Method for shearing defect steel bridge strengthening by employing GFRP

A technology for shearing and steel beams, used in building maintenance, construction, building construction, etc., can solve problems such as fatigue damage of components, and achieve the effect of cost saving and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

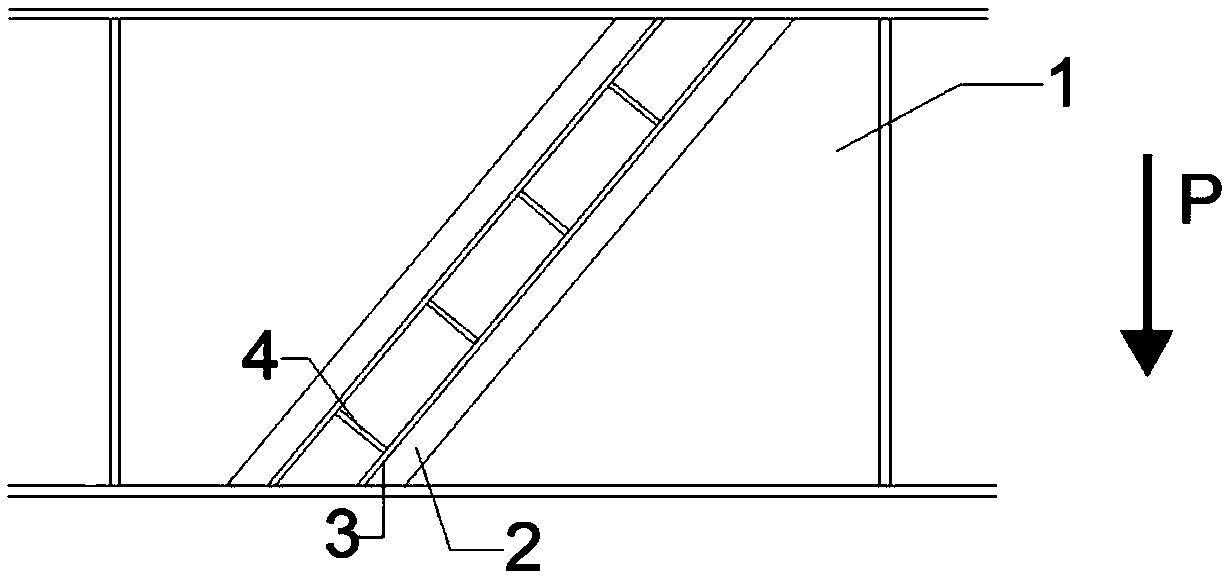

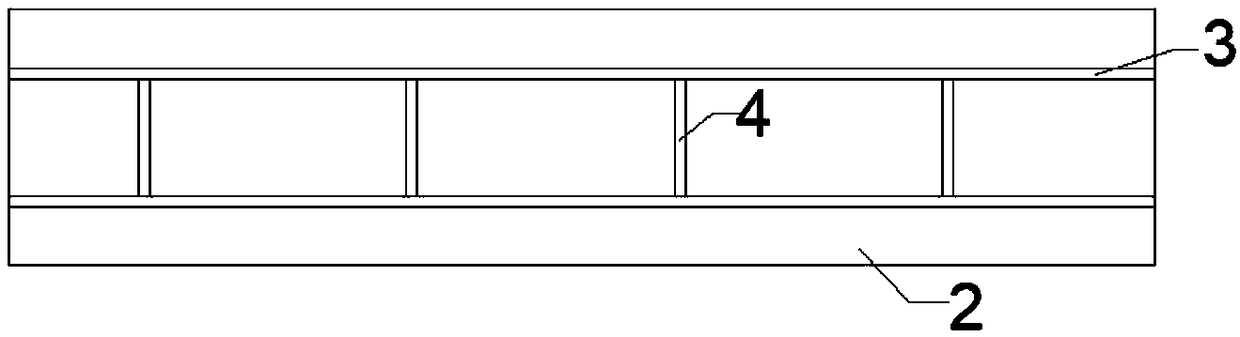

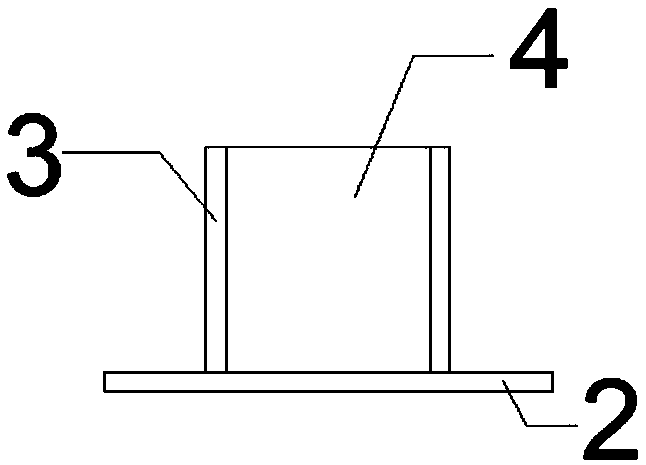

[0025] Such as figure 1 As shown in Fig. 1, a method for strengthening steel beams with shear defects by using GFRP is to arrange GFRP members symmetrically on both sides of the web 1 of the steel beam to be strengthened, wherein the GFRP members include a bottom plate 2, a pair of The vertical ribs 3 and a plurality of transverse ribs 4 vertically arranged on the bottom plate, the transverse ribs 4 are distributed between two vertical ribs 3 at intervals, and are perpendicular to the vertical ribs 3, the vertical ribs 3 and the transverse ribs 4 form a plurality of cuboid cavities The base plate 2 is bonded to the steel beam web 1. During implementation, various parameters of GFRP components, such as thickness, height, and width of the bottom plate, can be adjusted according to specific stress conditions.

[0026] In this embodiment, the size of the single cell of the steel beam web used is 800mm×500mm, and the GFRP bottom plate 2 and the steel beam web 1 are bonded by bondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com