Open-pit coal mine underground reservoir including core rockfill dam structure

A technology of open-pit coal mines and underground reservoirs, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of ecological fragility, land desertification, and destruction of large-scale coal power bases in the eastern grasslands, and achieve the green construction concept of turning waste into treasure , The effect of stabilizing the seismic performance of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

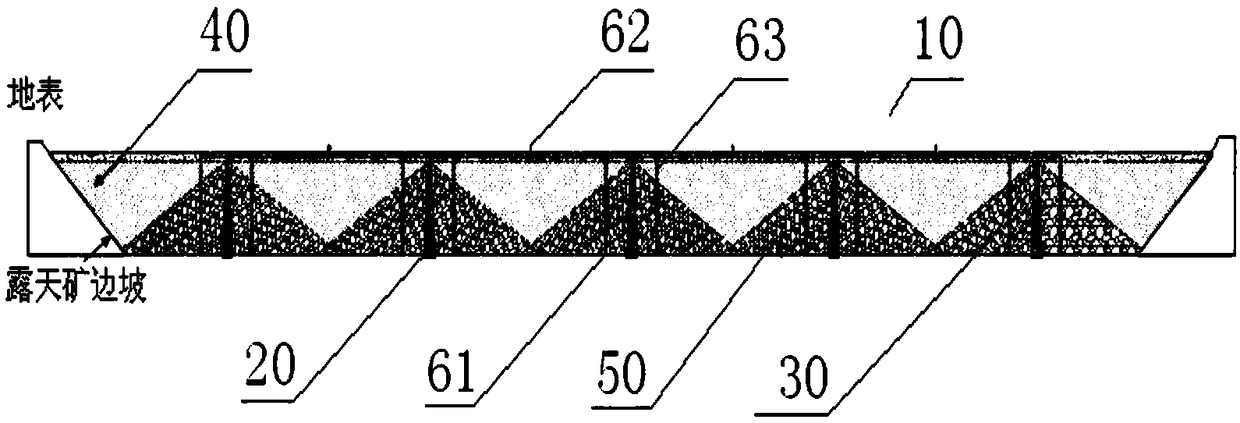

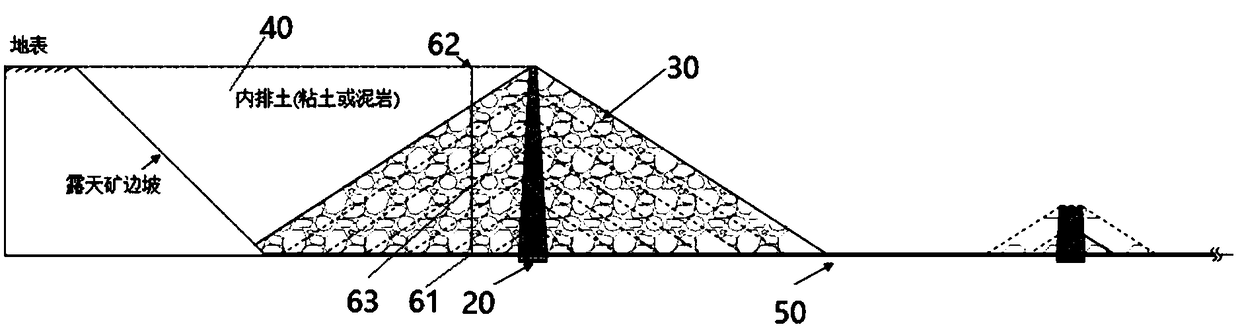

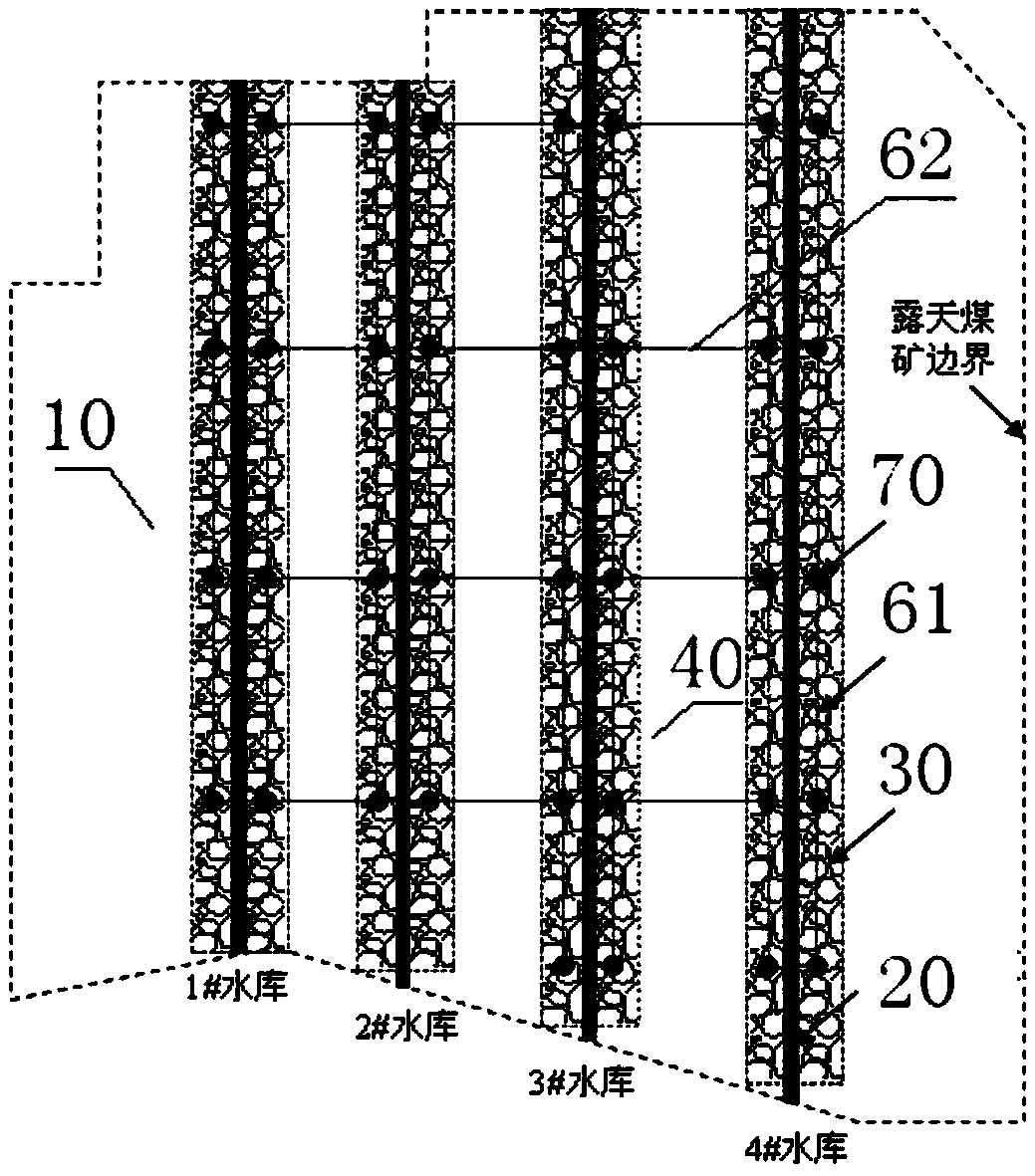

[0018] see figure 1 , figure 2 and image 3 The embodiment of the present invention provides an open-pit coal mine underground reservoir comprising a core rockfill retaining dam structure, including an open-pit coal mine pit 10 used as a water storage space, a core wall retaining dam 20 arranged in the open-pit coal mine pit 10, and The rockfill 30 used as a water storage body on both sides of the core wall retaining dam 20, and the inner dump 40 discharged from the inner dump operation filled on the rockfill 30, and the filling height of the inner dump 40 on the rockfill 30 It is equal to the height of the core wall retaining dam 20. Wherein, the core wall retaining dam 20 is formed by concrete pouring or earth-rock rolling, and the core wall retaining dam 20 includes a plurality of core wall retaining dams constructed sequentially along the internal soil discharge operation direction, so that the multiple core wall retaining dams will The pit 10 of the open-pit coal mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com