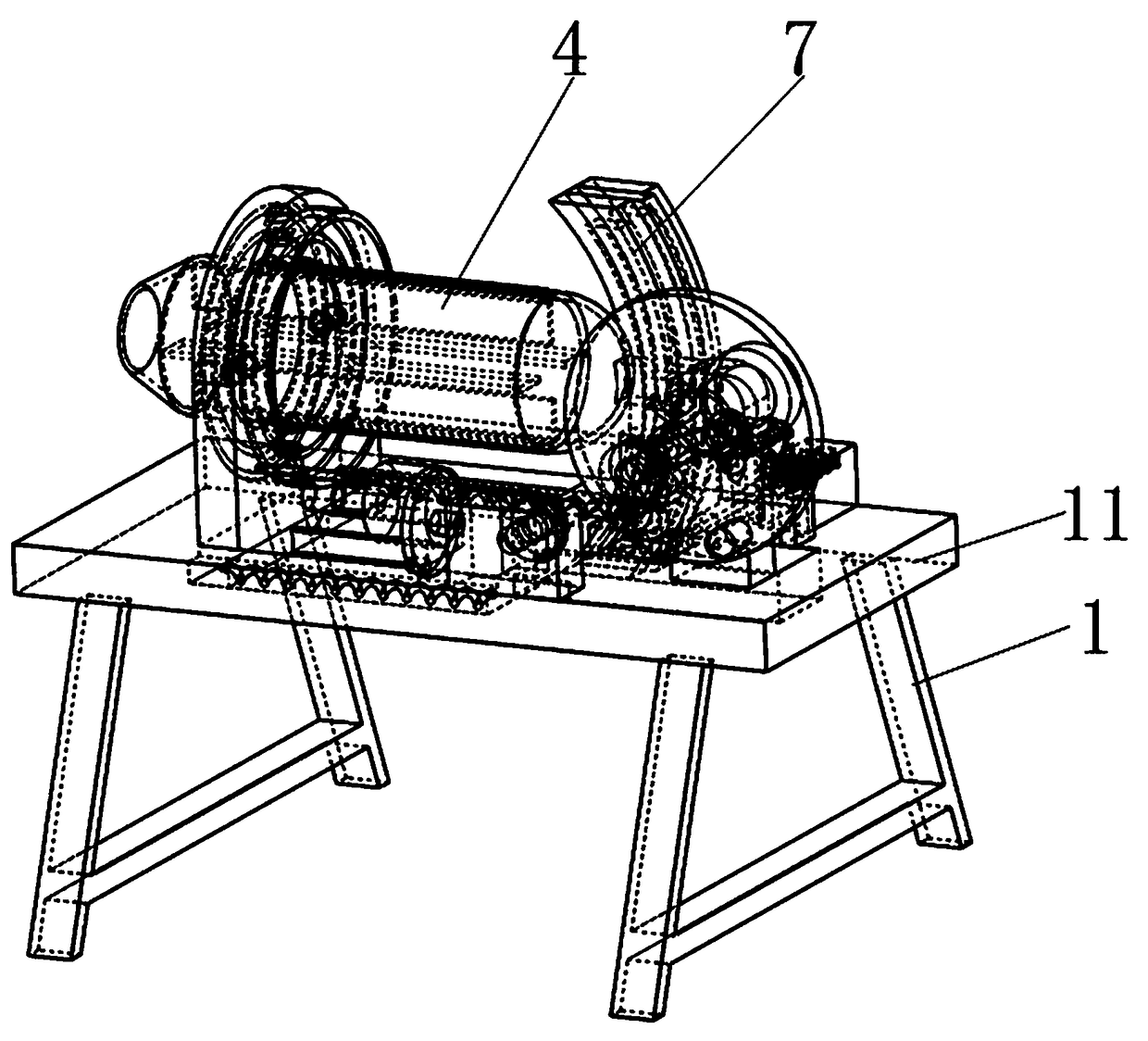

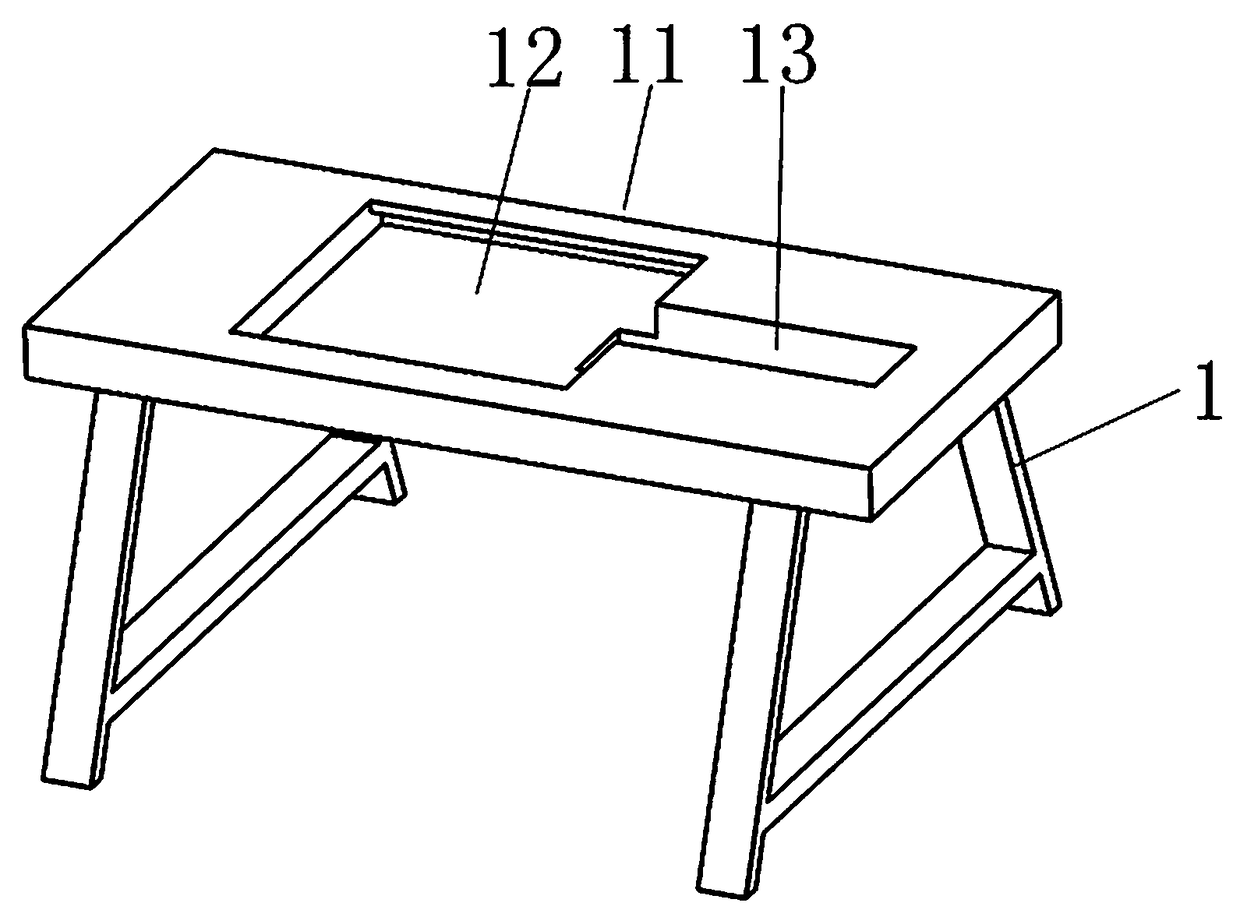

Method used

Image

Examples

specific Embodiment approach

[0035] The specific embodiment is as follows: in the initial state, the return spring 26 is in a freely retractable state; the mixing drum 4 is in a horizontal state, and the limit rack 17 is located in the first limit hole 20 and the second limit hole 21; in the device of the present invention During the mixing process of the concrete mixing device, the vertical center plane of the mixing drum 4 is located between the first support 2 and the arc-shaped rack 6 so as to provide more stable support for the mixing drum 4; When the mixing drum 4 needs to be loaded or unloaded, one of the staff at this time drives the driving column 55 to move, the moving driving column 55 will drive the second adjustment disc 56 to rotate, and the second adjustment of the movement The disc 56 will drive the input shaft of the gearbox 58 to rotate. At this time, the rotary motion of the second adjusting disc 56 will be driven by the speed reduction and torque increase of the gearbox 58. The transmi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap