Plastic particle cooling and sorting device

A sorting device, a technology for plastic particles, applied in the direction of coating, etc., can solve the problems of applicability and practicality limitations, affecting the operation of screen mesh, etc., achieve good practicability, reduce air-cooling and cooling operations, and facilitate sorting operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

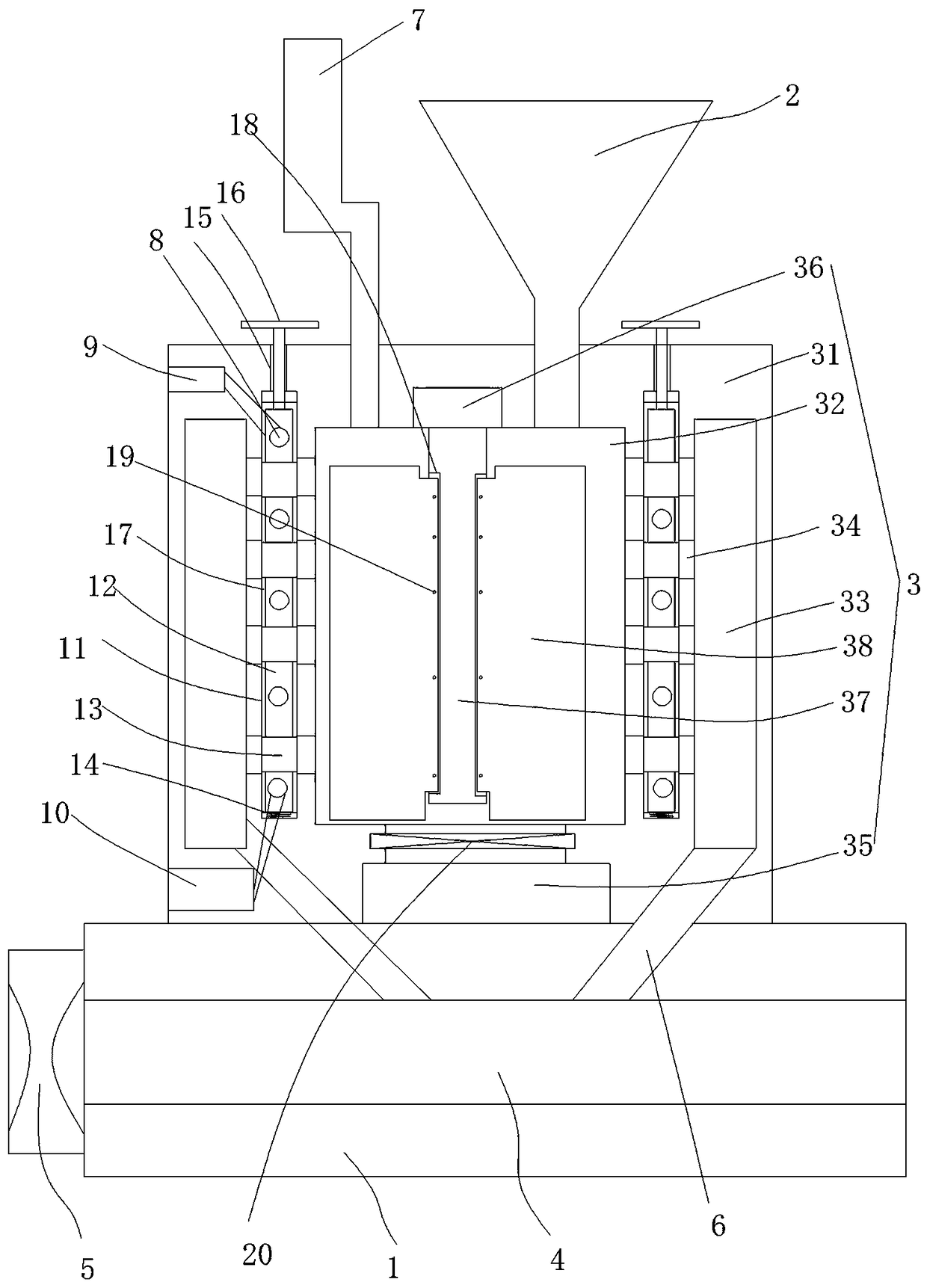

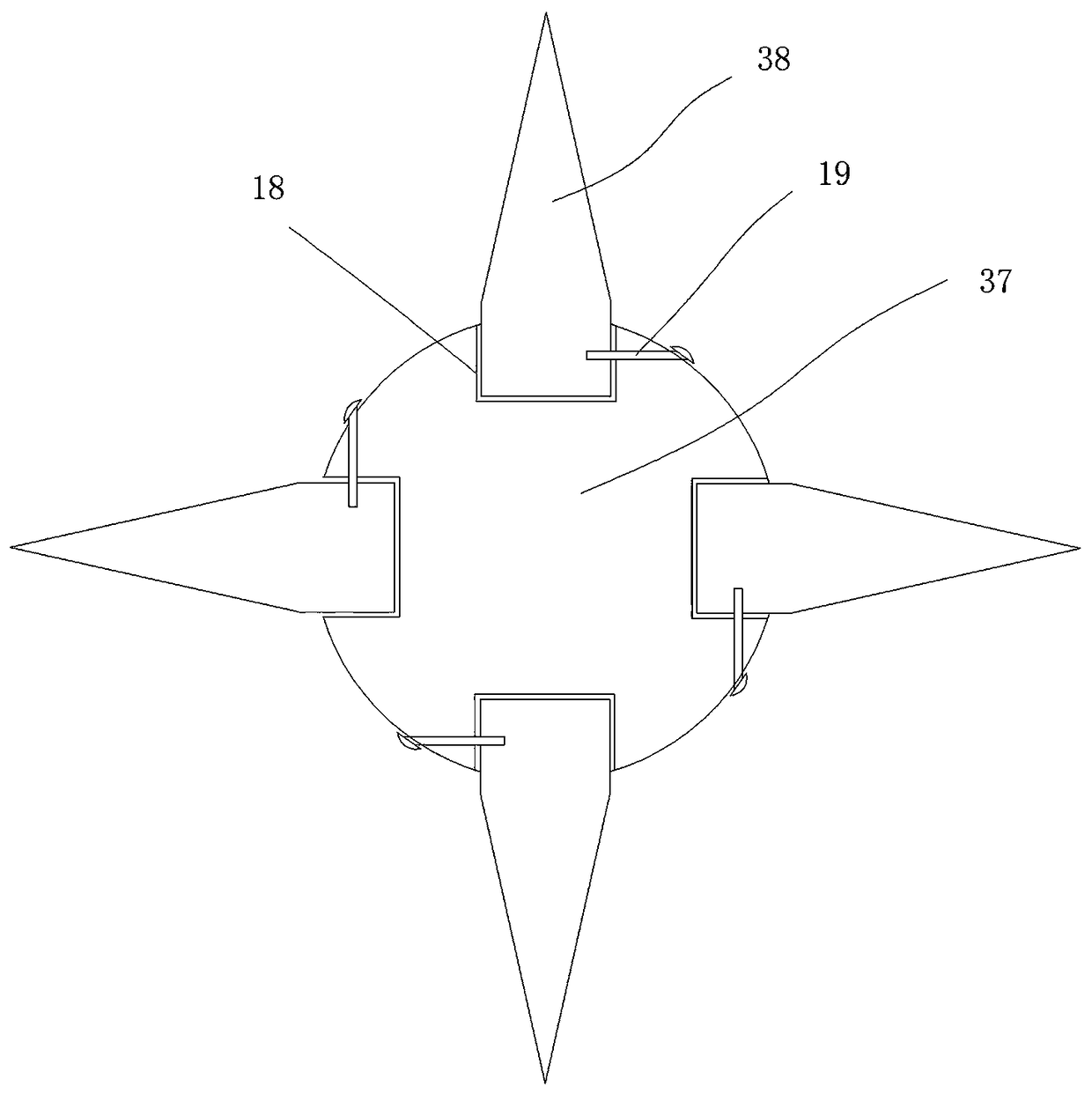

[0017] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a sectional view of the shaft rod and the pushing plate in the present invention. See figure 1 and figure 2 , a cooling and sorting device for plastic particles, comprising a base 1, a sorting structure 3 arranged on the base 1 and a hopper 2 arranged on the top of the sorting structure 3, and a feeding pipe is arranged in the base 1 4. A feeding fan 5 is fixed on the side wall of the base 1, the air outlet of the feeding fan is connected to the feeding pipe, and the bottom end of the outlet 6 of the sorting structure 3 is inserted into the In the center of the top wall of the feed pipe 4, the sorting structure 3 includes a sorting seat 31, a sorting chamber 32 is arranged in the sorting seat 31, and the hopper 2 is connected to the top of the sorting chamber 32, An annular feeding chamber 33 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com